9

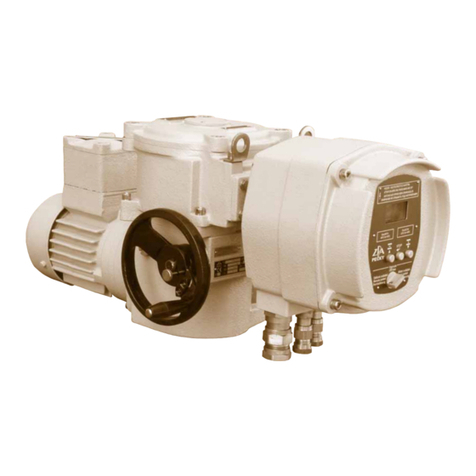

– Control section which is identical for all MODACT MOK actuators, Types MOK 125 to MOK 1000 type no., with the

only exception that, it differs in angular displacement of units on the base plate. In the actuator, Type No. 52 325, the unit of

position-limit signalling switches is arranged as shown in Fig 1. The control section (Fig.1) consists of position-limit switching

unit 1, resisence position transmitter 2, torque-limit switching unit 3, terminal block 4 and anti condensation heater 8.

The position-limit switching unit uses 4 microswitches of which 2 are always used for either direction of rotation of the output

shaft. The switching point of each microswitch can be adjusted independently within the working travel range of the actuator.

The torque-limit switching unit has independently adjustable microswitches, one for either direction of rotation.

The torque-limit switches are not secured against opening at the startig torque.

The potentiometer is fitted with a slipping clutch to permit automatic adjustment along with the output shaft.

The anti-condensation heater 8 (Fig.1, 2) prevents water vapours from condensing under the cover of the control

section. The position-limit switching unit and the position transmitter derive their movements from the output shaft of

the actuator via a driving gear (or in the actuators, Type Nos 52 326 and 52 327, via driving segment 7, as shown in

Fig. 1). The torque-limit switching unit is driven by a “floating worm” of the manual control mechanism where the worm

displacement is directly proportional to the torque of the actuator output shaft. This enables the actuator to be switched

off immediately the torque on the output shaft to whichthe torque-limit switching unit has been adjusted, is reached.

Note: The microswitches used are of a single-chamber type, i.e., they can operate as a one-pole cut-out switch a contact maker or

a change-ower switch, whereas the torque-limit switches can be used as cut-out switches only (see the respective circuit layout).

8. ADJUSTMENT OF THE ACTUATOR

a) Stop screws

Stop screws are used to limit the actuator working travel to 90° in compliance with the CLOSED and OPEN end positions of

the valves having no trip dogs of their own. The screw stops are mounted on the outside of the actuator along with the external

protective terminal. When viewing the stop screws, the right-hand stop screw is designedfor the CLOSED position, whereas the

left-hand stop screw is designed for the OPEN position under the assumption that, when viewing the local position indicator, the

output shaft rotates clockwise in the CLOSE direction of rotation. For adjustment of the stop screws, loosen the stop screws,

move the actuator with valve into the CLOSED position, and turn the corresponding stop screw till an increased resistance is felt

when the screw runs onto the stop face within the actuator. Secure the stop screw in position by retightening its lock nut. Then,

rotate the output shaft of the actuator through a 90° angle to bring it into the OPEN position and set the OPEN-position stop

screw by the same procedure.

When setting the stop screws in the actuators, Type Nos 52 326 ant 52 327, care should be taken to ensure that,

in the CLOSED or OPEN end position, the driving gear segment of the position-limit switching and auxiliary signalling

units cannot strike the electric motor. In either end position of the output shaft of the actuator, the local position indicator

should tally with the marks on the index plate.

If the valve is required to be tightly closed in the end position and thus the actuator is to be switched off by means of the torque-

limit switches, the tripping torque should be transferred to the valve. In this case, set the corresponding stop screw so that the valve

is properly sealed when the stops of the output shaft run against the stop screw at which the torque-limit switch operates.

In this case, the respective torque-limit switch is used for switching off the actuator. If stops are required to be used for

protection of the acutator and the valve against damage in the case of a failure of the position-limit switch set the stop screws

to such a position which ensures dependable operation of the position-limit switch and is still permissible for the valve. In this

case, the position-limit switch and the torque-limit switch should be connected in series. Nevertheless, this can only be done

when no tight closure of the valve is required.

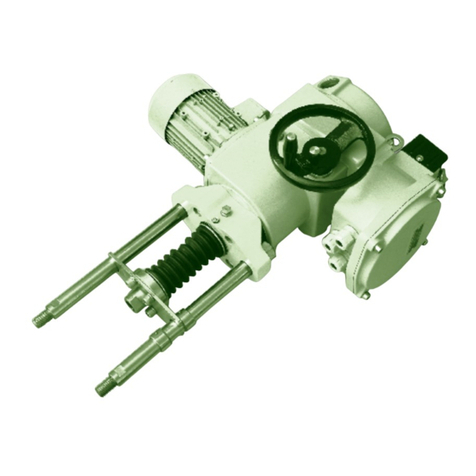

Legend:

1 – OPEN torque–limit switch cam

2 – CLOSE torque–limit switch cam

3 – OPEN torque–limit switch

4 – CLOSE torque–limit switch

5 – Releasing screw of CLOSE

torque–limit switch cam

6 – Releasing screw of OPEN

torque–limit switch cam

Fig. 3 - Torque-limit switches