Allis-Chalmers LA-1600 User manual

A

CONTROLS

ALUS-CHALMIRS

'INSTRUCTIONS

AIR CIRCUIT BREAKER

•

TYPE LA-1600 & LA-1600F (FUSED)

,

!

---------

,

8WX-6638-6

1SX4582

INDEX-----------------------------------------------------------

INSTALLATION AND INSPECTION. . . . . .

..

I

Introduction

..........................

I

Receiving and Inspection for Damage

..........

I

Installation . . . . . . . . . . . . . . . . . . . . . . . .

..

I

Storage

..............................

I

Maintenance

..........................

3

OPERATION 3

Description. . . . . . . . . . • • . . • . . . . . . . . . . .

..

3

Manually·Operated Breaker

..............

3

Electrically·Operated Breaker. . . . . . . . . . . .

..

4

Racking Mechanism, Drawout Interlock, and

Lifting Bar . . . . . . . . . . . . . . . . . . . . . . . .

..

6

Spring Discharge Mechanism . . . . . . . . . . . .

..

7

Description and Function

................

7

Adjustments

........................

7

MAINTENANCE AND ADJUSTMENTS. . . .

..

9

Maintenance

Lubrication 9

9

Maintenance Closing . . . . . . . . . . . . . . . . . . . . . 9

Adjustments

.........................

II

Trip·Latch Engagement

................

,

II

Main Contact Make

...................

II

Arcing Contact Make

.................

II

Electrically-Operated Breakers

...........

II

Contact Replacement

...................

II

Main Contact Fingers

....•••.....

_. .

..

12

Stationary Arcing Contact . . . . • . . . • . .

..

12

HInge

Contact Fingers

.................

12

Moving Arcing and Main Contact. . . . . . . . .

•.

13

Release Magnet. • . . . . . . . . . . . . . . . . . . . . .

..

13

FUSE FUNCTIONS

...................

14

Current Limiting Fuse

...................

14

Trigger Fuse

.........................

14

CURRENT TRANSFORMERS 16

t_

ILLUSTRATIONS

---------------------------------------

(

.'

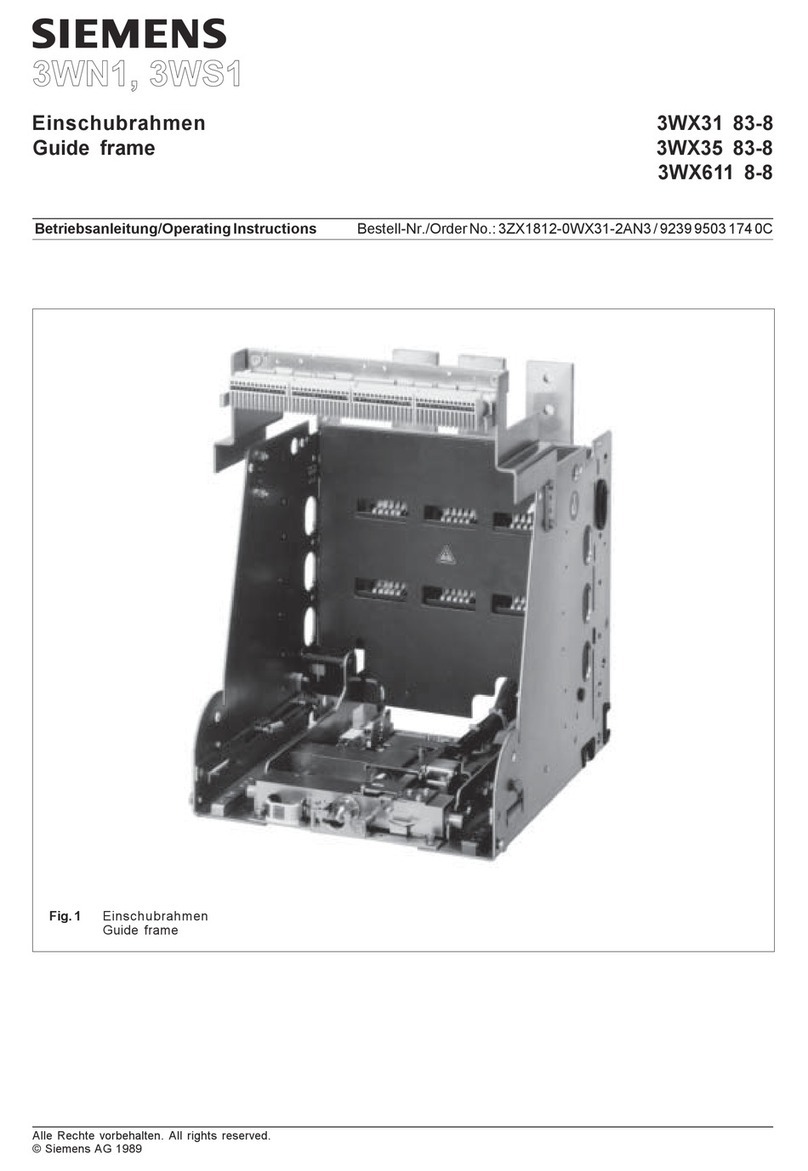

Figure I

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

-Typical LA-1600 Breaker Outline

.....

2

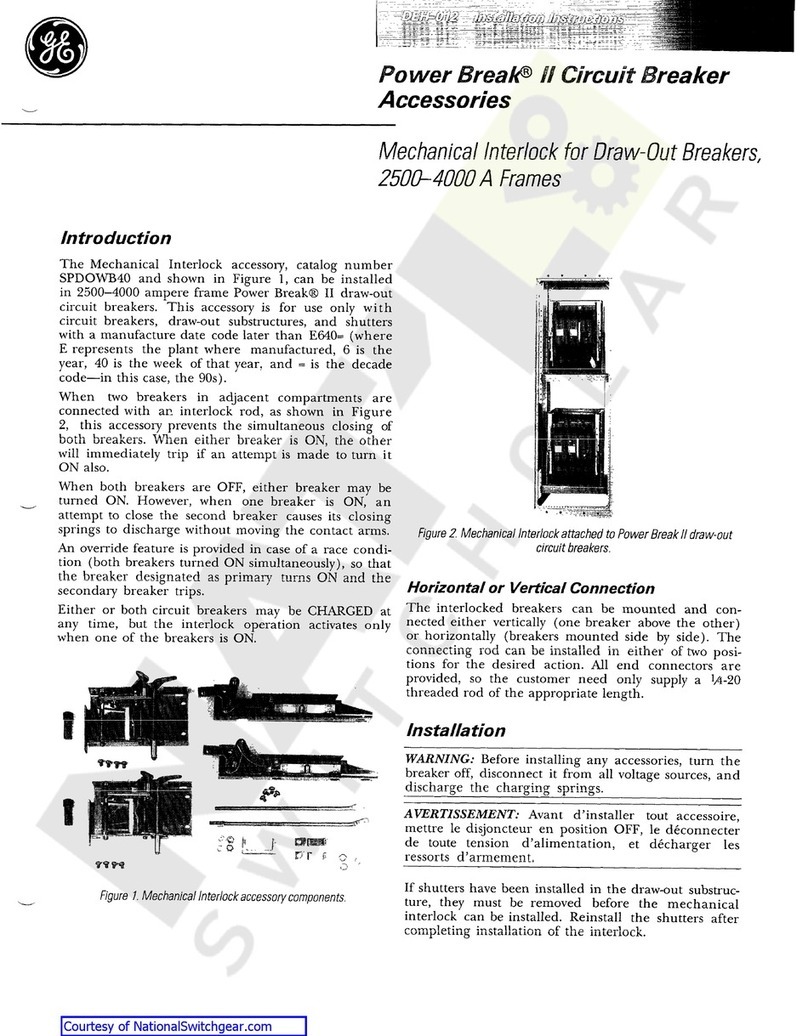

-Typical Operating Mechanism -

Manually Operated Breaker

.......

3

-TypicalOperatingMec:hanlsm -

Electrically Operated Breaker. . . . .

..

5

-Typical Wiring Diagram -Electrically

Operated Breakers

.............

5

-Typical Racking Mechanism and

Drawout Interlock

.•...........

6

-Spring Discharge Mechanism

.........

8

-Maintenance Closing. . . . . . . . . . . . . . . 10

•

Figure 8

Figure 9

Figure 10

Figure

11

Figure 12

Figure 13

Figure 14

Figure IS

Figure 16

Figure 17

-Typical Panel Assembly. . . . . . . . . . . . . 12

-Typical Release Magnet. . . . . . . • . . . . . 14

-Current

limiting

and Trigger Fuse

.....

IS

-TypicalBreaker RatingPlate

.......•.

16

-Typical Secondary Disconnects

..•...•

17

-Typical Auxiliary Switch

...........

18

-Typical

Shunt

Trip

..............•

19

-Typical Undervoltage Device

.........

20

-Typical

BeU

Alarm (Manual Reset) . :

...

21

-Typical

BeU

Alarm(Electricai Reset)

...

22

TABLES--------------------------------------------------------

Table I -Operating Procedure -ManuaUy-

Operated Breakers

.............

4

Table 2 -OperatingProcedure -ElectricaUy·

Operated Breakers

.............

4

Table 3

Table 4

-Maintenance Closing. . . . . . . • . . • . . • •

11

-Trip Rating Table -Amperes

.......

16

The

informalion

oo"",ned

with,n

i.

intended

to

us.1t

Oper.tlng

peoonnel

bV prOyidlng

informatIOn

on

the

gene'lIl

characr",SI'cs

01

equIpment

of

thIS

type.

11

do"

IlQI

.........

the

u_

of

responsibllitv

to

use

sound

qinetlf'll1I

practice.

In

the

i"$tell.l.on,

.pplication,

op'ration

end

.....

;..,1

....

0<.:11

01

In.

parlOcutar

t'qu'pmem

pUr<;hased.

II

dr_,,..

or

other

SYpplementarv

'nstructions

fOf Speo!;"'C

appllcatlonl

are

forwarded

w'th

Ill,s Il'lIInual

or

separately.

they

lake

pre<:edence

over

any

conflicllngor

mCX)mplet.

,nformallon

,n

Illis

...

nual.

PRINTED

IN

U.S.A.

SGM

& Co

••

Inc.

WARRANTY

Allis-Chalmers

"LA"

air

circuit

breakers

are

warranted

to

be free

of

defects in material and workmanship for a

period

of

one year after delivery to the original purchaser.

This warranty

is

limited to the furnishing

of

any part which

to our satisfaction has been proven defective.

A11i.s-

Chalmers will not in any case

assume

responsibility for

allied equipment

of

any kind.

Typical ShippingMethods Used

With

"LA"

Breakers

ii

. .

INSTALLATION

AND

INSPECTION

Introduction

The type "LA"

air

circuit breakers

may

be

furnished

for

mounting

in

anyone

of

three ways. They

may

be

used

in

metal-enclosed switchgear

of

the drawout type,

in

indio

vidual enclosures (pullout type), or for stationary mounting

in

a customer's own enclosing

case

or

switchboard.

All

"LA" breakers

are

completely assembled, tested, and

calibrated at the factory

in

a vertical position and must

be

so

installed to operate properly. Customer's primary con·

nections should

be

adequately braced against the effects

of short circuit currents to prevent overstressing the

breaker terminals.

Receiving

and

Inspaction for

Damage

Immediately upon receipt

of

this equipment, carefully

remove all packing traces and examine parts, checking

them against the packing list and noting any

damages

incurred in transit.

·If

such

is

disclosed, a damage

claim

should

be

filed at once by the customer with the trans-

portation company and Allis-Chalmers notified.

Two

shipping methods

are

used with "LA" breakers:

I.

Individually with protective covering.

2.

Within a cubicle when part

of

a switchgear lineup.

Breakers shipped in their cubicles are blocked to prevent

accidental tripping during shipment. Note all caution

tags, remove blocking bolts, and open breaker contacts

before installation.

Installation

The

"LA" air circuit breaker

is

completely adjusted, tested,

and inspected before shipment, but a careful check should

be

made to

be

certain that shipment or storage has not

reo

suIted

in

damage

or

change

of

adjustment. Circuit breakers

should be installed in a clean, dry, well-ventilated area

in

which the atmosphere

is

free from destructive

acid

or

alkali

fumes (see Figure 1 for dimensional data). Stationary·type

breakers should

be

mounted high enough to prevent injury

to

personneleither from circuit interruption

or

from moving

parts during automatic opening of the breaker.

Allow

suf-

ficient

space

to permit

access

for cleaning

and

inspection

and adequate clearance to insulating barrier

above

the

breaker to prevent damage from

arcing

during interruption.

Before

installing, make certain that the breaker contacts

are

in

the open position.

I. Mter the breaker

is

installed

in

position, close

it

manually by the maintenance closing method (see

MAINTENANCE

AND

ADJUSTMENTS,

page

9) to

check proper functioning

of

the mechanism and con·

tacts.

CAUTION

Make sure circuit is

not

energized.

During the closing operation, observe that the contacts

move

freely without interference

or

rubbing between

movable

arcing

contacts and parts of the

arc

chutes.

Then refer to OPERATION,

page

3 for a detailed

des-

cription of the circuit breaker operating characteristics

before putting the breaker

in

service.

2.

Trip units and accessory devices should

receive

a

thorough check prior to placing the breaker in

service

to

be

certain that adjustments

are

proper and parts

are

not damaged. Refer to Static Trip

Device

Instruction

Book (l8X4392).

3. Cubicle·mounted breakers

of

the drawout type

are

equipped with a drawout interlock to prevent movement

of

a closed breaker into or out of the connected posi·

tion.

See

OPERATION,

page

3 for a description of

the

interlock. Its operation should

be

checked before the

breaker

is

energized.

4. Upon completion

of

the installation inspection, the

breaker

is

ready to

be

energized after

the

control

wiring, if any,

is

checked and the insulation tested.

Storage

When

breakers

are

not to

be

put into immediate use, they

should

be

wrapped

or

covered with a non-absorbent mate·

CAUTIONS

TO

BE

OBSERVED IN

THE

INSTALLATION

AND

OPERATION OF

"LA"

CIRCUIT

BREAKERS

1.

Read Instruction

Book

before installing

or

makingany changes

or

adjustments on the breaker.

2.

As

the closing springs

on

stored-energy breakersmay

be

charged

in

either the breaker open

or

closedposition,

extreme care shouldbe taken

to

discharge the springs before working on the breaker.

3.

When

closing manually·operated breakers, always

grasp

closing handle

firmly

until

it

is returned to the normal

vertical position.

4.

Check current ratings against single line diagram to assure that breakers are properly located

in

switchgear

at

installation.

5.

C~eck

.the

all~nment

of

the secondary disconnect fingers to ensure against misalignment due to possible

distortion

of

fmgers during shipmentand handling.

6.

Once the breaker is energjzed,

it

should

not

be

touched,

except

for

operating, since

most

of

the component

partsare also energized

to

72_440_007-401

;-REAR

PAN

~~RIP

l&~\

S~AFT

DETAI L "A"

(LEFT

SIDE VIEW)

COVE~

(~FRAME

DETAIL"B"

(TOPVIEWl

BARRIER{

104

FRAME

DETAIL

lie

II

( LEFT

SIDE

VIEW)

RELEASE

MAGNET

'.0

-.062

21.625

1.

",.,

6.

250

1

I

'.06'1

~l.B12

I

I

~:

J , ...

~

It'

.-,

Jl

I

.1

.i1?2

f -

r<

!.062

20.719

STRAP RAIL

RADIUSG)

SEE TABLE 4

I

/'

t

I03)SARRIER

BELL

ALARM

~

116

~

~

ARC

CHUTE

RACKING (ATTACHMENT)

115

~

_

14

6-5~6~~

!

062

1 8 CURRENT

SCREW

(SEE DETAIL-B) .

r--6.437~

I TRANSFORMERS

UNOERVQLTAGE

127

INTERLOCK • 1.681

4.0

IO~.QiII1

4.~ga2M./'

/' 2.250

DEVICE

nLJ==L,LI;--:;:r

SLIDE

COVER

- - . •

--~~-'--11

-.--

/'

-

~-

f.

(ATTACHMENT)

.062

a'

/,

500

!062

..

PRIMARY

440&

RACKING

CRANK~

;

._,

1375

____

DISCONNECTS

--,

(ATTACHMENT) -

500

LATCH

f..........

! I

%062

-........

'1

---

..

FREE POSITION

.625

_

~

ON

ELECTRICALLY

--

5.625

18

250

OPER.

BREAKERS

I

NORMAL

OPER. POSITION

.187,

.

:;.

':

~'

MANUAL HANDLE !

062

.~

!.031

SECONDARY

L

~

•

:.~

~

IS NOT INCLUDED'

16'~

.,.......

9.500

DISCONNECTS

106:!"

OEli!

.625R

."

I

ON

THE

BREAKER.

1"'------

FREE

POSIT.

I1I.S63

.500~

',b::cr

'Q

.375

MARKINGS

ON'"

\.

•

--

5.125 t I

SECONDARY~

~

OPPOSITE

LV

............._

DISCONNECTS\!,~

ti·

812 SIDE

APPAOX'I

..

L...LL5-b&:!i

~

V RAIL

!062

9.687..........

~I

. 120

122

WASHER

"y".

RELAY a

20.500

.187 :t062

SHUNT

TRIP

108

~

0v

~

VERT.

TRAVEL:

2.250

BIER

(ATTACHMENT) TRIP ELECTRICAL

TO

TRIP

,.37

8

123

GROUND

(SEE

OETAIL:A")

ROD

110

SPRING

125

BAR

CONTROL SWITCH III

STATIC

e.c·

RELEASE CUBICLE --.--J 124 INTERLOCK

(ELECTRICALLY

OPER.

109 TRIP DEVICE (ATTACHMENT) INTERLOCK

BREAKERS) (SEE

DETAIL-MC'"

CAM

Figure

1.

-TypiClli

LA-l600

Breaker Outline

rial to provide protection from plaster, concrete dust,

or

other foreign matter. Breakers should not

be

exposed to

the action of corrosive

gases

or moisture. In areas of high

humidity or temperature fluctuations, space heaters or

the

equivalent should

be

provided.

Maintenance

Occasional checking and cleaning

of

the breaker

will

pro-

mote long and trouble·

free

service. A periodic inspection

and

servicing at least every six months should

be

included

in

the breaker maintenance routine.

If

the circuit breaker

is

not operated during extended

periods, the breaker should not remain

in

either the

closed or open position any longer than

six

months.

Maintenance opening and closing operations should

be

made

to

ensure freedom of movement

of

all

parts.

OPERATION

Description

The LA·1600air circuit breaker has

an

interrupting capacity

of 42,000 amperes and a maximum continuous current

rating of 1600 amperes at 600 volts, 60 cycles. For infor·

mation on other voltages or frequencies, the factory should

be consulted.

It

is

available as a manually-operated breaker

or an electrically·operated breaker. The two breakers

are

identical withthe exception of the medium

used

to transmit

power to charge the stored-energy springs.

A double.toggle, trip-free mechanism

is

used; that is, the

breaker contacts

are

free

to

open at any time,

if

required,

72-340-014-401

SPRING

SPRING

RACKING

SCREW

regardless of·the position of the mechanism or the

force

being applied.

MonuaUy-Operated

Breaker

As

the breaker has a single-frame type construction, most

of

the latches and linkages are arranged in pairs; however,

for

descriptive purposes, they will be referred to

as

single

items. Refer to Figure 2 and Table

I.

Detail

"A"

shows

the position

of

trip latch (216) when the breaker contacts

are

open with the closing spring discharged. Movement of

closing handle (201) downward rotates

cam

(208) against

roller (205), thus pivoting closing cam (210) clockwise

TOGGLE

LINKAGE

STOP

TRIP

SHAFT

TOGGLE

LINKAGE

DETAIL-MAil

DETAIL-"e"

DETAIL-lie"

DETAIL-"OII

Figure 2. -Typical Operating Mechanism -

ManUlllly

Operated Breaker

3

about pin (206) and extending stored-energy springs (209)

through link

(225)

and pin (226)_ Rotation of cam (210)

clockwise permits spring (217) to collapse toggle linkage

(213)

and (220)_ At the same time, trip latch (216)

is

reset

by

torsion spring (228)

as

shown in Detail

"B"_

Push-

ing down spring release latch hood (202A), after the closing

handle

is

returned to the normal vertical position, releases

the energy in springs (209)_ Through link (225), closing

cam

(210)

is

rotated counterclockwise against roller (219),

which moves toggle linkage

as

shown in Detail

"C",

to

close the breaker contacts. The closing operation may

be

interrupted at any point by functioning

of

the trip device,

thus ensuring "trip_free" operation.

TABLE 1. OPERATING

PROCEDURE-

MANUALL

V-OPERATED BREAKERS

Operation Procedure

Charging Springs Pull handle (201) down all the

way (approximately

120~

and

return to normal vertical posi-

tion. (Engagement

of

pawl (211)

with the ratchet teeth prevents

handle reversal until the down-

ward stroke is completed.)

Oosing Push down spring-release latch

hood (202A) after handle

is

returned to normal vertical posi-

tion.

Tripping Push in manual trip rod (207).

or

If

shunt trip

is

provided, operate

remote trip control switch (CST)

(See Figure 4.)

To

open the breaker contacts, trip rod (207)

is

actuated.

This rotates trip shaft (215) clockwise which releases trip

latch (216)

as

shown in Detail

"A".

On breakers equipped

with a shunt trip device, the breaker contacts may

be

opened

by

operation

of

a remote trip control switch. The

shunt trip device rotates the

trip'shaft

to release the trip

latch.

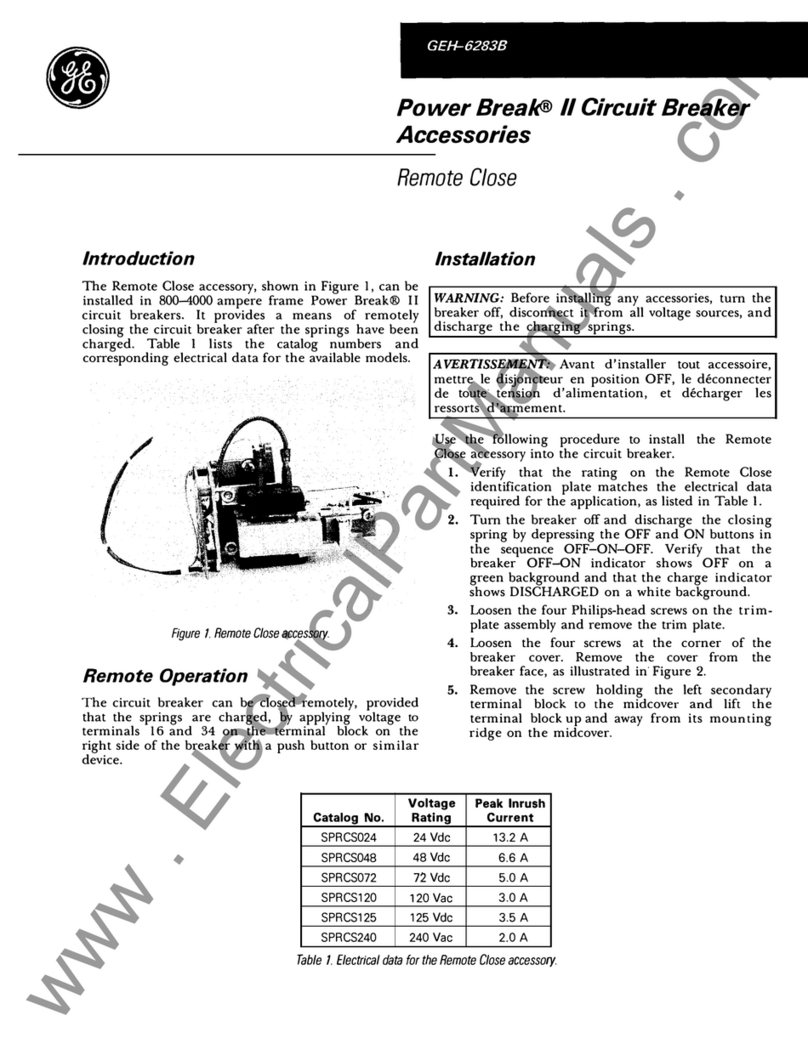

Electrically-Operated Broeker

The mechanism

of

the electrically-operated breaker

is

the

same

as

that

of

the manually-operated breaker except that

the manual closing handle

is

replaced by an electric motor

and the gear system.

Refer to Figures 3 and 4 and Table

2.

Movement

of

the

control switch (N) located on the front of the breaker to

the

"ON"

position,

when

the (';ontrol circuit

is

energized,

will

start

the

automatic

closing cycle. Motor gear

box

pinion (338) rotates gear (335) counterclockwise, and

pins (336) move across the top

of

!lat biasing spring (334).

This raises gear (335) to mesh with gear segment (340).

4

Since this gear segment

is

attached to closing cam (310),

the stored-energy springs are charged and latched in the

same sequence as described in the previous section_

As

gear (335) reaches the last

tooth

on segment it

is

dis-

engaged by means

of

spring (348)_

Spring-position switch (330) (SPS b)

is

actuated

to

the

open position by arm (331) attached to link (325)

as

the

stored-energy springs approach the charged position. This

switch initiates the spring recharging cycle and is connected

in parallel with motor cut-off switch (332)

(88

a) which

is

open initially, closes while the motor charges the springs,

and opens when the springs are charged with the gearing

disengaged. The motor cutoff switch is actuated

by

the

movement

of

plunger (333) over pins (336). Approximately

·twelve seconds are required for completion

of

the spring

charging cycle.

The breaker may now be closed

by

pushing down spring-

release latch hood (302A)

as

in the manually-operated

breaker, or it may be closed electrically through remote

close control switch (CSC). This switch energizes spring-

release coil (SRC) which moves pin (341) in a counter-

clockwise direction

to

trip spring release latch

hood

(302A)

and spring-release latch (302). The "Y" call is energized

simultaneously with the spring-release coil and causes

the "Y" contact to open the circuit to the motor_ Since

the "Y" relay will remain energized as long

as

the remote

close control switch (CSC)

is

held closed,

"YI"

contact

keeps the motor circuit open to prevent "pumping" or

repeated attempts

to

charge the stored-energy springs

when the breaker

is

closing.

After the stored-energy springs are discharged, they are

automatically recharged as long as the control circuit is

energized, and the

motor

toggle switch (N) is in the

"ON"

position. Figure 4 shows the spring-position switch (SPS b)

closed to complete the motor control circuit

as

it would

be when the springs are discharged.

TABLE 2. OPERATING PROCEDURE -

ELECTRICALLV-OPERATED BREAKERS

Operation Procedure

Charging Springs Energize control circuit.

Move

control switch (N)

on

front of

breaker to

"ON"

position.

Closing After springs are charged, actuate

remote close control switch

(CSC). or

Push down spring-release latch

hood (302A).

Tripping Actuate remote trip control

switch (CST). or

Push in manual trip rod (307).

,

/

•

ARM

............

• LINK

• PIN

.............

eTRIPROD

.SPRING

(X)I+)

SPRING

POSITION

SWITCH

,-i1

.....

LJ-\

331 REF

~.~--i--------

SWITCH

".9)..

__

.'

:

~~

BRACKET

\.

CLOSING

CAM

MOTOR

Cur·OFF

SWITCH

NUT

~~~NUT

FLAT

SPRING

GEAR

PINS

MOTOR GEAR-BOX

PINION

PLUNGER

EYE

END

Figure

3.

-Typical OperatingMechllnism -Electrically Operated Breaker

REF

NOTE:

SWITCHES

MOUNTED

ON

BRACKET

--

-----------

-----

- -

--

--

-r-"

-I·~---r;-------I~s-c----~

t~~

(X)(+)

_______________________

~

__

,

ee

SPS

'Y

t--'>"

I G I R

o b

'T2

~

S~

As

SUPPLY

M Y,

e":

Y 1

,T

-

f'

\IIJ>-

-Ti------Tcs.;----

-~'

*CS-T®:

nee

,x-

2

--

~PPLY:,

's

T

-

.~~+

IY)(-)

--7'

4

~

, ,

st'

61

v

:s

9

10

N S b r

3 b

•

AC

CONTROL

;,,;':'9:f

fir

r

4

,

~1

sf

v

~

9

10

DC

CONTROL

DVERCURRENT

STATIC

TRI P

DEVICE

WIRING

TRANSFORMERS

xt

'X2

Ixl2~211

"i'l>;ll

MAGNETIC

TRIP

COIL

o

2

2.

3

o 0 o 0 0 0 STATtC

TRIP

3 4 5 6 7 B

TERMINAL

BLOCK

Figure

4.

-Typical Wiring Diagram -Electrically Operated Breakers

5

Racking

Mechanism,

Drawout Interlock,

and

Lifting

Bar.

Cubicle-mounted breakers

of

the drawout type include

as

integral parts the mechanism to rack the breaker

in

and

out

of

the cubicle compartment, the drawout trip inter-

lock, and the drawout position markings_

72-440-010...01

RACKING

CLEVIS

DETAIL-IIA'•

RACKING

SCREW

RACKING

CLEVIS

,

TRIP

ROD

(ELECTRICALLY

OI'£R. BREAKERS)

CUBICLE

FIXED

PIN

TRIP

SHAFT

Refer to Figure

5_

Lifting bar (SOl) may be used to lift

the breaker when

it

is

being inserted

in

the cubicle_

With the breaker

in

position on the rails, the following

sequence should be used to rack the breaker into the fully

connected position.

LIFTING

BAR

INTERLOCK

SLIDE

---,

I.'

.""'e

••

CUBICLE

INTERLOCK INTERLOCK CAM

SIDE VIEW

Figure 5. -Typical Racking Mechanism and Drawout Interlock

6

CAUTION

On

electrically-operated breakers, be cenain that the

control switch on the front

of

the breaker

is

in

the

"OFF"

position.

I.

Push trip bar and lower the interlock slide

(502)

to

expose

racking screw (504). (Lowering the interlock slide will

also actuate trip rod

(506)

SO

that

a closed breaker will

be tripped.) While the interlock slide

is

in this position,

the

breaker

is

"trip·free"

and cannot be closed.

2. With the switchgear operating crank, rotate racking

screw

(504)

to move racking clevises (505)

to

the posi·

tion shown where they will engage with fixed pins (503)

in the cubicle.

3. The breaker should now be pushed along the rails to

the "DISCONNECTED" position. At the same time

the racking clevises (505) should be checked

to

see that

they

are in correct alignment with cubicle fixed pins

(503).

Counterclockwise rotation

of

the operating crank will

now rack the breakerintothe

"TEST"

and CONNECTED

·positions.

At

the

''TEST''

and

CONNECTED positions,

interlock

(508)

is

in its normal horizontal position.

By

removing operating crank

and

then raising interlock

slide (502), trip rod (506) returns

to

the extended posi·

tion permitting trip shaft

(507)

to reset and the breaker

may be operated.

Between

''TEST''

and CONNECTED positiQns, the cubicle

interlock cam

(509)

raises interlock (508)

to

hold trip

rod

(506)

and trip shaft

(507)

in the "trip·free" position

so that

the

breaker cannot

be

closed even

if

interlock

slide

(502)

is

raised. This

is

to

prevent movement

of

a

closed breaker into or

out

of

the CONNECTED position.

4.

To

withdraw the breaker from the CONNECTED position,

the procedure

is

the same except that the direction

of

rotation

of

the operating crank

is

clockwise.

5.

If

necessary

to

adjust racking screw stop (510) rotate

racking screw (504) until racking clevis (505) reaches

the

77

0 position

as

shown' (Detail

"A").

Position

stop (510) against crank (511) with

nut

(512).

CAUTION

To

avoid damage to the racking mechanism,

do

not

rotate the operating crank in the counterclockwise

direction

after

the breaker has reached the

fully

connected position.

Spring Discharge Mechanism

Description

and

Fu

netion

(See Figures 2 and 6.) When racking circuit breaker OUT

of

cubicle (see Racking Mechanism, Drawout Interlock.

7

and Lifting Bar, page

6)

the stored energy closing

springs

(209)

will automatically discharge prior to or when

circuit breaker reaches the DISCONNECT position.

This

is

accomplished by the following sequence:

1.

Lever (601) rotates clockwise during RACKOUT,

allowing roller

(602)

on

lever (601) to rotate

carn (603) counterclockwise.

2. Cam (603) moves rod

(604)

upward which in turn

rotates lever

(605)

clockwise.

3. Lever (605) in

turn

rotates spring release latch

(613)

clockWise allowing

the

storedenergy closing springs

(209)

to discharge.

4. When roller (602) strikes carn (603) and stored energy

springs discharge, cam (603) must snap back into reset

position prior to or when circuit breaker reaches the

DISCONNECT position.

Adjultmentl

If

adjustment becomes necessary

the

following procedure

will be required (see Figures

I,

2,

and

6):

1.

Remove cover

(126).

CAUTION

With cover removed and circuit breaker contacts

open, the circuitbreaker will CLOSE when the stored

energy springs

are

discharged automatically since

the

slide interlock is

not

inplace.

2.

Align scribed line

on

trunion

(606)

with center punch

mark (TEST position)

on

arm (607).

3. Remove cotter pin

(610,

remove washers (611),

remove rod

(604)

from cam (603). Adjust rod I (604),

by screwing into

or

out

of

yoke

(612)

until the nominal

.375 dimension

is

obtainedbetween the end

of

rod (604)

and inside

of

yoke (612). Insert rod (604) into

cam

(603),

replace washers

(611),

insert

cotter

pin (610) and bend.

4. Charge stored energy springs

(209)

and rotate racking

screw (222) in the clockwise direction (see Racking

Mechanism, Drawout Interlock, and Lifting Bar, page 6).

The stored energy closing springs should automatically

discharge (see caution note, above) prior

to

or when

circuit breaker reaches the DISCONNECT position.

Cam

(603)

must snap back

to

reset position as shown.

(See Step 4

of

Description and Function, above.)

5. If the stored energy closing springs DO NOT auto-

matically discharge as described in Step 4:

a)

Repeat Adjustments, Step 2.

b)

Readjust as necessary per Adjustments, Step 3 within

the prescribed tolerance limits

of

.375

:!:,.062.

6.

Repeat Adjustments, Step 4.

72-240-103-401

SET

SC~'EWr.o,i'\

NUT

j

-0-

SHAFT

---

(TEST POSITION)

ROLLER

DISCONNECT POSITION

Figure

6.

-SpringDischarge Mechanism

8

,

,

~

,

,

~

CAM

(RESET POSITION)

COTTER PIN

WASHER

LEVER

LATCH

<"\

•

-

MAINTENANCE

AND

ADJUSTMENTS

Maintenance

Occasional checking and cleaning

of

the breaker will pro-

mote long and trouble-free service. A periodic inspection

and servicing

at

intervals

of

six months or one year should

be

included in the maintenance routine. Circuit breakers

located in areas subject

to

acid fumes, cement dust, or

other abnormal conditions, require more frequent

ser-

vicing.

After a severe overload interruption, the breaker

should be inspected.

If

the circuit breaker

is

not operated during extended

periods, it should not remain

in

either the closed or open

position any longer than six months. Maintenance opening

and closing operations should be made to ensure freedom

of

movement

of

all parts.

A suggested procedure

to

follow during maintenance

inspections

is

given below.

I. De-energize the primary and control circuits.

2.

Rack cubicle-mounted breakers

of

the drawout type to

the disconnected position.

4. Remove breaker from cubicle.

5.

Remove arc chutes (117, Figure

I)

and examine for

burned, cracked

or

broken parts. To remove arc chutes,

proceed as follows (see Figure 5):

a.

Move

breaker

to

disconnect position.

b. Turn racking screw (504) until crank (511) IS m

vertical pOsition,

giving

maximum clearance between

screw and holding bar.

c. Remove wing nuts from holding bar.

d. Tilt top

of

holding bar toward back

of

breaker and

move

bar down.

NOTE

After inspection and before moving breaker to test

position,

turn

racking screw (504) until racking

clevis

(505) reaches its normal disengaged position.

6.

Wipe

the contacts with a clean'cloth saturated with a

non-toxic cleaning fluid.

7.

Replace badly burned or pitted contacts (see Contact

Replacement,

page

II).

8.

Wipe

all insulated parts with a clean cloth saturated

with a non·toxic cleaning fluid.

9. Bearing pins and other sliding or rotating surfaces should

be cleaned and then coated with a light film

of

grease

(see Lubrication, next paragraph).

10. Operate the breaker manually

in

maintenance closing

position (see Maintenance Closing, below)

to

check

latch and linkage movement.

9

II.

Check breaker adjustments (see Adjustments,

page

11).

Lubrication

Lubrication should be a part

of

the servicing procedure.

Needle bearings are packed with

grease

and should require

no further attention. Old grease should be removed from

bearing pins and other rotating or sliding surfaces, and

they should be wiped with a thin film

of

petroleum-oU·

base precision-equipment grease similar to

BEACON

P-290.

Greasing should be done with care because excess

grease

tends

to

collect foreign matter which in time may make

operation

sluggish

and may affect the dielectric strength

of

insulating members. Faces

of

main and arcing contacts

should not be lubricated. The rubbing surfaces

of

the main

contact fmgers and hinge contact fingers

are

lubricated

with micro

fme

dry graphite.

If

dust has accumulated,

dis-

assembly

is

necessary to relubrlcate these points (see

Contact Replacement,

page

II).

Maintenance

Closing

During inspection prior to installation and for routine

maintenance inspections, the breaker contacts may be

closed slowly

to

check clearances, contact adjustments, and

movement

of

links and latches. The manual closing handle

is

used for maintenance closing the breaker.

Electrically·operated breakers do not have a manual closing

handle,

but

a manual closing handle-carn assembly

is

available

as

a maintenance item. Figure 7 shows the main-

tenance closing handle being inserted in an electrically·

operated breaker after removal

of

the front cover from the

breaker.

When

the hole

in

the maintenance closing handle

assembly is aligned with the holes

in

the operating mech-

anism frarne, the pin which

is

attached

to

the chain

is

inserted. This pin holds the assembly

in

place and acts

as

a

pivot point for the earn.

After insertion

of

the maintenance closing handle assembly

on the electrically.operated breaker, the actual maintenance

closing operation

is

the

same

for both the electricaUy·

operated breaker and the manuaUy-operated breaker. Refer

to

Table 3 and Figure 7.

CAUTION

The

procedure

in

Tabl. 3 should

b.

used

for

main·

tenance closing

only

.

MAINTENANCE CLOSING H'ANOLI,

-;

:-

_______

J

(SEE

PAGE

9)

RELEASE LATCH

HOOD

____

~-

~

MAINTENANCE

CLOSING

HANDLE

ELECTRICALLY OPERATED BREAKERS

SEE

TABLE 3 a

FIG

2

{STEP

I

. STEP

TYPICAL MAINTENANCE

CL

OSI

NG

HANDLE

PROCEDURE

MA

N

UAL

TRI

PR

OD

Figure 7. - Maintenance Closi

ng

10

.,

~

.•

•

-

-.

TABLE 3. MAINTENANCE CLOSING

Operation Procedure

Closing Contacts

1.

Pull closing handle

DOWN

ALL THE

WAY

(approx·

imately

120~.

2. Place blade

of

screwdriver be·

tween hood and spring

reo

lease latch and hold it in

this position.

3. Slowly return handle

to

ver·

tical position.

(Contacts will close

to

arc-

ing contact touch position,

but

breaker will not close

completely.)

Opening Contacts Push in manual trip rod.

NOTE

Holding the spring release lateh down prevents the

stored-energy springs from propping in the charged

position. Thus, when the handle

is

slowly returned

to the normal vertical position, the energy in the

springs

is

slowly released against the closing handle

assembly cam face.

Adjustments

During maintenance inspections, the following items should

be checked to ensure that the original settings are main-

tained:

Trip-Latch Engagement

(Refer to Figure 2.) Trip latch (216) should have an engage-

ment

of

.062"

plus 0 minus

.015"

on trip shaft (215).

Measurement is made with the latch resting on the shaft in

the reset position. With this engagement, the trip shaft

must rotate between 10.50 and

ISO

to release the trip

latch.

Main Contact Make

(Refer to Figure 8.) Compression

of

contact fingers (817)

should be between

.093"

and .125". This

is

the difference

in the measurement from the breaker base to the

bottom

of

the finger contact surface when the breaker

is

open and the

measurement in the same place when the breaker

is

closed.

This is checked with a normal closing operation -not

maintenance closing. Adjustment is provided by positioning

screws (810) after loosening nuts (814). Counterclockwise

rotation

of

screws (810) increases compression. Care should

be

taken to retighten nuts (814) after adjustment.

If

it

is

desired

to

check

contact

pressure, a push-type spring scale

can

be

used to compress contact fingers (817) with the

11

breaker open. Contact pressure should be between

20

and

30

pounds.

Arcing Contact Make

(Refer to Figure 8.) With movable arcing contact in

anyone

phase touching the mating stationary contact when the

breaker

is

closed by the maintenance closing method (see

Table 3), the phase-te-phase variations should not exceed

.061

".

Adjustment may be made by positioning screws (810)

as in the preceding paragraph,

but

it is essential that the

maincontactcompression be maintained within the tolerance

of

.093" and .125". Arcing contact pressure can be checked

with the breaker contacts closed by pulling

both

contacts

at

the base

of

the arcing contact tip insert with a pull-type

spring scale until contacts part. The contact pressure should

be

between

70

and

80

pounds.

Electrically-Operated Breaker.

(Refer to Figures 3 and 4.)

I.

Motor-Cut-Off Switch and Spring-Position Switch

These switches are mounted

on

a common bracket which

is

set and roll-pinned in pOsition during production

testing.

If

replacement

is

required, the bracket must

be

pOSitioned so

that

when roll pins (336) in gear (335)

are

at the top position, they have moved plunger (333)

against the roller

of

motor cut-off switch (332) to shut

off the motor. As the springs are charged, arm (331)

must engage the roller

of

spring-pOsition switch (330).

Pilot holes are provided in the mounting bracket for

drilling and roll-pinning the replacement assembly in

the correct position.

2. Gear Disengagement

(Refer to Figure 3.) With the breaker closing cams (310)

in the horizontal position, adjust the tension

of

spring (348) by means

of

eye end (300) and nuts

(301, 304) until a dimension

of

2 3/8

!1/32

is

measured between spring loops. This dimension is

measured when gear (335) touches or meshes with gear

segment (340).

At

this point a force

of

5 1/2 to 7 Ibs

will

be

required to hold the gears in contact.

Contact Replacement

(Refer to Figure 8.) The contact structure consists

of

main

current carrying contacts and arcing contacts arranged

so

thatinitial contact make and final contact break

is

by means

of

the arcing contacts. The main contacts are not subject

to arcing. The actual contact surfaces are clad with an alloy

facing which greatly reduces mechanical wear and arc

erosion.

When

inspection

of

the alloy facing indicates that the con-

tacts should

be

replaced, it should be noted that hinge con-

tact fingers (820), main contact fingers (817) and arcing

72-340.()'21-401

CONTACT

FINGER

DETAIL-"A"

------

@

@

tKj tKj

0 0 0 0

IP<

:

>QJ

©¢"'5()

0 0 0 0

I

@

0 0

o 0

0

.187 DlA

CONTACT

ING

(J)

@

~ 0

0

SET

SCREW

WRENCH

DETAIL-"a"

BASE

SPRING

CLEVIS

SCREW

WASHER

PAN

SPACER-SEE

DETAIL--A-

I ARC RUNNER

Figure

8.

-Typical Panel Assembly

contacts (819) are spring loaded. Therefore, extreme care

must be exercised in removal and installation

of

any

of

the

contacts.

Main Contact Fingers

With the breaker contacts open and the stored-energy

springs discharged, main contact fingers (817) may be

reo

moved

by

loosening screws (823) enough to relieve the

compression

on

springs (822)

as

shown in Detail

"A".

There are two springs behind each fidger, and it

is

important

that they be positioned properly upon reinstallation.

If

difficulty is experienced in correctly positioning these

springs, the upper and lower primary disconnects (119,

Figure

I)

may be removed from each phase and the

breaker inverted to rest on the ends

of

connectors (824)

and (828).

After the contact fingers are replaced, connector (824)

should be positioned in the center

of

the slot

in

the molded

base to assure correct alignment

of

the primary disconnect

fmgers.

Stationary Arcing Contact

The stationary arcing contact

is

a

part

of

connector (824)

and may

be

replaced by proceeding

as

above. In this case.

12

screws (823) must

be

removed. However,

to

provide a

clearance for removal

of

connector (824), first insert a

.187" diameter rod

at

least

3"

long through the opening

in support (821)

as

shown in Detail "B". This

will

hold

hinge contact fmgers (820) in position to permit removal

of

pin (805).

It

may

be

necessary

to

compress contacts (820)

opposite arcing contacts

(8l9)

in order to insert the rod.

(As

an

aid in holding spacers (804) and (806)

in

their

correct positions, withdrawal

of

pin (805) can

be

followed

by the insertion

of

a shorter pilot pin

to

permit removal

of

the

complete movable contact assembly as a group from

support

(82l).)

The

pin

at the end

of

clevis (802) should

then

be

removed so

that

the complete movable contact

assembly can

be

positioned or removed to provide clearance

for removal

of

connector (824).

Hinge Contact Fingers

Hinge contact fingers (820) may

be

removed

as

follows:

Remove top screws

(826)

from support (82

I)

and

replace

them with two .250-20 screws at least

IS'

long. Remove

lower screws

(8l6)

and then gradually back

off

the

lS'·

screws

as

shown

in

Detail

"8".

to

relieve the loading from

springs (827). The hinge contact fingers can now

be

reo

moved.

Be

certain to replace the 1.5" long screws with the

original screws after replacement

of

the contact fingers.

in

position to permit removal

of

pin (803). After removal of

pin

(803). main contact (817) and arcing contact (820) can

be

positioned

so

that connector (829)

can

be removed.

Hinge Contact Finger.

Hinge contact fingers (814) may be removed

as

follows:

Remove top

screw

(827) from support (815) and replace it

with a 1/4·20 screw at least 1·1/2" long. Remove lower

screw (827) and then gradually back

off

the 1-1/2" screw

as shown

in

Detail

"B",

to relieve the loading from

springs (828). The hinge contact fingers can now

be

removed. To provide easier access

to

the

hinge

contact

fmgers, pin (803) may

be

removed after tbe loading

is

relieved from springs (828).

Moving Arcing

and

Main

Contact

Either moving arcing contact (820) or main contact (817)

or both may be removed and replaced as follows: Follow

the steps outlined

in

the above paragraph including removal

of pin (803) or

if

hinge contact fingers

are

not to

be

re-

placed, omit these steps and begin

by

placing a 3/16"

diameter rod

at

least 2" long through the opening

in

support (815) as shown

in

Detail "B". Remove pin (SOl)

and pin (S03)

if

these

have

not been removed previously.

The complete movable contact assembly may now

be

brought to a bench.

It

is

suggested

that

a

I/Z"

thick piece

of

wood or phenolic be placed upright in a

vise

and the open

slot in

clevis

(812) placed against

it

as

a rest. The. location

of

spacers (802), (S04) and (825) should

be

noted. To

minimize adjustment upon reassembly, the position

of

the

two screws (80S) relative to pin (818) should also

be

noted. Then the two elastic stop nuts (S21) should

be

loosened and screws (80S) backed

off

far enough to

remove them from pin(SIS).

CAUTION

Extreme care should be taken

to

hold

the assembly

firmly

to

retain spring guide (bID)

and

spring (809)

upon

removal

of

the

screws.

The moving arcing contact or the main contact may

now

be

easily replaced. The reverse procedure

is

followed for

re-

installation. Care should

be

taken to replace spacers (S02).

(804) and (S25) correctly. Check alignment and adjust-

ment

of

contacts upon reassembly.

Release

Magnet

When the static trip device senses a circuit condition

that

requires the circuit breaker to

open,

it produces an

output

that

is

fed

to the magnetic latch release device. This

device

then

causes the circuit breaker contacts to open and isolate

the circuit.

13

Mounted on the circuit breaker, the magnetic latch

release

is

held

in

a charged position by a permanent magnet.

It

contains a coil that

is

energized

by

the output

of

the static

trip device.

When

energized,

the

coil causes the magnetic

flux to shift to a

new

path, releasing the stored energy ofa

spring located

inside

the

magnetic latch

r~lease.

The spring

provides

the

energy to trip the breaker.

The

release

magnet

is

illustrated

in

Figure 9. During normal

operation. trip rod (901), which

is

attached to a spring

loaded armature inside the magnetic

release

latch cylinder,

cannot move due to a magnetic

field

set

up

by

permanent

magnet (902) which holds the internal armature against

plate (903) on the bottom of the magnetic release latch.

When

an

overload or fault condition exists, coil (904),

which

is

inside

on the bottom of the magnetic release latch.

is

energized

by

the static trip device creating a

flux

which

decreases the magnetic hold force on the spring loaded

internal armature allowing the armature to

be

forced

up-

ward due to the spring load, thereby allowing trip rod (901)

to

move

up against trip arm (905).

in

turn, tripping the

circuit breaker.

As

the breaker opens. coil (904) becomes

de-energized due to de-energization of the static trip

device, cam (906) rotates

arm

(907) forcing spring loaded

armature against plate (903) allowing trip rod (901) to

be

reset to the non·trip

pOSition.

If

the spring loaded armature does not reset during trip

operation

as

explained above, spacers (908) may

be

added

to

obtain positive reset

of

the armature.

If

adding spacers does not allow armature to be reset. th,

magnetic release latch should

be

replaced

(if

breaker

mech-

anism

is

not at fault).

NOTE

Do

not attempt to disassemble the magnetic release

latch as this

will

destroy the magnetic field

set

up by

the permanent magnet and

will

render

the

release

latch inoperative permanently.

When

replacing a magnetic release latch, the

coil

(904)

leads must be connected to the terminal block

of

the static

trip

in

the correct polarity relationship.

The black lead ofcoil (904) must

be

connected to terminal 7

(negative) and the red lead of

coil

(904) connected to

terminal 8 (positive) of the static trip device.

A clearance of .032" to .060"

shOUld

be

maintained

be-

tween the trip

arm

(905) and nut (909) with the circuit

breaker open, springs charged and trip

arm

(905) reset

by

the trip shaft. Adjustment

is

made by positioning nut (909)

while

holding trip rod (901).

When

the magnetic release latch

has

been replaced the

circuit breaker should

be

given

a

FUNCTION

TEST

to

ensure proper operation

of

all

components. Refer to

Allis-Chalmers Instruction Book 18X4392

for

the

procedures

of the FUNCTION TEST.

72·240-068-401

CAM POSITION

----~

(SREAKER

CLOSED)

CAM

POSITlON-_~

(BREAKER

OPEN)

SPACER

PLATE

TRIP

ARM

/

/

/

TRIP

ROD

CAUTiON

SEALED UNIT.

00

NOT DISASSEMBLE

NUT

TO

.060

'.

----,

RESET CAM

RESET ARM

COIL

Figure

9.

-Typical Release Magnet

FUSE

FUNCTIONS

Current

Limiting

Fuse

(See Figure 10.) The

C.L

fuse

(100\)

NEMA

Class

"J"

and

Class

"L"

have an interrupting rating

of

200,000 Amps

RMS

Symmetrical.

When replacement

is

required due to the

C.L

fuse inter·

rupting, replace only with a fuse

of

the same manufacturer

and rating

as

supplied with the circuit breaker. Fuses of

different manufactures may have

c~nsiderably

different

melting time·current characteristics and peak let·thru cur-

rents and, consequently, may not be completely inter-

changeable.

14

To remove the

C.L

fuse, remove bolts (1002) and as·

sociated hardware. Remove fuse.

To

replace the c.L. fuse,

reverse the above procedure.

Trigger

Fuse

(See Figure 10.) The trigger fuse (1003) and associated

trip mechanism has a dual function. The first function

is

to

trip the circuit breaker mechanically when the C.L. fuse

has interrupted.

The second function

is

to indicate which phase

C.L

fuse

has interrupted.

71·240·102-401

TRIP

ARM

!cL

l

FUSE

BOLTS

ARM

TRIGGER

FUSE

~.~.,.

LEVER

COVER

r--l~~~~~~:~

FUSE WIRED IN PARALLEL

WITH ASSOCIATED

C.L:

FUSE.

Figure

ZO.

-

Current

Limiting

and

Trigger

Fuse

The

plunger (1004) on top

of

the trigger fuse indicates

visually which phase C.L.

fuse

has interrupted.

The trigger fuses are wired in parallel with the C.L. fuse.

When

the C.L. fuse interrupts, its associated trigger

fuse

also

opens and releases a plunger

(l004)

which

is

operated

by a precompressed spring contained in the trigger

fuse

housing.

The plunger operates

arm

(l005)

which allows spring

loaded

lever

(1006) toengage circuit breaker trip arm (1007)

•

which trips the circuit breaker and holds the circuit breaker

in

the mechanical trip free position.

The circuit breaker will remain trip free (cannot be closed)

until the trigger

fuse

has been replaced and the associated

15

trip mechanism reset

lever

(I

ODS)

has been manually

reset (pushed in).

To

remove the trigger

fuse

remove strap

(l009),

remove

plastic cover (1010), then the trigger fuse.

To insert the trigger fuse, reverse the above procedure.

CAUTION

The

trigger fuse (T003) must be inserted

with

the

plunger11004) facing arm (1005).

The

.125 +

0-

.032

dimension

must

be

maintained.

CURRENT

TRANSFORMERS

There

are

a

number

of

tripping

tran~former

ratings

avail-

able, each with seven calibrated pickup settings (Table 4).

Figure

II

shows a typical breaker rating plate.

The current transformers on the upper connectors for

the

lA·6OQ circuit breaker are mounted with

the

polarity

marks facing breaker panel. .

Breaker Tripping

Type and XFMR

Frame

Rating

Size

tl A

LA·6oo

80

40

200

100

600

400

200

600

300

The

current

transformer

on

the

lower connector

is

mounted

with the polarity

mark

facing away from the breaker panel.

TABLE

4.

TRIP

RATING

TABLE -AMPERES

Ground Element

Long Time Element

Max

Calibrated Pick.Up

Calibrated Pick·Up Settings Cont

2~~~

B C D E F G

50

60

70

80

90

100 100

.

32

64

80

125

150 175

200

225

250 250

40

80

160

200

250

300

350

400

450

500

500

80

160

320

400

375

450

525

600

675

750

600

120

240

480

600

SERIAL

10.

Figure

11. - Typical Breaker RatingPillte

16

71·240-584-401

BRACKET 1203 1207 BRACKET 1204 SHIELD

~t:I~1

NG 1205

::-:

-

~~~CONTACT

1201

I

-t--

-,

_BLOCk

,

'I

i+

n

••

I

i.~,

,'

IO-DISCONNECT MOUNTING

lO-DISCONNECT

MOUNTING

TERMINAL I

TERMINAL

TAB

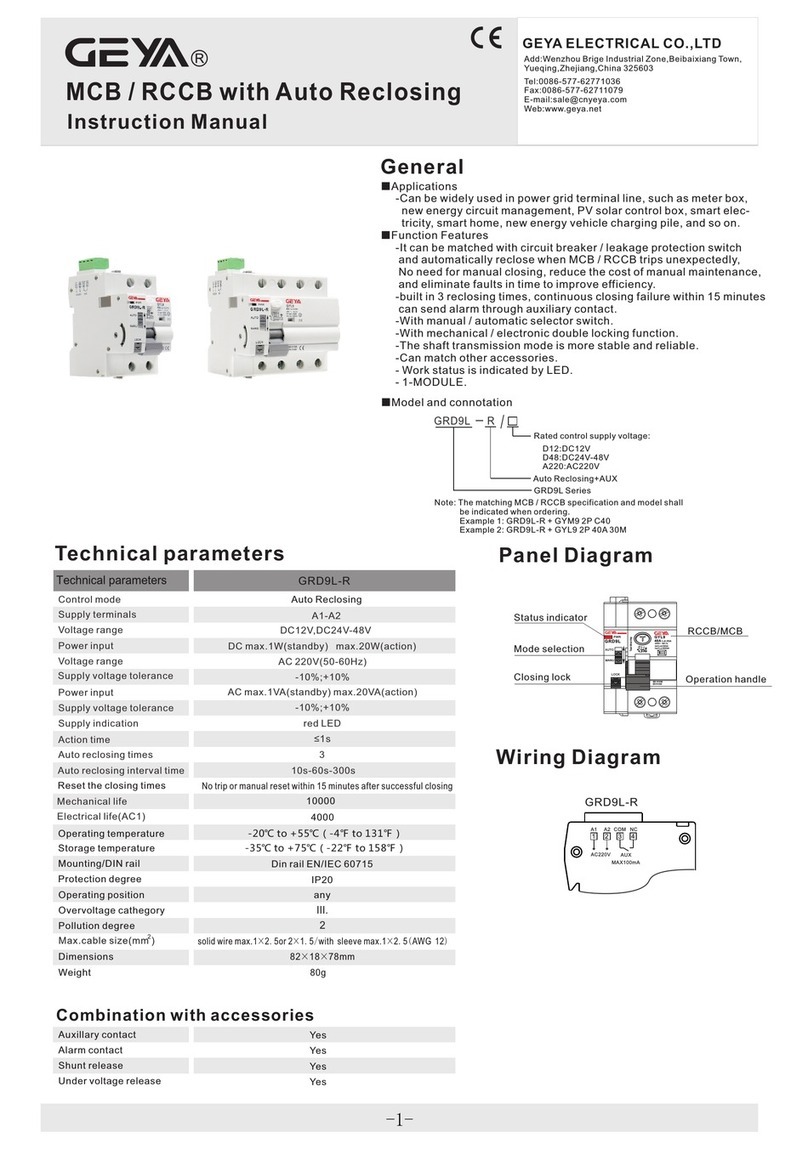

Figure

12. -

Typical

Secondary

Disconnects

The electrical attachments

are

wired to the terminals

of

a

secondary disconnect assembly which

is

mounted

on

the

left

side

of the breaker_

Two

blocks of ten terminals each

can be mounted on the breaker. The secondary disconnect

17

assembly

is

accessible from the front

of

the breaker and

aligns

with a stationary unit in the cubicle. The stationary

contact strips should

be

lucricated with a light film of

AERO

LUBRIPLATE which

is

furnished with the switch·

gear.

Other manuals for LA-1600

1

This manual suits for next models

1

Table of contents

Other Allis-Chalmers Circuit Breaker manuals

Allis-Chalmers

Allis-Chalmers MA-75B User manual

Allis-Chalmers

Allis-Chalmers MA-75 User manual

Allis-Chalmers

Allis-Chalmers LA-1600 User manual

Allis-Chalmers

Allis-Chalmers LA-600 User manual

Allis-Chalmers

Allis-Chalmers LA-600 User manual

Allis-Chalmers

Allis-Chalmers FB-500A-FC-750A User manual

Allis-Chalmers

Allis-Chalmers LA 3000 User manual

Allis-Chalmers

Allis-Chalmers LA-600 User manual

Allis-Chalmers

Allis-Chalmers LA-25 Installation manual