2

may cause intermittent operation. For installation convenience,

Rockwell Automation offers a wide range of mounting brackets

(see the Accessories section for more details).

Alignment Indication

For short range applications the visible light beam of the sensor

suffices as alignment aid.

The alignment feature may be used for longer range applications.

Alignment of the sensor is indicated via change in intensity of the

green LED in the Alignment Mode, as follows:

1. Press and release the push button twice within three seconds.

After three seconds, the green LED turns OFF for 0.5 second

indicating the sensor is in the alignment mode.

2. Align the sensor to the emitter. The intensity of green LED

increases with better alignment. Secure it in a position that

yields the highest intensity of the green LED. Press and release

the button once to return to the RUN mode—or the sensor

returns to the RUN mode automatically in two minutes.

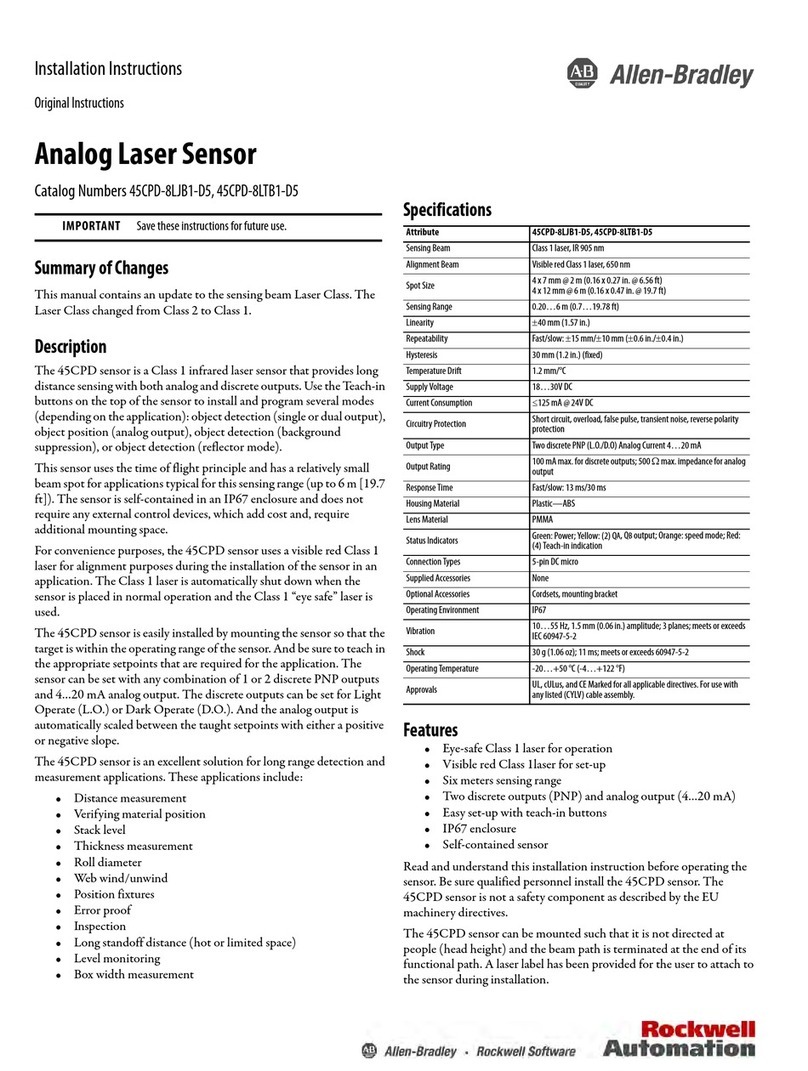

VisiSight™ Configuration

The 42JT VisiSight is configured using the push button Remote

Teach or IO-Link and the LED indicators on the sensor. There are

five features that can be configured:

• Static Teach: Standard sensitivity/sensing range adjustment

• Dynamic Teach (running process)

• Light operate (LO) or dark operate (DO) output

• Auto PNP/NPN, dedicated NPN or dedicated PNP

• Push button lock/unlock

The sensor output is disabled during Teach.

Teach Sensitivity/Sensing Range

The default setting is the maximum sensitivity/range.

Note: No teaching is needed for a vast majority of the

applications. Teaching is only necessary for targets that

are not fully opaque and the sensor may see through the

target (thus not detect the target) if set at maximum

sensitivity.

Static Teach:

Teach the receiver facing the emitter (first condition) and teach

the “target” (second condition).

Standard Teach:

1. To teach the receiver facing the emitter (first condition):

Align the sensor to the emitter. Press and hold button for three

seconds until yellow LED starts flashing. Release the button. The first

condition has now been taught.

2. Teach “target” (second condition):

Restore to factory default setting of maximum range:

Perform steps 1 and 2 with “no target” in the sensor’s field of

view and no emitter.

Dynamic Teach (Running Process):

If the targets to be detected are moving with the sensor aimed at

the running process, press and hold the button for three seconds

until the yellow LED starts flashing. The sensitivity will

automatically be taught in the next 30 seconds provided the

sensor sees two cycles of “target” and “no target.”

Teach Light Operate (L.O.) or Dark Operate (D.O.)

The default setting of the output is Dark Operate (D.O.)

D.O. setting means that output turns ON when the light between

the emitter and the receiver is blocked. If the application requires

the output to turn OFF when the target is blocking the light

between the emitter and receiver, the setting may be changed to

Light Operate (L.O.).

1. To access the teach output mode setting:

2. To change the sensor output mode setting:

Output Type Selection:

Auto PNP/NPN, Dedicated NPN, Dedicated PNP)

The default setting is Auto PNP/NPN. This means the sensor

monitors the load connection and automatically configures for

the proper operation, for example, PNP or NPN. If no load is

detected the sensor defaults to PNP.

Insert the target between the emitter and the receiver. Press and

release the button. The teach process is complete.

If the push button is not pressed within 30 seconds, the sensor exits

teach mode and returns to RUN mode without learning the new

setting.

Press and hold button for six seconds until the green LED starts

flashing. Release the button. The current setting is indicated by the

yellow LED:

L.O.: Yellow LED ON

D.O.: Yellow LED OFF

Press and release the button within ten seconds to toggle from L.O.

to D.O., the selection indicated by the yellow LED.

The sensor retains the setting per the last button depression and

returns to the RUN mode ten seconds after the last button is

depressed.

t > 6 s

t < 0.5 s