Allegro ASEK-02-T-KIT Quick start guide

ii

Copyright ©Allegro® MicroSystems, Inc., 2007. All rights reserved under copyright laws of the United States and other countries.

The following are trademarks or registered trademarks of Allegro MicroSystems (Allegro).

Microsoft® and Windows® are registered trademarks of the Microsoft Corporation.

IBM® is a registered trademark of the IBM Corporation.

Adobe® and Adobe Acrobat® are registered trademarks of Adobe Systems Incorporated.

All product names listed are trademarks of their respective manufacturers. Company names listed are trademarks or trade names of

their respective companies.

The material in this manual and any other documentation, electronic or hardcopy, that are provided with the software and hardware

described by this manual, is for informational purposes only and is subject to change, without notice. Allegro assumes no responsibil-

ity for any error or for consequential damages that may result from the use or misinterpretation of any of the procedures in this man-

ual.

The software described by this manual is provided under license and on an as is basis. No warranty of merchantability or fitness of

use for operation on any particular device, test system, or computer system is expressed or implied for the software or hardware

described in this manual. Liability is limited to the purchase price of the product. The software may be installed on more than one

computer owned by the licensee, but is not for resale or distribution, or for use with any product other than the Allegro ASEK Board

and Calibration Board described in this manual. The software and hardware are for use in programming of devices manufactured by

Allegro, or for calibrating the ASEK Board.

Allegro®

Downloaded from Arrow.com.Downloaded from Arrow.com.

Allegro® Sensor Evaluation Kit Technical Guide | ASEK2-UG iii

Quick Start

Before using the ASEK, Allegro recommends that you read and understand this entire document.

However, in most cases, basic configuration can be done very quickly so that you can start to

familiarize yourself with the ASEK. The basic steps are described in this section. The configura-

tions described are for operating the ASEK in a direct connection to a personal computer that has

an Internet Web browser installed.

To set up the ASEK, perform the following steps:

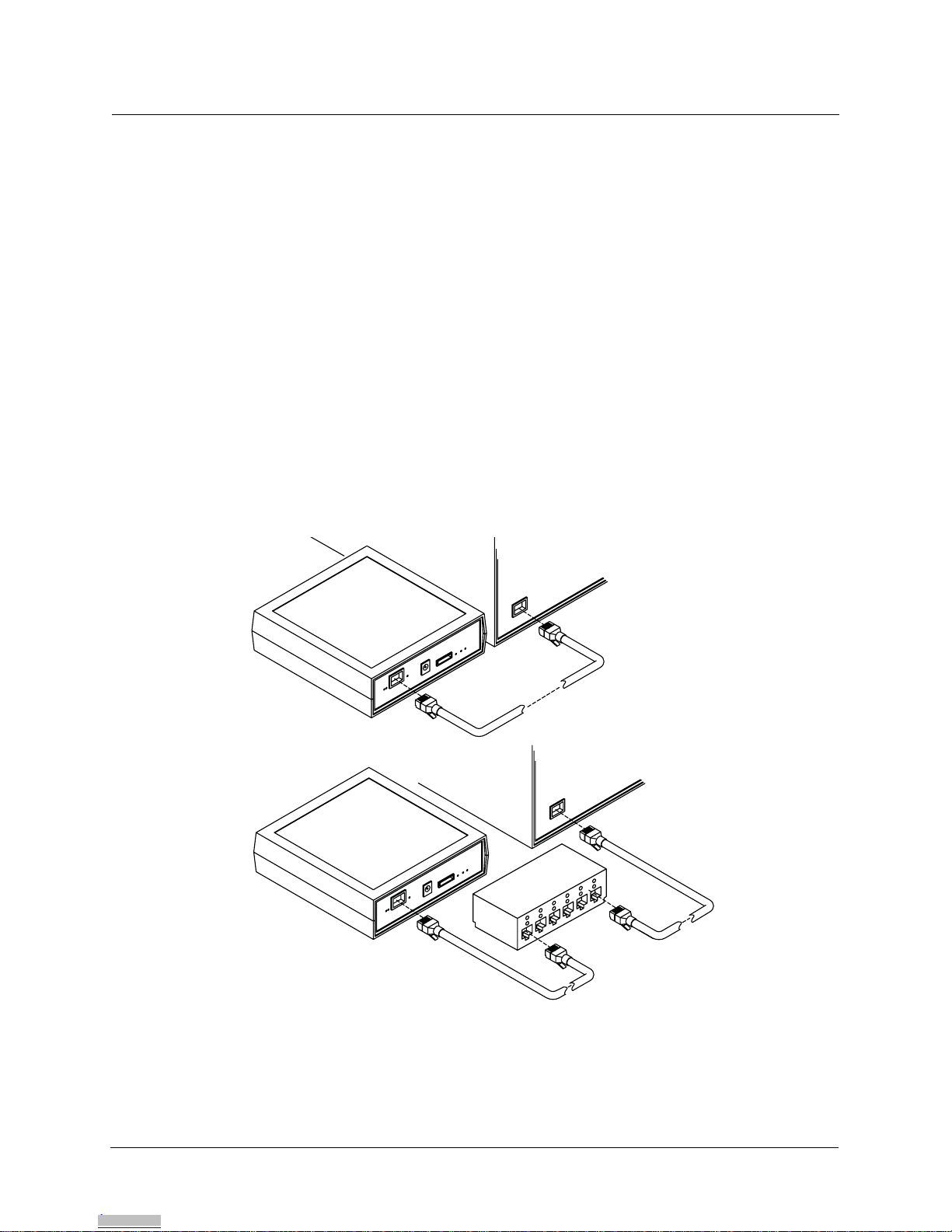

1Connect the ASEK Main Board module to the computer using either a standard Ethernet

crossover cable, or a separately-powered Ethernet hub and two standard Ethernet LAN cables

(the computer may be powered-on at any time).

Figure QS-1 Connecting the computer

Direct connection options: Ethernet crossover cable (above), or Ethernet hub and two standard cables (below).

ASEK Main Board

Module

Personal computer

Ethernet

Crossover Cable

ASEK Main Board

Module

Personal computer

Ethernet

Hub

(2) Ethernet LAN

Standard Cable

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Quick Start |

iv ASEK2-UG | Allegro® Sensor Evaluation Kit Technical Guide

2Solder the device-under-test (DUT) socket to the appropriate ASEK interface board, and

connect the ribbon cable between the interface board and the ASEK Main Board module

(Figure QS-2). (DUT connection without interface board is described later in this document.)

3CAUTION: ONLY USE the power supply included in the ASEK. Select a regional power plug

appropriate for the test facility, and swap it into the transformer body.Then connect the mini

plug to the ASEK module and connect the wall plug to the facility power mains.(Figure QS-3)

The ASEK powers-on immediately. Allow 30 seconds for the firmware to load.

4Open the Internet Web browser on the computer, and navigate to http://192.1.2.3. The ASEK

software opens as a Web page.

5Insert the DUT into the socket and use the ASEK software to perform demonstrations.

Figure QS-2 Connecting ribbon cable

For data transfer between ASEK Main Board module and an interface board with DUT socket.

Figure QS-3 Connecting power supply

Powers ASEK Main Board module, peripheral PCBs and a DUT for demonstration.

ASEK Main Board

Module

ASEK Interface Board

Connecting ribbon cable

to interface board

Mounting DUT

socket

Connecting ribbon cable to

ASEK Main Board module

ASEK Main Board

Module

Connect to power mains

Installing regional

power plug

Connecting power mini plug to

ASEK Main Board module

Insert DUT for

demonstration

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Allegro® Sensor Evaluation Kit Technical Guide v

Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Using This Manual

Compatibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Assumptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Relationship to Other Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Using PDF Hyperlinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Getting Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1. Introduction

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

ASEK Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

ASEK Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Allegro Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

Work Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 6

User-Provided Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 7

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 9

2. Network Configuration

Using the Default IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Changing the IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Configuring Simultaneous LAN Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 4

3. ASEK Hardware

ASEK Main Board Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Data Link Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 2

Power Supply Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3

ASEK Interface PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 5

Linear Device (Output Pin Programming) Interface PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 5

Switch or Latch Device (Supply Pin Programming) Interface PCB . . . . . . . . . . . . . . . . . . . . .3 - 7

Contents

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Contents

vi Allegro® Sensor Evaluation Kit Technical Guide

On-Board DUT Sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 9

Off-Board DUT Socket Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 10

DUT Connection Without Interface PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 11

Force/Sense Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 12

4. DUT Programming

Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Setting up for Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 2

Programming Standard Linear Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 3

Preparing the Board and DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 3

Performing Test and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 3

Programming 137x Linear Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 4

Preparing the Board and DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 4

Performing Test and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Programming Switch or Latch Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

Preparing the Board and DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

Performing Test and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

Programming with the Desktop Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

Preparing the Board and DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

Preparing the Desktop Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Performing Test and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 12

Using the 136X Utility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 13

Preparing the Board and DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 14

Preparing the 136X Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 14

Performing Test and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 16

5. ASEK Main Board Calibration

When to Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Performing Calibrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Preparing the ASEK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 2

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

1

Figure QS-1 Connecting the computer.....................................................................................................................QS-iii

Figure QS-2 Connecting ribbon cable ......................................................................................................................QS-iv

Figure QS-3 Connecting power supply.....................................................................................................................QS-iv

Figure 1-1 ASEK System Configuration ...................................................................................................................... 1-3

Figure 2-1 ASEK software interface, Main page.......................................................................................................... 2-3

Figure 2-2 ASEK software interface, IP address setting page..................................................................................... 2-4

Figure 3-1 ASEK Main Board module, rear view......................................................................................................... 3-2

Figure 3-2 Direct connection options........................................................................................................................... 3-3

Figure 3-3 ASEK Power supply set............................................................................................................................. 3-4

Figure 3-4 Changing power supply prongs.................................................................................................................. 3-4

Figure 3-5 Linear device, output-pin programming PCB (PN 85-0329-101) layout..................................................... 3-6

Figure 3-6 Linear device, output-pin programming PCB (PN 85-0329-101) basic schematic..................................... 3-6

Figure 3-7 Layout of C2, CBLOW, socket on linear device (output pin programming) interface board......................... 3-7

Figure 3-8 Bipolar switch or latch device, supply-pin programming PCB (PN 85-0329-102) layout............................ 3-8

Figure 3-9 Bipolar switch or latch device, supply-pin programming PCB (PN 85-0329-102) basic schematic............ 3-8

Figure 3-10 Pre-designed DUT socket mounting ........................................................................................................ 3-9

Figure 3-11 Jumping unused GND terminals on the VCC programming PCB.......................................................... 3-10

Figure 3-12 ASEK Main Board ribbon cable header pin-out...................................................................................... 3-11

Figure 4-1 ASEK Interface, page for programming standard linear devices ............................................................... 4-3

Figure 4-2 ASEK Interface, page for programming A137x style linear devices........................................................... 4-5

Figure 4-3 ASEK page for switch/latch programming.................................................................................................. 4-7

Figure 4-4 ASEK Interface, opening page for the Desktop Utility downloads.............................................................. 4-9

Figure 4-5 Security confirmation box for the Desktop Utility download ..................................................................... 4-10

Figure 4-6 ASEK Desktop Utility interface................................................................................................................. 4-11

Figure 4-7 ASEK 136X Utility interface...................................................................................................................... 4-15

Figure 5-1 Board Calibration Utility page..................................................................................................................... 5-2

Figures

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Allegro® Sensor Evaluation Kit Technical Guide | ASEK2-UG 2

Using This Manual

This chapter introduces the purpose and use of this document. It also includes information on con-

tacting Allegro® MicroSystems (Allegro) support groups. Information in this document is subject to

change without notice. For additional information, contact your local Allegro field service represen-

tative or sales representative, as described in this chapter.

Compatibilities

This guide describes the use of the Allegro Sensor Evaluation Kit (ASEK) Version 2, and applies to

the following release levels:

• Allegro Sensor Evaluation Kit firmwareandhardware compatiblewiththe ASEK-02Main Board

revision 1

In addition to these releases, certain additional configuration files contain information on specific

devices and configurations that may be updated from time to time for compatibility with new prod-

ucts. For information on updated configuration files, contact your local Allegro field service repre-

sentative.

The ASEK is designed to operate only with the power supply transformer supplied in the kit. Do not

use with any other transformer.

The network interface operates on IEEE 802.3, 10/100Base-T Ethernet

The ASEK kit and contents are lead (Pb) free and RoHS compliant.

Outline

The following sections are presented:

• Chapter 1, Introduction, provides a reference for the applications covered, kit parts list, system

requirements, user-supplied parts specifications, system electrical characteristics, and safety

considerations.

• Chapter2,NetworkConfiguration, describestheprocedure forconfiguringthe ASEKtoconnect

to the operator computer via LAN or by direct connection.

• Chapter 3, ASEK Hardware, describes the ASEK board, power supply, and connections.

• Chapter 4, DUT Programming, describes procedures for using the various programming and

evaluation tools provided in the ASEK software.

• Chapter 5, ASEK Main Board Calibration, describes the use of the Calibration board.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Using This Manual | Audience

3ASEK2-UG | Allegro® Sensor Evaluation Kit Technical Guide

Audience

This guide is intended for:

• Qualified technicians and engineers who are employees of companies that purchase of the cor-

responding Allegro products.

• Computer network administrators of companies who purchase the kit.

• Allegro field applications engineers.

• Allegro design, sales, and support staff

Assumptions

Users of this guide should have a working knowledge of the Microsoft Windows operating system

for using certain of the software modules, Hall effect sensor technology, electronic test and mea-

surement techniques, electrical power supply operation, and have a knowledge of the application

being designed.

Relationship to Other Documents

This document replaces all previous user guides for the Allegro Sensor Evaluation Kit, version 2.

The data in this manual constitutes the available documentation on the ASEK-02 kit. The kit is

intended to be used as is, and Allegro does not support modifications to the kit, other than those

specified in this document.

Using PDF Hyperlinks

When viewed online as an electronic book in PDF format, the cross-references in the text, such

as: see Figure 1-1, are active hyperlinks. To go to the cited figure, table, or section, click the link

text. To do so, position the arrow-shaped pointer over the hyperlink text, and when it changes to a

pointing hand , click to go to the target.

In addition to the links embedded in the text, the page numbers in the Table of Contents and list of

figures are hyperlinks. Click the page number to go to the cited page.

The Adobe Acrobat viewer also provides an interactive set of links in the Bookmarks tab in the

Navigation pane. The Navigation pane is displayed by default, but if it has been closed in the

instance that you are using, in the Acrobat main menu, click View > Navigation Tabs > Book-

marks, or press the F4 key.

CAUTION: Check for the latest version of this manual, on the Allegro On-line Store

website at www.allegromicro.com.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Using This Manual | Document Conventions

Allegro® Sensor Evaluation Kit Technical Guide | ASEK2-UG 4

Document Conventions

The following document conventions are used throughout the documentation set.

Getting Help

A PDF version of this manual is available on the Allegro On-line Store website.

For additional information on the ASEK system or to report problems, contact your local Allegro

field applications engineering office.

Convention Description

Bold text Literal text appearing in the interface of the software product

Monospace text Text that is entered or returned by the software

Italic text When describing data input, a variable data placeholder (the text is replaced with

appropriate text for entry); in other contexts, text to be considered literally

[text | text]Optional fields, with the pipe ( | ) character indicating to select one of the alternatives

given within the brackets

{text, text} Mandatory fields, with the comma (,) character indicating to select one or more

choices within the braces

Information about potential loss of data

Additional information of interest

Information about potential hazard to operator or equipment

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Using This Manual | Getting Help

5ASEK2-UG | Allegro® Sensor Evaluation Kit Technical Guide

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Allegro® Sensor Evaluation Kit Technical Guide | ASEK2-UG 1 - 1

Chapter 1

Introduction

Welcome to the Allegro Sensor Evaluation Kit (ASEK). The ASEK boards, together with the Web-

based firmware application, provide a powerful and flexible system for evaluation and program-

ming of Allegro Hall-effect sensors. The kit includes a calibration board that provides a rapid and

repeatable method for calibrating the ASEK Main Board.

Applications

The ASEK system is intended for use with field-programmable Hall effect devices offered by sale

by Allegro. This includes the following types of devices:

• 2-, or 3- or 4-wire switches or latches that are programmed using the supply pin

• 3-wire linear sensors that are programmed using the output pin

The firmware for the kit includes configuration data for specific Allegro devices that are supported

at the time of release of the kit. From time to time, as additional devices become available, the

firmware may be updated to adapt to those devices, and made available in updated versions of

this kit. Contact your local Allegro field applications engineering office for details on supported

devices.

The kit is intended for use as:

• a benchtop engineering tool for evaluating individual Allegro sensor devices; it can be used to

characterize and understand the performance of the various types of sensor devices

• calibrating field-programmable Allegro devices in small volumes; the device is ideal for charac-

terizing the effects of the various register value increments and for understanding and develop-

ing procedures for programming code streams for use on production systems

Additional device development kits for other Allegro devices may be available on the Allegro web-

site, www.allegromicro.com, by following the On-line Store link.

ASEK Software

The programs required to access and operate the ASEK are pre-installed as firmware on the Main

Board of the ASEK. The firmware falls into the following categories:

• Main Application. One graphical interface provides access to all functions, and it opens auto-

matically upon accessing the IP address of the ASEK Main Board. These functions are sum-

marized in the following items.

CAUTION: The ASEK system is intended for low-volume engineering applications. It is not

intended to be used in volume production environments, other than for system

development purposes.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Introduction | ASEK Hardware

1 - 2 ASEK2-UG | Allegro® Sensor Evaluation Kit Technical Guide

• Board Configuration Utility. This module allows a network system administrator to change the

LAN address of the ASEK Main Board.

• Board Calibration Utility. This module allows the operator to calibrate the ASEK Main Board.

• DeviceDemonstratormodules.Thesearesimplifiedinterfaceapplicationsusedtoevaluateand

program the device under test (DUT). There are three demonstrator modules: for switches (2-

or 3-wire), for standard linear devices, and for linear devices with additional programming

modes (the 137x family).

• Desktop Utility. This module allows the operator to perform hands-on benchtop and in situ sys-

tem evaluations of the behavior of various Allegro field-programmable devices. It includes:

– Desktop Utility. This module provides an interface to sending and receiving data

from the ASEK.

– 136X Utility. This module provides a specific interface for working with linear

devices in the A136x family.

– Configuration File. This contains information about particular devices, used with

the Desktop and 136X utilities.

ASEK Hardware

The kit hardware consists of a module housing the main controller and system interface printed cir-

cuit board (PCB) assembly, with peripheral PCB assemblies that serve as interfaces for mounting

or connecting to DUT sockets. Interconnect cables and a multiregional power supply are also pro-

vided. The general layout of the ASEK system is shown in Figure 1-1 on page 1-3.

Allegro Kit Contents

Before opening the ASEK package, ensure that the necessary support items are available, as

described in System Requirements, on page 1-6. At the minimum, an ESD-resistant pad should be

available for placing the contents as they are unpacked.

The ASEK Board kit comprises several circuit board assemblies, with supporting elements, identi-

fied in Table 1-1.

When the package is received, immediately compare its contents to Table 1-1. If there are any

missing or damaged items, contact your local Allegro field applications engineering office immedi-

ately.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Introduction | Allegro Kit Contents

Allegro® Sensor Evaluation Kit Technical Guide | ASEK2-UG 1 - 3

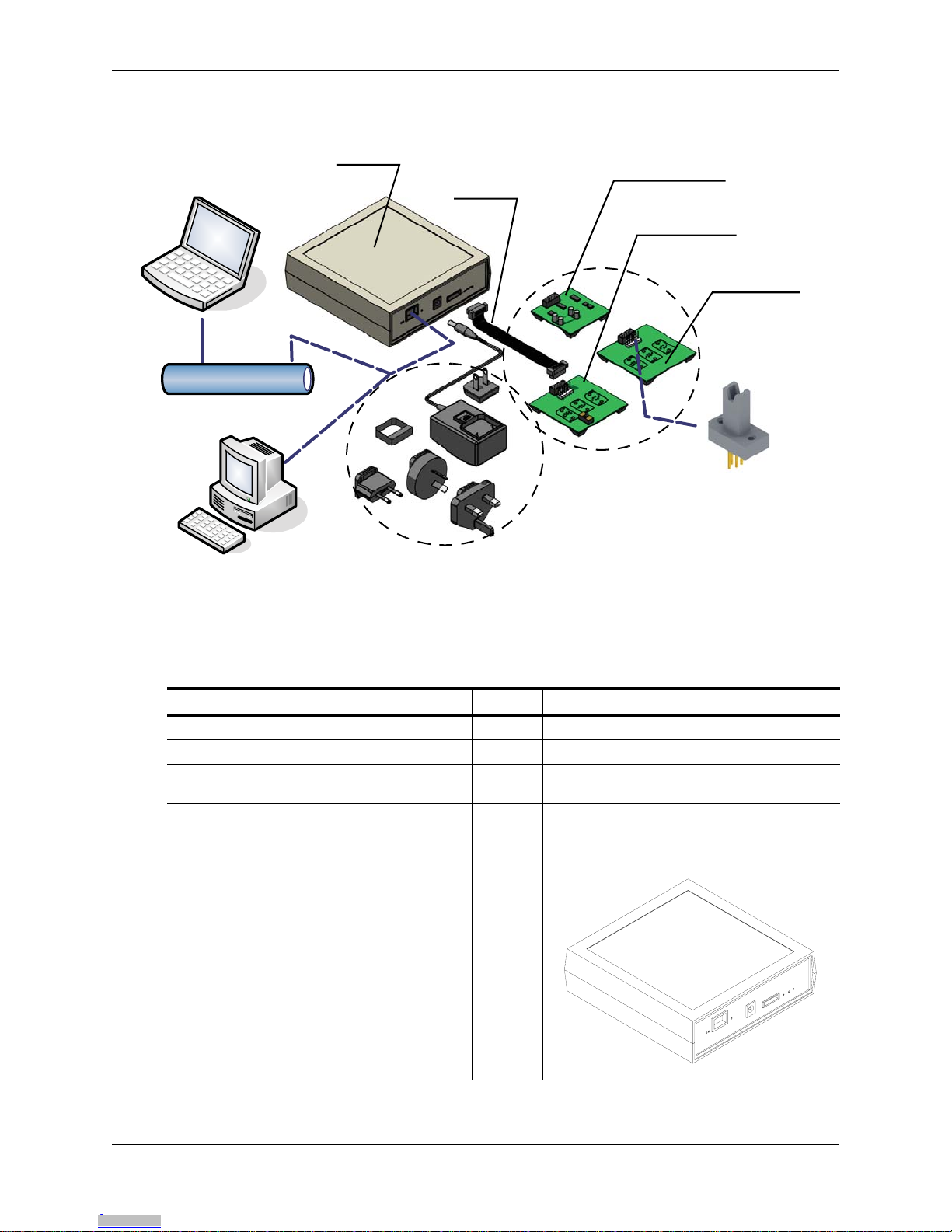

Figure 1-1 ASEK System Configuration

The system can operate over an Ethernet LAN or a direct-wired connection to the Main Board module by addressing the ASEK IP

address. The connection is compatible with common process control systems. A ribbon cable connection from the Main Board mod-

ule can be connected to either of the product interface boards or to the ASEK system calibration board.

Table 1-1 ASEK-02 Parts List

Item Part Number Quantity Description

Allegro Sensor Evaluation Kit ASEK-02 – Consisting of the components listed in this table

Application software N/A 1 Installed as firmware on the Main Board of the ASEK

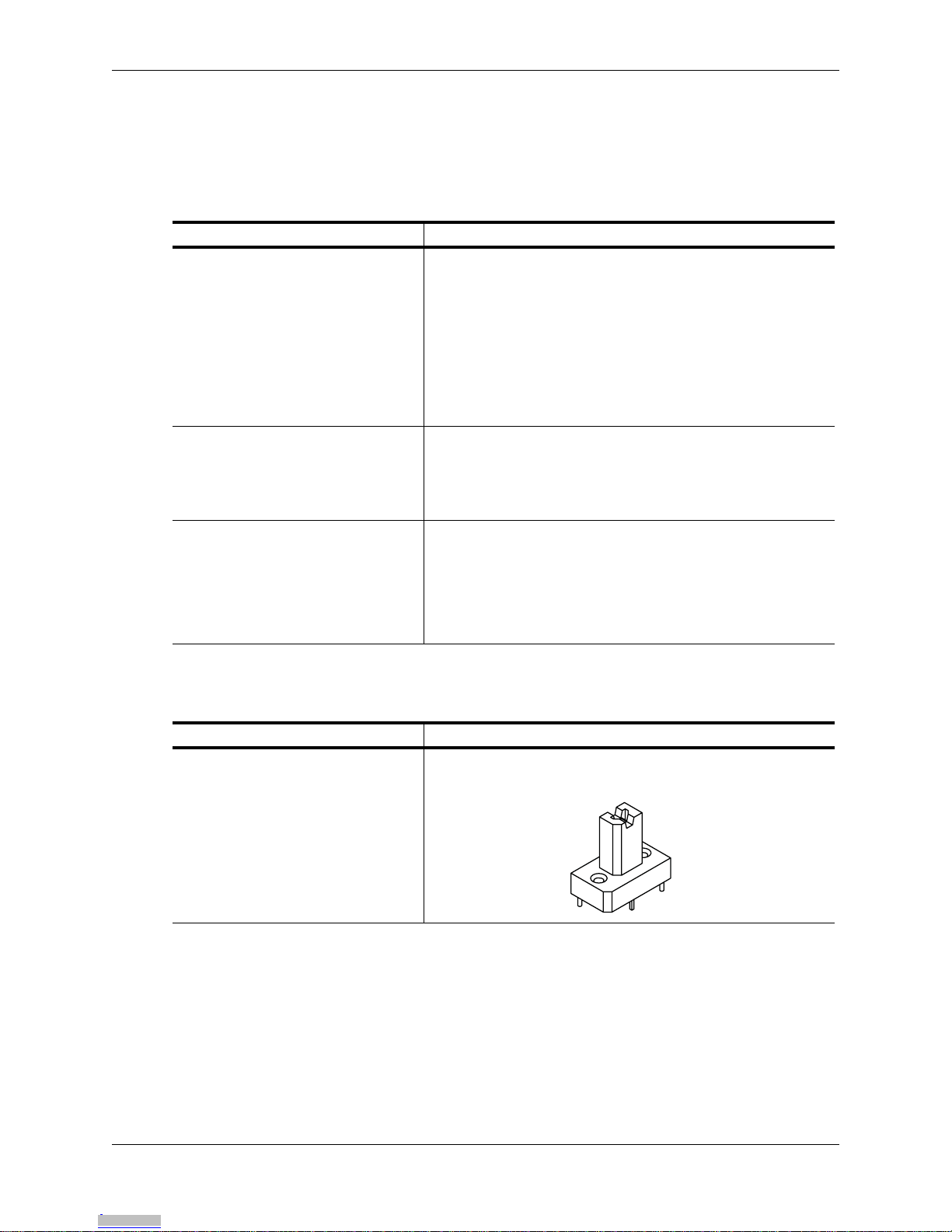

Main Board module N/A 1 Primary demonstrator module consisting of the

following components

Protective Housing N/A 1

13 cm x 13 cm, 4 cm overall height approximately;

apertures for power supply socket, Ethernet socket,

peripheral interface cable socket; windows for power

and signal LEDs

Ethernet

Alternative operator

computer location

via Ethernet LAN

ASEK calibration

board assembly

ASEK ribbon cable for

connecting peripheral

PCBs individually

ASEK linear device

interface board

assembly

ASEK Main Board

module

ASEK power transformer

with regional adapters

Local operator

computer

location

ASEK switch/latch

device interface board

assembly

DUT sockets may be

soldered to PCBs or

remotely connected

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Introduction | Allegro Kit Contents

1 - 4 ASEK2-UG | Allegro® Sensor Evaluation Kit Technical Guide

Main Board 85-0329-001

Rev. 1

(Installed in

housing) 1

Main Board should only be operated inside of the

protective housing due to the heat generated by the

Ethernet interface board.

Firmware version is available using the ASEK

Desktop Utility.

Peripheral Connection

Ribbon cable 85-0329-300

(Installed on

housing) 1

10 cm length, with IDC male 14-pin ribbon cable

connector each end

Calibration Peripheral PCB 85-0329-100

Rev. 1

Calibration Board 1

5 cm x 5 cm, IDT female 14-pin ribbon cable header

(Molex 87831-1429), used for calibrating the ASEK

Main Board

Linear Device (Output Pin

Programmed) Demonstrator

Peripheral PCB

85-0329-101

Rev. 1

Socket Board 1

6.3 cm x 6.3 cm, IDT female 14-pin ribbon cable

header (Molex 87831-1429), 6-pin solid header

2.54 mm centers (Molex 22-11-2062), 3 device

socket areas; used for Allegro linear Hall devices

Table 1-1 ASEK-02 Parts List (Continued)

Item Part Number Quantity Description

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Introduction | Allegro Kit Contents

Allegro® Sensor Evaluation Kit Technical Guide | ASEK2-UG 1 - 5

Switch Device (Supply Pin

Programmed) Demonstrator

Peripheral PCB

85-0329-102

Rev. 2

VCC

Programming

Socket Board

1

6.3 cm x 6.3 cm, IDT female 14-pin ribbon cable

header (Molex 87831-1429), 6-pin solid header

2.54 mm centers (Molex 22-11-2062), 3 DUT socket

areas; switch for programming pin selection; used for

Allegro switch or latch Hall devices

External DCPower Supply Module

(Wall-mount) 85-0329-400 1

6 cm x 4 cm, 4 cm overall height approximately;

5 VDC 1.2 A 5%, 90-264 VAC, 5.5 mm diameter

center positive, mini plug cable, 4 regional power

plug adapters, contact protective shroud

Table 1-1 ASEK-02 Parts List (Continued)

Item Part Number Quantity Description

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Introduction | System Requirements

1 - 6 ASEK2-UG | Allegro® Sensor Evaluation Kit Technical Guide

System Requirements

This kit includes hardware and software, and requires additional user-supplied equipment to oper-

ate properly.

Network Connections

The ASEK must be operated by a computer, but it is designed to allow the computer to be located

either at the test bench using a direct wired connection, or to be located remotely, connected by

Ethernet LAN. The ASEK includes an Ethernet port.

Although operation of the ASEK for device demonstrations can be performed either locally or via

LAN, changing of the IP address of the ASEK must be performed via direct connection (see

Changing the IP Address, on page 2-2).

For direct connection to the operator computer, the following alternatives can be used:

• A CAT5e 0.9 m Ethernet crossover cable between the ASEK and the operator computer.

• Ethernet standard LAN cable connected to a local separately-powered Ethernet hub, with a

second Ethernet cable connecting from the hub to the operator computer.

• For computers that do not have an Ethernet interface, either type of cable can be connected to

the computer by means of a wired USB Ethernet adapter.

• Wireless, serial port, and parallel port protocols are not supported.

Work Area

The work area should allow the printed circuit board assemblies, as well as the DUT (device under

test) to be protected from ESD (electrostatic discharge) at all times. Standard temperature and

humidity levels should be maintained to suppress ESD.

The boards should be placed on a level work surface, free of objects and obstructions. The sur-

face should be located at an ergonomic height.

The work area should allow the printed circuit board assemblies to be located as near as practica-

ble to each other. For data and power connections between the ASEK Main Board and the periph-

eral PCBs, the ASEK includes a ribbon cable that is approximately 10 cm in length. It is

recommended that the supplied cable always be used as the interface to the peripheral PCBs, and

for best results, it should not be extended in length.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Introduction | System Requirements

Allegro® Sensor Evaluation Kit Technical Guide | ASEK2-UG 1 - 7

User-Provided Equipment

Certain equipment and materials must be provided by the user. These are described in the follow-

ing tables.

Table 1-2 User-provided Equipment: Computer and Network Peripherals

Item Description

Computer

CPU and memory: processing is performed primarily on the ASEK Main

Board

Hard disk space: if the Desktop Utility is used, that requires under 100 kB

Interfaces: Ethernet port with RJ45 female connector, or USB 2.0 or

higher female port that can accommodate an Ethernet adapter

Computer monitor, color; 1024 x 768 pixels minimum recommended for

optimum viewing of user interface application

Mouse and keyboard

Operating system

Supports a graphical user interface

Web browser application installed

For use of the Desktop Utility module, Microsoft Windows and .NET

Framework 2.0 installed

LAN

Direct connection (required for changing IP address of ASEK):

Ethernet crossover cable, RJ45 male/male CAT5e, or

Separately-powered Ethernet hub connected between ASEK and

operator computer by 2 standard Ethernet connection cables

LAN connection:

IEEE 802.3, 10/100Base-T Ethernet LAN with standard Ethernet

connection cable

Table 1-3 User-provided Equipment: Programming Tasks

Item Description

DUT sockets

DUT sockets for standard device package types are available directly

from Azimuth Electronics (www.azimuth-electronics.com). Otherwise, as

required by the package type of the Allegro DUT.

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Introduction | System Requirements

1 - 8 ASEK2-UG | Allegro® Sensor Evaluation Kit Technical Guide

Off-Board Connection

For connection from an ASEK interface PCB to a user-provided DUT

socket that is mounted off-board, connection to on-board Molex 6373

series 6-pin solid header (such as Molex 6471 series Crimp Terminal

Housing 22-01-2025, accepts Molex 4809 series Crimp Terminals 22-30

AWG, such as 85-50111), shielded cable with 4 to 8 conductors and length

as short as possible.

For direct connection from ASEK Main Board to a user-provided DUT

socket (without ASEK interface board), connection to on-board Molex

87833-1420 14-pin ribbon cable PCB header, 2 mm centers (such as

Molex 87568-1494 IDT cable-to-board receptacle).

Ethernet Crossover Cable

Used for IP address setting. 0.9 m or shorter, male RJ45 connectors both

ends; CAT5e crossover cable; compatible with Ethernet 10/100Base-T.

Soldering Equipment DUT sockets acquired from Azimuth Electronics are manually soldered

onto the peripheral PCBs. Additional filter components may be required to

be soldered to the PCBs for certain applications.

DUT bypass capacitor As required by application, see DUT datasheet for rating.

Recommended maximum rating of 0.1 µF to avoid creating instability in

ASEK system, and minimum 50 V.

Table 1-3 User-provided Equipment: Programming Tasks (Continued)

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Introduction | Safety

Allegro® Sensor Evaluation Kit Technical Guide | ASEK2-UG 1 - 9

Safety

In order to prevent damage to the operator or to the kit or DUT, only qualified electronics techni-

cians or individuals with equivalent training should operate the product.

Follow the safety precautions required by local laws and regulations, and by the procedures of

your company.

The following specific warnings are not meant to be exclusive, or to limit the application of normal

safety precautions in any way:

DUT blowing capacitor

As required by application, see DUT datasheet for rating. Capacitor must

be capable of withstanding higher voltages required for blowing solid state

fuses internal to the DUTs while programming them.

This capacitor may be required to be inserted and removed at different

stages of programming, and a socket should be used. On the ASEK linear

DUT interface PCB, an optional socket is installed with 2.54 mm and 5.08

mm pitch holes, accepts capacitor leads 0.38 mm to 0.64 mm in diameter

and 2.54 mm to 3.71 mm in length (Aries series 0513 collet socket).

CAUTION: Only use the power supply provided with the ASEK. Do not substitute any

other power supply, or damage to the ASEK electronics may occur.

CAUTION: Always take precautions to avoid ESD before handling boards. This includes:

using ESD resistant clothing and gloves, and personal conductive straps, properly

connected to an earth ground. The work surface should be on an ESD-resistant pad, and

the operator should be standing or sitting on an ESD-resistant mat.

Table 1-3 User-provided Equipment: Programming Tasks (Continued)

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Table of contents

Other Allegro Motherboard manuals

Popular Motherboard manuals by other brands

ABACOM Technologies

ABACOM Technologies RX-AUDIO-24-D manual

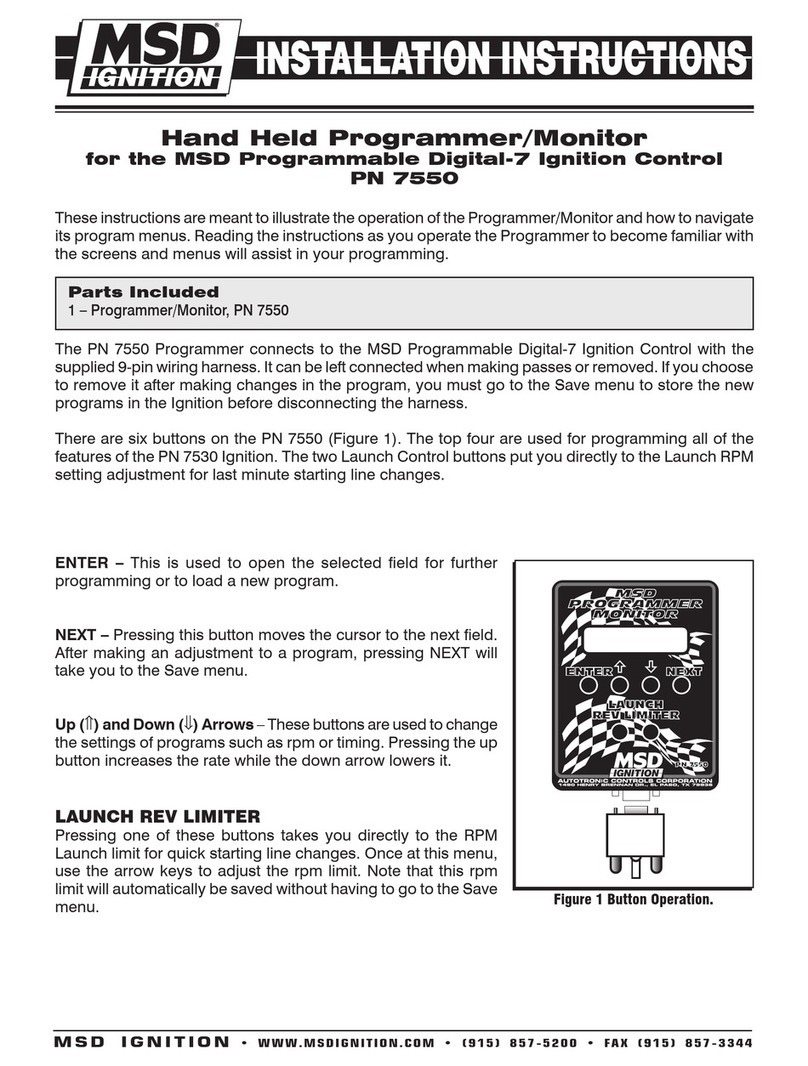

MSD Ignition

MSD Ignition 7550 installation instructions

VIA Technologies

VIA Technologies K8T890 user manual

Asus

Asus ROG MAXIMUS Z690 FORMULA manual

ASROCK Rack

ASROCK Rack EP2C612D16-2L2T Quick installation guide

Lattice Semiconductor

Lattice Semiconductor USB3-GbE VIP I/O Board user guide

NXP Semiconductors

NXP Semiconductors S12ZVM-EWP quick start guide

Advantech

Advantech PCM-9579 Startup manual

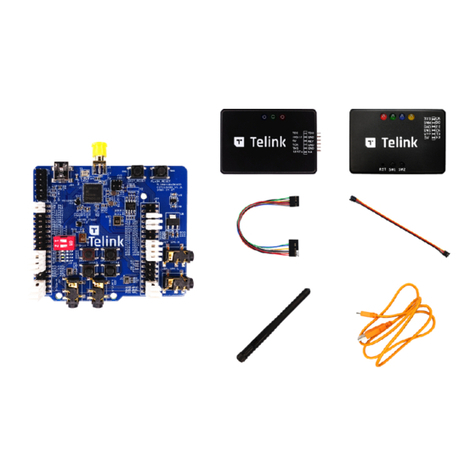

TELink

TELink B91 quick start guide

Biostar

Biostar G965 MICRO 775 Setup manual

Connect Tech

Connect Tech Photon NVIDIA Jetson AI Camera Platform user guide

Sapphire Audio

Sapphire Audio PI-A9RX480 user manual