Allegro A80803 User manual

User Manual

A80803 Evaluation Board and Programming GUI

UM-A80803, Rev. 1

MCO-0001115

February 4, 2022

INTRODUCTION

The A80803 Evaluation Board (EVB) is designed to aid sys-

tem designers with the evaluation of the operation and per-

formance of the A80803, a multi-topology, fixed frequency,

switch-mode DC/DC controller for LED lighting applica-

tions with built-in support for low/high-beam operation and

remote configuration via SPI.

The A80803 EVB is available in four configurations to sup-

port low/high-beam and fixed LED string applications. The

EVB arrives configured to operate in one of four modes and

has a mark on one of the silkscreen boxes in the top right of

the EVB to identify in which mode the EVB is configured.

The Allegro A80803 configuration GUI is a tool provided to

simplify interaction with the device using the SPI interface.

The tool can read and write all configuration registers as

well as report and clear the fault status and diagnostic bits.

The tool provides a tabbed interface to group similar options

together to help the user quickly find configuration options.

The GUI is not required for operation but simplifies con-

figuration register modifications.

Table 1: A80803 EVB Available Configurations

Configuration Name Part Number Low/High-Beam

Support

Low-Beam

Topology

High-Beam

Topology

Low/High Beam Topology Switch APEK80803KET-TS Yes Buck-Boost Boost

Low/High Beam Single FET APEK80803KET-SF Yes Boost Boost

Boost Only APEK80803KET-BO No Boost –

Buck-Boost Only APEK80803KET-BB No Buck-Boost –

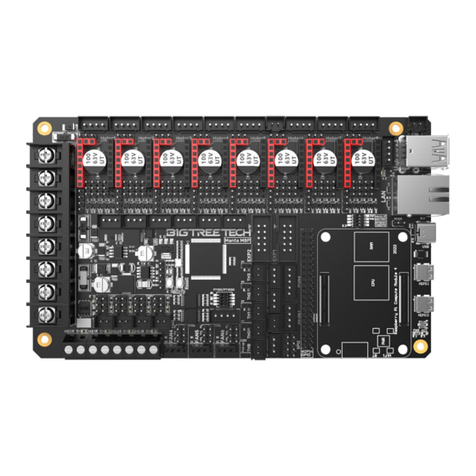

Figure 1: A80803 EVB

Table of Contents

Introduction ...................................................................................1

General Setup...............................................................................2

Power Input ...............................................................................2

LED Connection ........................................................................2

Control Pins...............................................................................2

Bin Select ..................................................................................3

SPI Communication...................................................................3

Fault Flags.................................................................................3

Sense Resistor ..........................................................................4

Switching Frequency .................................................................4

NTC LED Current Derating .......................................................4

Getting Started with the GUI ......................................................... 5

GUI Troubleshooting .................................................................7

Device Configuration .................................................................8

Configuration Files and Default EEPROM ............................9

Diagnostics Tab ...................................................................10

Configuration Tab ................................................................ 11

Binning Tab.......................................................................... 11

Thermal Foldback Tab.........................................................12

VIN Foldback Tab ................................................................12

PWM Dimming Tab..............................................................13

High/Low-Beam Tab ............................................................14

Faults Flags Tab ..................................................................15

Writing to EEPROM.................................................................16

Low/High-Beam Topology Switch EVB .......................................17

APEK80803KET-TS Schematic ..............................................18

APEK80803KET-TS Bill of Materials.......................................19

Low/High-Beam Single FET EVB ...............................................20

Confirm HBGCTRL Bit.............................................................21

APEK80803KET-SF Schematic ..............................................22

APEK80803KET-SF Bill of Materials.......................................23

Boost Only EVB ..........................................................................24

APEK80803KET-BO Schematic..............................................25

APEK80803KET-BO Bill of Materials ......................................26

Buck-Boost Only EVB .................................................................27

APEK80803KET-BB Schematic ..............................................28

APEK80803KET-BB Bill of Materials....................................... 29

Board Layout...............................................................................30

Revision History ..........................................................................32

2

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

GENERAL SETUP

This section provides an overview of the connections that are generally applicable to all EVB configurations. Each group of connec-

tions is highlighted in Figure 2.

Figure 2: A80803 EVB I/O Connections

Power Input

Connect a power supply using the either X1 terminal block or the VBAT and GND test points.

LED Connection

Connect the anode of the LED string to the X2 connector terminal A (anode) and the cathode of the LED string to the X2 connec-

tor terminal K (cathode). For low/high-beam applications, tie the CT terminal to the LED string to mark the bottom of the low-beam

string. The APEK80803KET-BB and APEK80803KET-BO options have R18 and R23 installed to tie CT to the K terminal.

Control Pins

The LBEAMn, EN/PWM, and DIMn pins of the A80803 can be tied to VIN with jumpers or left open and controlled with external

signals. These test points could be tied to VIN externally or driven from a logic level source such as a microcontroller.

The jumpers J1, J2, and J3 can be installed or opened to set the operating state as shown in Table 2 and Table 3. To operate in external

dimming mode, install J2 or tie DIMn to a logic high signal and EN/PWM to an external PWM source for controlled dimming or logic

high for 100% dimming. To use internal dimming, open J2 and connect EN/PWM to logic high or install J3 and use the A80803 GUI

tool to set the LED brightness.

Table 2: Low/High-Beam Jumper

J1 (LBEAMn) State

Open Low-Beam

Installed High-Beam

3

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Table 3: Internal/External Dimming Jumpers

J2 (DIMn) J3 (EN/PWM) Dimming Mode

Installed Installed External - 100%

Installed Open External - PWM

Open Installed Internal

Bin Select

Jumpers J4 to J7 select the bin for analog dimming.

Note: Only one bin select jumper should be installed at a time. See Table 4 for bin selection.

Table 4: BIN Selection Jumpers

Jumper Installed BIN

J4 BIN1 selected

J5 BIN2 selected

J6 BIN3 selected

J7 BIN4 selected

Gain can be modified for each bin using the A80803 GUI tool; see the Binning Tab section of this document. The jumpers J4 to J7

select a resistor for the bottom of a voltage divider. If all four jumpers are open, the BINSEL pin will be pulled up to VCC and BIN1

will be selected.

SPI Communication

The A80803 supports SPI for serial communication to control the configuration registers. The silkscreen labels are intended for use

with the FTDI USB to Serial adapter cable, part number C232HM-EDHSL-0, to be used with the A80803 GUI tool. See Table 5 to

compare the silkscreen labels to the SPI pin names. The jumpers J1, J2, and J3 can be installed or opened to set the operating state as

shown in Table 2 and Table 3. To operate in external dimming mode, install J2 or tie DIMn to a logic high signal and EN/PWM to an

external PWM source for controlled dimming or logic high for 100% dimming. To use internal dimming, open J2 and connect EN/

PWM to logic high or install J3 and use the A80803 GUI tool to set the LED brightness.

Table 5: J8 Header SPI Labels

Silkscreen Label USB-Serial Breakout Wire SPI Pin

ORN Orange SCK

YEL Yellow MOSI

GRN Green MISO

BRN Brown CSn

BLK Black GND

Fault Flags

There are two active low fault flag pins on the A80803, FFn1 and FFn2. Both are available as test points on the EVB. The fault flags

are pulled up to VCC with a 10 kΩ resistor on the EVB.

4

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Sense Resistor

The LED current is set by the sense resistor R2 and the equation:

ILED = VIDL / R2

Each EVB configuration is designed for a 1 A LED current; with VIDL = 200 mV then R2 = 0.2 Ω.

Switching Frequency

The switching frequency for the power converter stage is set by R16 and the equation:

fSW = 35000 / R16

where fSW is in kHz and R16 is in kΩ. Each EVB configuration is designed for a switching frequency of 400 kHz with R16 = 86.6 kΩ.

NTC LED Current Derating

There is a NTC thermistor on the EVB, RT1, in a voltage divider leading to the NTC pin. The thermistor, part number NTCS0603E-

3103FHT, has a base resistance of 10 kΩ. See the Thermal Derating section in the A80803 datasheet for more information about

programming the derating values.

5

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

GETTING STARTED WITH THE GUI

Download the A80803 GUI tool from https://registration.allegromicro.com. The GUI tool is an executable that can be run directly

without any additional installation steps once downloaded and extracted. The tool depends on the FTDI D2xx driver for USB to Serial

communication.

Note: Text highlighted in blue monospaced font refers to a button in the GUI.

The tool opens to the Diagnostic tab but does not attempt to communicate with the part until the user requests a read or write opera-

tion. The initial state of the GUI is shown below in Figure 3.

Figure 3: First screen after starting the GUI

Figure 4: USB Serial Connection Established

Press the Read Faults button to start a read and initialize the USB connection. Upon successful connection, the USB status will

change to USB Connected in green text in the bottom left corner of the window.

6

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

At the top of the diagnostics tab there are buttons to read all configuration data from shadow or EEPROM into the state of GUI

controls, and to write the full state of the GUI controls to the configuration registers or EEPROM. A good practice is read the shadow

registers, once the connection to the A80803 has been established, by clicking the Read Shadow button shown in Figure 5, to align the

GUI controls with the state of the device. Reading the full contents of the EEPROM can be used to understand what is programmed

into EEPROM and is loaded into shadow at each power-on, but the shadow registers are what the A80803 uses during operation.

Figure 5: Read All of Shadow to Align GUI Controls with the Device

7

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

If this error appears and the D2xx drivers are believed to be installed, then ensure the USB cable is fully connected to the PC. If the

USB cable was recently plugged-in, then ensure the PC has had enough time to recognize the USB device.

If the GUI shows USB Connected and Parity check failed as shown in Figure 7, this means the USB-to-serial converter is con-

nected but cannot communicate to the A80803. Ensure the A80803 SPI pins are properly connected in the correct order (refer to the

SPI Communication section of this document), and the device is powered. A parity error while reading the fault registers will reset the

fault indicators to black text to indicate the state is unknown.

Figure 7: GUI is connected to USB-Serial but cannot nd A80803

The window on the right side of the GUI window shows the details of each SPI transaction as they are processed. The bottom of the

window shows the diagnostic information from on the MISO pin after each SPI read or write. See the Serial Communication section in

the datasheet for more details about the SPI interface.

GUI Troubleshooting

After the first read or write request, the tool will attempt to communicate using the FTDI D2xx driver. If the driver is not installed, or

the FTDI USB-Serial device cannot be found, an error message will be displayed as shown in Figure 6.

Figure 6: Error when FTDI device cannot be found

8

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Device Configuration

Each of the other tabs after the Diagnostics tab has two buttons in the top right corner, one to read just the registers represented on

that tab, Read config, and one to write the state of the GUI controls in that tab to those registers, Write config. The numbers in

the button label indicate the Config registers affected. There is also a checkbox near the top of the window for Write to register

every change which will update configuration registers every time a change is made without having to make the change and click

the Write button.

Figure 8: Read, Write, and Write Every Change

9

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Configuration Files and Default EEPROM

The GUI tool has an option to save its state to a file to be recalled later. Click on the Save/Open Configuration menu item, then

click Save this configuration to afile..., and select a location and name the file, shown in Figure 9. Recall this configura-

tion by clicking the Save/Open Configuration button, select Open device configuration file..., and select the file to

load. After loading a configuration file, the GUI will update to match the state when it was saved.

At any time, the factory default EEPROM state can be loaded into the GUI controls by selecting Load default configuration to

application option from the Save/Open menu.

Note: Loading a configuration (including the default) does not automatically send the configuration to the device, giving an oppor-

tunity to modify a loaded configuration before writing to the device.

Figure 9: Save and Load Conguration Files

10

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

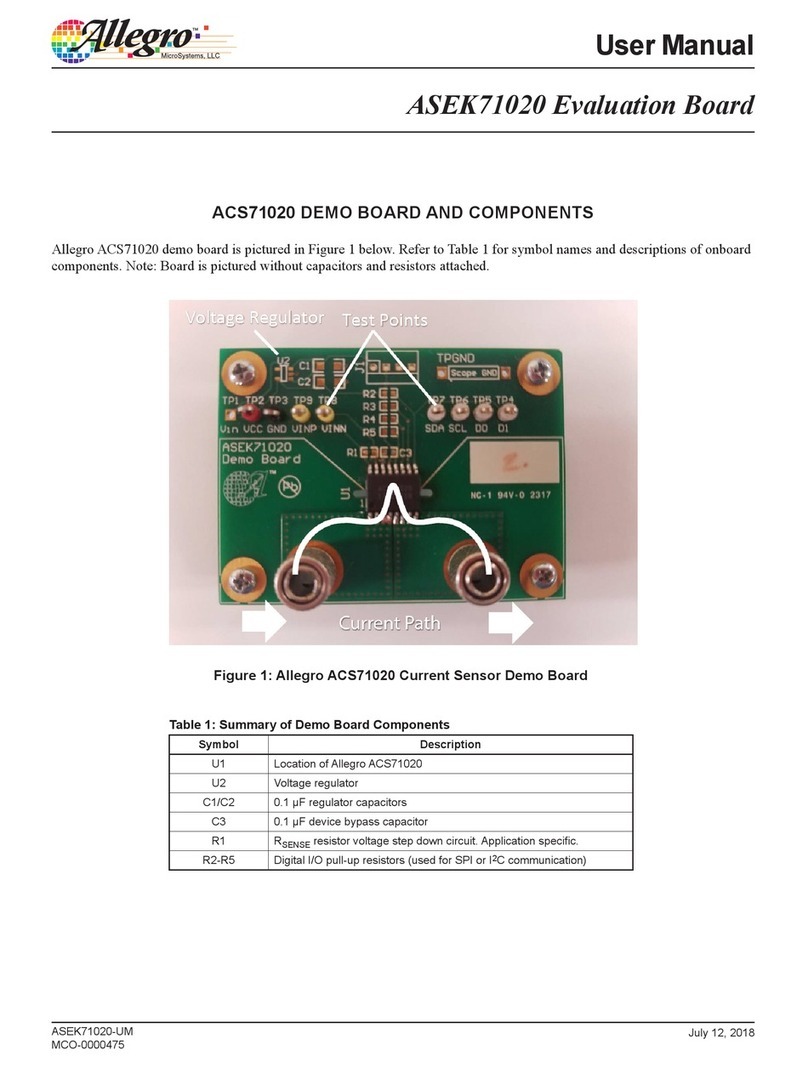

Diagnostic Tab

In addition to the buttons to read or write the full register set, the Diagnostic tab also shows the status of the faults captured in the

DIAG0 and DIAG1 registers. The fault status indicators will update with each click of the Read Faults button or continuously if the

Continuous Fault Read button is pressed. The fault status indicators will be green and show a value of 0 when no fault is present

and red with a value of 1 when a fault is present. Some faults are latched and must be cleared with the Clear Faults button. See

DIAG0 and DIAG1 register descriptions in the datasheet for more information.

Figure 10: Fault Indicators

The bottom of the GUI window shows the faults that are on the MISO line during every SPI transaction. The faults in gray in Fig-

ure 10 are only available on the MISO line during a write. See the SPI Data Frames section of the datasheet for more information.

11

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Configuration Tab

The Configuration tab provides several general purpose options to configure the A80803, as shown in Figure 11.

Figure 11: General Conguration

Binning Tab

The Binning tab has four sliders to control the bin gain for each of the four bins. The binning level acts as a derating for the maximum

LED current. The BINSEL pin (a resistor divider from VCC selectable by jumpers on the evaluation board) selects which bin is active;

see the Bin Select section of this document and the LED Analog Dimming section of the datasheet for more information about binning

with the A80803.

Figure 12: Binning Conguration

12

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Thermal Foldback Tab

The Thermal Foldback tab has sliders for the NTC analog dimming options. See the Thermal Derating section and the Thermal Derat-

ing Example in the datasheet for more information about calculating these values.

Figure 13: Thermal Foldback Conguration

VIN Foldback Tab

The VIN Foldback tab has sliders for the VIN derating analog dimming options. See the Input Voltage Derating section and the Input

Voltage Derating Example in the datasheet for more information about calculating these values.

Figure 14: Input Voltage Foldback Conguration

13

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

PWM Dimming Tab

This tab has options related to PWM dimming and includes the following options for internal PWM dimming: a toggle selection for

Internal PWM Dimming Override, four options for Internal PWM Dimming Frequency, and a slider for Internal PWM Dim-

ming Duty Cycle. The Internal/External PMOSFET Gate Current option applies to the PWMOUT gate driver for both inter-

nal and external PWM dimming. See the LED PWM Dimming section of the datasheet for more information about PWM dimming

with the A80803.

Note: If the DIMn pin is low, the Internal PWM Dimming Duty Cycle slider will set the PWM dimming duty cycle even if

Internal PWM Dimming Override is set to Disabled because the device will honor the DIMn selection for internal PWM.

Figure 15: PWM Dimming Conguration

14

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

High/Low-Beam Tab

The High/Low-Beam tab has options to set the overvoltage and undervoltage thresholds for both low-beam and high-beam, the

overvoltage behavior, the additional dead time setting, and high-beam gate controls. The high-beam gate can be forced on with the

High-beam Gate On/Off option, and the HBG Control option can be set to invert how HBG reacts to the LBEAMn pin (this

option should only be used with the application circuit for low/high-beam transitions that short out the high-beam LEDs; see APE-

K80803KET-SF for an evaluation board of this application. Also see Low and High Beam Control section of the datasheet for more

information.

Note: Allegro recommends setting low-beam and high-beam overvoltage limits approximately 5 V above the expected output voltage.

Figure 16: PWM Dimming Conguration

15

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Figure 17: Fault Flag Conguration

Fault Flags Tab

The Fault Flags tab has options to set which faults are reported on FFn2, the FFn2 delay, the overcurrent detection filter, and the one-

out-all-out behavior.

16

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

Writing to EEPROM

The EEPROM must be unlocked before it can be written. Unlocking the EEPROM must be the first SPI transaction after the device is

powered. To unlock and write EEPROM with the GUI, follow this procedure:

1. Power on the device and read the faults to verify communication.

2. Power cycle the A80803 while keeping the GUI open.

3. Click the Unlock EEPROM button (this must be rst button after A80803 is powered).

4. If the unlock was successful, the text above the unlock button will read EEPROM Writes Unlocked in green text.

5. Click the Read Shadow button to read the full shadow register contents into the GUI.

Note: If this step is skipped, the full state of the GUI will still be written into the full EEPROM in Step 7. Reading shadow

before making changes to the GUI is the best practice to ensure only the desired settings are modified in EEPROM.

6. Update the controls on any tab to the desired state to be written into EEPROM.

7. Return to the Diagnostic tab and click the Write EEPROM button to write all conguration data to EEPROM.

8. Optionally, power-cycle and use the Read Shadow button to verify the shadow registers are updated with the new values on

power-up.

Figure 18: EEPROM Writes Unlocked

Note: If needed, to restore the EEPROM to the factory settings, load the default configuration into the GUI (see Configuration Files)

and write it to EEPROM.

17

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

LOW/HIGH-BEAM TOPOLOGY SWITCH EVB

The low/high-beam topology switch configuration operates in buck-boost mode while in low-beam and in boost mode while in high-

beam. This allows for shorter low-beam strings that may have an output voltage less than the input voltage. Connect the LED string to

terminal block X2 as shown in Figure 19, where terminal A to CT is the low-beam string, and terminal A to K is the high-beam string.

Connect a power supply as described in the Power Input section of this document and set the jumpers to achieve the desired dimming

option as described in the Control Pins section. Connect the FTDI USB breakout cable to J8 for optional software configuration and

fault readback.

When LBEAMn is low, Q4 is on and Q5 is off, directing the LED current from the LED anode through the CT terminal and through

Q4 back to VIN. When LBEAMn is high, Q4 is off and Q5 is on, directing the LED current through the full LED string and through

Q5 to ground.

Figure 19: APEK80803KET-TS PCB with LED Connection

18

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

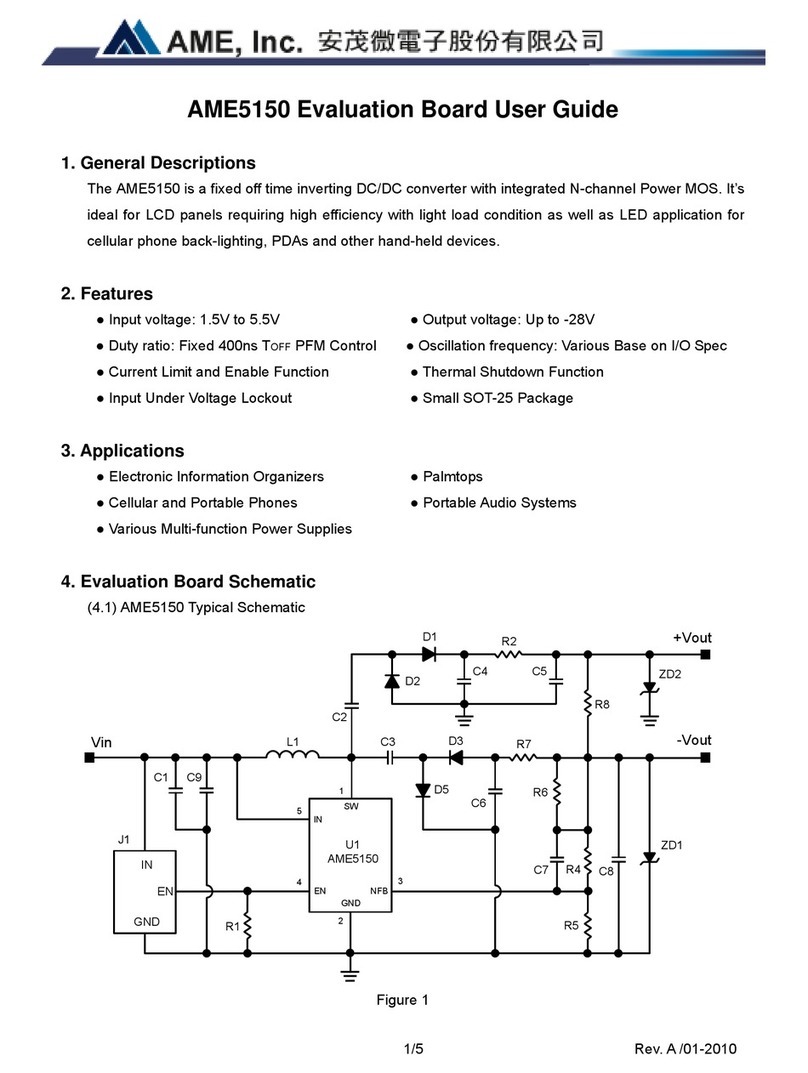

APEK80803KET-TS SCHEMATIC

Figure 20: APEK80803KET-TS Schematic

19

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

APEK80803KET-TS Bill of Materials

Designator Description Quantity Manufacturer Manufacturer P/N

U1 A80803 in the QFN-32 1 Allegro MicroSystems

C1 Capacitor, Ceramic, 0.1 µF, 50 V, X7R, 0603 1

C2, C3, C4 Capacitor, Ceramic, 4.7 µF, 50 V, X7R, 1210 3 Murata GCM32ER71H475KA55K

C5, C9 Capacitor, Ceramic, 0.1 µF, 50 V, X7R, 0805 2

C6, C7, C8 Capacitor, Ceramic, 4.7 µF, 100 V, X7R, 1210 3 TDK CNA6P1X7R2A475K250AE

C10 Capacitor, Ceramic, 47 nF, 25 V, X7R, 0402 1

C11 Capacitor, Ceramic, 0.1 µF, 16 V, X7R, 0402 1

C12 Capacitor, Ceramic, 4.7 µF, 16 V, X7R, 0805 1

C13, C14 Capacitor, Ceramic, 2.2 µF, 16 V, X7R, 0805 2

C15, C19 Capacitor, Ceramic, 4.7 nF, 50 V, X7R, 0402 2

C16 Capacitor, Ceramic, 33 pF, 50 V, C0G, 0603 1

C17 Capacitor, Ceramic, 820 nF, 25 V, X7R, 0603 1

C18 Capacitor, Ceramic, 47 nF, 50 V, X7R, 0603 1

D1 Diode, Schottky, 60 V, 5 A, SOD-128 1 Nexperia PMEG60T50ELPX

D4 Diode, Schottky, 100 V, 2 A, SOD123W 1

GND1, GND2 Ground Bar, 18 AWG Bus Bar, 15 mm Body 2

J1, J2, J3, J4, J5, J6, J7 Connector, Header, 2 Position, 0.1" 7 Wurth 61300211121

J8 Connector, Header, 5 Position, 0.1" 1 Wurth 61300511121

L1 Inductor, 33 µH, ±20%, 8 A sat, 85.5 mΩ Max 1 Eaton HCMA1305-330-R

Q1, Q3 MOSFET, N-Channel, 30 A, 100 V, LFPAK56 2 Nexperia PSMN038-100YL

Q2, Q4 MOSFET, P-Channel, 100 V, 15 A, TO252-3 2 Infineon SPD15P10PLGBTMA1

Q5 MOSFET, N-Channel, 14.8 A, 100 V, LFPAK56 1 Nexperia BUK9Y104-100B

R1 Resistor, 100 kΩ, 1/16W, 1%, 0402 1

R2 Resistor, 0.2 Ω, 1 W, 1%, 2512 1

R3 Resistor, 150 Ω, 1/16 W, 1%, 0402 1

R4, R5, R11, R12, R13, R20 Resistor, 10 kΩ, 1/16 W, 1%, 0402 6

R6, R10 Resistor, 0 Ω, 1/16 W, 1%, 0402 2

R7, R23 Resistor, 0 Ω, 1/10 W, 0603 2

R9, R26 Resistor, 2.4 kΩ, 1/16 W, 1%, 0402 2

R14 Resistor, 2.21 kΩ, 1/16 W, 1%, 0402 1

R15 Resistor, 1.54 kΩ, 1/16 W, 1%, 0402 1

R16 Resistor, 86.6 kΩ, 1/16 W, 1%, 0402 1

R17 Resistor, 45.3 Ω, 1/10 W, 1%, 0603 1

R19 Resistor, 24.9 kΩ, 1/16 W, 1%, 0402 1

R21 Resistor, 5.1 kΩ, 1/16 W, 1%, 0402 1

R22 Resistor, 1 kΩ, 1/16 W, 1%, 0402 1

R24, R25 Resistor, 0.12 Ω, 1 W, 1%, 2512 2

R28 Resistor, 5.36 kΩ, 1/16 W, 1%, 0402 1

RT1 Thermistor, NTC, 10 kΩ, 0603 1 Vishay NTCS0603E3103FHT

TP1, TP2, TP4, TP5, TP6, TP7,

TP8, TP9, TP10, TP11 Test Point, Red, 0.063" Diameter 10 Keystone 5010

TP3 Test Point, Black, 0.063" Diameter 1 Keystone 5011

X1 Terminal Block, 5.08 mm, Vertical, 2 position 1 TE Connectivity 282837-2

X2 Terminal Block, 5.08 mm, Vertical, 4 position 1 TE Connectivity 282837-4

20

Allegro MicroSystems

955 Perimeter Road

Manchester, NH 03103-3353 U.S.A.

www.allegromicro.com

LOW/HIGH-BEAM SINGLE FET EVB

The low/high-beam single FET configuration operates in boost mode for both low-beam and high-beam and shorts out the high-beam

part of the LED string while in low-beam. The LED string must have enough LEDs for the boost output voltage to be higher than the

input voltage for both low-beam and high-beam. Connect the LED string to terminal block X2 as shown in Figure 21, where A to CT

is low-beam, and A to K is high-beam. Connect a power supply as described in the Power Input section of this document and set the

jumpers to achieve the desired dimming option as described in the Control Pins section. Connect the FTDI USB breakout cable to J8

for optional software configuration and fault readback.

When LBEAMn is low, the high-beam LEDs are shorted to ground by Q5, and when LBEAMn is high, Q5 is open and the LED cur-

rent flows through the high-beam LEDs and returns through the cathode terminal to ground.

Figure 21: APEK80803KET-SF PCB with LED Connection

Note: This EVB requires EEPROM bit HBGCTRL = 1, which is different from the other EVBs and the default EEPROM which sets

HBGCTRL = 0. See the Confirm HBGCTRL Bit section before powering up LEDs.

This manual suits for next models

4

Table of contents

Other Allegro Motherboard manuals

Popular Motherboard manuals by other brands

InvenSense

InvenSense AN-000013 user guide

YIC Technologies

YIC Technologies EVK-YIC51612EBGG-33 user guide

Global American Inc.

Global American Inc. 2801020 user manual

Global American Inc.

Global American Inc. 3302140 manual

HIK VISION

HIK VISION DS-5116HFI Series user manual

USOUND

USOUND TARVOS 1.0 UC-E3010 user manual