MVP3 INSTRUCTION MANUAL Page 2

SHAW-ALMEX INDUSTRIES LIMITED 49908-006 NOV 97

Rev. DEC98, SEP99, MAY02

Table of Contents

1. RECORD OF PURCHASE ...............................................................................................................3

2. DECLARATION OF CONFORMITY ................................................................................................4

3. SAFETY .............................................................................................................................................5

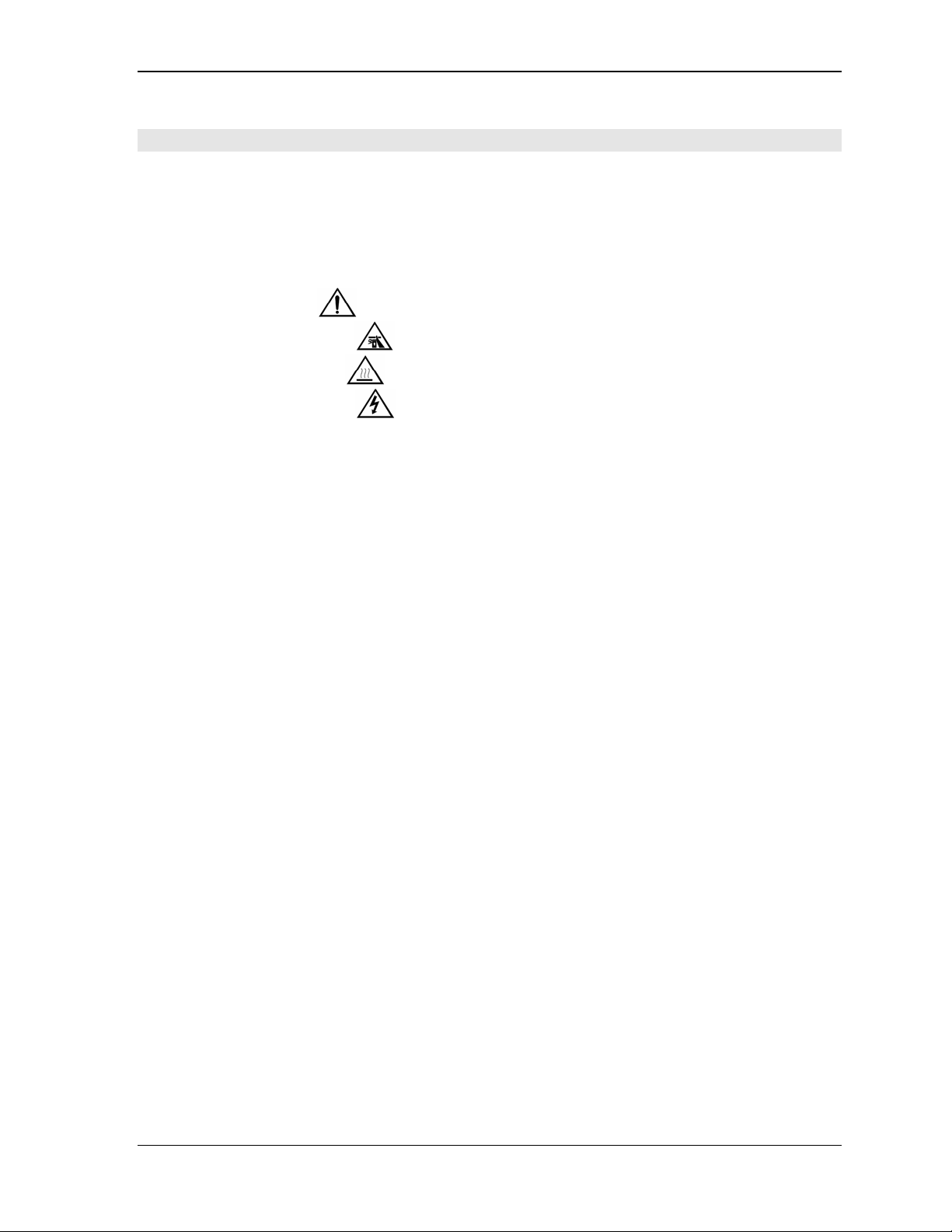

3.1. Definition of Pictograms .................................................................................................5

3.1.1. Safety Alert .......................................................................................................5

3.1.2. Crushing Hazard ...............................................................................................5

3.1.3. Burning Hazard .................................................................................................5

3.1.4. Electrical Hazard ...............................................................................................6

3.2. Limitation of use .............................................................................................................6

3.3. Hazardous Materials and Products ................................................................................6

3.4. Safe Handling .................................................................................................................6

4. ASSEMBLY .......................................................................................................................................7

4.1. Functional Diagram ........................................................................................................7

4.2. Unpacking.......................................................................................................................7

4.3. Vulcanizer Set-Up...........................................................................................................7

4.3.1. Basic Assembly...........................................................................................................8

4.3.2. Hinging Top Frame .....................................................................................................8

4.3.3. Short Circumference Belt............................................................................................8

5. OPERATION......................................................................................................................................9

5.1. Splice Set-Up..................................................................................................................9

5.2. Pressurizing with Air.......................................................................................................9

5.3. Heating the Vulcanizer ...................................................................................................9

5.4. Cooling the Vulcanizer .................................................................................................10

5.5. Depressurize ................................................................................................................10

6. MAINTENANCE ..............................................................................................................................10

6.1. Routine Maintenance ...................................................................................................10

6.2. Replacing the Pressure Bag.........................................................................................11

6.3. Replacing Heating Element..........................................................................................11

6.4. Replacing the Temperature Sensor (RTD Probe)........................................................11

7. TROUBLESHOOTING....................................................................................................................12

7.1. Vulcanizer Not Heating.................................................................................................12

7.2. Vulcanizer Over Heating ..............................................................................................12

7.3. No Pressure or Loss of Pressure .................................................................................13

8. SERVICE..........................................................................................................................................13

8.1. Emergency Service ......................................................................................................13

8.2. Return of Goods Authorization .....................................................................................13

8.3. Guarantee.....................................................................................................................13