v

Contents

Safety Summary .........................................................i

General ....................................................................1-1

Introduction...............................................................1-1

Description ...............................................................1-1

Unit Identification ...............................................1-2

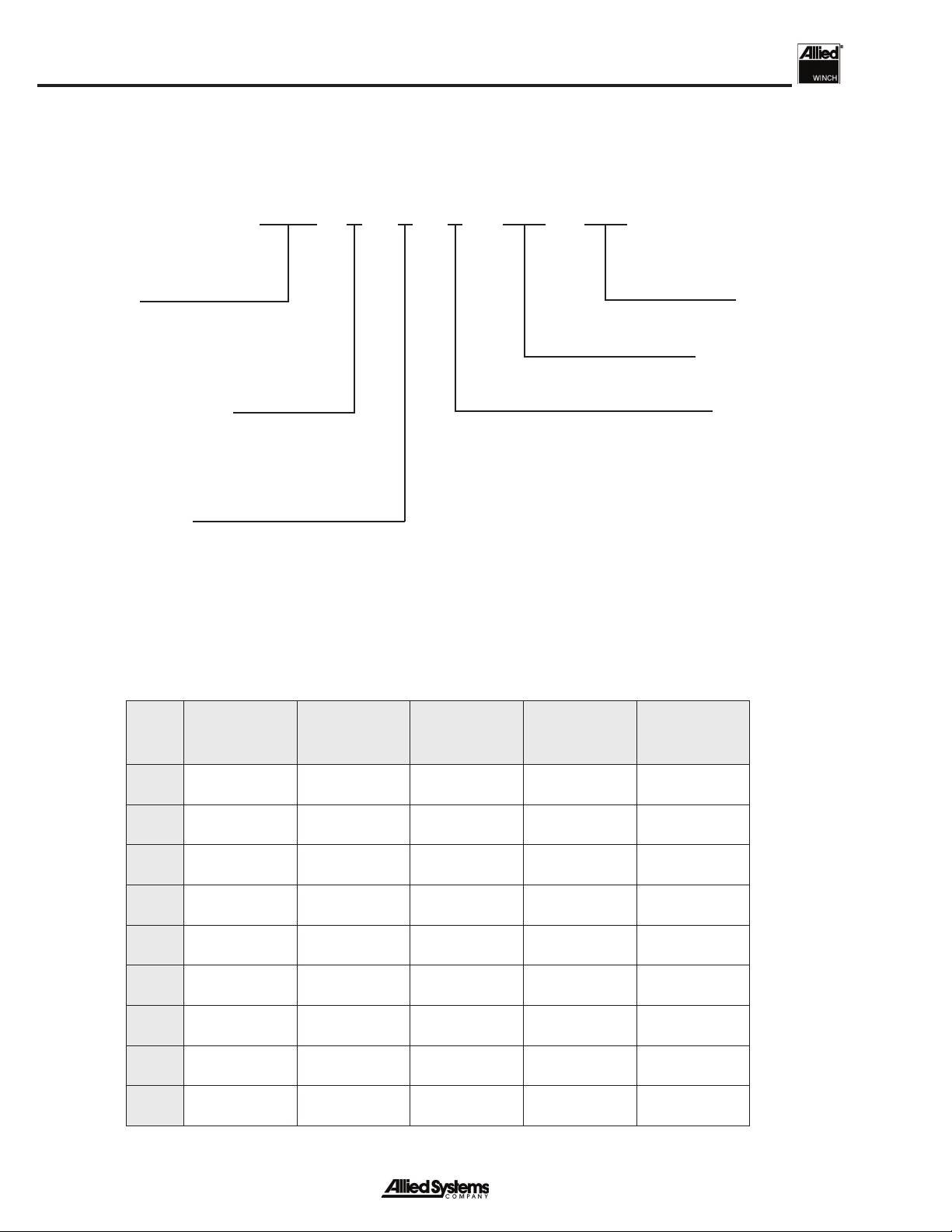

Serial Number Codes.........................................1-3

Nameplate .........................................................1-3

Specifications ...........................................................1-4

Drum Wire Rope Capacities...............................1-4

Hydraulic Specifications.....................................1-4

Oil Specifications ...............................................1-4

Oil Capacity........................................................1-4

Maintenance Decal ............................................1-5

Torque Specifications.........................................1-5

Gear Train ................................................................1-6

Operation and Control ..............................................1-7

Hydraulic System......................................................1-8

Motor................................................................. 1-9

Brake................................................................1-10

Planetary Reducer ...........................................1-11

Counterbalance Relief Manifold .......................1-12

Control Manifold ...............................................1-13

Sequence of Operation...........................................1-14

Option Code B

BRAKE-ON ......................................................1-14

LINE-IN ............................................................1-16

LINE-OUT ........................................................1-18

BRAKE-OFF ....................................................1-20

Option Code D

BRAKE-ON ......................................................1-22

LINE-IN ............................................................1-24

LINE-IN Hi-Speed ............................................1-26

LINE-OUT ........................................................1-28

BRAKE-OFF ....................................................1-30

Komatsu D155AX-6/7 (K64)

BRAKE-ON ......................................................1-32

LINE-IN ............................................................1-34

LINE-OUT ........................................................1-36

BRAKE-OFF ....................................................1-38

Schematics.............................................................1-41

Troubleshooting......................................................2-1

General.....................................................................2-1

Mechanical/Hydraulic Troubleshooting Charts..........2-1

Service.....................................................................3-1

General ....................................................................3-1

Maintenance.............................................................3-1

Maintenance Points............................................3-1

Maintenance Schedule ......................................3-1

Hydraulic System Pressure Tests Ports .............3-2

Checks Before Operation...................................3-3

Checks During Operation...................................3-3

Hydraulic System Pressure Checks .........................3-3

Preparation.........................................................3-3

Pilot Supply Pressure Check..............................3-4

Motor Supply Pressure Check ...........................3-5

Brake Pressure Check .......................................3-6

BRAKE-OFF Pressure Check............................3-7

Brake Valve Pressure Check & Adjustment .......3-8

LINE-IN Pressure Check....................................3-9

LINE-OUT Pressure Check..............................3-10

PCOR Pressure Check ....................................3-11

Repairs ...................................................................4-1

General ....................................................................4-1

Winch Removal ........................................................4-1

Winch Disassembly ..................................................4-1

Intermediate Shaft Removal...............................4-2

Drum Shaft & Drum Removal.............................4-4

Hydraulic System Disassembly..........................4-8

Motor Shaft Removal & Disassembly...............4-10

BRAKE-OFF Clutch Disassembly....................4-14

Brake Disassembly ..........................................4-16

Planetary Reducer Disassembly......................4-18

Winch Assembly .....................................................4-20

Visual Inspection..............................................4-20

Brake Assembly ...............................................4-22

BRAKE-OFF Clutch Assembly.........................4-24

Motor Shaft Assembly & Installation ................4-28

Planetary Reducer Assembly...........................4-31

Hydraulic System Assembly.............................4-34

Drum & Drum Shaft Installation .......................4-36

Intermediate Shaft Installation .........................4-42

Contents