Allen-Bradley 1391B Series User manual

Other Allen-Bradley Controllers manuals

Allen-Bradley

Allen-Bradley PLC-5 series User manual

Allen-Bradley

Allen-Bradley SMC-3 User manual

Allen-Bradley

Allen-Bradley PowerFlex 70 User manual

Allen-Bradley

Allen-Bradley PowerFlex 527 User manual

Allen-Bradley

Allen-Bradley powerflex 700 User manual

Allen-Bradley

Allen-Bradley Micro800 User manual

Allen-Bradley

Allen-Bradley PLC-5/12 Setup guide

Allen-Bradley

Allen-Bradley 1305-RFB-5-A User manual

Allen-Bradley

Allen-Bradley PowerFlex 7000 User manual

Allen-Bradley

Allen-Bradley PowerFlex DC User manual

Allen-Bradley

Allen-Bradley PowerFlex 750 Series User manual

Allen-Bradley

Allen-Bradley SLC 500 User manual

Allen-Bradley

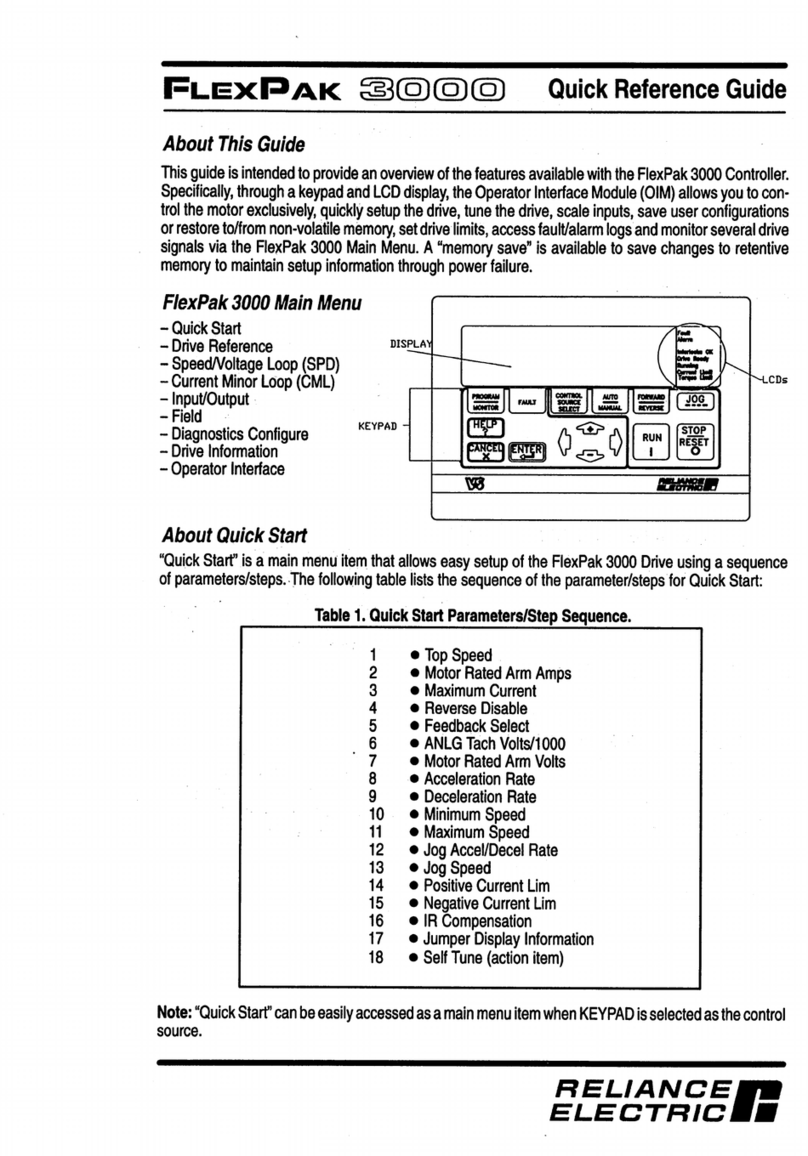

Allen-Bradley FlexPak 3000 User manual

Allen-Bradley

Allen-Bradley Micro800 User manual

Allen-Bradley

Allen-Bradley powerflex 700 Instruction manual

Allen-Bradley

Allen-Bradley ControlLogix 1756-STRT3 Instruction manual

Allen-Bradley

Allen-Bradley 1769 CompactLogix User manual

Allen-Bradley

Allen-Bradley PowerFlex 527 User manual

Allen-Bradley

Allen-Bradley ArmorStart 290E User manual

Allen-Bradley

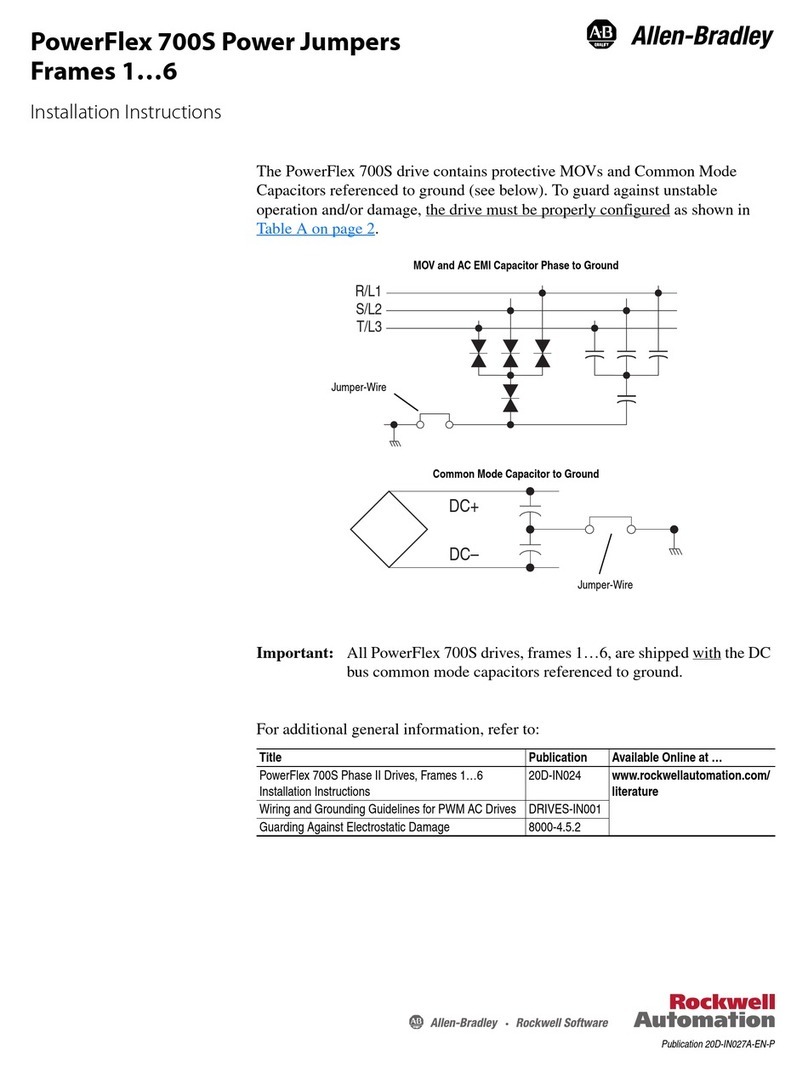

Allen-Bradley PowerFlex 700S User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions