2

1.0 SAFETY PRECAUTIONS..........................................................................................................................................3

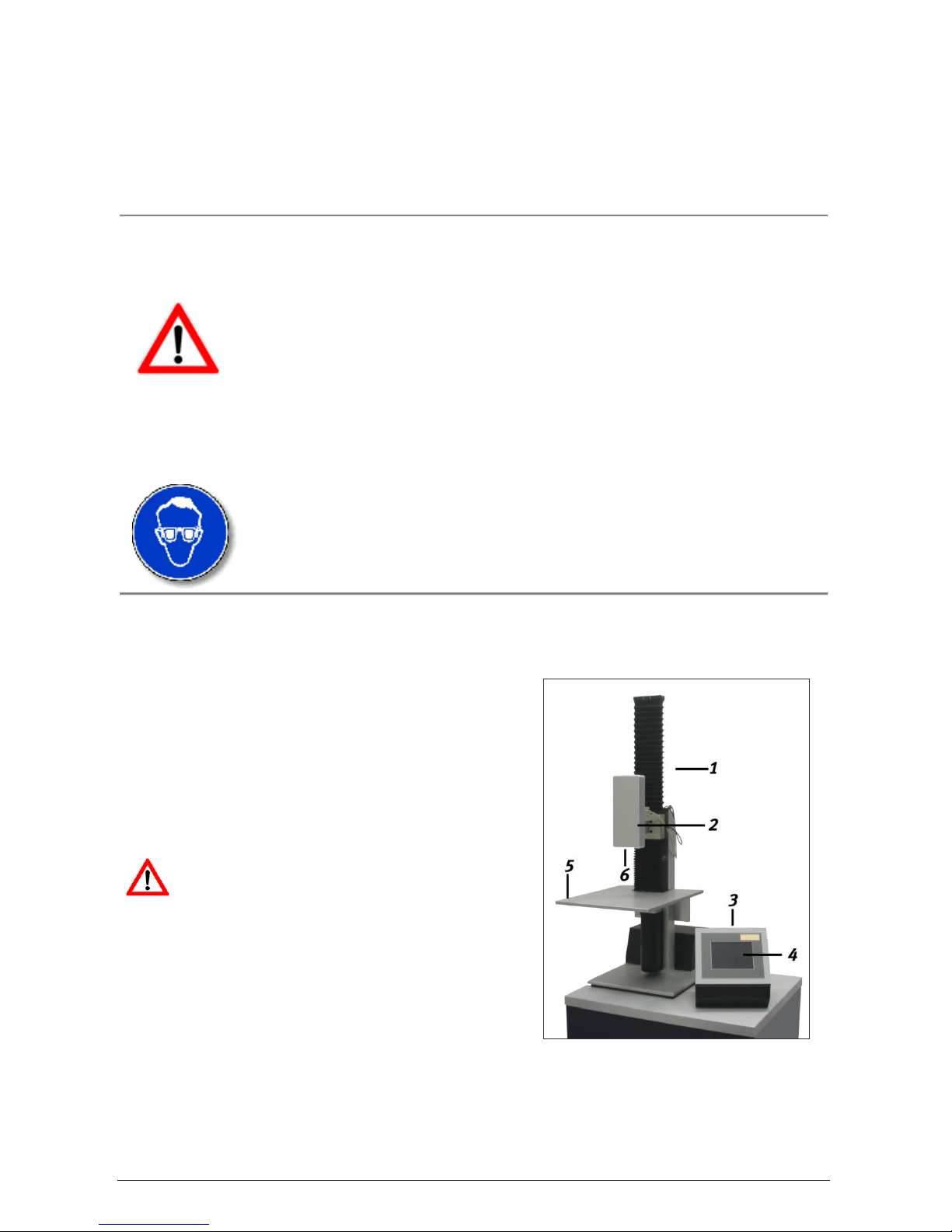

2.0 OVERVIEW OVER THE COMPONENTS AND THE INITIATION ..................................................................3

3.0 ENGAGING THE INSTRUMENT AND PREPARATING THE MEASURMENT.............................................4

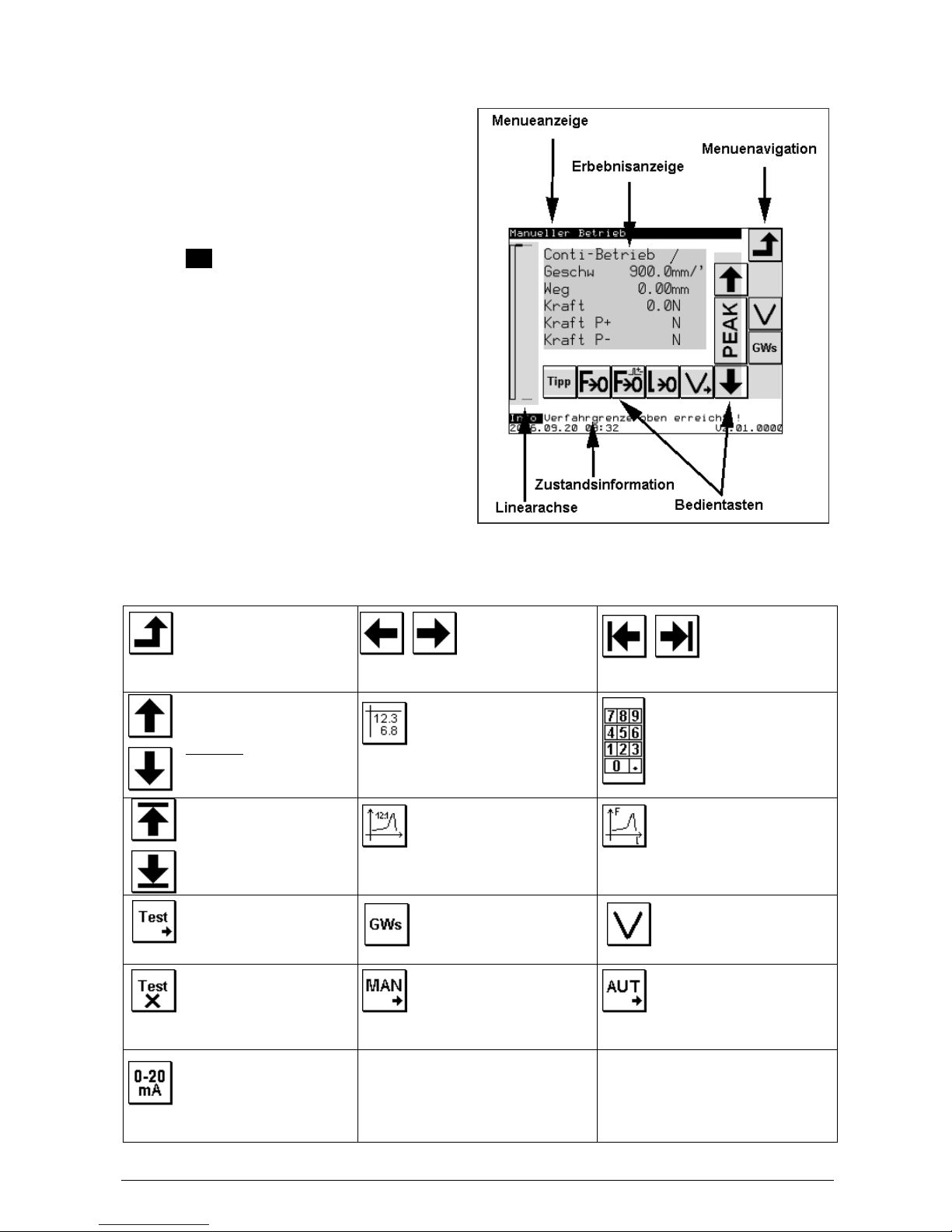

4.0 MENUSTRUCTURE, FUNCTIONS, SIMBOLS AND GENERAL HANDLING................................................5

4.1 MENUSTRUCTURE ..................................................................................................................................................5

4.2 GENERAL OPERATING ADVICES AND SYMBOLS..........................................................................................5

4.2.1 NAVIGATIONBUTTONS FOR OAGING AND CHANGE OF THE LEVEL OF THE MENU ............................6

4.2.2. HANDLING ARROWS TO CONTROL THE TEST STAND.................................................................................7

5.0 MODE OF OPERATION ...........................................................................................................................................7

5.1 EXPLANATION OF INSTRUMENTATION.............................................................................................................................................................7

5.1.1 FORCE MEASURMENT........................................................................................................................................7

5.1.2 PATH MEASURMENT...........................................................................................................................................8

5.1.3 DISCONNECT CONDITIONS / LIMITS 8

5.2. MANUAL MODE.......................................................................................................................................................8

5.2.1 REGULATION OF THE SPEED LEVELS...........................................................................................................8

5.2.2 REGULATION OF THE LIMITS......................................................................................................................................................................................9

5.2.3 CONTINUOUS MODE (CONTI) ...........................................................................................................................9

5.2.4 RIDE IN THE TIPP-MODE (TIPP).......................................................................................................................9

5.2.5 INDICATION AND RESET OF THE PEAK VALUES ( MAXIMUM VALUES)............................................9

5.2.6 TARE THE FORCE AND PATH INDICATION................................................................................................10

5.3. AUTOMATICAL MODE WITH PREDEFINED INSPECTION PROCESSES ...............................................10

5.3.1 GENERAL ..............................................................................................................................................................10

5.3.2. DEFINITION OF THE VALVE POSITION......................................................................................................10

5.3.3 PREDEFINED FUNCTIONS................................................................................................................................10

5.3.3.1 ZERO-POINT-SEARCH ...........................................................................................................................................................................................11

5.3.3.2 BREAKDETECTION................................................................................................................................................................................................11

5.3.3.3 FORCE REGULATION .............................................................................................................................................................................................11

5.3.3.4 PATH REGULATION ...............................................................................................................................................................................................11

5.3.3.6 HARDNESSGRADE.................................................................................................................................................................................................11

5.3.4 PREDEFINED TEST PROGRAMMS .................................................................................................................12

5.3.4.1 BREAK TESTING 1-DIAGRAMM ............................................................................................................................................................................13

5.3.4.2 BREAK TESTING 2–PEAK VALUES .......................................................................................................................................................................13

5.3.4.3 BEND TESTING –PATH DEPENDING .......................................................................................................................................................................14

5.3.4.4 ENDURANCE TESTING (PRESSURE)WITH PRESSURE-FORCE-REGULATION ............................................................................................................15

5.3.4.5 TOW TESTING 1-DIAGRAMM ...............................................................................................................................................................................16

5.3.4.6 TOW TESTING 2–PEAK VALUES...........................................................................................................................................................................16

5.3.4.7 STRECH TESTING –PATH DEPENDING....................................................................................................................................................................17

5.3.4.8 ENDURANCE TESTING WITH TENSION FORCE REGULATION ...................................................................................................................................18

5.3.5 CLIENT-SPECIFIC/CUSTOM DESIGNED INSPECTION PROCESSES.....................................................18

6.0 SERVICE FUNCTIONS..........................................................................................................................................19

6.1 BASIC SETTINGS....................................................................................................................................................19

6.1.1 LANGUAGE ...........................................................................................................................................................19

6.1.2 PASSWORD............................................................................................................................................................19

6.1.3 PATH AND SPEED BASE PLATE......................................................................................................................19

6.2. CALIBRATION........................................................................................................................................................20

6.2.1 CALIBRATION OF THE LOAD CELL..............................................................................................................20

6.2.2 PATH CALIBRATION..........................................................................................................................................20

6.3. ADJUST DATE AND TIME ...................................................................................................................................21

6.4. REPORT-MEMORY ...............................................................................................................................................21

6.5. CANCELING THE RESULT-MEMORY .............................................................................................................21

8.0 TECHNICAL DATA.................................................................................................................................................22

7.0 CONNECTION TO THE PC ...................................................................................................................................21

9.0 MAINTENANCE.......................................................................................................................................................22

9.1 LINEAR BEARING..................................................................................................................................................22

9.2 UPDATES (SOFTWARE) ........................................................................................................................................22

9.3. CHANGE COMPONENTS .....................................................................................................................................23

10.0TROUBLESHOOTING...........................................................................................................................................23

11.0 WARRANTY ...........................................................................................................................................................23

12.0 PRODUCT REGISTRATION................................................................................................................................23