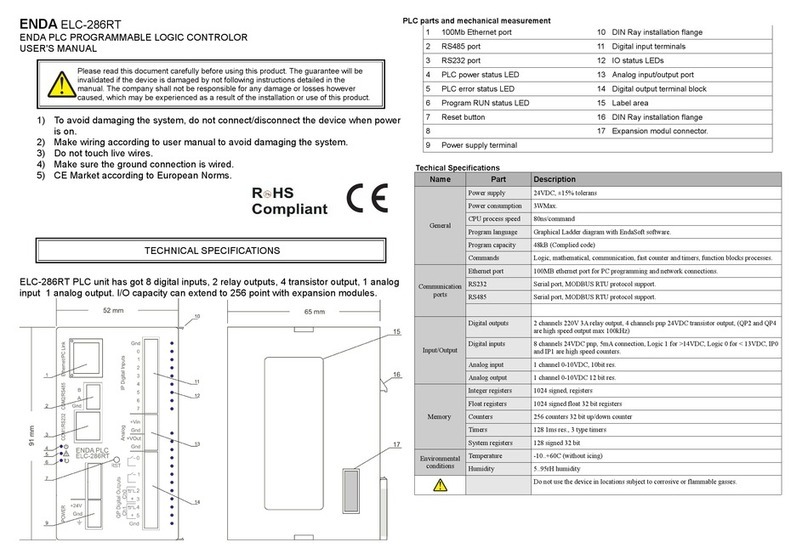

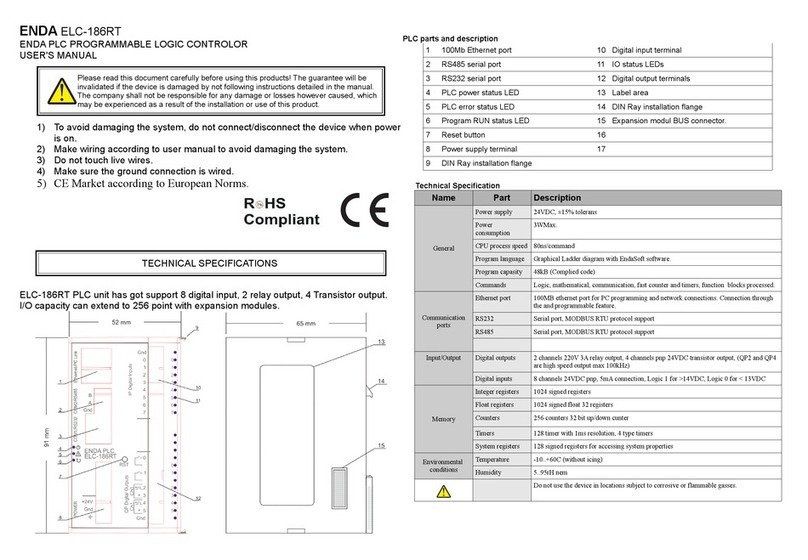

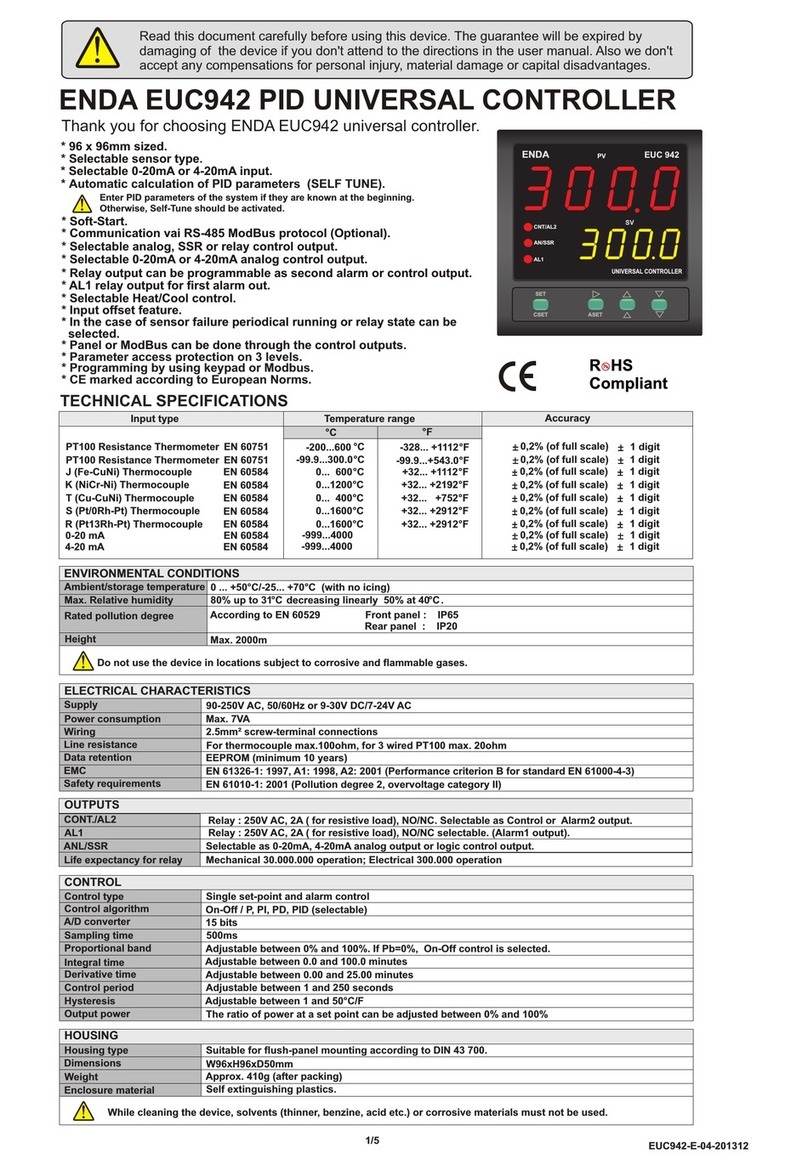

ENDA EDT3011 Series User manual

ENDA EDT3011 COOLING / DEFROST CONTROLLER

1 / 2

77 x 35mm sized

Single NTC prob input

Additional offset feature for input

Defrosting duration and interval time settings

Delay time and minimum operating time settings for

compressor protection

Compressor or door alarm control via digital input

Upper, lower and delay time settings for alarm

In case of probe failure, output status can be set to ON,

OFF or periodic

Upper and Lower setpoint value limits can be adjusted

Temperature unit can be selected as °C or °F

CE marked according to European Norms

Panel Cut-out

71,5mm

29mm

CONNECTION DIAGRAM

ELECTRICAL CHARACTERISTICS

230V AC +10% -20%, 50/60Hz or 12/24V AC/DC ±10% or 9-30V DC / 7-24V AC SMPS

Max. 3VA

Power connection : 2.5mm² screw-terminal, Signal connection : 1,5mm² screw-terminal connections

EN 61326-1: 2013 (Performance criteria B has been satisfied for EN 61000-4-3 standard)

EEPROM (Min. 10 years)

±1% - 1sec.

Max. 100ohm

EN 61010-1: 2010 (Pollution degree 2, overvoltage category II ).

Suitable for flush-panel mounting according to DIN 43 700.

W77xH35xD61mm

Approx. 215g (after packing)

Self extinguishing plastics

Single set-point and alarm control

12-bit accuracy, 100ms sampling time

Adjustable between 0.1 and 15.0 °C/F

Max.2000m

KEEP AWAY device from exposed to corrosive, volatile and flammable gases or

liquids and DO NOT USE the device in similar hazardous locations.

80% Relative humidity for temperatures up to 31°C, decreasing linearly to 50% at 40°C.

0 ... +50°C/-25 ... +70°C (with no icing)

According to EN 60529 ; Front Panel : IP65, Rear Panel : IP20

Avoid any liquid contact when the device is switched on.

DO NOT clean the device with solvent (thinner, gasoline, acid etc.) and / or abrasive cleaning agents.

Scale Range Accuracy

EN 60751

-60.0...150.0 °C -76.0...302.0°F

± 1% (Full scale) ± 1 digit

Supply

Power Consumption

Wiring

Line Resistance

Data Protection

Time Accuracy

EMC

Safety Requirements

HOUSING

Housing Type

Dimensions

Weight

Enclosure Material

CONTROL

Control type

Kontrol yöntemi

A/D converter

Hysteresis

ENVIRONMENTAL CONDITIONS

INPUT

Height

Ambient / Storage Temperature

Relative Humidity

Protection Class

Input Type

NTC Resistive Sensor

3.5 digit, 7-segment 19mm red LED

Scale

For 8A : NO and NC 250V AC, 8A (resistive load), Control output.

For 20A : NO 250V AC, 20A (resistive load), Control output.

For 8A : Mechanical 30.000.000; Electrical 300.000 operation. 250V AC, 8A (resistive load).

For 20A : Mechanical 30.000.000; Electrical 100.000 operation. 250V AC, 20A (resistive load).

OUTPUT

Life expectancy for relay

C1 Output

1

3

3

4

Covers

For mounting device ;

Push the device in direction 1

Order Code : EDT3011 - - -

1 2 3

1- Supply Voltage

230......230V AC

024........24V AC/DC

012........12V AC/DC

SM........9-30VDC/7-24VAC

2- Output Selection

08.....8A Relay output

20.....20A Relay output

3- ModBus

Blank.....N/A

RS.........ModBus

(Specify at Order)

Read this document carefully before using this device. The guarantee will be expired by device

damages if you don't attend to the directions in the user manual. Also we don't accept any

compensations for personal injury, material damage or capital disadvantages.

Thank you for choosing ENDA EDT3011 series cooling / defrost controller devices.

ENDA EDT3011 is intended for installation in control panels. Make sure that the device is used

only for intended purpose. The electrical connections must be carried out by a qualified staff

and must be according to the relevant locally applicable regulations. During an installation, all of the cables

that are connected to the device must be free of electrical power. The device must be protected against

inadmissible humidity, vibrations, severe soiling and make sure that the operation temperature is not

exceeded. The cables should not be close to the power cables or components.

SUPPLY:

NOTE:

184-253V AC

50/60Hz 4VA

Line

Neutral

230V AC

Supply

Switch

Note:

Cable size: 1,5mm²

Fuse

F 100 mA

250V AC

Fuse should

be connected

1) Mains supply cords shall meet the requirements of

IEC 60227 or IEC 60245.

2) In accordance with the safety regulations, the power

supply switch shall bring the identification of the

relevant instrument and it should be easily

accessible by the operator.

11

12

Holding screw

0.4-0.5Nm

Equipment is protected throughout

by DOUBLE INSULATION.

DIMENSIONS

Note :

1) Panel thickness should

be maximum 7mm.

2) If there is no 60mm free

space at the back side of

the device,it would be

difficult to remove it from

the panel.

For removing device from panel :

- Push the flush-mounting clamps in

direction as shown in the figure.

Then, pull out the clamp in direction

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18

8 680 407 7224 40

C1

1 2 3 4 5 6 7 8 9 10

ENDA INDUSTRIAL ELECTRONICS

SN: XXXXXXXXX

EDT3011-230-08

DIGITAL THERMOSTAT

230V AC +10% -20%

50/60Hz 5VA

11 12

250V AC 8A

RESISTIVE LOAD

NTC

DOOR

SW.

MADE IN TURKEY

8 680 407 7224 57

C1

1 2 3 4 5 6 7 8 9 10

ENDA INDUSTRIAL ELECTRONICS

SN: XXXXXXXXX

EDT3011-230-20

DIGITAL THERMOSTAT

230V AC +10% -20%

50/60Hz 5VA

11 12

250V AC 20A

RESISTIVE LOAD

NTC

DOOR

SW.

MADE IN TURKEY

C1

1 2 3 4 5 6 7 8 9 10

ENDA INDUSTRIAL ELECTRONICS

SN: XXXXXXXXX

EDT3011-230-08-RS

DIGITAL THERMOSTAT

230V AC +10% -20%

50/60Hz 5VA

11 12

250V AC 8A

RESISTIVE LOAD

NTC

DOOR

SW.

MADE IN TURKEY

+-

AB

RS485

8 68040 7 72 2464

1

3

2

3

2

2

2

1

EDT3011-EN-02-191202

ENDA

TM

EDT3011-EN-02-191202

In order to access security

menu 311 should be entered

r0 C0

o1

r1 C2

P1

r2 C3

C5

P2

i1

i5

P5

C4

d0.

d3

d4

d8

-Cn -rE -CP -dE -AL -SC

S.Cd

Cn.s

rE.s

CP.S

dE.S

Al.S

SP.S

GENERAL SETTINGS TEMPERATURE SETTINGS COMPRESSOR SETTINGS DEFROST SETTINGS ALARM SETTINGS SECURITY SETTINGS

Programming Mode

Default

Value

Default

Value

Default

Value

Default

Value

Default

Value

Default

Value

2.0 1

P.YE

P.YE

P.YE

P.YE

P.YE

P.YE

0

0.0

-60.0

3

0.0

150.0 0

10

°C

n.c

3

t.d

10

8

30

d.no

0

Programming Diagram

If this key is pressed

for 2 seconds, SP

message appears on

display and access to

temperature settings.

Temperature value

4.0

SP

Runnig Mode

-18.0

C1 Set Value

-18.1 -18.2 -18.1

Default Value

0.0 If any key is not pressed for 4 seconds, "Running Mode" is entered.

d5

0

d6

1

Operating Temperature

Hysteresis.

It can be adjusted

between 0.1 and 15.0 .

Compressor Power-up

Delay Time

Can be adjusted

between 0 and 199

minutes.

Defrosting Interval.

It can be adjusted between 0

and 199 hours. If 0 is selected,

defrost is never performed.

See d8 parameter.

Defrost Running Time

It can be adjusted between 0

and 199 hours. If 0 is selected,

defrost is never performed.

Defrosting interval Type

Selection.

0 = Defrosting timer ( d0 )

counts during the device is

running.

1 = Defrosting timer ( d0 )

counts during the compressor is

running.

Indicator Value Selection

During Defrost.

0 = Cabin temperature is

displayed.

1 = Displayed if the cabin

temperature is below SP + r0 ,

otherwise SP + r0 is displayed.

When the defrost ends, the

display value does not change

until the cabin temperature falls

below SP + r0 .

P r o b e C a l i b r a t i o n

Can be adjusted between

-25.0 and 25.0

Minimum Temperature

Can be adjusted

between -60.0 and r2

Required Minimum Stop

Duration for Compressor

Can be adjusted between

0 and 199.

Maximum Temperature

Can be adjusted

between r1 and150.0 .

D e c i m a l N o t a t i o n

0 = Without decimal

0.0 = With decimal

Temperature Unit

°C = Celsius

°F = Fahrenheit

Digital Input Relay State

n.o = Will be activated when

switch position is closed.

n.c = Will be activated when

switch position is opened.

Digital Input Behavior

0 = No act.

1 = External alarm is active.

At the end of i7 time, iA

flashes on the screen until the

external alarm is OFF.

2 = External alarm is active.

At the end of the i7 time,

the compressor is stopped

until the external alarm is

turned off and iA flashes

on the display.

3 = Door is open.

Compressor is stopped until

the door closes and id

flashes on the screen when

i7 time is up.

Indicator Selection During

"Running Mode”

t.d = Indicates cabin

temperature.

SP.d = Indicates SP value Compressor Stop Time

In Case of Probe Failure.

Can be adjusted between

0 and 199.

-60.0

150.0

abs

AbS

120

30

15

15

A1

A4

A2

A5

A6

i7

pfa psC iA

___ aH id

___ al

A7

A8

Low Temperature

Alarm Set Value.

Can be adjusted between

-60.0 and 150.0°C.

Hysteresis value is

2°C / 4°F.

Hight Temperature

Alarm Set Value.

Can be adjusted between

-60.0 and 150.0°C.

Hysteresis value is

2°C / 4°F.

Low Temperature

Alarm Type Selection.

No = No alarm

rEL = Dependent on SP

value.

AbS = Independent alarm.

Hight Temperature Alarm

Type Selection.

No = No alarm

rEL = Dependent on SP

value.

AbS = Independent alarm.

Digital Input Delay Time

Can be adjusted between

0and 120 minutes.

Temperature Alarm

Delay Time.

Can be Adjusted

between 0 and 240

minutes.

High Temperature Alarm

Delay Time After Defrost.

Can be adjusted between 0

and 240 minutes.

CAUTION !

During defrost process, alarms will

not be activated.

If the door is open, the high

temperature alarm will not be active.

-Cn Menu Security Level

Non = Menu invisible.

P.YE = Can be modified.

P.np = Read only.

ERROR MESSAGES

Sensor Broken

(Cannot Communicate

with the Sensor ) NTC Sensor Short Circuit External Alarm

High Temperature Alarm Door Open

Measured Temperature

Above the Scale

Move ENDAKEY-RF towards the top left of the

device in direction 1 .

If this key is pressed

for 4 seconds,

“Programming Mode”

is entered.

First time pressed any of the

keys, temperature set value

appears by flashing.

And, temperatures set value can be adjusted by using keys.

Accessing to "Running Mode" from "Programming Mode" :

if no key is pressed within 30 seconds during “Programming Mode”,

data is stored automatically and "Running Mode" is entered.

Alternatively, by pressing key for 4 seconds, data is stored and

"Running Mode" is entered.

If this button is pressed for 2 seconds, device turned ON or OFF.

If this key is pressed for 1 second while the alarm buzzer is active,

buzzer is turned OFF. If this key is pressed for 4 seconds, the manual

defrost mode is entered or exited.

Required Minimum

Running Duration for

Compressor

Can be adjusted between

0 and 199.

Compressor Running

Time In Case of Probe

Failure.

Can be adjusted between

0 and 199.

Defrost Time Performed at

Power-up

d.no = Defrost not performed at

power-up

d.yE = Defrost performed at

power-up

Defrost Power-up Start Delay

Time

Can be adjusted between 0 and

199 minutes. Will be valid if ;

d4 = d.yE

While in a parameter menu, if

key is pressed for 2 seconds

“Programming Mode" is entered.

High Temperature Alarm

Delay Time After Power-up.

Can be adjusted between

0 and 240 minutes.

SETTING UP THE PARAMETERS

If key is pressed, the current value of the parameter appears by

flashing on the display.

After the setting up the parameters, if set key is pressed again,

adjusted parameter name appears on display.

By using “UP” or “DOWN” navigation keys, selected

parameter can be adjusted to the desired value.

During a parameter adjustment, If one of the or navigation key is

pressed continuously for 0.6 seconds, adjusted value to be changed increases or

decreases rapidly.

If it continues to press for longer than 0.6 seconds, hundered digits will increases or

decreases rapidly. If the key released and wait for a second, then process returns

to the units digit.

r2 50.0 49.9 50.0

Whilst in S.Cd = 0

parameter, by pressing and

held down key and

by pressed key for 3

seconds, dEF parameter is

displayed and the device

returns to default settings.

-rE Menu Security Level

Non = Menu invisible.

P.YE = Can be modified.

P.np = Read only.

-CP Menu Security Level

Non = Menu invisible.

P.YE = Can be modified.

P.np = Read only.

-dE Menu Security Level

Non = Menu invisible.

P.YE = Can be modified.

P.np = Read only.

-AL Menu Security Level

Non = Menu invisible.

P.YE = Can be modified.

P.np = Read only.

SP Menu Security Level

P.YE = Can be modified.

P.np = Read only.

If the pressed for 4 seconds, device switch to "Programming Mode". If you keep pressing the key for 6

seconds, then the message H.rd appears on display and device is moved to the reading position from the

ENDAKEY. In this case the device waits for the parameters to be read from ENDAKEY. In this case,

ENDAKEY should touching the upper left the corner of device and pressing the button on the ENDAKEY.

Parameters reading is performed with ENDAKEY the PyE is shown before return to the operating mode. If

reading is not performed, the device waits for 1 minute and returns to the "Running Mode".

Programing From the Device to ENDAKEY-RF

Programing With ENDAKEY-RF

If the button on the ENDAKEY is pressed and ENDAKEY will transfer the parameters to the device then

the PyE message is shown. And the device switches to the "Running Mode".

Measured Temperature

Below the Scale High Temperature Alarm

2 / 2

1

1

EDT3011-EN-02-191202

ENDA

TM

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

R / W

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

Word

0000d (0000h)

0001d (0001h)

0

0

1

3

30

0

0

0

1

20

-50.0

150.0

0

3

0

10

10

8

30

0

0

10.0

10.0

1

1

120

15

15

1

1

1

1

0

1

3

1

1

0003d (0003h)

0004d (0004h)

0036d (0024h)

0006d (0006h)

0007d (0007h)

0002d (0002h)

0005d (0005h)

0008d (0008h)

0010d (000Ah)

0011d (000Bh)

0012d (000Ch)

0013d (000Dh)

0014d (000Eh)

0015d (000Fh)

0016d (0010h)

0017d (0011h)

0018d (0012h)

0019d (0013h)

0020d (0014h)

0021d (0015h)

0024d (0018h)

0026d (001Ah)

0025d (0019h)

0027d (001Bh)

0028d (001Ch)

0029d (001Dh)

0030d (001Eh)

0032d (0020h)

0033d (0021h)

0034d (0022h)

0035d (0023h)

0023d (0017h)

0022d (0016h)

0009d (0009h)

H0

H1

H2

H3

H4

H36

H6

H7

H5

H8

H10

H11

H12

H13

H14

H15

H16

H17

H18

H19

H20

H21

H24

H26

H25

H27

H28

H29

H30

H32

H33

H34

H35

H23

H22

H9

H31

Configuration Parameters

Security Parameters

Alarm Parameters

Defrost Parameters Compressor

Parameters

Main Regulator

Parameters

SP : Temperature setpoint value.

O1 : Offset value for temperature sensor ( Can be set between -25.0 and 25.0 ).

-Cn (Configuration) menu security level. Can be set between 0 and 2.

0 = Menu Invisible, 1 = Menu parameters can be modified, 2 = Menu parameters are read only.

SP (H0) parameter security level. Can be set between 1 and 2.

1 = Menu parameters can be modified, 2 = Menu parameters are read only.

P1 : Decimal point (place) selection ( 0 = No Decimal point added , 1 = Enable ).

I1 : Relay state selection for digital input. ( 0 = N.O. , 1 = N.C. )

Ad : ModBus address

R0 : Temperature setpoint hysteresis (Can be set between 0.1 and 15.0 °C or °F).

R1 : Minimum setpoint value (Can be set between -50.0°C and R2 (H12) parameter value).

R2 : Maximum setpoint value (Can be set between R1 (H11) parameter value and 150.0°C).

C0 : Compressor delay time duration on power-up (Can be set between 0 and 199 minutes).

C2 : Minimum stop time duration for compressor (Can be set between 0 and 199 minutes).

C3 : Minimum operating time duration for compressor (Can be set between 0 and 199 seconds).

C4 : Stop time duration for the compressor on probe failure (Can be set between 0 and 199 minutes).

C5 : Operating time duration for the compressor on probe failure (Can be set between 0 and 199 minutes).

D0 : Interval time duration for the defrosting process (Can be set between 0 and 99 hours. 0 = No Defrosting).

D3 : Defrosting time duration (Can be set between 1 and 99 minutes).

D4 : Defrosting process behaviour on power-up ( 0 = No Defrosing, 1 = Yes )

D5 : Defrosting delay time duration on power-up

(If D4 is set to 1, feature will be enabled. Can be set between 0 and 199 minutes).

A1 : Lower temperature alarm setpoint value (Can be set between -50.0 and 150.0°C ).

A4 : Upper temperature alarm setpoint value (Can be set between -50.0 and 150.0°C).

A2 : Lower temperature alarm type selection (0 = No Alarm, 1 = Relative Alarm (SP -A1) , 2 = Independent Alarm).

A5 : Upper temperature alarm type selection (0 = No Alarm, 1 = Relative Alarm (SP +A4) , 2 = Independent Alarm).

A6 : Alarm start delay time duration on power-up (Can be set between 0 and 199 minutes).

A7 : Temperature alarm delay time duration (Can be set between 0 and 199 minutes).

A8 : Alarm delay time duration after the defrosting process (Can be set between 0 and 199 minutes).

-rE ( Regulator ) menu security parameter (can be set like H31 parameter).

-CP ( Compressor ) menu security parameter (can be set like H31 parameter).

-dE ( Defrost ) menu security parameter (can be set like H31 parameter).

-AL ( Alarm ) menu security parameter (can be set like H31 parameter).

D6 : Temperature displaying selection during defrosting (0 = Yes, 1 = Will be displayed if the temperature value

below setpoint value, if not, temperature setpoint value (SP) will be displayed).

D8 : Defrost interval time procedure

(If set to 0, D0 counts the time with the power-up. If set to 1, D0 counts the time when the compressor starts).

I5 : Action selection for digital input.

0 = No action,

1 = External alarm active. (When the I7 time is over, IA message flashes until the input

activation is removed.)

2 = External alarm active. (When the I7 time is over, IA message flashes until the input

activation is removed and the compressor will shut OFF.)

3 = Door open. (Compressor output is OFF until the door is closed. And Id message flashes until

at the end of the I7 duration.)

I7 : Digital input delay time duration (Can be set between 0 and 120minutes).

Digital input activation will be delayed according to the set time duration.

P2 : °C / °F unit selection ( 0 = °C, 1 = °F ).

P5 : Display parameter selection in Running Mode.

( 0 = Current temperature of the cabinet , 1 = SP temperature value ).

br : Modbus baud rate :

0 = Disable, 1 = 2400 bps, 2 = 4800 bps, 3 = 9600 bps,

4 = 19200 bps, 5 = 38400 bps, 6 = 57600 bps

Word

0031d (001Fh)

Function control parameter. When the following codes are written to this parameter,

corresponding operation is performed :

( 23040d 5A00h ) = No action.

( 23041d 5A01h ) = Returns to default (All parameters are returned to the default value).

( 23042d 5A02h ) = Manual defrost starts or stops.

( 23043d 5A03h ) = The device is turned ON or OFF.

( 23044d 5A04h ) = The buzzer is switched off.

( 23045d 5A05h ) = Device restarts.

R / W

Word 0

0800d (0320h)

H800

1.2 Function Parameter Memory Map

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18

1/2

EDT3011-EN-02-191202

ENDA

TM

Holding Register

Adress

Decimal (Hex)

Parameter

Number

Data

Type

Default

Value

Data Content

Read / Write

Permission

ENDA EDT3011 COOLING / DEFROST CONTROLLER

MODBUS PROTOCOL ADDRESS MAP

1.1 Holding Registers

1.3 Input Registers

Word

0000d (0000h)

I0

0012d (000Ch)

0015d (000Fh)

1.4 Discrete Inputs

Compressor output indicator (0 = OFF ,1 = ON).

Compressor active/inactive indicator (0 = Inactive , 1 = Active (Standing by for compressor output).

Low temperature alarm active/inactive indicator ( 0 = Inactive, 1 = Active (Standing by for Alarm output).

ON/OFF status indicator (0 = OFF, 1 = ON).

Digital input status indicator (0 = Input inactive, 1 = Input active).

Reserved

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9-D15

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

(0000)h

(0001)h

(0002)h

(0003)h

0004d (0004h)

0005d (0005h)

0006d (0006h)

0007d (0007h)

0008d (0008h)

14

Word

Word

1

Word

2

Word

3

Word

4

Word

5

Word

6

Word

7

Word

8

Word

9

Word

10

Word

11

Word

12

Word

13

Word

14

0920d (0398h)

E40-12e205

M4008Fb1.

...... .......

{01}

{02}

{03}

CRC DATA

LSB

MSB

(0A)h

(81)h

(02)h

(B0)h

(53)h

Komut mesajında görüldüğü gibi (4A1)h

= 1185 nolu Coilin bilgisi istenmiş ancak

1185 adresli herhangi bir coil olmadığı

için (02) nolu hata kodu (Geçersiz Veri

Adresi) gönderilmiştir.

MODBUS ERROR MESSAGES

Modbus protocol has two types error, communication error and operating error. Reason of the communication error is data corruption in transmission. Parity and CRC control should

be done to prevent communication error. Receiver side checks parity and CRC of the data. If they are wrong, the message will be ignored. If format of the data is true but function

doesn’t perform for any reason, operating error occurs. Slave realizes error and sends error message. Most significant bit of function is changed '1' to indicate error in error message

by slave. Error code is sent in data section. Master realizes error type via this message.

Device Address

Function Code

Beginning address

of coils.

Number of coils (N)

CRC DATA

MSB

LSB

MSB

LSB

LSB

MSB

(0A)h

(01)h

(04)h

(A1)h

(00)h

(01)h

(AC)h

(63)h

Device Address

Function Code

Error Code

R

Discrete Input

Address

Parameter

Number

Input Register

Adress

Decimal (Hex)

Data

Type Parameter Description

Read / Write

Permission

Measured temperature value (Decimal).

Parameter

Number

Data

Type Parameter Description

1.5 Memory Map for Software Revision Input Registers

Software

Revision

Software name and update is read in ASCII format and as 14 word.

Memory Formats

For example : EM4400-01 28 Feb 2015.

:

NOTE :

To view each word correctly by changing the byte sequences should be displayed as ASCII TEXT

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18

2/2

EDT3011-EN-02-191202

ENDA

TM

ENDA EDT3011 COOLING / DEFROST CONTROLLER

MODBUS PROTOCOL ADDRESS MAP

R

Read / Write

Permission

R

R

R

R

R

R

R

R

R

R

High temperature alarm active/inactive indicator ( 0 = Inactive, 1 = Active (Standing by for Alarm output).

Low temperature alarm output indicator ( 0 = OFF, 1 = ON).

High temperature alarm output indicator ( 0 = OFF, 1 = ON).

Defrost output indicator (0 = OFF ,1 = ON).

Error

Code Meaning

Name

ILLEGAL

FUNCTION

ILLEGAL DATA

ADDRESS

ILLEGAL DATA

VALUE

The function code received in the query is

not an allowable action for the slave. If a

Poll Program Complete command was

issued, this code indicates that no program

function preceded it.

The data address received in the query is

not an allowable address for the slave.

A value contained in the query data field is

not an allowable value for the slave.

ModBus Error Codes

* MODBUS CONNECTION DIAGRAM

120 Ohm

120 Ohm

Master Slave - 1 Up to 127 slave devices

can be controlled.

Slave - 2

Slave - 127

A

BA

B

A

BA

B

Termination should be accomplished by

attaching 120 Ohm resistors to the start

and at the end of the communication line. * Applies to devices with Modbus function.

Structure of response message

(Byte Format)

Structure of command message

(Byte Format)

Message Sample ;

This manual suits for next models

3

Other ENDA Controllers manuals

Popular Controllers manuals by other brands

Servomech

Servomech ATL 02 Installation, operation and maintenance manual

BLEMO

BLEMO ER41 manual

Seada

Seada G88 HDMI user guide

SMC Networks

SMC Networks MXQ6 Series Operation manual

DROPSA

DROPSA ADVANCED LUBRICATION CONTROLLER INSTRUCTION AND PRODUCT DATA SHEET

Eurotech

Eurotech Helios Platform Hardware reference manual

Infineon

Infineon ICE2HS01G Application note

Elation

Elation SDC12 user manual

Nemtek

Nemtek SOL-REG140 user manual

Yisutongma Network Technology

Yisutongma Network Technology ESM-9013 instruction manual

Digital Equipment

Digital Equipment DEC WANcontroller 618 Problem Solving

Centurion

Centurion TB-CN2R1 instruction manual