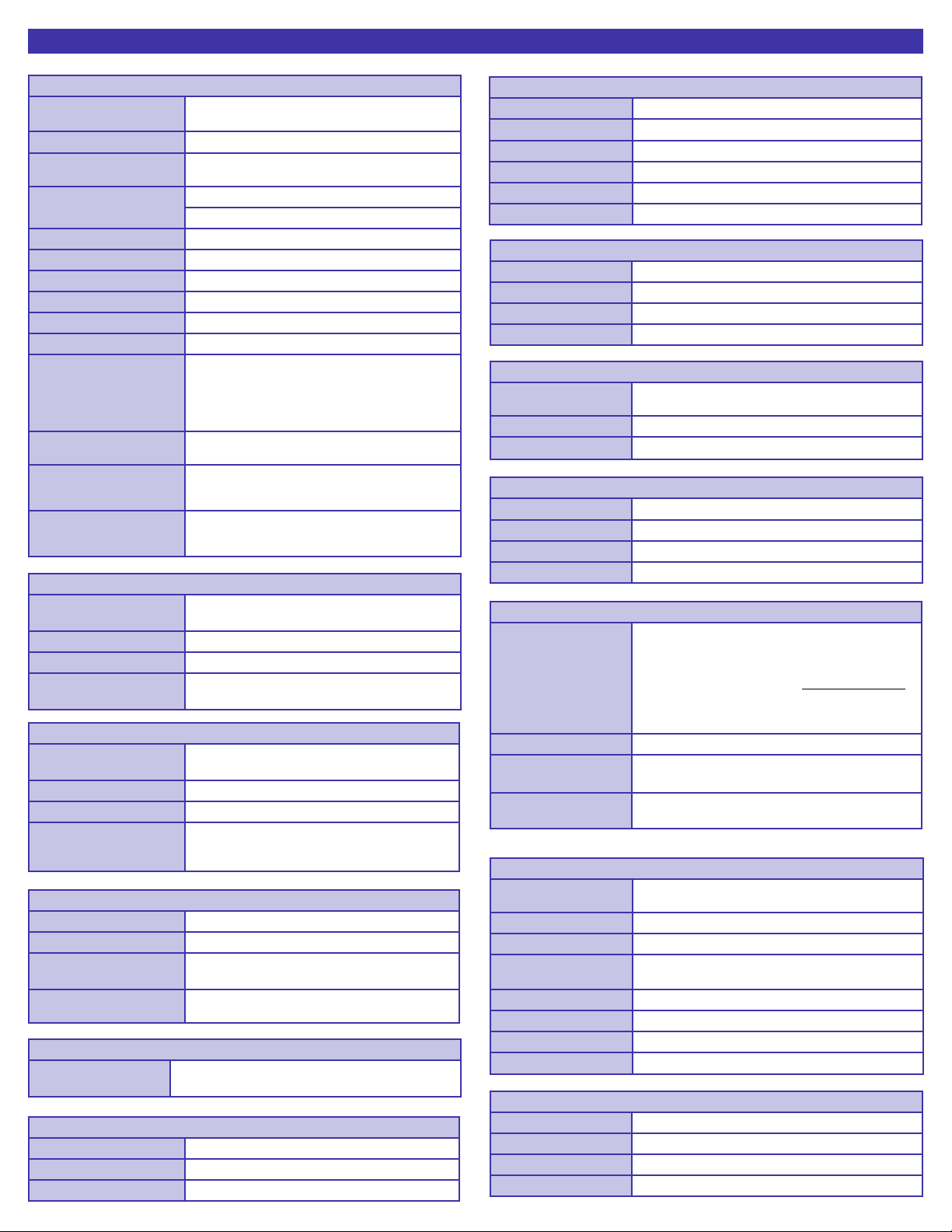

PIE 850 Specifications

(Unless otherwise indicated all specifications are rated from a nominal 23°C, 70% RH for 1 year from calibration)

General

Operating Temperature

Range

-20 to 60 °C (-5 to 140 °F)

Storage Temperature Range -30 to 60 °C (-22 to 140 °F)

Temperature effect ≤ ± 0.005 %/°C of Full Scale; Cold Junction Sensor

≤ ±25 ppm/°C

Relative Humidity Range 10 % ≤RH ≤90 % (0 to 35 °C), Non-condensing

10 % ≤RH≤ 70 % (35 to 60 °C), Non-condensing

Common Mode Rejection 50/60 Hz, 100 dB

Normal Mode Rejection 50/60 Hz, 50 dB

Noise ≤ ± ½ Least Significant Digit from 0.1 to 10 Hz

Size 5.63 x 3.00 x 1.60 in, 143 x 76 x 41mm (L x W x H)

Weight 12.1 ounces, 0.34 kg (including boot & batteries)

Batteries Four “AA” Lithium 1.5V (LR6)

Battery Life

Read Functions ≥ 20 hours; Read Pressure ≥ 7 hours

Source mA: ≥ 14 hours @ 12 mA into 250Ω

≥ 9.5 hours @ 30 mA into 250Ω

Pwr/Meas: ≥ 12 hours @ 20 mA, ≥ 4.5 hours @ 50 mA

Source V, Ω, T/C, pH, RTD & Hz ≥ 20 hours

Low Battery Low battery indication with nominal 1 hour of

operation left

Protection against

misconnection

Over-voltage protection to 60 vrms (rated for 30

seconds). Red LED indicates OVERLOAD or out of

range conditions

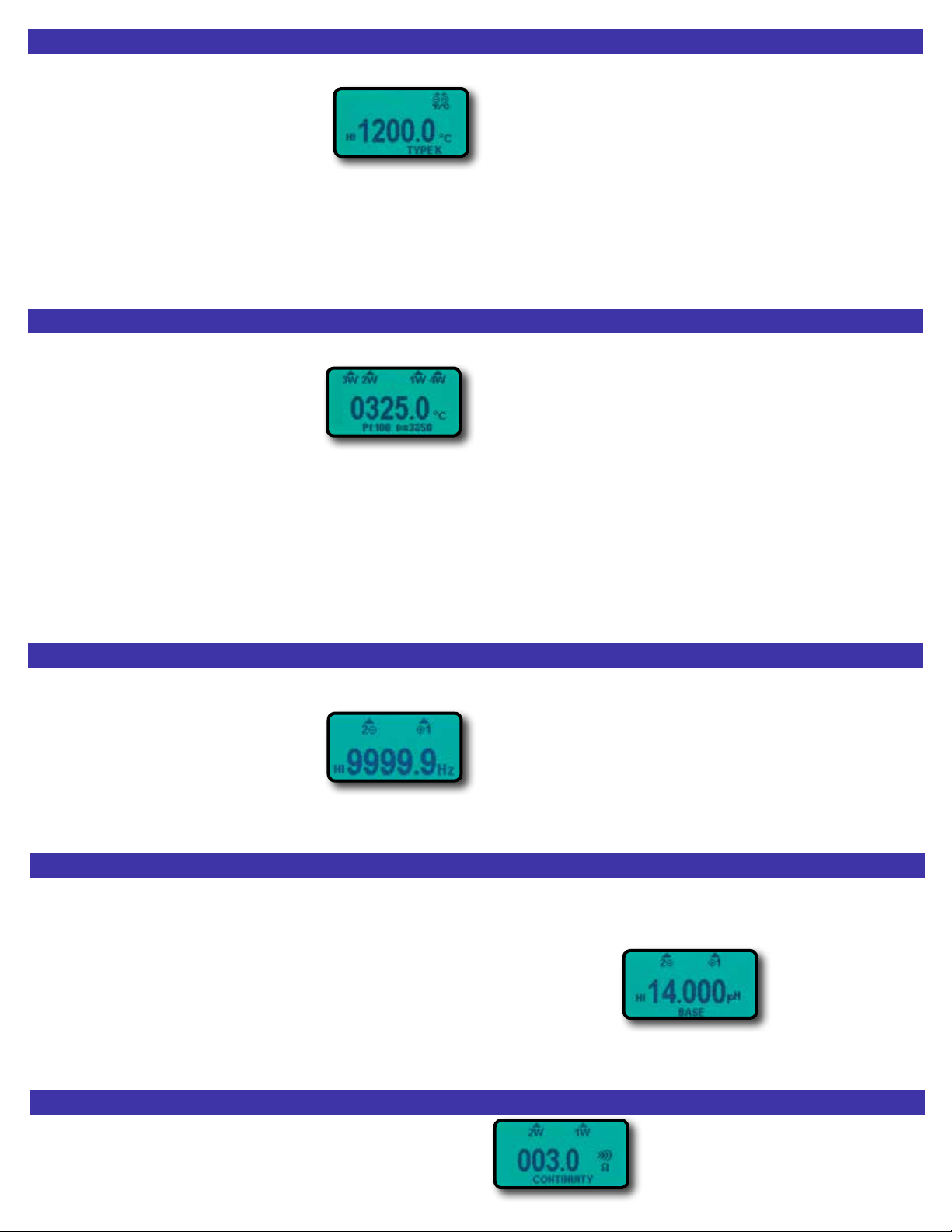

Display High contrast graphic liquid crystal display with

0.35” (9 mm) high digits on main & 0.2” (5 mm) on

mA display. LED backlighting for use in low lit areas.

Read mA

Ranges and Resolution

0.000 to 24.000 mA or -25.00 to 125.00% of 4-20 mA

0.000 to 52.000 mA or -25.00 to 105.00% of 10-50 mA

Accuracy ≤ ± (0.02 % of Reading + 0.003 mA)

Voltage burden ≤ 2V at 24 mA. ≤ 2 V at 52 mA.

Overload/Current limit

protection

25 mA nominal in 20 mA range

52.5 mA nominal in 50 mA range

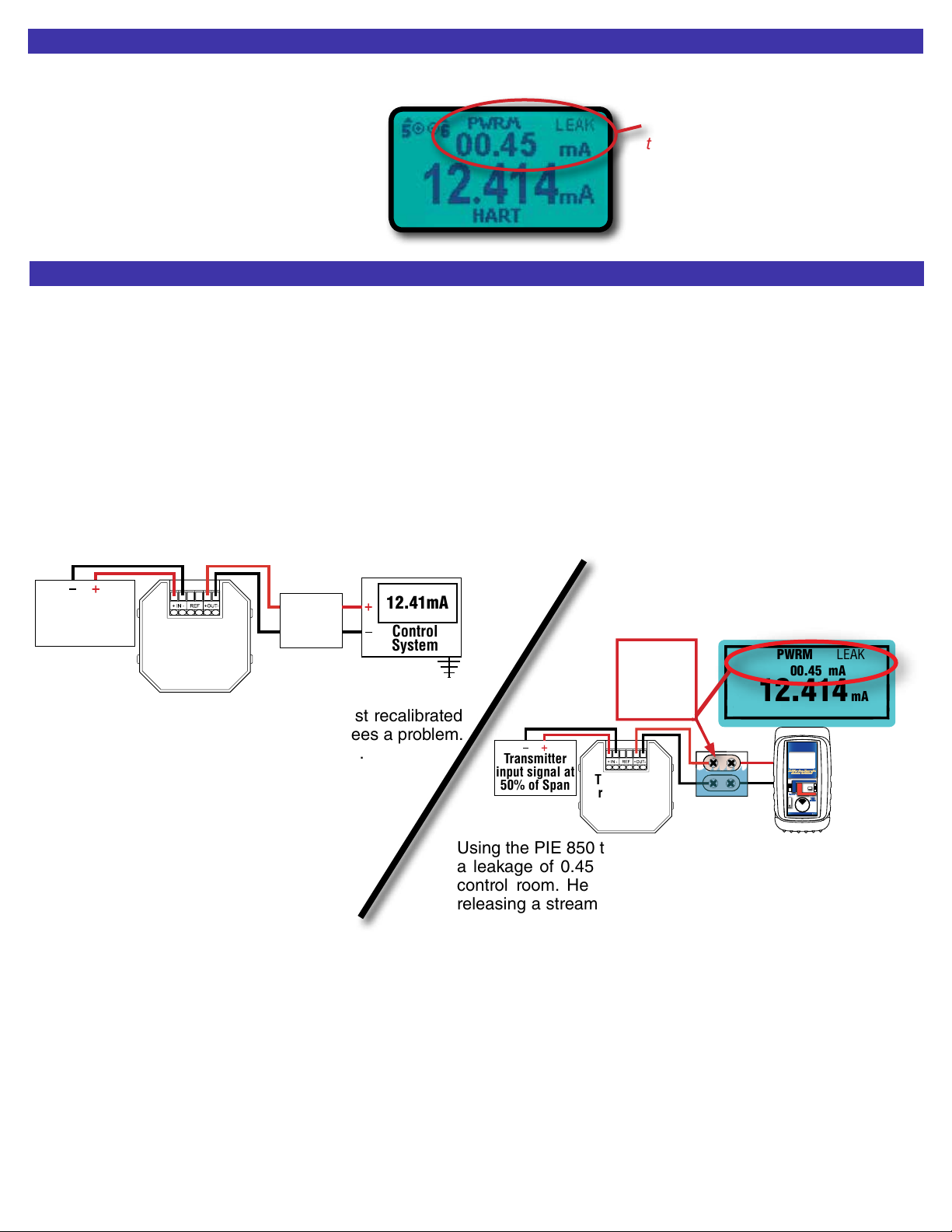

Source mA / Power & Measure Two Wire Transmitters & PWRM LEAK

Ranges and Resolution

0.000 to 24.000 mA or -25.00 to 125.00% of 4-20 mA

0.000 to 52.000 mA or -25.00 to 105.00% of 10-50 mA

Accuracy ≤ ± (0.02 % of Reading + 0.003 mA)

Loop compliance voltage

≥ 24 DCV @ 20.00mA. ≥ 2 DCV @ 50.000mA

Loop drive capability 1200 Ω at 20 mA for 15 hours nominal; 800 Ω at

50 mA for 4.5 hours nominal

Subtract 250Ω with Hart Resistor enabled (4-20 Only)

mA 2-Wire Transmitter Simulation

Accuracy Same as Source/Power & Measure

Voltage burden ≤ 2V at 24 mA. ≤ 2 V at 52 mA.

Overload/Current limit

protection

25 mA nominal in 20 mA range

52.5 mA nominal in 50 mA range

Loop voltage limits 2 to 60 VDC (fuse-less protected from reverse

polarity connections)

Source V dc

Ranges and Resolution

-20.000 to 99.999 mV, -500.00 to 999.99 mV, 0.000 to 10.250V

Accuracy ≤ ± (0.02 % of Reading + 0.01% Full Scale)

Source Current

≥ 20 mA

Sink Current > 16 mA

Output Impedance < 1 Ohm

Short Circuit Duration Infinite

Thermocouple Source

Accuracy ≤ ± (0.02 % of Reading + 0.01 mV)

Cold Junction Compensation

± 0.05°C - Thermistor traceable to NIST for 11 years

Output Impedance < 1 Ohm

Source Current > 20 mA (drives 80 mV into 10 Ohms)

Thermocouple Read

Accuracy & Cold

Junction Compensation

Same as Thermocouple Source

Input Impedance

> 1 Megohms

Open TC Threshold; Pulse

10K Ohms; <5 µamp pulse for 300 milliseconds (nominal)

RTD, OHMS and Continuity Read

Resistance Ranges 0.00 to 401.00, 0.0 to 4010.0 Ohms

Accuracy ±(0.025% of Reading + 0.075 Ohms)

Excitation Current

1.0 mA to 401 Ohms, 0.5 mA to 4010 Ohms (nominal)

Continuity 0.0 to 401.0 Ohms; Beeps from 0.0 to 100.0 Ohms

RTD and OHMS Source

3 Wire & 4 Wire Accuracy

F r o m 1 t o 1 0 . 2 m A

External Excitation Current

B e l o w 1 m A o f E x t e r n a l

Excitation Current

2 Wire Accuracy

±(0.025% of Reading + 0.075 Ohms)

±(0.025% of Reading+0.075 Ohms

+ )

Add 0.1 Ohms to 3 Wire & 4 Wire Accuracy

Resistance Ranges 0.00 to 401.00, 0.0 to 4010.0 Ohms

Allowable Excitation

Current Range

<401 Ohm:10.2 mA max; steady or pulsed/intermittent

401 to 4000 Ohms: 1 mA max; steady or pulsed/intermittent

Pulsed Excitation

Current Compatibility

DC to 0.01 second pulse width

0.025 mV

mA Excitation Current

Frequency Source

Ranges 1 to 2000 CPM, 0.01 to 999.99 Hz, 0.1 to 9999.9 Hz,

0.001 to 20.000 kHz

Accuracy ±(0.02% of Reading + 0.01% of Full Scale)

Output Waveform

Square Wave, Zero Crossing -1.0 to +5 V peak-to-peak ±10%

Risetime (10 to 90% of

amplitude)

< 10 microseconds

Output Impedance < 1 Ohm

Source Current > 1 mA rms at 20 kHz

Short Circuit Duration Infinite

Optical Coupling Green LED (HZ SYNC) flashes at output frequency

Frequency Read

Ranges & Accuracy Same as Frequency Source

Accuracy ±(0.02% of Reading + 0.01% of Full Scale)

Trigger Level 1 V rms, dc coupled

Input Impedance > 1 Meg Ohm + 60 pF

Specifications subject to change without notice.

pH Source

Accuracy in mV

Accuracy in pH

≤ ± (0.02 % of Reading in mV + 0.1 mV)

≤ ± 0.003 pH @ 25°C

Voltage Read

Range and Resolution

±99.999 mV, ±999.99mV, 0 to 10.250 V, 0.00 to 60.00 V DC

Accuracy ≤ ± (0.02 % of Reading + 0.01% Full Scale)

Input resistance ≥ 1 MΩ