v

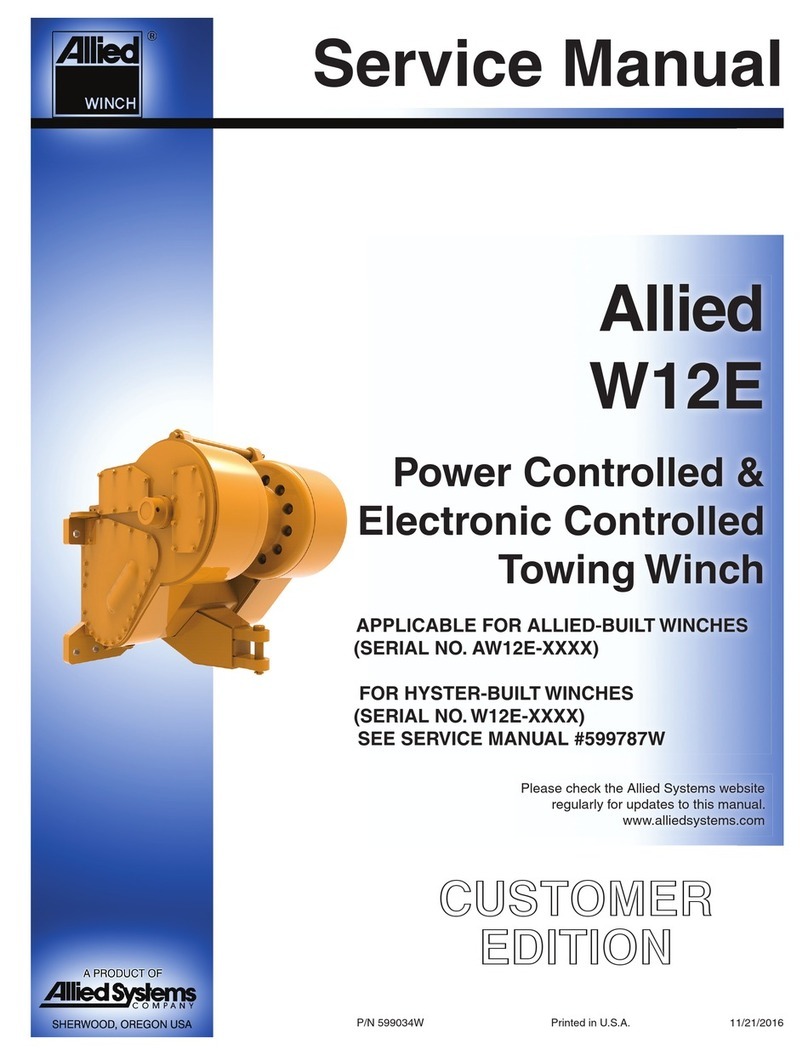

Contents

Safety Summary..........................................................i

General......................................................................... 1-1

Introduction........................................................................ 1-1

Description ........................................................................ 1-1

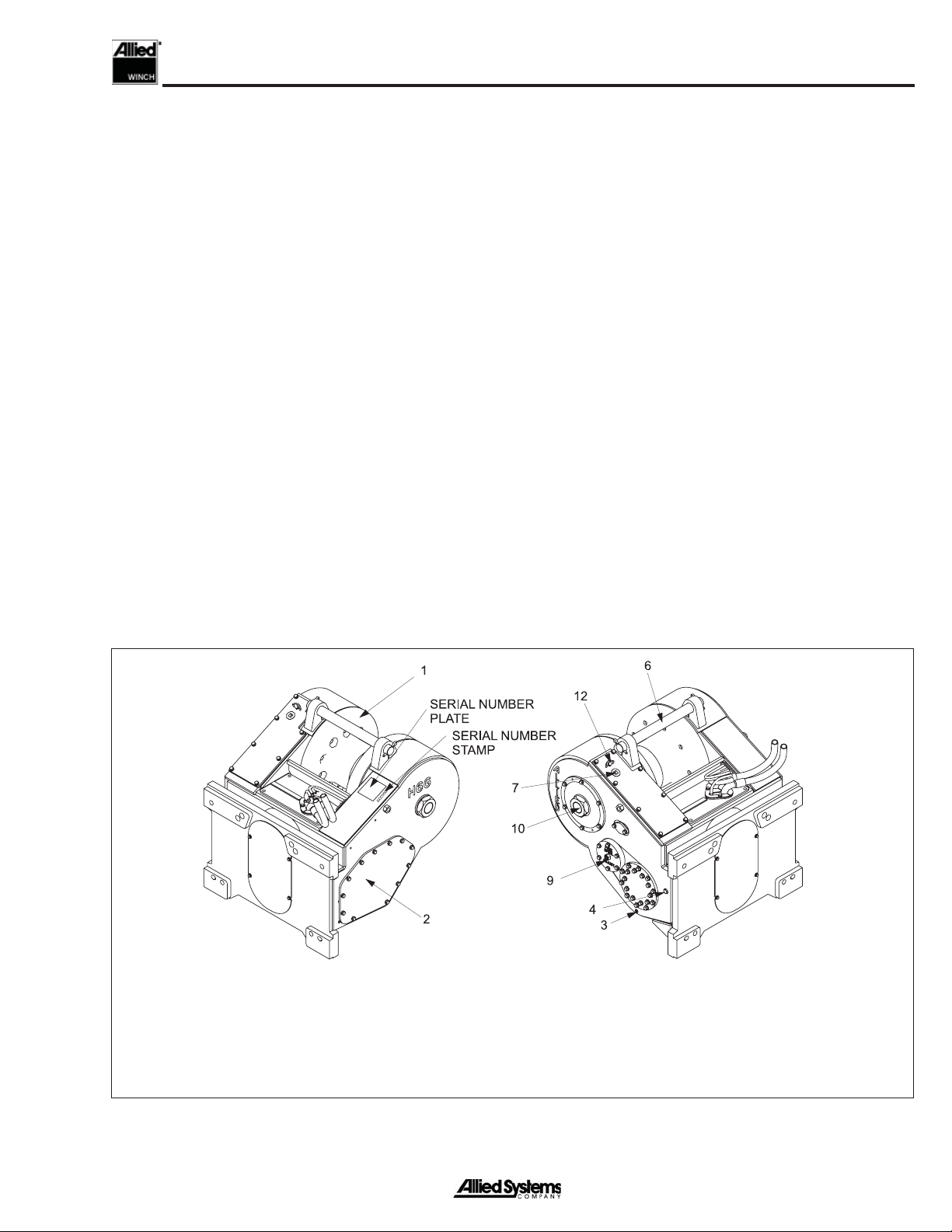

Unit Identification........................................................ 1-2

Serial Number Codes................................................. 1-3

Nameplate.................................................................. 1-3

Specifications .................................................................... 1-4

Drum Wire Rope Capacities....................................... 1-4

Hydraulic Specifications ............................................. 1-4

Oil Specifications........................................................ 1-4

Oil Capacity ................................................................ 1-4

Torque Specifications ................................................. 1-5

Gear Train ......................................................................... 1-6

FREESPOOL Operation............................................. 1-7

Operation and Control ....................................................... 1-8

Hydraulic System............................................................... 1-9

Planetary Reducer ..................................................... 1-9

Brake ........................................................................ 1-10

Motor ........................................................................ 1-11

Directional Control Manifold ..................................... 1-12

Logic Control Manifold.............................................. 1-12

HI-SPEED Limit Switch............................................ 1-12

Electronic Control Panel ........................................... 1-12

Sequence of Operation.................................................... 1-13

BRAKE-ON............................................................... 1-13

LINE-IN..................................................................... 1-14

HI-SPEED LINE-IN................................................... 1-16

LINE-OUT................................................................. 1-18

HI-SPEED LINE-OUT............................................... 1-20

FREESPOOL ........................................................... 1-22

Schematics...................................................................... 1-25

Troubleshooting ..................................................... 2-1

General.............................................................................. 2-1

Step-By-Step Pump & Controller Troubleshooting............. 2-2

Troubleshooting Analysis Check Chart.............................. 2-4

Service ......................................................................... 3-1

General ............................................................................. 3-1

Maintenance...................................................................... 3-1

Maintenance Points.................................................... 3-1

Maintenance Schedule............................................... 3-1

Checks Before Operation ........................................... 3-2

Checks During Operation........................................... 3-2

FREESPOOL Drag Adjustment......................................... 3-2

Hydraulic System Pressure Checks .................................. 3-2

Preparation................................................................. 3-2

Pressure Gauges ....................................................... 3-2

Standby Pilot Supply Pressure Check........................ 3-2

Maximum Pilot Supply Pressure Check ..................... 3-3

Counterbalance Valve Pressure Check...................... 3-3

Motor Supply Pressure Check.................................... 3-3

Brake Pressure Check................................................ 3-3

Brake Valve Pressure Check ...................................... 3-3

FREESPOOL Pressure Check................................... 3-4

High Speed Pressure Check...................................... 3-4

LINE-IN Pressure Check............................................ 3-5

LINE-OUT Pressure Check ........................................ 3-5

Valve Setting Procedures .................................................. 3-5

Load Sense Relief Valve ............................................ 3-5

Pilot Supply Reducing Valve ...................................... 3-5

Hydraulic System Pressure Tests Table............................. 3-6

Repairs ........................................................................ 4-1

General ............................................................................. 4-1

Winch Removal.................................................................. 4-1

Winch Disassembly ........................................................... 4-1

Intermediate & FREESPOOOL Shaft Removal.......... 4-2

Drum Shaft & Drum Removal..................................... 4-5

Hydraulic System Disassembly.................................. 4-9

Motor Shaft Removal & Disassembly ....................... 4-14

Motor Disassembly................................................... 4-17

Brake Disassembly................................................... 4-20

Planetary Reducer Disassembly .............................. 4-22

Winch Assembly .............................................................. 4-24

Visual Inspection ...................................................... 4-24

Planetary Reducer Assembly................................... 4-26

Brake Assembly ....................................................... 4-28

Motor Assembly........................................................ 4-30

Motor Shaft Assembly & Installation......................... 4-33

Hydraulic System Assembly..................................... 4-36

Drum & Drum Shaft Installation................................ 4-41

Intermediate & FREESPOOL Shaft Installation ....... 4-46

Winch Installation ............................................................ 4-50

Contents