Allied Pumps Levikos M18 Manual

Levikos M18

Level Controller

OPERATION & MAINTENANCE MANUAL

alliedpumps.com.au

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

Document No.

IOM-LAI-001

Document Title

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

Revision No.

A

Number of Pages

21

REVISION HISTORY

REV

DATE

DESCRIPTION OF CHANGES

PREPARED

CHECKED

APPROVED

A

26.11.2018

ISSUED FOR REVIEW

JFD

LAS

NOTES

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

1INTRODUCTION

This manual is designed to provide all parties concerned with relevant information on installation and operation of the Levikos M18

Controller.

The Levikos M18 Controller is engineered to provide a dedicated Single or Dual (optional) tank level management system to the end

user. It is designed to withstand harsh and diverse environments. The controller incorporates a unique combination of features ensuring

total reliability when it comes to tank level indication, monitoring and control.

The Levikos M18 Controller is ideally suited for applications including but not limited to fire, sewage, effluent, storm, and potable water

tank level monitoring.

The controller uses a versatile 4-20mA level and can be configured to display level and provide alarms at desired level depending on

the end user requirements.

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

2INDEX

1INTRODUCTION

2INDEX

3SAFETY SUMMARY

4TECHNICAL ASSISTANCE

5SYSTEM SPECIFICATIONS

6SYSTEM OVERVIEW

6.1 COMPONENTS FUNCTION

7INDICATOR PROGRAM KEYS

7.1 RELEVANT PARAMETERS TABLE

8INDICATOR CONFIGURATION

8.1 PRE-REQUISITES

8.2 PARAMETER SET-UP

8.3 SPECIAL FUNCTIONS

8.3.1 ALARM TIMER

8.3.2 ALARM INITIAL BLOCKING

9REMOTE MONITORING

9.1 VOLT FREE CONTACTS

9.2 MODBUS RTU (SERIAL RS-485)

9.2.1 RS485 INTERFACE

9.2.2 GENERAL CHARACTERISTICS

9.2.3 COMMUNICATION PROTOCOL

9.2.4 CONFIGURATION

9.3 MOXA MGATE CONFIGURATION

9.3.1 INSTALLTING MGATE MANAGER

9.3.2 STARTING MGATE MANAGER

9.3.3 CONNECTING TO THE UNIT

9.3.4 MODIFYING THE CONFIG.

9.3.5 CONFIGURE SERIAL PORT

9.3.6 CONFIGURE IP ADD. & SETTINGS

9.3.7 CONFIGURE SERIAL PARAMETERS

10 ORDERING INFORMATION

11 APPENDICES

11.1 APPENDIX A–DRAWINGS

12 WARRANTY INFORMATION

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

3SAFETY SUMMARY

The symbols below are used on the equipment and throughout

this document to draw the user’s attention to important

operational and safety information.

CAUTION or WARNING

Read complete instructions

prior to installation and

operation of the unit

CAUTION or WARNING

Read complete instructions

prior to installation and

operation of the unit

All safety related instructions that appear in the manual must

be observed to ensure personal safety and to prevent damage

to either the instrument or the system. If the instrument is

used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

4TECHNICAL ASSISTANCE

All parties involved shall read and understand this manual prior

to installation and commissioning of the product. The

Controller shall be handled with care and shall be used

according to this manual for optimum results.

If the indicator (display unit) requires repairs, some special

handling care should be taken. The device must be withdrawn

from the case and immediately placed in an anti-static wrap;

protected from heat and humidity.

Allied Pumps is committed to customer service and the Service

Team can be contacted for assistance via below methods.

Telephone: +61 (0) 8 9350 1000

Fax: +61 (0) 8 9356 5255

Website: www.alliedpumps.com.au

Address: 2 Modal Crescent (Cnr Baile Rd), Canning Vale,

WA 6155

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

5SYSTEM SPECIFICATIONS

MECHANICAL (ENCLOSURE)

DIMENSIONS………………...… 300(H) x 250(W) x 150(D)

APPROXIMATE WEIGHT…….…….…………5.85 – 6.76kg

MATERIAL FINISH…………..…. STEEL PAINTED RAL7032

INGRESS PROTECTION………………...………….…. IP66

ENVIRONMENT OPERATING TEMPERATURE… 5 - 50°C

ELECTRICAL

POWER…….. 240VAC,50Hz, 3 PIN PLUG CONNECTION

MAX. COMSUMPTION…………………….…….......... 60W

INPUT…………………………..… 4-20mA, Passive, 2 Wire

INPUT ACCURACY…………..……...…………0.15% SPAN

OUTPUTS………………..……. VFC, RATED 250VAC, 10A

BOOT-UP TIME………………….………………. 3s DELAY

ETHERNET COMMUNICATION……….……...…….. RJ-45

6SYSTEM OVERVIEW

The system consists of the following components.

ITEM

NO.

ITEM

DESCRIPTION

TAG

QUANTITY

1

Enclosure

n/a

1

2

240VAC/24VDC

Power Supply

U0101

1

3

N1500 Indicator

F0109

1

4

Buzzer

H0119

1

5

Alarm Strobe

H0122

1

6

Mute Button

S0122

1

7

Mute Relay

K0125

1

8

Low Tank Level VFC

Terminals X1:3, X1:4

n/a

1

9

High Tank Level VFC

Terminals X1:5, X1:6

n/a

1

10

4-20mA Level Sensor

n/a

1

11

N1500 Indicator

(Dual Tank Only)

F0128

1

12

Low Tank Level VFC

Terminals X1:9,

X1:10 (Dual Tank

Only)

n/a

1

13

High Tank Level VFC

Terminals X1:11,

X1:12 (Dual Tank

Only)

n/a

1

14

4-20mA Level Sensor

(Dual Tank Only)

n/a

1

15

Moxa Mgate Switch

(Optional)

F0143

1

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

6.1 COMPONENTS FUNCTION

ITEM

FUNCTION

240VAC/24VDC

Power Supply

Transforms Single phase Power into

24VDC extra low voltage power

N1500 Indicator

Indicates Value of sensor reading and

activates alarms

Buzzer

Provides audible warning when high or

low level alarms are active

Alarm Strobe

Provides visual warning when high or

low level alarms are active

Mute Button

Deactivates audible warning (if alarms

are active) only when pressed

4-20mA Level

Sensor

Measures Liquid Level and transmit 4-

20mA signal to Indicator

Moxa Mgate

Switch

(Optional)

Provides communication gateway for

TCP connection (Optional)

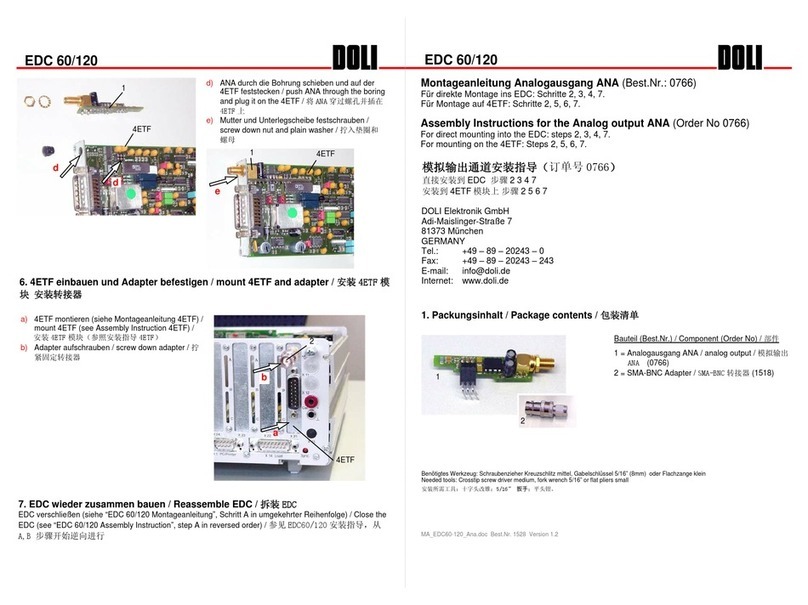

STROBE

ENCLOSURE

INDICATOR

INDICATOR

MUTE

BUTTON

LEAD &

PLUG FOR

POWER

BUZZER

FIGURE 1.

LEVIKOS PANEL

FIGURE 2.

INDICATOR FASCIA

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

7INDICATOR PROGRAM KEYS

The following describes the program keys that the end user

shall use to program the Levikos Indicator.

PROGRAM KEY

This Key is used to access different displays with

programmable parameters of the device

BACK KEY

This Key is used to go back to previous parameter displayed

in the menu cycle

UP/MAX KEY

This Key is used to increase parameters or display maximum

values stored in memory

DOWN/MIN KEY

This Key is used to decrease parameters or display minimum

values stored in memory

FUNCTION KEY

This SPECIAL function key is NOT USED

7.1 RELEVANT PARAMETERS TABLE

TYPE

CODE

DESCRIPTION

4-20mA

Custom Linearization, user

defined

4-20mA

Linear, scalable from

(-)31000 to 31000

Input

Type

Selects the input signal or

sensor type to be connected to

the PV terminals. Refer to

Table 1 for options.

Changing the input type causes

all other parameters related to

PV and alarms to be changed as

well.

Input

Low

Limit

Sets the low limit fort input

type 0-50mV, 4-20mA, 0-5V or

0-10V. When the PV

Retransmission is used this limit

defines the corresponding 4mA

(or 0mA) in relation to the

input value

Input

High

Limit

Sets the high limit fort input

type 0-50mV, 4-20mA, 0-5V or

0-10V. When the PV

Retransmission is used this limit

defines the corresponding

TYPE

CODE

DESCRIPTION

20mA in relation to the input

value

Alarm

Set

Points

1,2,3,4

Defines the operation point of

each alarm programmed with

“ ” or “ ” functions,

When an alarm is programmed

with a differential function, the

alarm setpoint value represents

the deviation value of the alarm

relative to the reference

Alarm

Functions

1,2,3,4

Defines functions for the alarms

1,2,3,4.

Alarm off

Broken or Shorted Sensor

Low value

High value

Differential low

Differential high

Differential outside the range

Differential within range

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

8INDICATOR CONFIGURATION

The Levikos M18 is configured via the Front fascia of the

Indicator (see Figure 2.).

The installer/User shall step through the following to complete

configuration.

8.1 PRE-REQUISITES

1. System is plugged into recommended Power Supply

2. Level Sensor’s 4-20mA output is connected to

Controller’s terminals X1:1 and X1:2

3. Indicator N1500 is turned on (note indicator takes

3s to boot-up)

8.2 PARAMETER SET-UP

Provided all pre-requisites are actioned the user shall proceed

according to the steps below.

SETTING INPUT TYPE –Configuration Cycle

1. From main menu press Program and Back Key

simultaneously until the display shows

2. Move up or down the menu using the Up or Down

Key to select

SETTING INPUT LIMITS –Configuration Cycle

3. will display again after a short time. When

it does using the Program Key navigate to

& set the decimal point to desired location using Up

or Down Key

4. will display again after a short time. When

it does using the Program Key navigate to

5. Using the Up or Down Key set the lower range value

to be displayed for 4mA

6. will display again after a short time. When

it does using the Program Key navigate to

7. Using the Up or Down Key set the higher range

value to be displayed for 20mA

SETTING ALARM SET POINTS –Work Cycle

8. From main menu use the Up or Down Key navigate

to & set the desired high level alarm value

(this set point shall be within range set in

& )

9. will display again after a short time. When

it does use the Program Key to navigate to

& set the desired low level alarm value

using the Up or Down Key (this set point shall be

within range set in & )

10. will display again after a short time. When

it does use the Program Key to navigate to

& set the desired high level alarm value

using the Up or Down Key (this set point shall be

set identical to )

11. will display again after a short time. When

it does use the Program Key to navigate to

& set the desired low level alarm value

using the Up or Down Key (this set point shall be

set identical to )

SETTING ALARM FUNCTIONS –Alarm Cycle

12. From main menu press Program and Back Key

simultaneously until the display shows .

Using the Up and Down Key set the function to

13. will display again after a short time. When

it does use the Program Key to navigate to

. Using the Up and Down Key set the

function to

14. will display again after a short time. When

it does use the Program Key to navigate to

. Using the Up and Down Key & set the

function to

15. will display again after a short time. When

it does use the Program Key to navigate to

. Using the Up and Down Key & set the

function to

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

8.3 SPECIAL FUNCTIONS

8.3.1 ALARM TIMER

The alarms can be configured to perform timing functions. The

configuration allows the alarm output to be delayed, or to

deliver a single pulse or a train of pulses. The delay, the pulse

width and the period are defined by the user.

Table 4 shows these advanced functions. Times T1 and T2 can

be programmed from 0 to 6500 seconds. Programming 0

(zero) in the timer parameters T1 and T2 disables the timer

function.

The LEDs associated with the alarm always light up when the

alarm condition occurs, regardless of the current state of the

output relay, which may be de-energized momentarily due to

a time delay.

FUNCTION

T1(s)

T2(s)

OUTPUT

Normal

0

0

Delayed

0

1 -

6500

Pulse

1 -

6500

0

Oscillator

1 -

6500

1 -

6500

8.3.2 ALARM INITIAL BLOCKING

The initial blocking option inhibits the alarm from being

recognized if an alarm condition is present when the controller

is first energized. The alarm will be triggered only after the

occurrence of a non-alarm condition followed by a new

occurrence for the alarm.

The initial blocking is disabled for the sensor break alarm

function.

9REMOTE MONITORING

The Levikos M18 has 3 methods of monitoring.

1. Volt free Contacts (Low and High Level)

2. Modbus RTU (Serial RS 485)

3. Modbus TCP (Ethernet)

9.1 VOLT FREE CONTACTS

FUNCTION

TERMINALS

STATE

RATING

TANK 1

LOW LEVEL

X1:3

X1:4

Normally

Open

250VAC,

10A

TANK 1

HIGH LEVEL

X1:3

X1:4

Normally

Open

250VAC,

10A

TANK 2

LOW LEVEL

(if installed)

X1:5

X1:6

Normally

Open

250VAC,

10A

TANK 2

LOW LEVEL

(if installed)

X1:7

X1:8

Normally

Open

250VAC,

10A

9.2 MODBUS RTU (SERIAL RS-485)

The optional serial interface RS485 allows to address up to

247 indicators in a network communicating remotely with a

host computer or master controller.

9.2.1 RS485 INTERFACE

•Compatible line signals with RS485 standard

•2 wire connection from master to up to 31 slaves

indicators in a multi drop bus. It is possible address

247 nodes with multiple outputs converters.

•Maximum communication distance: 1000m

•The RS485 signals are:

D1=D: Bidirectional data line.

D0=D: Bidirectional inverted data line.

C=GND: Optional connection.

OUTPUT

ALARM

OUTPUT

ALARM

T2

T1

ALARM

OUTPUT

ALARM

T2

T1

T1

OUTPUT

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

9.2.2 GENERAL CHARACTERISTICS

•Optically isolated serial interface

•Programmable baud rate: 1200, 2400, 4800, 9600,

19200, 38400, 57600 or 115200bps.

•Data Bits: 8

•Parity: None or even.

•Stop Bits: 1

9.2.3 COMMUNICATION PROTOCOL

All configurable parameters can be accessed through the

Registers Table 5 below. Broadcast commands are also

supported (address 0).

The available Modbus commands are:

03 - Read Holding Register

05 - Force Single Coil/Digital Output state

06 - Preset Single Register

The registers are arranged in a table in such a way that several

registers can be read in the same request.

9.2.4 CONFIGURATION

Two parameters must be configured in the device for serial

communication:

•: Baud rate. All devices with same baud rate.

•: Device communication address. Each

device must have an exclusive address.

HOLDING REGISTERS

Equivalent to the registers reference 4XXXX.

The holding registers are basically a list of the internal indicator

parameters. All registers above address 12 can be read or be

written to. The registers up to this address are read only. Each

table parameter is a 16 bits two complement signed word.

HOLDING

REGISTERS

PARA-

METER

REGISTER DESCRIPTION

0000

PV

Read: Process variable.

Write: not allowed.

Range: the minimum value is

in set and the

maximum value is in

set and the decimal point

position depends on .

HOLDING

REGISTERS

PARA-

METER

REGISTER DESCRIPTION

0001

PV min

Read: Minimum value of PV

Write: not allowed.

0002

PV max

Read: Maximum value of PV

Write: not allowed.

0003

PV

Read: Process variable.

Write: not allowed.

Maximum range: 0 to 62000.

0004

Display

Value

Read: Current display value.

Write: Current display value.

Maximum range:

-31000 to 31000.

The range depends of the

showed display.

0005

Display

Number

Read: Current display

Number.

Write: not allowed.

0006

Status

Word 1

Read: Digital Inputs and

Alarms (high part) and

Hardware type (low part).

Write: not allowed.

Range: 0000h to FFFFh

Value format: XXYYh, when:

XX: Hardware type

bit 0 - Alarm 1

bit 1 - Alarm 2

bit 2 - Alarm 3

bit 3 - Alarm 4

bit 4 - Analog output

bit 5 - RS 485

bit 6 –reserved

bit 7 - reserved.

YY: digital inputs & alarms

bit 0 - Alarm 1 state:

0=inactive; 1=active

bit 1 - Alarm 2 state:

0=inactive; 1=active

bit 2 - Alarm 3 state:

0=inactive; 1=active

bit 3 - Alarm 4 state:

0=inactive; 1=active

bit 4 - Digital Input:

0=inactive; 1=active

bit 5 - reserved

bit 6 - reserved

bit 7 –reserved

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

HOLDING

REGISTERS

PARA-

METER

REGISTER DESCRIPTION

0007

Software

Version

Read: Software version.

Write: not allowed.

If the version is V1.00, for

example, value will be 100.

0008

ID

Read: Identification device

Number.

Write: not allowed.

Values:

1 –N1100/N2000; 3 –N1500.

Other values: special devices.

0009

Status

Word 2

Read: Indicator status bits.

Write: not allowed.

Read value: verify each bit:

bit 0 –Sensor error

bit 1 –Cable error

bit 2 –Underflow

bit 3 –Overflow

bit 4 –reserved

bit 5 –Alarm 1 power-up

inhibit (0-no; 1-yes)

bit 6 –Alarm 2 power-up

inhibit (0-no; 1- yes)

bit 7 –Alarm 3 power-up

inhibit (0-no; 1- yes)

bit 8 –Alarm 4 power-up

inhibit (0-no; 1- yes)

bit 9 –Unit (0-°C; 1-°F)

bit 10 –reserved

bit 11 –Output 1 state

bit 12 –Output 2 state

bit 13 –Output 3 state

bit 14 –Output 4 state

bit 15 –Output 5 state

0010

Special

Command

Special function command.

Write:

Value 0 –Tare reset;

Value 5 –Hold & Peak-hold

clean;

Value 10 –Maximum and

minimum clean;

Value 15 -Tare

0011

Decimal point position of PV.

Range: 0 to 4

0=XXXXX; 1=XXXX.X;

2=XXX.XX; 3=XX.XXX;

4=X.XXXX

0012

F key Function.

Standard Model:

0= ; 1= ; 2= ;

3=

LC Model:

0= ; 1= ; 2= ;

3= ;

4= ; 5= ; 6=

0013

Digital Input Function.

Standard Model:

0= ; 1= ; 2= ;

3= ;

LC Model:

0= ; 1= ; 2= ;

3= ; 4= ; 5= ;

6= ;

0014

Input digital filter.

Range: 0 to 60

0015

Input Offset value.

Range: from to

0016

SCALE parameter condition.

Configurable indication from

–31000 to + 31000.

Configurable indication from

0 to + 60000.

Configurable indication from

0 to +120000.

0017

Input Square Root.

Range: 0 to 1

0=no; 1=yes

0018

4-20mA analog output on

error condition.

0=down; 1=up

0019

Alarm Reference.

Range: from to

0020

Retransmission type of PV.

Range: 0 to 1

0=4 to 20mA retransmission;

1=0 to 20mA retransmission

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

0021

Alarm 1 Preset. Range:

The minimum value is in

set for not differential

alarm or ( - )

for differential alarm;

The maximum value is in

set for not differential

alarm or ( - ) if

differential alarm.

0022

Alarm 2 Preset

Range: same as or

.

0023

Alarm 3 Preset

Range: same as or

.

0024

Alarm 4 Preset

Range: same as or

.

0025

Alarm 1 Function. Range:

0 to 6

0= ; 1= ; 2= ;

3= ; 4= ; 5= ;

6= .

0026

Alarm 2 Function

Range: same as .

0027

Alarm 3 Function

Range: same as .

0028

Alarm 4 Function

Range: same as .

0029

Alarm 1 power-up inhibit.

Range: 0 a 1

0=no; 1=yes.

0030

Alarm 2 power-up inhibit

Range: same as .

0031

Alarm 3 power-up inhibit

Range: same as .

0032

Alarm 3 power-up inhibit

Range: same as .

0033

Alarm 1 Hysteresis

(engineering unit)

Range: 0 to span of sensor

0034

Alarm 2 Hysteresis

(engineering unit)

Range: same as

0035

Alarm 3 Hysteresis

(engineering unit)

Range: same as

0036

Alarm 4 Hysteresis

(engineering unit)

Range: same as

0037

Input sensor type

Standard model

(types 0 to 22):

0= tc J;

1= tc K;

2= tc T;

3= tc E;

4= tc N;

5= tc R;

6= tc S;

7= tc B;

8= Pt100;

9= 0 to 50mV;

10= 0 to 5V;

11= 0 to 10V;

12= 0 to 50mV

(custom linearization);

13= 0 to 5V

(custom linearization);

14= 0 to 10V

(custom linearization);

15= Lin J;

16= Lin K;

17= Lin T;

18= Lin E;

19= Lin N;

20= Lin R;

21= Lin S;

22= Lin B;

23= Lin Pt100;

24= 0 to 20mA;

25= 4 to 20mV;

26= 0 to 20mA

(custom linearization);

27= 4 to 20mV

(custom linearization);

LC - Load Cell model

(types 0 to 9):

0= 0 to 20mV;

1= -20 to 20mV;

2= 0 to 50mV;

3= 0 to 20mV

(custom linearization);

4= -20 to 20mV

(custom linearization);

5= 0 to 50mV

(custom linearization);

6= 0 to 20mA;

7= 4 to 20mV;

8= 0 to 20mA

(custom linearization);

9= 4 to 20mV

(custom linearization);

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

0038

Temperature Unit.

Range: 0 to 1

0=°C; 1=°F.

Not available on LC model.

0039

Indication Low limit.

Range: the minimum value

depends on input type

configured in and the

maximum is in .

0040

Indication High limit.

Range: from to the

input maximum configured in

.

0041

Slave address

Range: 1 to 247

0042

Communication Baud Rate.

Range: 0 to 4

0 to 1200; 1 to 2400;

2 to 4800; 3 to 9600;

4 to 19200; 5 to 38400;

6 to 57600; 7 to 115200;

8 to 15 repeat baud rates

from 1200 to 115200, but

with invert polarity.

0043

Serial

Number

High

Serial Number (High Display)

Range: 0 to 9999. Read only

0044

Serial

Number

Low

Serial Number (Low Display)

Range: 0 to 9999. Read only

0045

Reserved

0046

Alarm 1 Time 1 of timer.

Range: 0 to 6500sec

See operation manual for

details.

0047

Alarm 1 Time 2 of timer (in

seconds)

Range: same as .

0048

Alarm 2 Time 1 of timer (in

seconds)

Range: same as .

0049

Alarm 2 Time 2 of timer (in

seconds)

Range: same as .

0050

Alarm 3 Time 1 of timer (in

seconds)

Range: same as .

0051

Alarm 3 Time 2 of timer (in

seconds)

Range: same as .

0052

Alarm 4 Time 1 of timer (in

seconds)

Range: same as .

0053

Alarm 4 Time 2 of timer (in

seconds)

Range: same as .

0054

Low Limit for Analog

Retransmission –Defines the

PV value that results in a 4mA

(or 0mA) analog output

current.

0055

High Limit for Analog

Retransmission –Defines the

PV value that results in a

20mA analog output current.

0056-0060

Reserved

0061-0090

to

Custom linearization value.

0091-0120

to

Value to be displayed in point

of custom linearization

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

9.3 MOXA MGATE CONFIGURATION

The Moxa MGate that is used to extract information from the

display unit uses a software base configuration tool called

MGate Manager. The complete manual for the device can be

found under the link below

https://www.moxa.com/support/sarch_result.aspx?type=doc&

prod_id=73&type_id=7

For the Levikos, below is the summarised configuration

information necessary to communicate with the Levikos.

9.3.1 INSTALLTING MGATE MANAGER

The following instructions explain how to install MGate

Manager, a utility for configuring and monitoring MGate

MB3000 units over the network.

1. To install MGate Manager, insert the MGate

Documentation and Software CD into your PC's

CD-ROM drive, and then run the following setup

program to begin the installation process from the

"Software" directory:

MGM_Setup_[Version]_Build_[DateTime].exe

The filename of the latest version may have the

following format:

MGM_Setup_Verx.x.x_Build_xxxxxxxx.exe,

for example:

2. You will be greeted by the Welcome Window. Click

Next to Continue

3. When the Select Destination Location window

appears, click Next to continue. You may change the

destination directory by first clicking on Browse....

4. When the Select Additional Tasks window appears,

click Next to continue. You may select Create a

desktop icon if you would like a shortcut to MGate

Manager on your desktop.

5. Click Install to start copying the software files.

6. A progress bar will appear. The procedure should

take only a few seconds to complete.

7. A message will indicate that MGate Manager is

successfully installed. You may choose to run it

immediately by selecting Launch MGate Manager.

8. You may also open MGate Manager through Start

>> Programs >> MGate Manager >> MGate

Manager.

9.3.2 STARTING MGATE MANAGER

MGate Manager is a Windows-based utility that is used to

configure the MGate MB3000.

Before running MGate Manager, make sure that your PC and

the MGate MB3000 are connected to the same network.

Alternatively, the MGate MB3000 may be connected directly

to the PC for configuration purposes.

You may open MGate Manager from the Windows Start menu

by clicking Start >> Programs >> MGate Manager >> MGate

Manager.

9.3.3 CONNECTING TO THE UNIT

1. Click On Search and a new Search Window will pop-

up

2. Click on Specify IP Search Address of the unit, enter

the IP address and click OK

3. If the search is successful, the unit will be listed in

MGate Manager. Configuration can be done in two

ways: left click the unit to begin the MGate Manager

configuration; right click the unit to begin the Web

Console configuration.

9.3.4 MODIFYING THE CONFIG.

Once your unit is displayed in MGate Manager, select it by

clicking on it. The Configuration button will become

available. Click Configuration to open the configuration

window. Before going into configuration page, if the firmware

version is after v3.0, you have to input the default password

moxa. If you prefer to use web console for configuration, the

default account and password are admin and moxa

respectively.

9.3.5 CONFIGURE SERIAL PORT

The Mode tab is where each serial port’s operation mode is

configured. The operation mode determines whether the

device(s) that are connected to the serial port will operate as

a master or a slave and whether the Modbus RTU or Modbus

ASCII protocol will be used. There are four operation modes

as follows:

•RTU Slave

•RTU Master

•ASCII Slave

•ASCII Master

RTU Slave shall be selected for the Levikos.

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

9.3.6 CONFIGURE IP ADD. & SETTINGS

The Network tab is where the unit’s network settings are

configured. You can modify the Name, Network

Configuration, IP Address, Netmask, Default Gateway, and

DNS. You may also select a Password to protect the unit from

unauthorized access.

PARAMETER

VALUE

NOTES

Name

(an

alphanumeric

string)

You can enter a name

to help you identify

the unit, such as the

location, function, etc.

Network

Configuration

Static IP, DHCP,

BootP, or

DHCP/BootP

Select Static IP if you

are using a fixed IP

address. Select one of

the other options if

the IP address is set

dynamically.

IP Address

192.168.127.254

(or other 32-bit

number)

The IP (Internet

Protocol) address

identifies the server

on the TCP/IP

network.

Netmask

255.255.255.0

(or other 32-bit

number)

This identifies the

server as belonging to

a Class A, B, or C

network.

Gateway

0.0.0.0

(or other 32-bit

number)

This is the IP address

of the router that

provides network

access outside the

server’s LAN.

DNS1

0.0.0.0 (or

other 32-bit

number)

This is the IP address

of the primary domain

name server.

DNS2

(an

alphanumeric

string)

This is the IP address

of the primary domain

name server.

Password

(an

alphanumeric

string)

You can set a

password to prevent

unauthorized users

from configuring the

unit. The password

will be required when

anyone attempts to

configure the unit

over the network.

Modbus operation is

not affected by the

password.

PARAMETER

VALUE

NOTES

Confirm

password

(an

alphanumeric

string)

Re-type the password

again for confirmation.

9.3.7 CONFIGURE SERIAL PARAMETERS

The Serial tab is where each serial port’s communication

parameters are configured. You can configure Baud Rate,

Parity, Stop Bit, Flow Control, FIFO, and Interface

Mode.

PARAMETER

VALUE

LEVIKOS SETTINGS

Interface

Mode

RS-232

RS-485, 2W

RS-422

RS-485, 2W

RS-485, 4W

BAUD Rate

50 bps to

961200 bps

96200 bps

Parity

None, Odd,

Even, Space,

Mark

Even

Stop Bits

1,2

1

Flow Control

None,

RTS/CTS, RTS

Toggle

Default

UART FIFO

Enable, Disable

Default

RTS On

Delay

0 to 100 ms

Default

RTS Off

Delay

0 to 100 ms

Default

10 ORDERING INFORMATION

SYSTEM

MODEL NO.

DESCRIPTION

ENCLOSURE

INSTRUMENTATION

(Note: Other Depth and Cable

Length available)

SIZE(mm)

MATERIAL

LVK-S-X-X

SINGLE TANK BASIC MODEL

300(H)

250(W)

150(D)

METAL

1 x (0-4m) Level Transducer

complete with 1 x 10m Cable

SKU: KJ308100

LVK-S-X-ETH

SINGLE TANK WITH ETHERNET TCP/IP

SKU: KJ308200

LVK-S-RTU-X

SINGLE TANK WITH SERIAL MODBUS

RTU

SKU: KJ308300

LVK-D-X-X

DUAL TANK BASIC MODEL

2 x (0-4m) Level Transducers

complete with 1 x 10m Cable

each

SKU: KJ308500

LVK-S-X-ETH

DUAL TANK WITH ETHERNET TCP/IP

SKU: KJ308600

LVK-D-X-RTU

DUAL TANK WITH SERIAL MODBUS RTU

SKU: KJ308700

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

11 APPENDICES

11.1 APPENDIX A –DRAWINGS

DT

LVK RTU ETHX X

ST

TANK 2 LEVEL (%)

TANK 1 LEVEL (%)

LEVIKOS PANEL

MUTE

COPYRIGHT. THIS DRAWING AND DESIGN MUST NOT BE COPIED IN WHOLE OR IN PART WITHOUT THE

WRITTEN CONSENT OF ALLIED PUMPS AND AS REPRODUCED MUST CARRY ALLIED PUMPS DESIGNATION.

Specialists in Package Pumping Solutions

2 Modal Crescent (Cnr Baile Rd)

Canning Vale, WA 6155

+61 (08) 9350 1000

www.alliedpumps.com.au

P

P

P

P

P

P

P

P

P

P

LEVIKOS M18

LEVEL CONTROLLER

INSTALLATION & OPERATION MANUAL

IOM-LAI-001

REV. A

12 WARRANTY INFORMATION

Warranty is subject to Allied Pumps Pty Ltd terms and conditions of sale and limited to replacement or repair, at Manufacturer’s

discretion, of any parts or equipment, excluding and travel, site, removal or reinstallation costs, for a period of twelve months from

date of invoice, provided such part of equipment that is deemed by the respective manufacturer to be faulty. Any work done on site

to inspect or remedy faults that are subsequently not accepted as being under warranty by the manufacturer, or are caused by misuse,

fair wear or operating procedures, will be charged at parts and labour and travelling time rates applicable at the time.

Warranty does not provide for circumstances outside Allied Pumps control including (but not limited to); seismic activity, base or

ground movement, mechanical impact, abuse or negligence, or general wear and tear.

Warranty does not cover equipment that is not installed, continuously monitored and maintained in accordance with the

manufacturer’s requirements, including, but not limited to, regular servicing, and/or regulatory requirements and applicable Australian

Standards. Warranty does not cover damage caused by dry running the pumps.

If Buyer requires our services in respect of site inspection or service outside of what is covered by Manufacturers’ warranties, then

Buyer should enter into a separate agreement with ALLIED PUMPS in respect to the same. In the event of no such separate agreement,

all operations, calibrating, cleaning and maintenance of plant is the responsibility of the buyer.

ALLIED PUMPS have not acted as a consultant nor charged design fees on this project, and is in no way responsible for, nor guarantee

any particular level of performance of the plant supplied or effluent quality unless such guarantee is specially given in writing.

Under no circumstances is ALLIED PUMPS liable for any direct or consequential loss or business interruption or damage to persons

or properties of any nature due to any cause whatsoever.

Application of warranties is conditional on ALLIED PUMPS having received in cash the total contract price. Furthermore, ALLIED

PUMPS reserves the right to withdraw any code compliance, Australian Standard compliance or selection compliance, should the

contract not be paid in full.

Table of contents

Popular Controllers manuals by other brands

Renkforce

Renkforce 1374456 operating instructions

EAS Electric

EAS Electric ECEN Series instruction manual

National Instruments

National Instruments CompactRIO cRIO-9002 manual

ENDA

ENDA EDT3011 Series manual

Texas Instruments

Texas Instruments TMS320C6000 DSP reference guide

National Instruments

National Instruments Quanser QNET 2.0 Set up and configuration