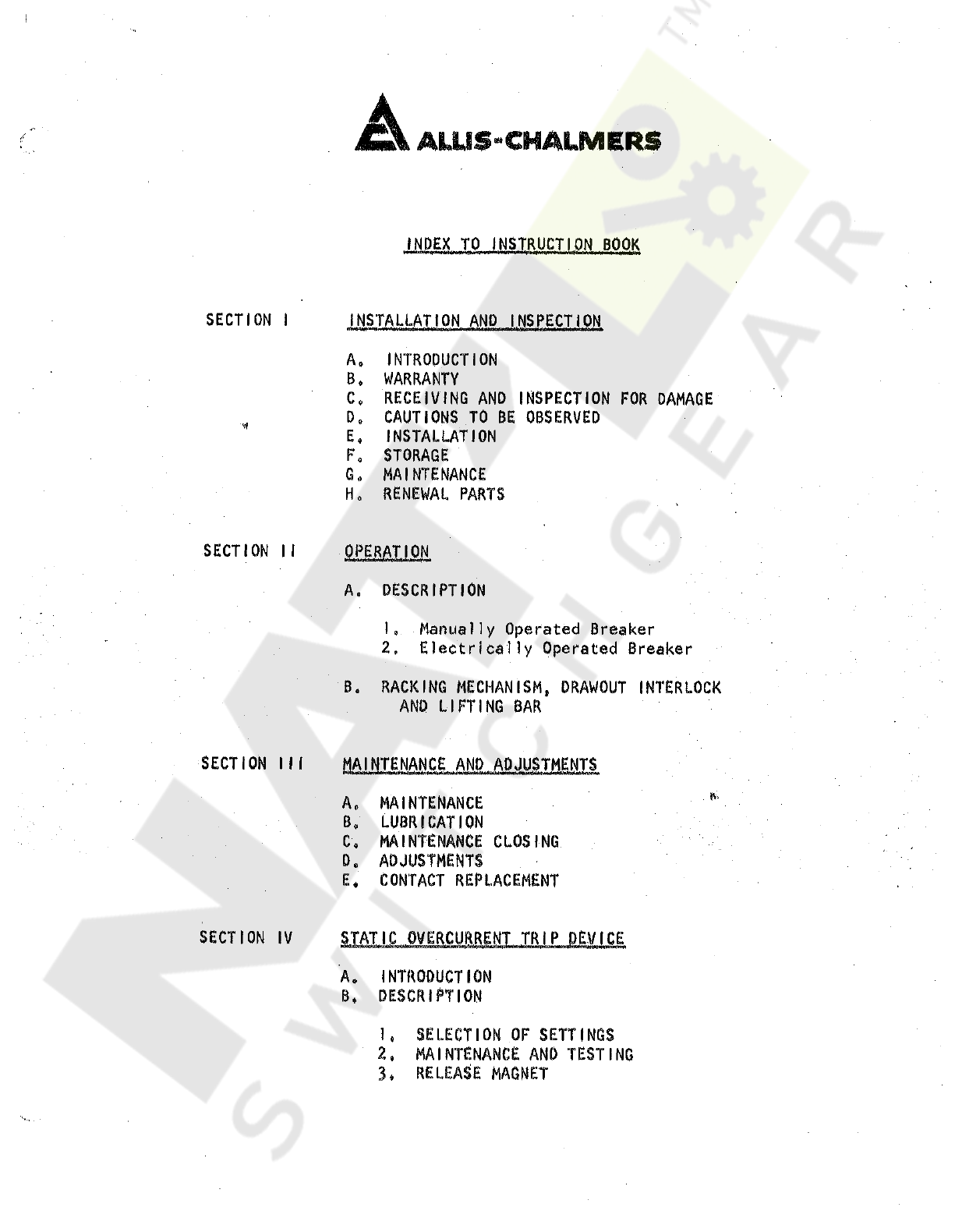

Allis-Chalmers LA-600 User manual

INDEX

TO

INSTRUCTION

BOOK

rr

r

‘

“

am

•

if

4

Tiiki

<

mimo

>

wT

>

r

‘

“

mir

‘

i

“

t

Tufiii

urTinrni

^

BviV

SECTION

I

INSTALLATION

AND

INSPECTION

A

.

INTRODUCTION

B

.

WARRANTY

C

.

RECEIVING

AND

INSPECTION

FOR

DAMAGE

D

.

CAUTIONS

TO

BE

OBSERVED

E

.

INSTALLATION

F

.

STORAGE

Go

MAINTENANCE

H

o

RENEWAL

PARTS

SECTION

II

OPERATION

A

,

DESCRIPTION

1

Manually

Operated

Breaker

Electrically

Operated

Breaker

o

2

,

RACKING

MECHANISM

,

DRAWOUT

INTERLOCK

AND

LIFTING

BAR

B

.

SECTION

III

(

V

A

.

MAINTENANCE

B

.

LUBRICATION

C

.

MAINTENANCE

CLOSING

D

CONTACT

REPLACEMENT

SECTION

IV

A

.

INTRODUCTION

1

.

SELECTION

OF

SETTINGS

2

,

RELEASE

MAGNET

3

Courtesy of NationalSwitchgear.com

f

ALUS

-

CHALMERS

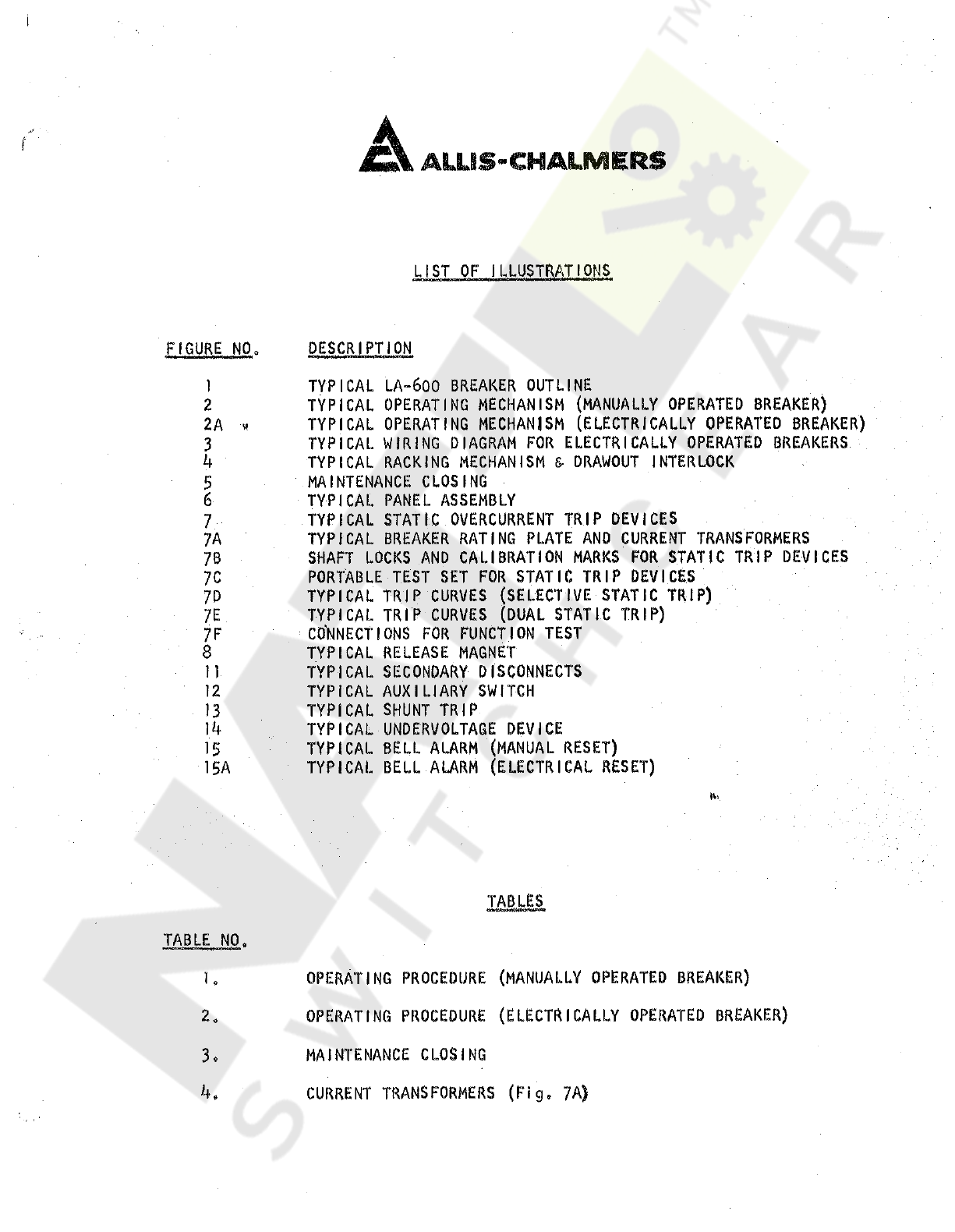

LIST

OF

ILLUSTRATIONS

DESCRIPTION

FIGURE

NO

.

TYPICAL

LA

-

600

BREAKER

OUTLINE

TYPICAL

OPERATING

MECHANISM

(

MANUALLY

OPERATED

BREAKER

)

TYPICAL

OPERATING

MECHANISM

(

ELECTRICALLY

OPERATED

BREAKER

)

TYPICAL

WIRING

DIAGRAM

FOR

ELECTRICALLY

OPERATED

BREAKERS

TYPICAL

RACKING

MECHANISM

S

-

DRAWOUT

INTERLOCK

MAINTENANCE

CLOSING

TYPICAL

PANEL

ASSEMBLY

TYPICAL

STATIC

OVERCURRENT

TRIP

DEVICES

TYPICAL

BREAKER

RATING

PLATE

AND

CURRENT

TRANSFORMERS

SHAFT

LOCKS

AND

CALIBRATION

MARKS

FOR

STATIC

TRIP

DEVICES

PORTABLE

TEST

SET

FOR

STATIC

TRIP

DEVICES

TYPICAL

TRIP

CURVES

(

SELECTIVE

STATIC

TRIP

)

TYPICAL

TRIP

CURVES

(

DUAL

STATIC

TRIP

)

CONNECTIONS

FOR

FUNCTION

TEST

TYPICAL

RELEASE

MAGNET

TYPICAL

SECONDARY

DISCONNECTS

TYPICAL

AUXILIARY

SWITCH

TYPICAL

SHUNT

TRIP

TYPICAL

UNDERVOLTAGE

DEVICE

TYPICAL

BELL

ALARM

(

MANUAL

RESET

)

TYPICAL

BELL

ALARM

(

ELECTRICAL

RESET

)

1

2

2

A

«

3

4

5

6

7

7

A

7

B

7

C

7

D

7

E

7

F

8

11

12

13

14

15

ISA

V

>

.

TABLES

TABLE

NO

.

OPERATING

PROCEDURE

(

MANUALLY

OPERATED

BREAKER

)

OPERATING

PROCEDURE

(

ELECTRICALLY

OPERATED

BREAKER

)

1

.

2

*

3

.

MAINTENANCE

CLOSING

4

»

CURRENT

TRANSFORMERS

(

Fig

.

7

A

)

Courtesy of NationalSwitchgear.com

iHSIIWiONS

FOR

THE

INSTALLATION

AND

OPERATION

OF

ALUS

-

CHALHERS

TYPE

"

LA

"

LOW

VOLTAGE

AIR

CIRCUIT

BREAKERS

AND

AUXILIARY

EQUIPMENT

SECTION

I

.

INSTALLATION

AND

INSPECTION

A

.

INTRODUCTION

The

type

"

LA

”

air

circuit

breakers

may

be

furnished

for

mounting

In

any

one

of

three

ways

.

They

may

be

used

in

metal

enclosed

switch

-

gear

of

the

drawout

type

,

in

individual

enclosures

(

pullout

type

)

,

or

for

stationary

mounting

in

a

customer

'

s

own

enclosing

case

or

switchboard

,

"

LA

1

?

breakers

are

completely

assembled

,

tested

,

and

calibrated

at

the

factory

in

a

vertical

position

and

must

be

so

installed

to

operate

properly

.

Customer

'

s

primary

connections

should

be

adequately

braced

against

the

effects

of

short

circuit

currents

to

prevent

overstressing

the

breaker

terminals

,

WARRANTY

Allis

~

ChaImers

"

LA

"

air

circuit

breakers

are

warranted

to

be

free

of

defects

in material

and

workmanship

for

a

period

of

one

year

after

delivery

to

the

original

purchaser

.

This

warranty

Is

limited

to

the

furnishing

of

any

part

which

to

our

satisfaction

has

been

proven

defective

Chalmers

will

not

in

any

case

assume

responsibility

for

allied

equipment

of

any

kind

.

C

,

RECEIVING

AND

INSPECTION

FOR

DAMAGE

immediately

upon

receipt

of

this

equipment

,

carefully

remove

all

packing

traces

and

examine

parts

,

checking

them

against

the

packing

list

and

noting

any

damages

incurred

in

transit

.

If

such

is

disclosed

,

a

damage

claim

should

be

filed

at

once

with

the

.

transportation

company

and

A

!

Hs

-

Chalmers

notified

,

D

,

CAUTIONS

TO

BE

OBSERVED

IN

THE

INSTALLATION

AND

OPERATION

OF

"

LA

"

CIRCUIT

BREAKERS

1

,

Read

Instruction

Book

before

Installing

or

making

any

changes

or

adjustments

on

the

breaker

,

2

,

As

the

closing

springs

on

stored

-

energy

breakers

may

be

^

charged

in

either

the

breaker

open

or

closed

position

,

extreme

care

should

be

.

taken

to

discharge

the

springs

before

working

on

the

breaker

.

3

,

When

closing

manually

-

operated

breakers

,

always

grasp

-

'

dosing

handle

firmly

until

it

is

returned

to

the

normal

vertical

position

.

Check

current

ratings

and

serial

numbers

against

single

line

diagram

to

assure

that

breakers

are

properly

located

in

switchgear

at

insta

1

latf

on

.

A

11

4

,

Check

the

alignment

of

the

.

secondary

disconnect

fingers

to

ensure

against

misalignment

due

to

possible

distortion

of

fingers

during

shipment

and

handling

.

Once

the

breaker

Is

energised

,

it

should

not

be

touched

,

except

for

operating

,

since

most

of

the

component

parts

are

also

energized

.

5

»

6

,

Courtesy of NationalSwitchgear.com

E

.

INSTALLATION

The

"

LA

"

air

circuit

breaker

is

completely

adjusted

,

tested

,

and

Inspected

at

the

factory

before

shipment

,

but

careful

check

should

be

made

to

be

certain

that

shipment

or

storage

has

not

resulted

in

damage

or

change

of

adjustment

.

Circuit

breakers

should

be

Installed

in

a

clean

,

dry

,

wel

1

-

ventiiated

place

in

which

the

atmosphere

is

free

from

destructive

acid

or

alkali

fumes

.

Stationary

-

type

breakers

should

be

mounted

high

enough

to

prevent

injury

to

personnel

either

from

circuit

interruption

or

from

moving

parts

during

automatic

opening

of

the

breaker

.

Allot

*

/

sufficient

space

to

permit

access

for

cleaning

and

inspection

and

adequate

clearance

to

insulating

barrier

above

the

breaker

to

prevent

damage

from

arcing

during

Interruption

.

Before

installing

,

make

certain

that

the

breaker

contacts

are

in

the

open

position

.

1

,

After

the

breaker

Is

installed

in

position

,

close

it

manually

by

the

maintenance

closing

method

(

See

Section

III

)

to

check

proper

functioning

of

the

mechanism

and

contacts

.

(

CAUTION

:

MAKE

SURE

CIRCUIT

IS

NOT

ENERGIZED

)

.

During

the

closing

operation

,

observe

that

the

contacts

move

freely

without

interference

or

rubbing

between

movable

arcing

contacts

and

parts

of

the

arc

chutes

.

Then

refer

to

Section

II

of

the

Instruction

Book

for

a

detailed

description

of

the

circuit

breaker

operating

characteristics

before

putting

the

breaker

in

service

.

2

,

Trip

units

and

accessory

devices

should

receive

a

thorough

check

prior

to

placing

the

breaker

In

service

to

be

certain

that

adjustments

are

proper

and

parts

are

not

damaged

,

3

.

Cubicle

-

mounted

breakers

of

the

drawout

type

are

equipped

with

a

draw

-

out

interlock

to

prevent

movement

of

a

closed

breaker

into

or

out

of

the

connected

position

.

See

Section

II

of

the

Instruction

Book

for

a

description

of

the

interlock

.

Its

operation

should

be

checked

before

the

breake

*

'

is

energized

,

4

.

Upon

completion

of

the

installation

Inspection

,

the

breaker

is

ready

to

be

energized

after

the

control

wiring

,

if

any

,

Is

checked

and

the

Insulation

tested

.

JV

«

v

>

F

.

STORAGE

When

breakers

are

not

to

be

put

into

immediate

use

,

they

should

be

wrapped

or

covered

with

a

non

-

absorbant

material

to

provide

protection

from

plaster

,

concrete

dust

or

other

foreign

matter

.

Breakers

should

not

be

exposed

to

the

action

of

corrosive

gases

or

moisture

.

In

areas

of

high

humidity

or

temperature

fluctuations

,

space

heaters

or

the

equivalent

should

be

provided

.

G

.

MAINTENANCE

Occasional

checking

and

cleaning

of

the

breaker

will

promote

long

and

trouble

-

free

service

.

A

periodic

inspection

and

servicing

at

least

every

six

months

should

be

included

In

the

breaker

maintenance

routine

.

If

the

circuit

breaker

Is

not

operated

during

extended

periods

,

the

breaker

should

not

remain

in

either

the

closed

or

open

position

any

longer

than

six

months

,

Maintenance

opening

and

closing

operations

should

be

made

to

ensure

freedom

of

movement

of

all

parts

.

H

.

RENEWAL

PARTS

When

ordering

renewal

parts

,

specify

the

complete

name

-

plate

data

including

breaker

serial

number

.

Courtesy of NationalSwitchgear.com

X

0

-

RELEASE

MAGNET

.

156

RAIL

RADIUS

4

Z

FRAME

I

r

1

/

DE

7

A

1

L

-

A

OS

2

378

S

{

LEFTSIDE

VIEW

)

!

±

£

3

S

2

i

*

T

COVER

WDTH

OF

GROUND

BAR

-

j

tOS

2

KX

70

t

i

PETA

1

L

-

C

>

CLEFT

-

SIDE

VIEW

)

t

-

C

6

?

14563

-

F

.

D

-

.

0

*

2

15.875

DETAIL

-

B

>

<

TOP

VIEW

)

l

F

RACKING

SCREW

3

BARRIER

-

4104

)

BARRIER

-

(

103

\

RAIL

RAOCUS

INTERLOCK

SLIDE

4

m

UWOERVOLTAGE

DEVICE

»

S

27

ji

(

ATTACHMENT

)

BELL

ALARM

„

(

ATTACHMENT

)

i

!

7

>

ARC

CHUTE

epoo

h

*

i

(

SEE

DETAIL

-

B

)

I

1

ft

1.062

6.062

CURRENT

TRANSFORMERS

J

118

W

.

7

»

+

IT

1.031

r

^

i

OH

Tut

M

9

CVT

4000

—

~

X

DISCONNECTS

cm

r

lo

T

>

i

:

<

«

*

“

-

f

!

L

_

LX

1

4

.

±

C

62

'

3.6

S

7

AUX

.

SWITCH

{

ATTACHMENT

j

C

44

/

TW

»

V

*

T

5

t

33

5

4

SUPPORT

1062

X

RACKING

CRANK

FREE

POSITION

.

625

CPES

POSITION

-

J

®

?

;

MW

4

:

;

n

&

1

&

c

WASHER

T

m

!

<

.

•

•

SECONDARY

.

DISCONNECTS

H

2

J

<

D

(

06

;

it

aSt

#

i

\

SPRING

\

RELEASE

\

LATCH

73

BSWiF

%

^

r

.

i

:

fcS

posmo

*

4300

fci

Q

HI

.

500

~

z

RAIL

"

MAXIMUM

IELE

7

WWEL

-

750

-

1

*

—

2230

VERTICAL

TRAVEL

TO

TWP

437

ELECTRICAL

SPRING

RELEASE

)

24

}

-

INTERLOCK

’

123

ID

BAR

TRIP

ROD

-

I

,

HO

CONTROL

SJV

>

T

(

ELECTRICALLY

OP

BREAKERS

^

(

A

.

(

SEE

DETAIL

-

A

)

(

ATTACHMENT

)

(

SEE

DETA

1

L

-

C

)

CUBICLE

INTERLOCK

CAM

Fiat

TYPICAL

LA

-

600

BREAKER

OUTLINE

MARCH

7

,

1967

72

-

440

-

006

-

405

Courtesy of NationalSwitchgear.com

•

•

DETAIL

-

'

BU

.

DETAIL

-

’

#

’

>

4

-

&

>

DETA

1

L

-

DU

219

218

,

in

i

217

,

A

2

f

6

\

JSEE

X

DETAILS

'

-

JS

;

S

>

ND

"

C

"

.

DETAIL

-

G

*

'

>

1

PI

73

209

.

SPRING

201

.

CLOSING

HANDLE

217

SPRING

218

.

STOP

219

.

ROLLER

220

.

TOGGLE

UNKAGE

22

L

SCREW

222

.

RACKING

SCREW

223

.

CLEVIS

224

.

RAIL

225

.

LINK

226

.

PIN

227

PIN

228

.

SPRING

210

.

CLOSING

CAM

202

.

SPRING

RELEASE

LATCH

in

202

A

.

HOOD

211

.

PAWL

•

•

203

.

SPRING

212

.

SPRING

204

SPRING

213

.

TOGGLE

LINKAGE

205

.

ROLLER

214

NUT

215

.

TRIP

SHAFT

4

•

206

.

PIN

207

TRIP

ROD

216

.

TRIP

LATCH

208

.

CAM

FIG

.

2

TYPICAL

OPERATING

MECHANISM

MANUALLY

OPERATED

BREAKER

v

72

-

340

-

014

-

401

MARCH

2

,

1967

•

W

•

•

Courtesy of NationalSwitchgear.com

SECTION

Ik

OPERATtQN

•

rtr

)

iniv

Mau

/

Ukm

*

rp

*

mm

m

i

«

'

-

*

•

(

A

„

0

ESCRIIPT

3

ON

The

LA

-

600

ah

*

circuit

breaker

has

an

interrupting

capacity

of

25

»

000

amperes

and

a

maximum

continuous

current

rating

of

600

amperes

at

600

volts

,

60

cycles

.

For

information

on

other

voltages

or

frequencies

,

the

factory

should

be

consulted

.

St

is

available

as

a

manually

-

operated

breaker

or

an

electrical

1

y

-

operated

breaker

.

The

two

breakers

are

identical

with

the

.

exception

of

the

medium

used

to

transmit

power

to

charge

the

stored

-

en

&

rgy

springs

.

A

double

-

toggle

,

trip

-

free

mechanism

is

used

;

that

is

,

the

breaker

contacts

are

free

to

open

at

any

time

,

if

required

,

regardless

of

the

position

of

the

mechanism

or

the

force

being

applied

.

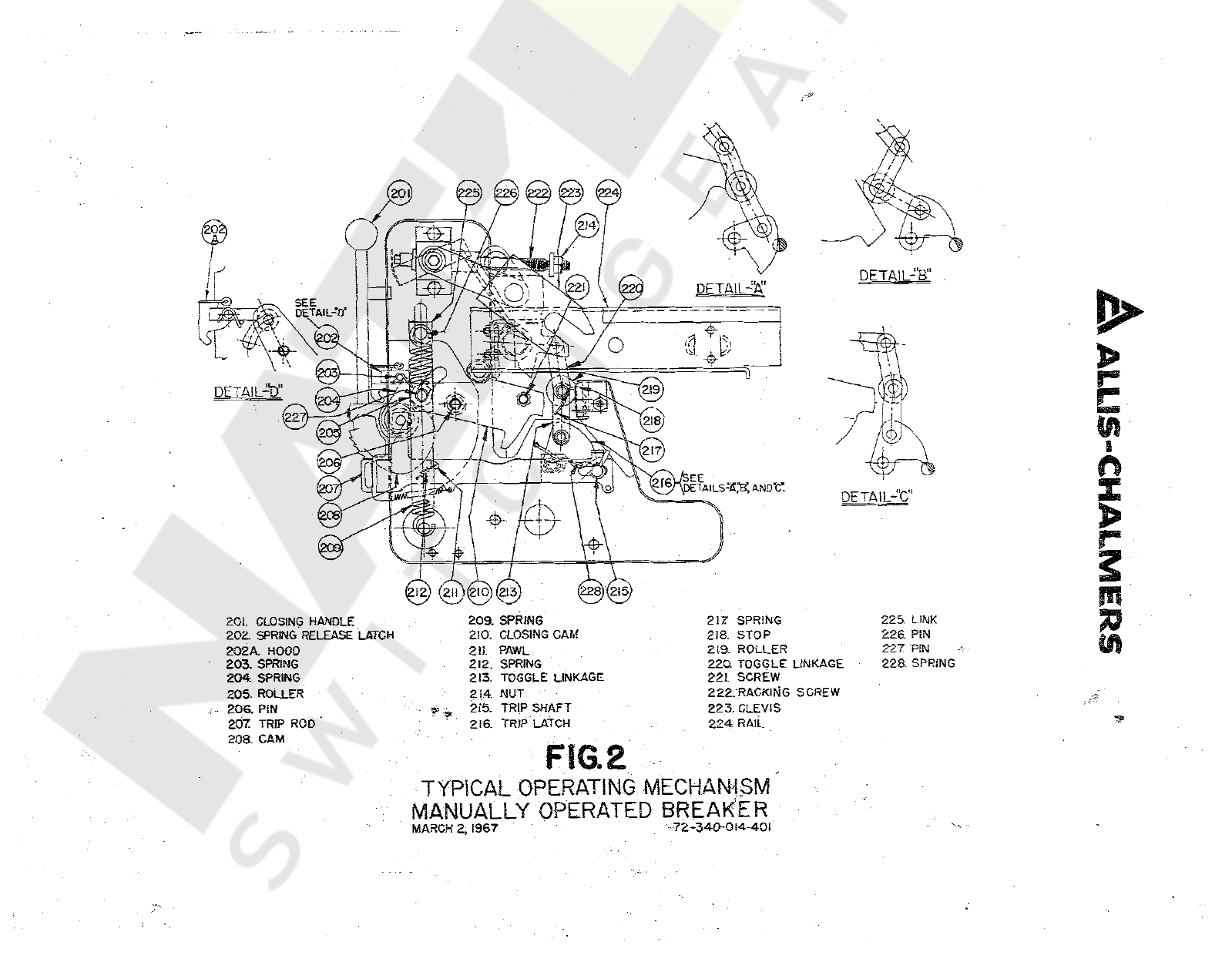

L

Manually

-

Operated

Breaker

As

the

breaker

has

a

single

-

frame

type

construction

,

most

of

the

latches

and

linkages

are

arranged

in

pairs

;

however

,

for

descriptive

purposes

,

they

will

be

referred

to

as

:

'

s

irvg

!

e

items

,

«

Refer

to

Figure

2

.

Detail

"

A

"

shows

the

position

of

..

trjfk

%

tch

(

216

)

when

the

breaker

contacts

are

open

with

the

closing

charged

.

Movement

of

closing

handle

(

20

)

)

downward

rotates

against

roller

(

205

)

thus

pivoting

closing

cam

(

210

)

clockw

|

;

«

^

|

^

M

^

^

;

Wv

.

pin

(

206

)

and

extending

stored

^

e

^

roy

springs

(

209

)

’

through

I

Iff

and

pin

(

226

)

,

Rotation

of

cam

(

2

T

0

)

clockwise

permits

sprIng

^

21

$

J

5

'

collapse

toggle

linkage

(

213

)

and

(

220

)

.

At

the

same

time

,

trip

latch

(

2.16

)

Is

reset

by

torsion

spring

(

228

)

as

shown

in

Detail

"

Bn

„

Pushing

down

spring

release

latch

hood

(

202

A

)

after

the

closing

handle

is

returned

to

the

normal

vertical

position

,

releases

the

energy

in

springs

(

209

)

,

Through

link

(

22.5

)

,

closing

cam

(

210

)

is

rotated

counterclockwise

against

roller

(

219

)

which

moves

toggle

linkage

as

.

shown

in

Detail

"

C

*

1

,

to

close

the

breaker

contacts

.

The

closing

operation

may

be

interrupted

at

any

point

by

functioning

of

the

trip

device

,

thus

ensuring

"

tr

i

p

-

.

f

ree

,

!

-

operation

.

To

open

the

breaker

contacts

,

trip

rod

trip

shaft

(

215

)

c

1

ockwlse

which

releases

trip

.

latch

(

2

(

6

)

as

shown

In

Detail

"

A

"

.

On

breakers

equipped

with

a

shunt

trip

device

,

the

breaker

contacts

may

be

opened

by

operation

of

a

remote

trip

control

switch

,

,

The

shunt

trip

device

rotates

the

trip

shaft

to

release

the

trip

latch

.

7

)

-

Is

actuated

.

This

rotates

MANUALLY

“

0

PERATED

6

REAKER

$

TABLE

1

OPERATING

PROCEDURE

i

ti

miimvft

.

MM

WA

*

*

*

«

«

*

«

I

n

*

fTm

’

l

*

*

*

*

#

*

*

*

"

*

*

K

*

.

•

«

1

H

Puli

handle

(

201

)

down

all

the

way

(

approximately

320

)

j

and

return

to

normal

vertical

position

.

(

Engagement

of

j

paw

)

(

211

)

with

the

ratchet

teeth

prevents

handle

re

-

versal

until

the

downward

stroke

is

completed

.

)

1

Push

down

spring

-

release

latch

hood

(

2

,

02

A

)

after

handle

is

returned

to

norma

!

vertical

position

.

Push

tn

manual

trip

rod

(

207

)

»

J

If

shunt

trip

Is

provided

,

operate

remote

trip

control

(

See

Figure

3

.

)

sm

&

uiLswm

-

-

CLOSING

:

TRIPPING

:

!

*

*

*

*

»«

r

»

o

OR

switch

(

CST

)

.

“

MW

-

3

“

Courtesy of NationalSwitchgear.com

(

*

’

A

ALLIS

“

CHALM

ERS

CONTROL

SWITCH

-

234

.

FLAT

SPRING

235

.

GEAR

236

.

PINS

237

TOGGLE

LINKAGE

238

.

MOTOR

GEAR

-

BOX

PINION

239

.

MOTOR

240

.

GEAR

SEGMENT

:

241

.

PIN

202

.

SPRING

RELEASE

LATCH

202

A

.

HOOD

207

TRIP

ROD

'

210

.

CLOSING

CAM

225

.

LINK

.

230

.

SPRING

-

POSITION

SWITCH

231

.

ARM

•

232

.

MOTOR

CUT

-

OFF

SWITCH

233

.

PLUNGER

FIG

.

2

A

TYPICAL

OPERATING

MECHANISM

|

ELECTRICALLY

OPERATED

BREAKE

72

-

340

-

017

-

4

01

MARCH

10

,

1967

f

-

I

-

LCS

i

T

-

r

ID

-

*

-

*

-

-

lo

8

r

o

&

2

A

1

5

4

3

/

N

/

s

®

©

©

3

O

J

-

3

P

9

I

o

7

-

N

T

0

^

toeb

u

\

t

V

10

9

4

=

a

^

b

-

^

Yl

-

J

~

o

I

«

7

t

?

AH

XI

Xft

5

-

4

TRANSFORMERS

\

MAGNETIC

.

/

TrtlP

COIL

}

F

*

,

Tf

.

°

6

o

'

TERMINAL

BLOCK

TYPICAL

WIRING

OIACRAM

FOR

EL

.

ECTRICAL

.

LY

OPERATED

BREAKERS

FIG

.

3

•

b

S

*

'

>

«

<

*

3

-

401

WAftOW

fO

,

1967

Courtesy of NationalSwitchgear.com

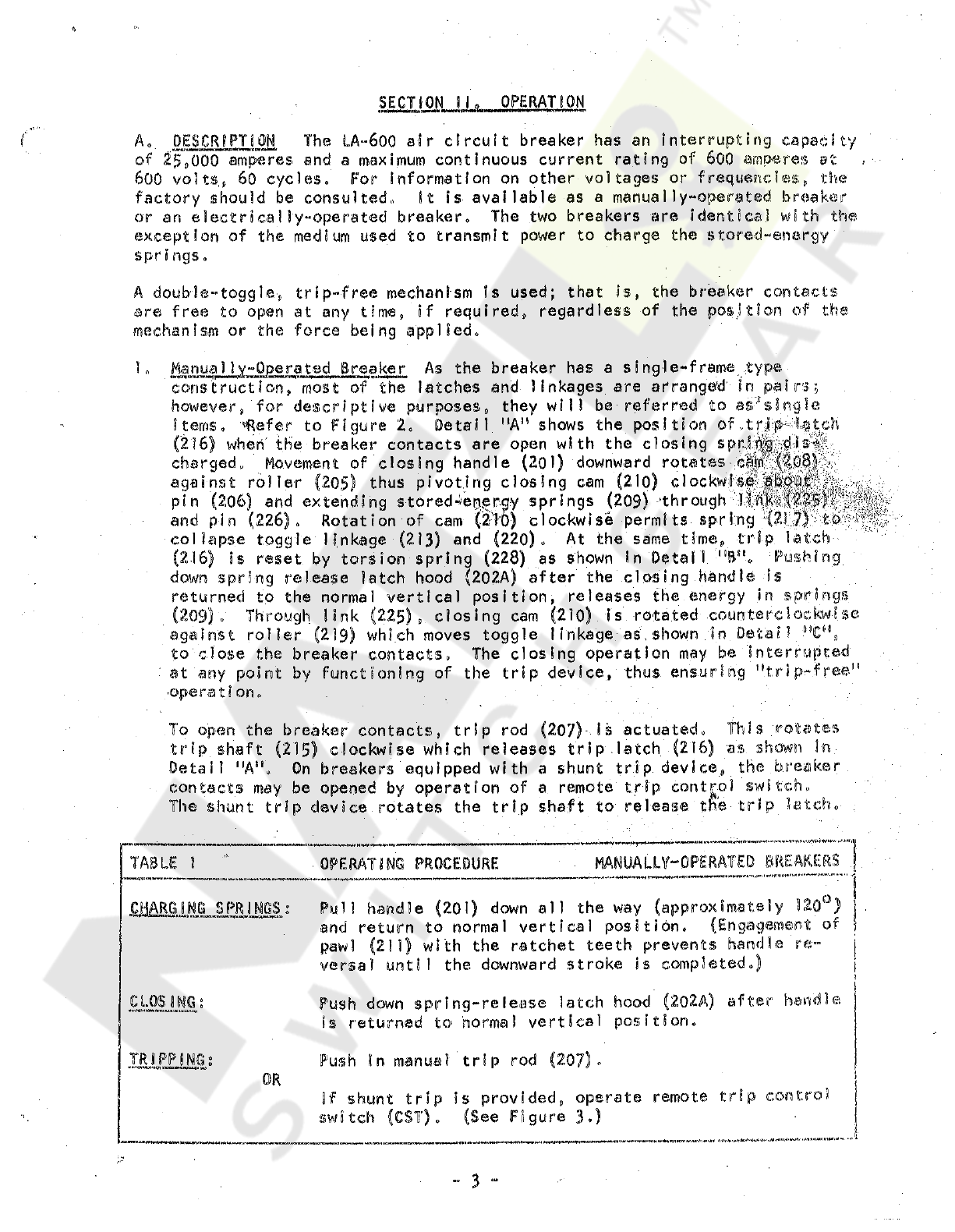

The

mechanism

of

the

electrically

-

operated

2

»

Electrica

11

v

-

Qperated

Breaker

Mr

.

ftiu

Ml

MKAWUW

enKWUWinWlrtiiMl

.

v

/

ttWWWoiWrtrfMinMWM

"

breaker

is

the

same

as

that

of

the

manually

-

operated

breaker

except

that

the

manual

closing

handle

is

replaced

by

an

electric

motor

and

the

gear

system

.

f

Refer

to

Figures

2

A

and

3

.

Movement

of

the

control

switch

(

N

)

located

on

the

front

of

the

breaker

to

the

"

ON

"

position

*

when

the

control

circuit

is

energized

,

wi

11

start

the

automatic

closing

cycle

.

Motor

gear

box

pinion

(

238

)

rotates

gear

(

235

)

counterclockwise

,

and

pins

(

236

)

move

across

the

top

of

flat

biasing

spring

(

234

)

.

This

raises

toggle

linkage

(

237

)

«

ver

center

and

positions

gear

(

235

)

to

mesh

with

gear

segment

(

240

)

*

Since

this

gear

segment

is

attached

to

closing

cam

(

210

)

,

the

stored

-

energy

springs

are

charged

and

latched

in

the

same

sequence

as

described

in

the

previous

section

.

The

lower

extension

of

closing

cam

(

210

)

engages

a

roller

on

toggle

linkage

(

237

)

to

disengage

gear

(

235

)

from

gear

segment

(

240

)

after

the

stored

-

energy

springs

are

latched

In

the

charged

position

by

spring

-

release

latch

(

202

)

,

Spring

-

position

switch

(

230

)

(

SPS

b

)

is

actuated

to

the

open

position

by

arm

(

231

)

attached

to

link

(

225

)

as

the

stored

-

energy

springs

approach

the

charged

position

.

This

switch

initiates

the

spring

recharging

cycle

and

Is

connected

in

parallel

with

motor

cut

-

off

switch

(

£

32

)(

88

a

)

which

is

open

initially

#

closes

while

the

motor

charges

the

springs

,

and

opens

when

the

springs

are

charged

with

the

gearing

disengaged

.

The

1

motor

cut

-

off

switch

is

actuated

by

the

movement

of

plunger

(

233

)

over

pins

(

236

)

,

Approximately

twelve

seconds

are

required

for

completion

of

the

spring

charging

cycle

.

The

breaker

may

now

be

closed

by

pushing

down

spring

«

release

latch

hood

(

2

Q

2

A

)

as

In

the

manually

-

operated

breaker

,

or

it

may

be

closed

electri

-

cally

through

remote

close

control

switch

spring

-

release

coil

(

SRC

)

which

moves

pin

(

241

)

in

a

counterclockwise

direction

to

trip

spring

release

latch

hood

(

202

A

)

and

spring

-

release

latch

(

202

)

,

The

"

Y

"

coll

Is

energized

simultaneously

with

the

spring

-

release

coil

and

causes

the

"

Y

"

contact

to

open

the

circuit

to

the

motor

.

Since

the

"

Y

"

relay

will

remain

energized

as

long

as

the

remote

close

control

swi

tch

(

CSC

)

is

held

closed

,

"

Y

1

"

contact

keeps

the

motor

.

!

ci

rcul

t

open

to

prevent

"

pumping

"

or

repeated

attempts

to

charge

the

.

stored

-

energy

springs

when

the

breaker

Is

closing

.

This

switch

energizes

After

the

stored

-

energy

springs

are

discharged

,

they

are

automatically

recharged

as

long

as

the

control

circuit

is

energized

,

and

the

control

Is

in

the

"

ON

"

position

.

Figure

3

shows

the

spring

-

position

swi

tch

switch

(

SPSjfrb

)

closed

to

complete

the

motor

control

circuit

as

it

would

be

when

the

springs

are

discharged

.

M

UJ

*

*

»

A

*

«

\

*

*

W

*

I

»

«

*

*

AI

'

Wi

ELECTRICALLY

-

OPERATED

BREAKERS

TABLE

2

OPERATING

PROCEDURE

Move

control

switch

(

N

)

on

Charging

Springs

:

Energize

control

circuit

,

front

of

breaker

to

"

ON

"

position

After

springs

are

charged

,

actuate

remote

close

control

switch

(

CSC

)

.

Push

down

spring

-

release

latch

hood

(

202

A

)

.

X

:

#

Actuate

remote

trip

control

switch

(

CST

)

Push

In

manual

trip

rod

(

207

)

.

Closing

;

OR

Tripping

2

ca

i

|

>

Courtesy of NationalSwitchgear.com

ALLIS

-

CHALMERS

a

h

u

^

-

LIFTING

BAR

l

|

1

'

II

CSJ

a

RACK

'

OUT

c

:

:

r

:

i

i

ZL

7

.

LT

.

7

ID

rL

c

.

.

.

.

(

%

)

(

402

MNTERL

0

CK

SLIDE

i

1

-

i

!

rb

(

§

)

\

~

~

LL

_

~

.

dk

CONTROL

SWITCH

^

FRONT

VIEW

(

ELECTRICALLY

OPER

,

"

-

*

-

“

“

BREAKERS

)

.

J

OJ

r

@

CUBICLE

FIXED

PIN

r

c

>

,

iv

J

o

v

*

RACKING

.

CLEVIS

(

408

,

rs

-

1

“

1

:

1

l

lr

~

X

*

I

TRIP

ROD

.

•

t

i

i

r

n

CV

^

J

l

J

UT

.

0

®

)

*

SITUR

LOC

K

CAM

(

408

rlNTERL

0

CK

TRIP

SHAFT

-

MOT

SIDE

VIEW

FIG

.

4

TYPICAL

RACKING

MECHANISM

&

DRAWOUT

INTERLOCK

72

-

440

-

010

-

40

I

APRIL

3

,

1967

Courtesy of NationalSwitchgear.com

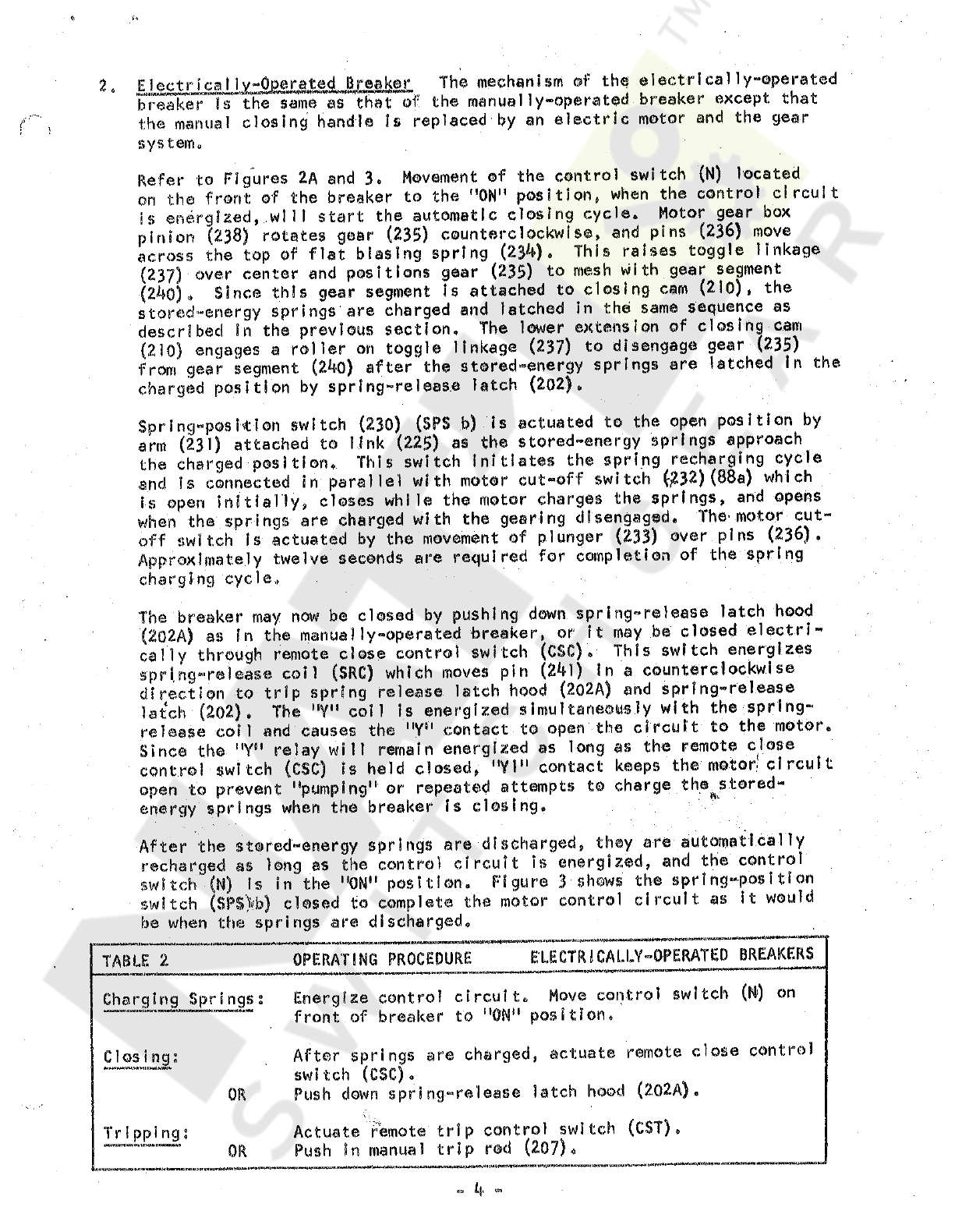

8

.

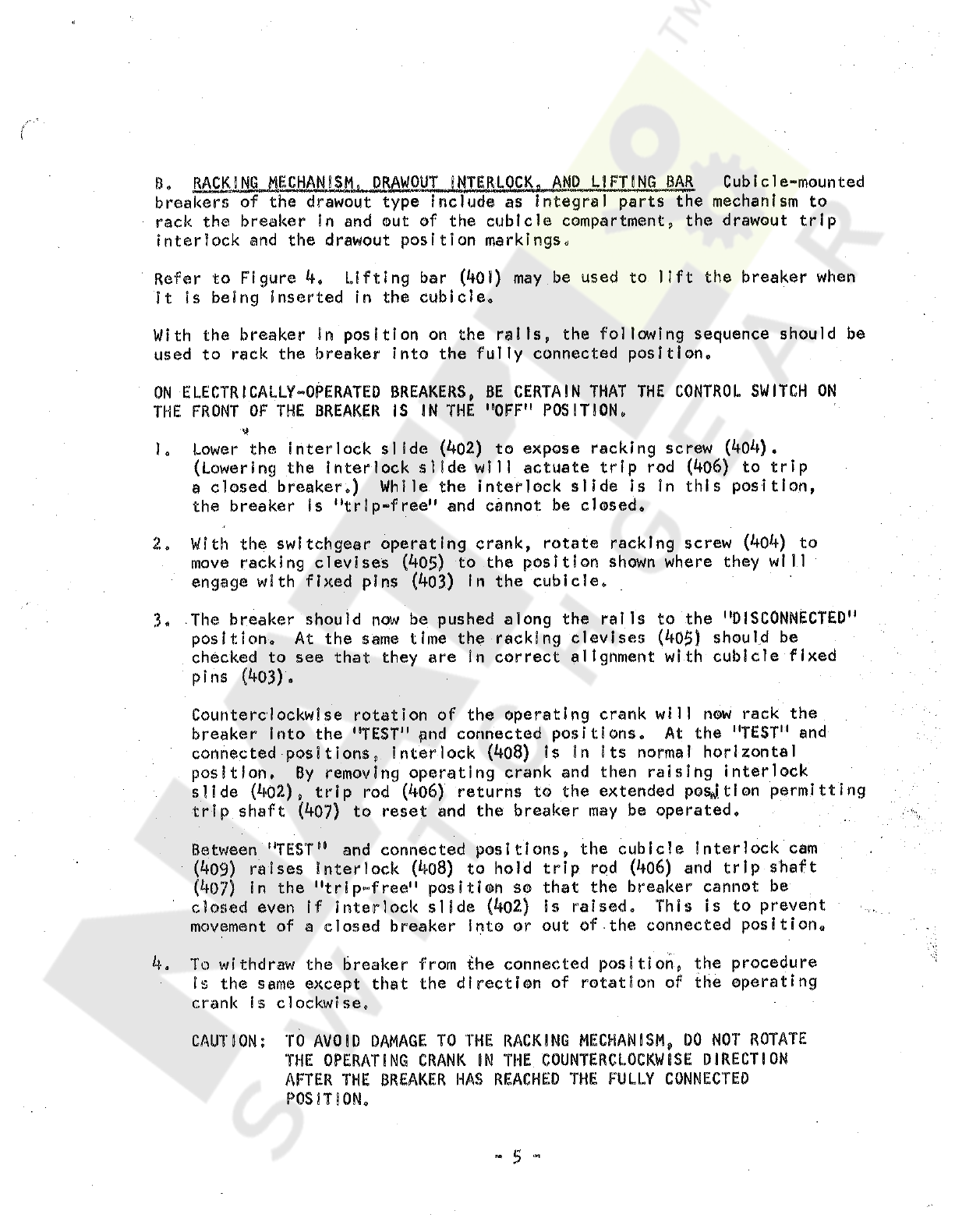

RACKING

MECHANISM

,

DRAWOUT

INTERLOCK

.

AND

LIFTING

BAR

Cubicle

-

mounted

breakers

of

the

drawout

type

Include

as

Integral

parts

the

mechanism

to

rack

the

breaker

In

and

out

of

the

cubicle

compartment

,

the

drawout

trip

interlock

and

the

drawout

position

markings

.

Lifting

bar

(

401

)

may

be

used

to

lift

the

breaker

when

Refer

to

Figure

4

«

it

is

being

inserted

in

the

cubicle

.

With

the

breaker

in

position

on

the

rails

used

to

rack

the

breaker

into

the

fully

connected

position

.

the

following

sequence

should

be

ON

ELECTRICALLY

-

OPERATED

BREAKERS

,

BE

CERTAIN

THAT

THE

CONTROL

SWITCH

ON

THE

FRONT

OF

THE

BREAKER

IS

IN

THE

"

OFF

"

POSITION

.

M

1

.

Lower

the

interlock

slide

(

402

)

to

expose

racking

screw

(

404

)

.

(

Lowering

the

Interlock

slide

will

actuate

trip

rod

(

406

)

to

trip

a

closed

breaker

.

)

While

the

interlock

slide

is

in

this

position

,

the

breaker

Is

"

trip

-

free

"

and

cannot

be

closed

.

2

.

With

the

switchgear

operating

crank

,

rotate

racking

screw

(

404

)

to

move

racking

clevises

(

405

)

to

the

position

shown

where

they

will

engage

with

fixed

pins

(

403

)

In

the

cubicle

.

3

.

The

breaker

should

now

be

pushed

along

the

rails

to

the

"

DISCONNECTED

"

position

.

At

the

same

time

the

racking

clevises

(

405

)

should

be

checked

to

see

that

they

are

in

correct

alignment

with

cubicle

fixed

pins

(

403

)

.

Counterclockwise

rotation

of

the

operating

crank

will

now

rack

the

breaker

Into

the

"

TEST

"

pnd

connected

positions

.

At

the

"

TEST

"

and

connected

positions

,

interlock

(

4

o

8

)

is

in

its

normal

horizontal

position

.

By

removing

operating

crank

and

then

raising

interlock

slide

(

4

-

02

)

,

trip

rod

(

406

)

returns

to

the

extended

position

permitting

trip

shaft

(

407

)

to

reset

and

the

breaker

may

be

operated

.

Between

"

TEST

"

1

and

connected

positions

,

the

cubicle

interlock

cam

(

409

)

raises

interlock

(

4

o

8

)

to

hold

trip

rod

(

4

o

6

)

and

trip

shaft

(

4

o

?

)

in

the

"

trip

-

free

"

position

so

that

the

breaker

cannot

be

closed

even

if

interlock

slide

(

4

o

2

)

is

raised

.

This

is

to

prevent

movement

of

a

closed

breaker

into

or

out

of

the

connected

position

.

4

.

To

withdraw

the

breaker

from

the

connected

position

,

the

procedure

is

the

same

except

that

the

direction

of

rotation

of

the

operating

crank

is

clockwise

.

/

*

'

J

TO

AVOID

DAMAGE

TO

THE

RACKING

MECHANISM

,

DO

NOT

ROTATE

THE

OPERATING

CRANK

IN

THE

COUNTERCLOCKWISE

DIRECTION

AFTER

THE

BREAKER

HAS

REACHED

THE

FULLY

CONNECTED

POSITION

.

CAUT

J

ON

:

-

5

-

Courtesy of NationalSwitchgear.com

SECTION

.

III

.

MAINTENANCE

AND

ADJUSTMENTS

MWrMomHwiM

n

>

g

*

M

morjM

^

oiw

.

X

'

l

•

n

WWW

y

.

wrri

a

*

>

»

HCTWiiwauM

*

'

i

Occasional

checking

and

cleaning

of

the

breaker

will

promote

long

and

trouble

-

free

service

,

A

periodic

inspection

and

servicing

at

intervals

of

six

months

or

one

year

should

be

included

In

the

maintenance

routine

.

Circuit

breakers

located

in

areas

subject

to

acid

fumes

,

cement

dust

,

or

other

abnormal

conditions

,

require

more

frequent

servicing

,

After

a

severe

overload

interruption

,

the

breaker

should

be

inspected

.

If

the

circuit

breaker

Is

not

operated

during

extended

periods

,

it

should

not

remain

in

either

the

closed

or

open

position

any

longer

than

six

months

.

Maintenance

opening

and

closing

operations

should

be

made

to

ensure

freedom

of

movement

of

all

parts

.

A

suggested

procedure

to

follow

during

maintenance

inspections

is

given

below

:

A

.

MAINTENANCE

x

.

De

-

energize

the

primary

and

control

circuits

.

i

.

Rack

cubicle

-

mounted

breakers

of

the

drawout

type

to

the

disconnected

pos

S

t

i

on

»

2

O

3

.

Discharge

stored

-

energy

springs

.

4

.

Remove

arc

chutes

and

examine

for

burned

,

cracked

,

or

broken

parts

.

5

.

Wipe

the

contacts

with

a

clean

cloth

saturated

with

a

non

-

toxic

cleaning

fluid

.

6

»

Replace

badly

burned

or

pitted

contacts

.

(

See

paragraph

£

)

.

7

.

Wipe

all

Insulated

parts

with

a

clean

cloth

saturated

with

a

non

-

toxic

cleaning

fluid

,

8

.

Bearing

p

.

lns

and

other

sliding

or

rotating

surfaces

should

be

cleaned

and

then

coated

with

a

light

film

of

grease

(

See

paragraph

B

)

,

9

»

Operate

the

breaker

manually

in

maintenance

closing

position

(

see

to

check

latch

and

linkage

movement

,

10

.

Check

breaker

adjustments

(

see

paragraph

D

)

.

8

,

LUBRICATION

Lubrication

should

be

a

part

of

the

service

procedure

.

Needle

bearings

are

packed

with

grease

and

should

require

no

further

attention

.

0

)

d

grease

should

be

removed

from

bearing

pins

and

other

rotating

or

sliding

surfaces

,

and

they

should

be

wiped

with

a

thin

film

of

petroleum

-

oi

1

-

base

precision

-

equipment

grease

similar

to

BEACON

P

-

290

.

Greasing

should

be

done

with

care

because

excess

grease

tends

to

collect

foreign

matter

which

in

time

may

make

operation

sluggish

and

may

affect

the

dielectric

strength

of

insula

-

ting

members

.

ft

.

paragraph

KtmWK

»

,

«

«

<

I

»

1

TOMf

.

UlhCVU

HXKWI

3

.

M

)

6

“

Courtesy of NationalSwitchgear.com

ALLIS

-

CHALMERS

(

REFER

SECTION

MIC

PG

.

7

)

MAINTENANCE

CLOSING

HANDLE

RELEASE

LATCH

HOOD

205429

i

TYPICAL

MAINTENANCE

CLOSING

HANDLE

ELECTRICALLY

OPERATED

BREAKERS

i

<

!

STEP

1

STEP

2

205450

MANUAL

TRIP

ROD

(

REFER

FIG

.

2

DETAIL

"

D

"

)

(

REFER

TABLE

5

,

PG

.

7

)

TYPI

CAL

MAINTENANCE

CLOSING

HANDLE

PROCEDURE

FIGURE

5

MAINTENANCE

CLOSING

Courtesy of NationalSwitchgear.com

f

.

Co

MAINTENANCE

CLOSUMGs

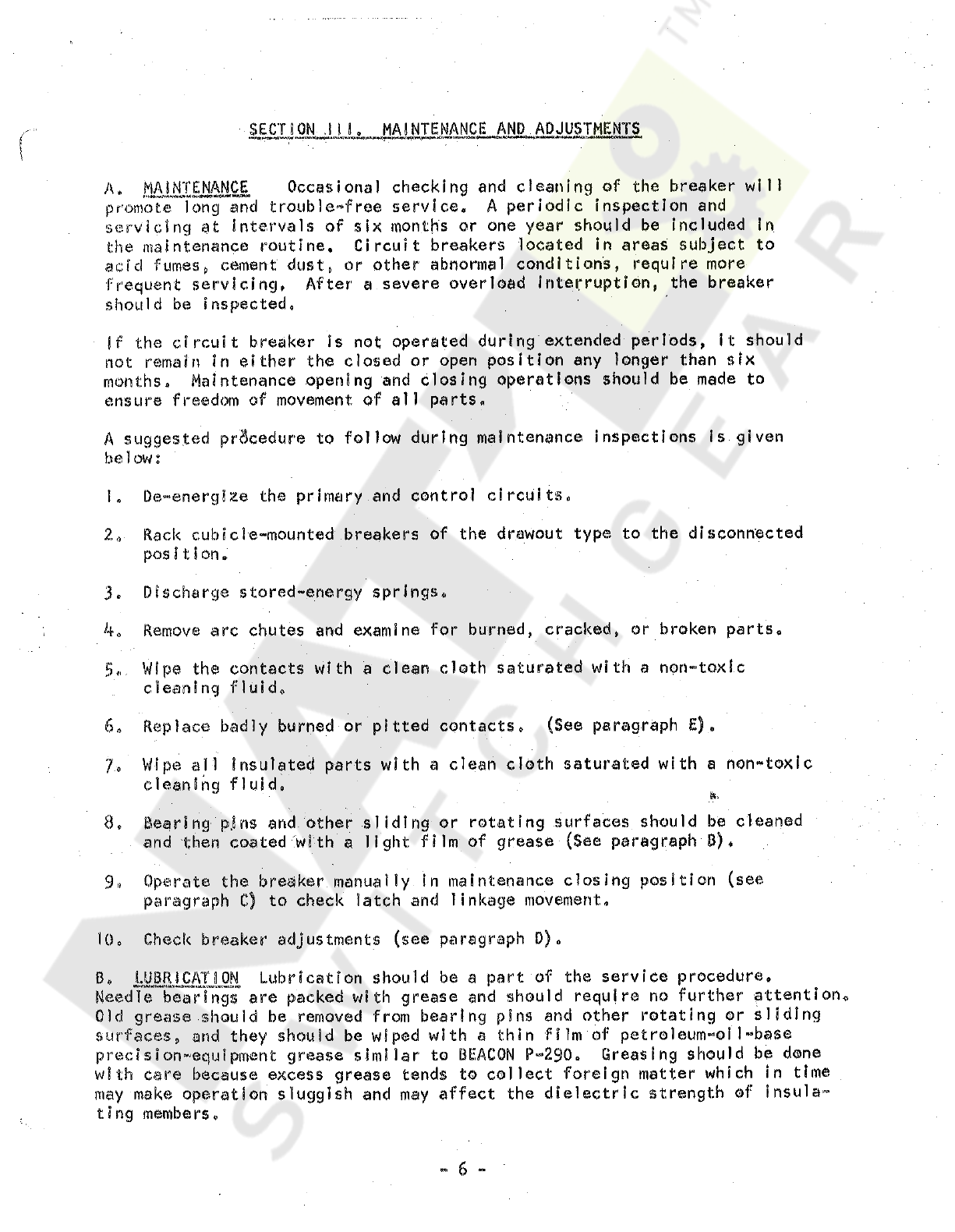

During

inspection

prior

to

Installation

and

for

routine

maintenance

inspections

,

the

breaker

contacts

may

be

closed

slowly

to

check

clearances

,

contact

adjustments

,

and

movement

of

links

and

latches

.

The

manual

closing

handle

Is

used

for

maintenance

closing

the

breaker

.

Electrlea

11

y

“

Operated

breakers

do

not

have

a

manual

closing

handle

.

,

but

a

manual

closing

handle

-

cam

assembly

5

s

available

as

a

maintenance

Stem

.

Figure

5

shows

the

maintenance

closing

handle

being

Inserted

in

an

electrically

-

operated

breaker

after

removal

of

the

front

cover

from

the

breaker

.

When

the

hole

In

the

maintenance

closing

handle

assembly

is

aligned

with

the

holes

in

the

operating

mechanism

frame

,

the

pin

which

is

attached

to

the

chain

fs

inserted

.

This

pin

holds

the

assembly

in

place

and

acts

as

a

pivot

point

for

the

cam

.

After

insert

'

s

on

of

the

maintenance

closing

handle

assembly

on

the

electrically

-

operated

breaker

,

the

actual

maintenance

closing

operation

fs

the

same

for

both

the

electrically

-

operated

breaker

and

the

manually

operated

breaker

.

Refer

to

Table

3

and

Figure

5

.

TABLE

3

MAINTENANCE

CLOSING

CLOSING

CONTACTS

2

Place

blade

of

screwdriver

between

hood

and

spring

.

release

latch

.

Push

down

spring

release

latch

and

hold

it

in

this

position

.

Pull

closing

handle

DOWN

ALL

THE

WAY

(

approximately

120

°

)

and

SLOWLY

return

to

normal

vertical

position

.

a

)

Contacts

wi

11

close

to

arcing

contact

'

touch

position

,

but

breaker

will

not

-

close

completely

.

2

,

OPENING

CONTACTS

;

Push

In

manual

.

trip

rod

*

&

Biwwr

.

:

!

THE

ABOVE

PROCEDURE

SHOULD

BE

USED

FOR

MAINTENANCE

CLOSING

ONLY

.

CAUTION

?

NOTE

:

Holding

the

spring

release

latch

down

prevents

the

stored

-

energy

springs

from

propping

in

the

charged

position

.

Thus

when

the

handle

is

slowly

returned

to

the

normal

vertical

position

,

the

energy

in

the

springs

Is

slowly

released

against

the

closing

handle

assembly

cam

face

.

D

.

ADJUSTMENTS

?

RmMiac

^

ji

*

imC

»

lCNOi

-

'

*

“

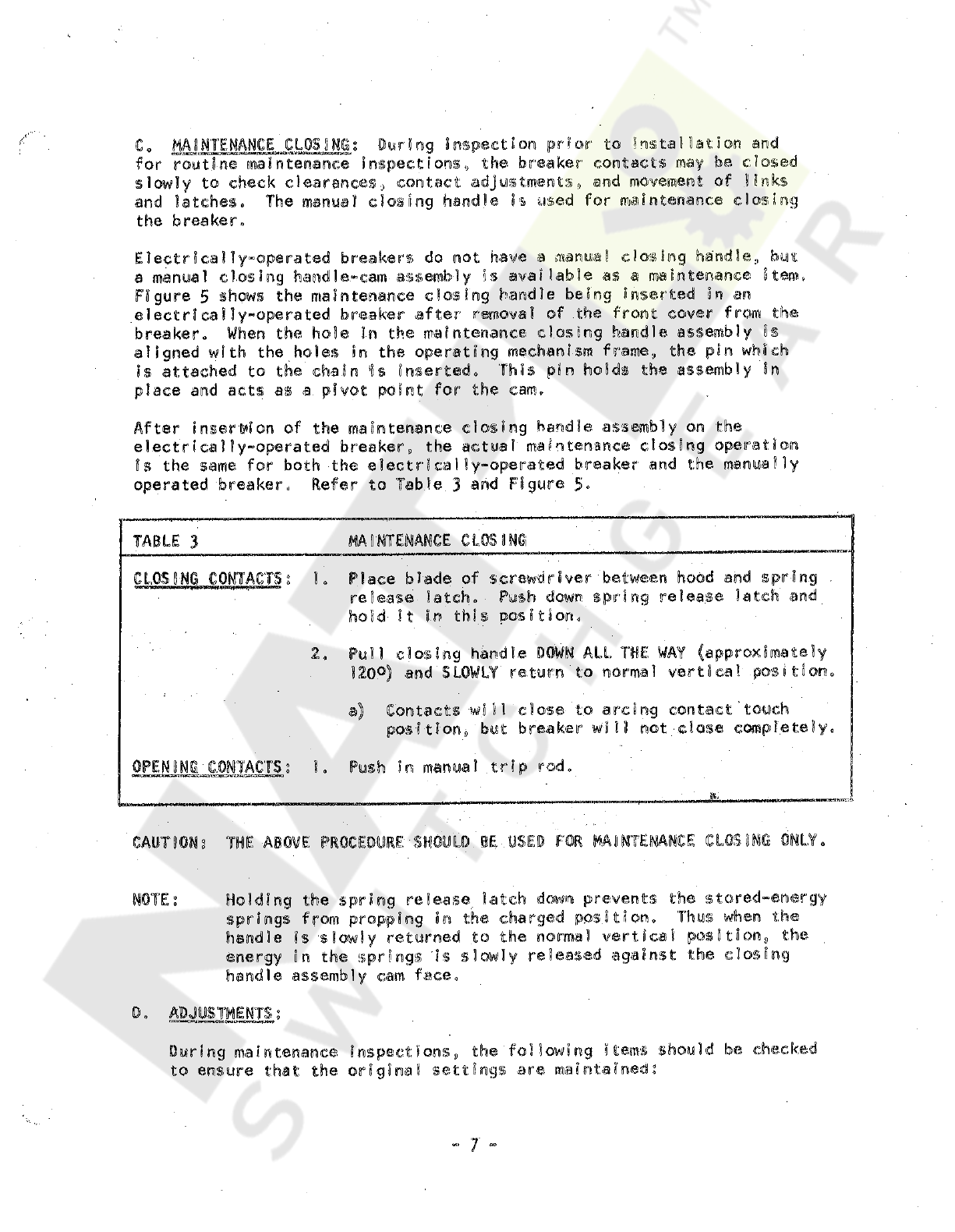

During

maintenance

inspections

,

the

following

items

should

be

checked

to

ensure

that

the

original

settings

ar

©

maintained

;

7

-

Courtesy of NationalSwitchgear.com

'

•

'

ft

.

'

V

\

)

Trip

Latch

Engagement

(

Refer

to

Figure

2

)

Trip

latch

(

2

)

6

)

should

have

an

engagement

of

,

062

"

plus

or

minus

.

015

"

on

trip

shaft

(

215

)

»

Measurement

is

made

with

the

latch

resting

on

the

shaft

in

the

reset

position

,

1

.

Main

Contact

Make

(

Refer

to

FIgure

6

)

2

.

Compression

of

contact

fingers

(

6

,

125

"

.

base

to

the

center

of

the

finger

contact

surface

when

the

breaker

Is

open

and

the

measurement

in

the

same

place

when

the

breaker

Is

closed

.

This

is

checked

with

a

normal

closing

operation

»

not

maintenance

closing

.

Adjustment

is

provided

by

positioning

screws

(

608

)

after

loosening

nuts

(

621

)

,

Counterclockwise

rotation

of

increases

compression

.

Care

should

be

taken

to

re

-

after

adjustment

.

If

it

is

desired

to

check

should

be

between

.

093

"

and

This

is

the

difference

in

the

measurement

from

the

breaker

screws

tighten

nuts

contact

pressure

,

,

a

push

-

type

spring

scale

can

be

used

to

compress

contact

fingers

(

619

)

»

with

breaker

open

.

Contact

pressure

should

be

between

20

and

30

pounds

.

Arcing

Contact

Make

(

Refer

to

Figure

6

)

3

.

With

movable

arcing

contact

mating

stationary

contact

when

the

breaker

is

closed

by

the

main

-

tenance

closing

method

should

not

exceed

,

062

"

.

screws

in

any

one

phase

touching

the

ee

Table

3

)

*

the

phase

to

phase

variation

Adjustment

may

be

made

by

positioning

as

in

paragraph

2

»

but

it

is

essentia

)

that

the

main

contact

compression

be

maintained

within

the

tolerance

listed

in

paragraph

2

»

Arcing

contact

pressure

should

be

between

30

and

40

pounds

when

checked

with

a

pull

-

type

spring

scale

at

the

base

of

the

arcing

contact

tip

insert

with

the

breaker

contacts

closed

.

4

«

,

Electricaily

Operated

Breakers

Motor

Cut

-

Off

Switch

and

Sprinq

-

Pos

?

tion

Switch

-

er

to

Figures

2

A

and

3

)

These

switches

are

mounted

on

a

common

bracket

that

is

set

and

ace

-

roll

-

pinned

in

position

during

production

testing

*

ment

i

$

required

*

the

bracket

must

be

positioned

so

that

when

roll

plus

(

236

)

In

gear

(

235

)

are

at

the

top

position

*

they

have

moved

plunger

(

233

)

against

the

roller

of

motor

cut

-

off

switch

(

232

)

to

shut

off

the

motor

.

As

the

springs

are

charged

*

arm

(

231

)

must

engage

the

roller

of

.

spring

-

position

.

switch

;

(

230

)

•

Pilot

holes

are

provided

In

the

mounting

bracket

for

drilling

and

roll

-

pinning

the

replacement

assembly

I n

the

correct

Courtesy of NationalSwitchgear.com

A

ALUS

-

CHALMERS

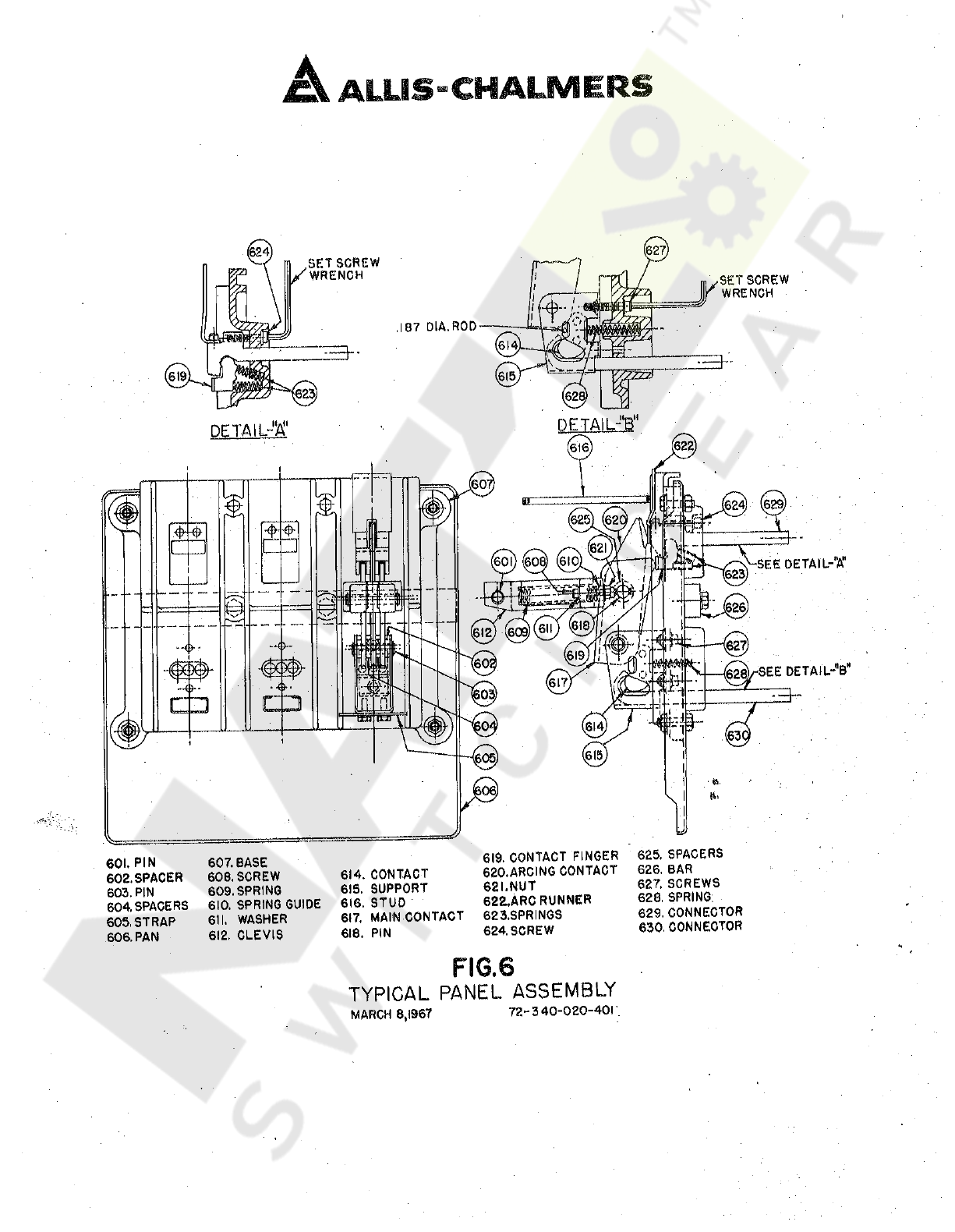

(

624

.

SETSCREW

/

WRENCH

I

.

SETSCREW

/

WRENCH

DETA

1

LJ

<

BM

DETAILS

o

SEE

DETAIL

-

V

.

-

'

•

V

S

3

~

0

~

SEE

DETAIL

-

B

"

CD

"

©

605

,

&

-

•

J

)

625

.

SPACERS

626

.

BAR

627

.

SCREWS

628

.

SPRING

.

629

.

CONNECTOR

630

.

CONNECTOR

619

.

CONTACT

FINGER

620

.

ARCING

CONTACT

621

.

NUT

622

.

.

ARC

RUNNER

623

.

SPRINGS

624

.

SCREW

601

.

PIN

602

.

SPACER

603

.

PIN

604

.

SPACERS

605

.

STRAP

606

.

PAN

607

.

BASE

606

,

SCREW

609

.

SPRING

610

.

SPRING

GUIDE

611

.

WASHER

612

.

CLEVIS

614

.

CONTACT

615

.

SUPPORT

616

.

STUD

6

(

7

.

MAIN

CONTACT

618

.

PIN

FIG

.

6

TYPICAL

PANEL

ASSEMBLY

72

-

3

40

-

020

-

401

MARCH

8

,

1667

Courtesy of NationalSwitchgear.com

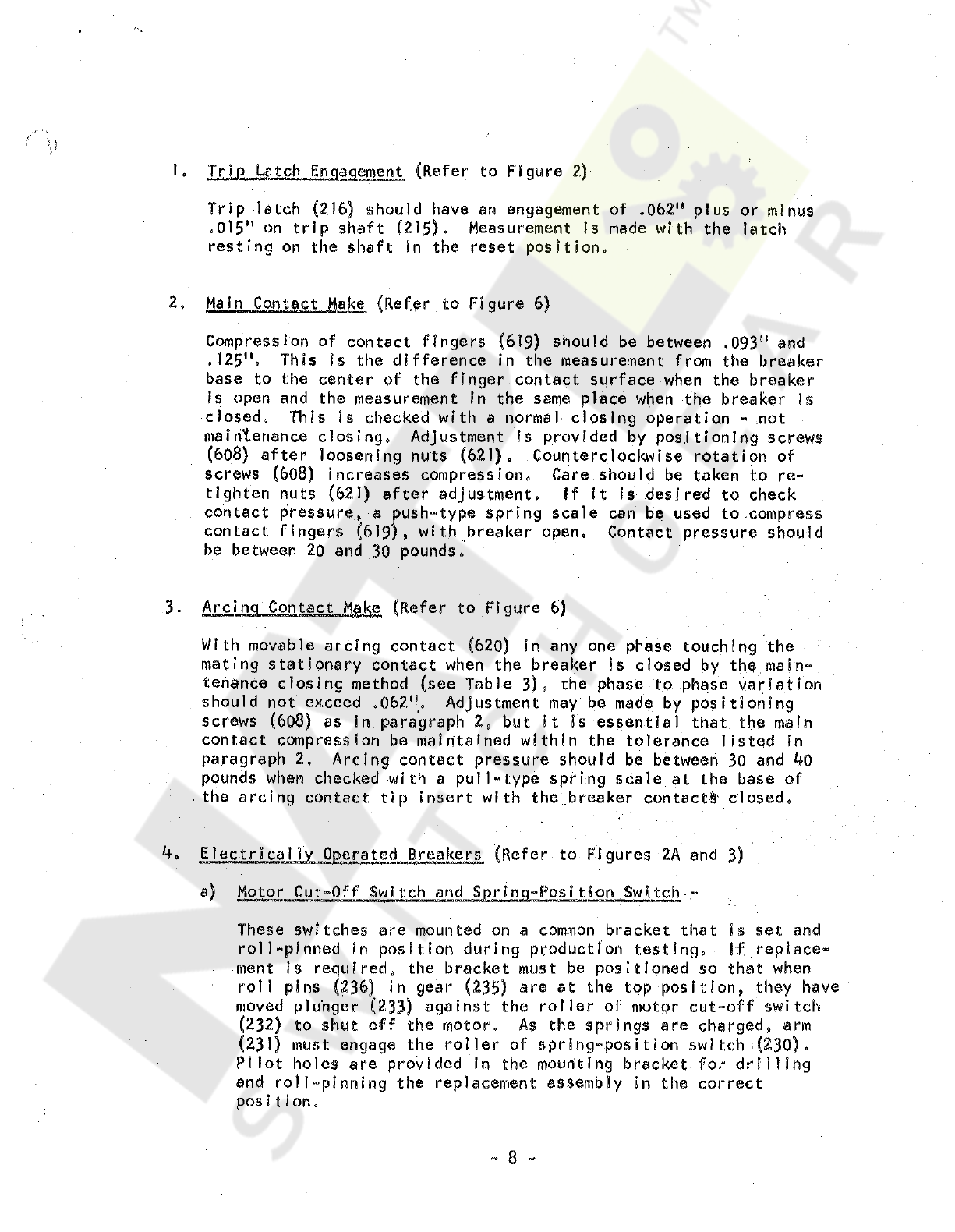

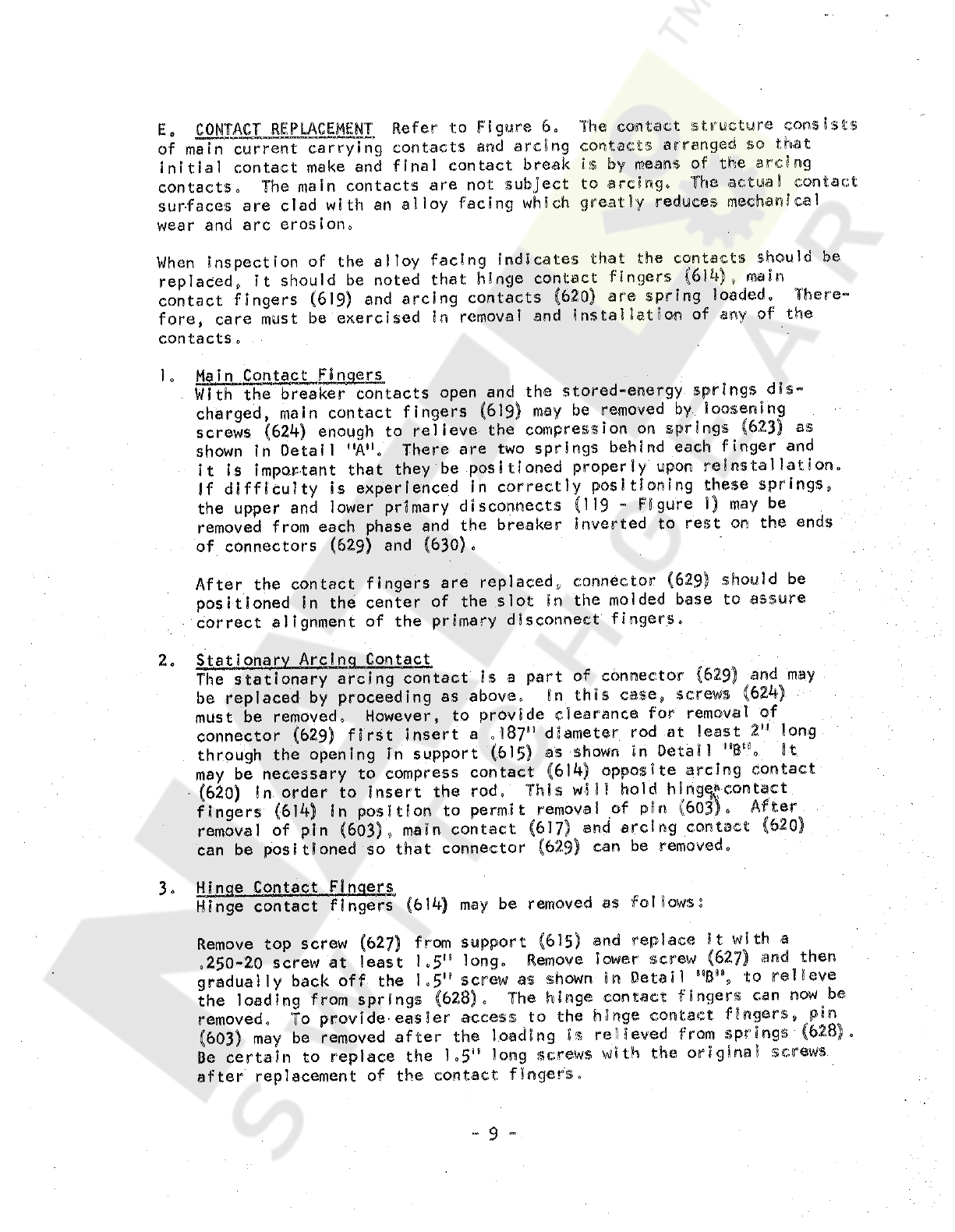

E

„

CONTACT

REPLACEMENT

Refer

to

Figure

6

,

The

contact

structure

consists

of

main

current

carrying

contacts

and

arcing

contacts

arranged

so

that

initial

contact

make

and

final

contact

break

is

by

means

of

the

arcing

contacts

.

The

main

contacts

are

not

subject

to

arcing

.

The

actual

contact

surfaces

are

clad

with

an

alloy

facing

which

greatly

reduces

mechanical

wear

and

arc

erosion

,

,

When

inspection

of

the

alloy

facing

indicates

that

the

contacts

should

be

replaced

,

it

should

be

noted

that

hinge

contact

fingers

(

614

)

,

main

contact

fingers

(

619

)

and

arcing

contacts

(

620

)

are

spring

loaded

.

There

-

fore

,

care

must

be

exercised

in

removal

and

installation

of

any

of

the

contacts

.

1

,

Main

Contact

Fingers

With

the

breaker

contacts

open

and

the

stored

-

energy

springs

dis

-

charged

,

main

contact

fingers

screws

(

624

)

enough

to

relieve

the

compression

on

springs

(

623

)

as

shown

in

Oetall

"

A

"

,

There

are

two

springs

behind

each

finger

and

it

is

important

that

they

be

positioned

properly

upon

reinstallation

.

If

difficulty

is

experienced

in

correctly

positioning

these

springs

,

the

upper

and

lower

primary

disconnects

(

119

-

Figure

1

)

may

be

removed

from

each

phase

and

the

breaker

Inverted

to

rest

on

the

ends

of

connectors

(

629

)

and

(

630

)

,

may

be

removed

by

loosening

After

the

contact

fingers

are

replaced

,

connector

positioned

In

the

center

of

the

slot

in

the

molded

base

to

assure

correct

alignment

of

the

primary

disconnect

fingers

.

2

.

Stationary

Arcing

Contact

The

stationary

arcing

contact

is

a

part

of

connector

(

629

)

and

may

be

replaced

by

proceeding

as

above

.

In

this

case

,

screws

must

be

removed

.

However

,

to

provide

clearance

for

removal

of

connector

(

629

)

first

insert

a

.

187

"

diameter

rod

at

least

2

"

long

through

the

opening

in

support

(

615

)

as

shown

in

Detail

"

B

"

»

It

may

be

necessary

to

compress

contact

(

614

)

opposite

arcing

contact

(

620

)

In

order

to

Insert

the

rod

.

This

will

hold

hing

^

contact

fingers

(

614

)

in

position

to

permit

removal

of

pin

(

603

)

.

After

removal

of

pin

(

603

)

»

main

contact

(

617

)

and

arcing

contact

can

be

positioned

so

that

connector

(

629

)

can

be

removed

.

should

be

3

.

Hinge

Contact

Fingers

Hinge

contact

fingers

(

6

!

4

)

may

be

removed

as

follows

;

Remove

top

screw

(

627

)

from

support

(

615

)

and

replace

it

with

a

.

250

-

20

screw

at

least

1.5

"

long

.

Remove

lower

screw

(

62

?

)

and

then

gradually

back

off

the

1

,

5

"

screw

as

shown

In

Detail

"

B

"

,

to

relieve

the

loading

from

springs

(

628

)

,

The

hinge

contact

fingers

can

now

be

removed

.

To

provide

easier

access

to

the

hinge

contact

fingers

,

pin

(

603

)

may

be

removed

after

the

loading

is

relieved

from

springs

-

(

62

,

8

)

.

Be

certain

to

replace

the

1

,

5

"

long

screws

with

the

original

screws

after

replacement

of

the

contact

fingers

.

-

9

-

Courtesy of NationalSwitchgear.com

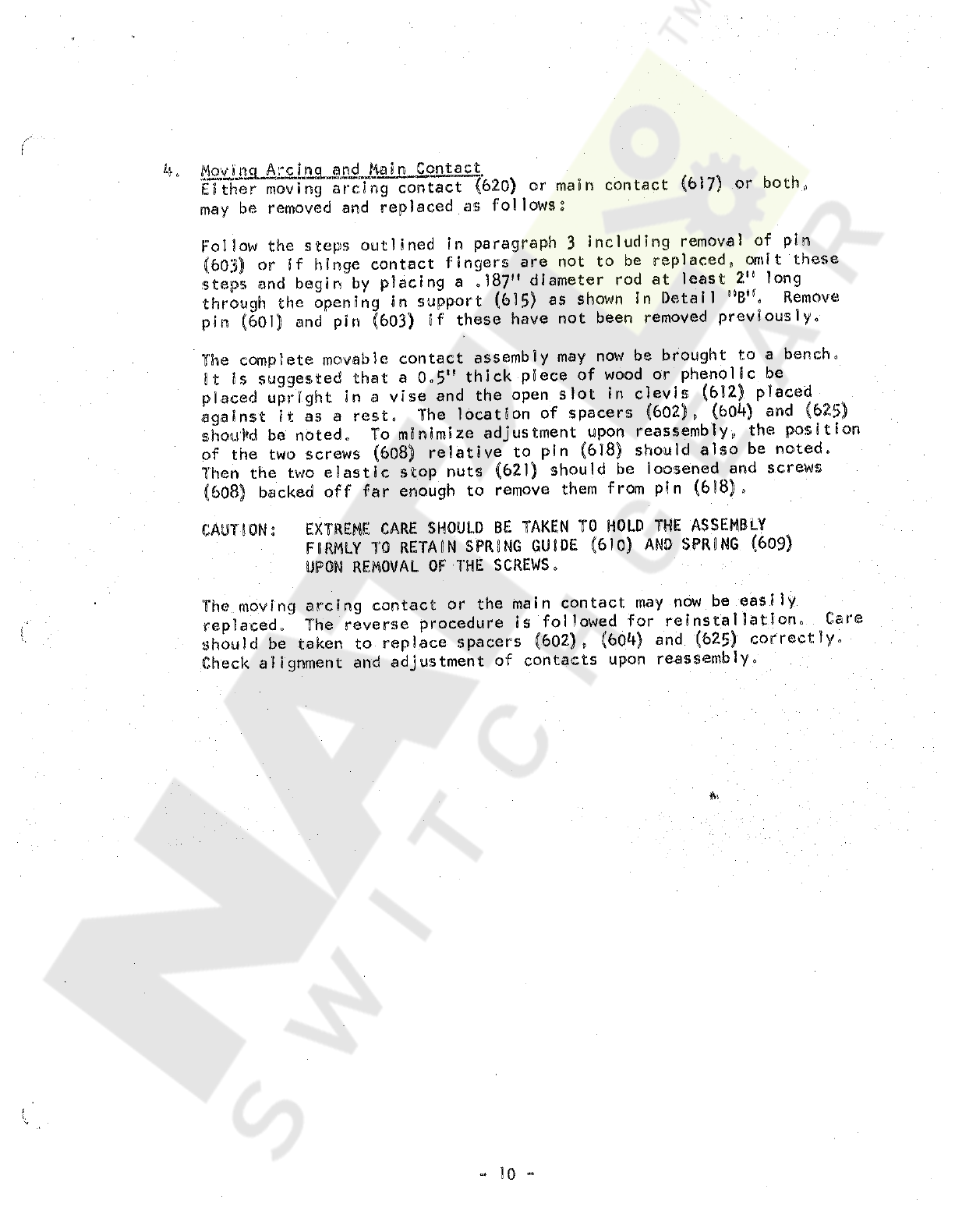

4

.

Movinq

Arclna

and

Main

Contact

I R

*

WAJ

-

ito

*

*

*

*

m

.

i

—

i

.

>

.

ww

«

wiin

»

»

n

>

.

-

Either

moving

arcing

contact

(

620

)

or

main

contact

(

617

)

or

both

,

,

may

be

removed

and

replaced

as

follows

?

Follow

the

steps

outlined

In

paragraph

3

including

removal

of

pin

(

603

)

or

if

hinge

contact

fingers

are

not

to

be

replaced

,

omit

these

steps

and

begin

by

placing

a

.

187

M

diameter

rod

at

least

2

"

long

through

the

opening

in

support

(

615

)

as

shown

in

Detail

"

B

*

'

.

Remove

pin

(

601

)

and

pin

(

603

)

if

these

have

not

been

removed

previously

.

The

complete

movable

contact

assembly

may

now

be

brought

to

a

bench

.

It

is

suggested

that

a

0

„

5

,

!

thick

piece

of

wood

or

phenolic

be

placed

upright

in

a

vise

and

the

open

slot

in

clevis

(

612

)

placed

against

it

as

a

rest

.

The

location

of

spacers

(

602

)

,

(

604

)

and

(

623

)

shou

+

d

be

noted

.

To

minimize

adjustment

upon

reassembly

,

the

position

of

the

two

screws

(

608

)

relative

to

pin

(

618

)

should

also

be

noted

.

Then

the

two

eiastic

stop

nuts

(

621

)

should

be

loosened

and

screws

(

608

}

backed

off

far

enough

to

remove

them

from

pin

(

618

)

,

EXTREME

CARE

SHOULD

BE

TAKEN

TO

HOLD

THE

ASSEMBLY

FIRMLY

TO

RETAIN

SPRING

GUIDE

(

610

)

AND

SPRING

(

609

)

UPON

REMOVAL

OF

THE

SCREWS

.

CAUTION

;

The

moving

arcing

contact

or

the

main

contact

may

now

be

easily

replaced

.

The

reverse

procedure

is

followed

for

reinstallation

.

Care

should

be

taken

to

replace

spacers

(

602

)

,

(

604

)

and

(

625

)

correctly

.

Check

alignment

and

adjustment

of

contacts

upon

reassembly

.

fa

10

Courtesy of NationalSwitchgear.com

SECTS

ON

IV

.

STATIC

OVERCURRENT

TRIP

DEVICE

MnftjoK

(

A

.

INTRODUCTION

The

Allis

-

Chalmers

Static

Overcurrent

Trip

Devices

are

completely

static

;

that

is

there

are

no

moving

parts

or

contacts

.

The

circuits

of

the

device

are

designed

for

light

loading

of

components

and

are

temperature

compensated

for

accuracy

and

stability

of

calibration

over

wide

temperature

ranges

for

Indefinite

periods

of

time

.

The

static

overcurrent

trip

devices

,

which

replace

the

electro

-

mechanicaI

series

overcurrent

trip

devices

,

perform

the

same

function

with

a

higher

degree

of

accuracy

and

versatility

.

In

common

with

series

overcurrent

trip

devices

,

all

energy

for

operation

is

obtained

from

overload

or

fault

current

.

No

batteries