ii

TABLE OF CONTENTS

1INTRODUCTION ............................................................................................................................................................. 1

1.1 Scope of the Manual.........................................................................................................................................1

1.2 Product Overview ............................................................................................................................................. 1

1.3 Part Numbers and List Options.........................................................................................................................2

1.4 Accessories.......................................................................................................................................................2

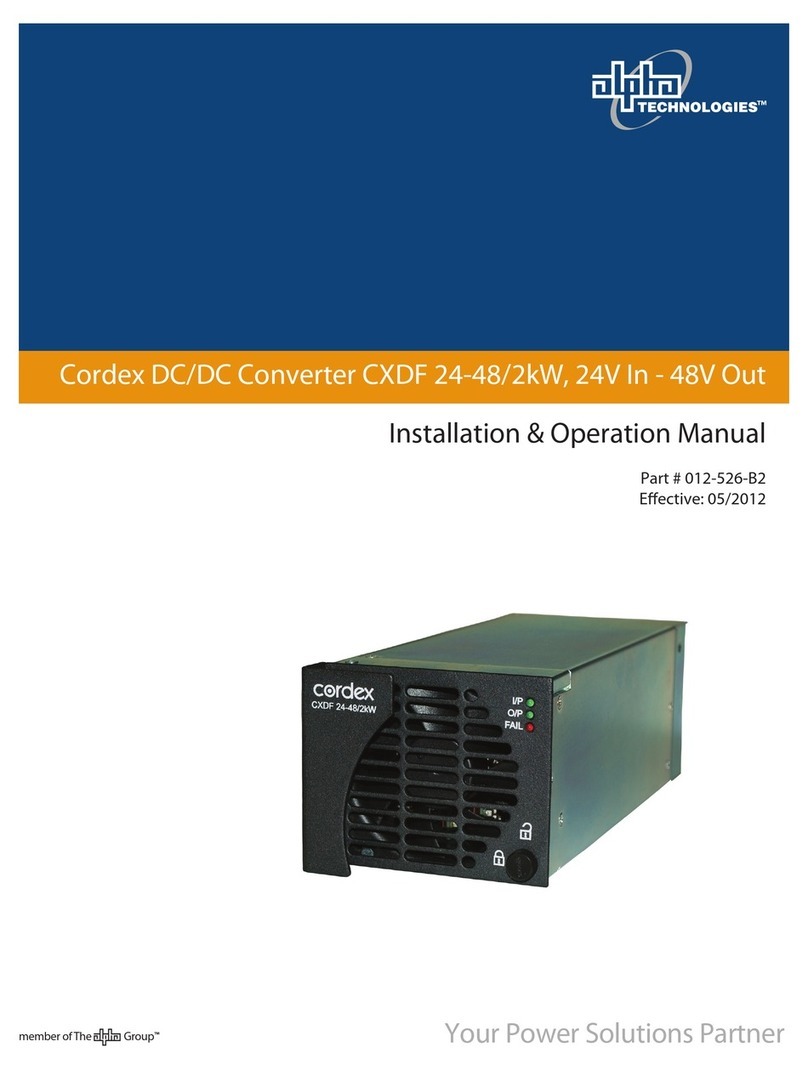

2CONVERTER MODULE FEATURES .................................................................................................................................. 3

2.1 Microcontroller .................................................................................................................................................. 3

2.2 Indicators ..........................................................................................................................................................3

2.3 Fail Alarm..........................................................................................................................................................3

2.4 Alarm Masking Switch ...................................................................................................................................... 4

2.5 Test Points........................................................................................................................................................4

2.6 Output Power.................................................................................................................................................... 4

2.7 Over Voltage Protection (OVP) ........................................................................................................................4

2.8 Current Limit ..................................................................................................................................................... 4

2.9 Input Low Voltage Lockout ...............................................................................................................................5

2.10 Regulation and Paralleling..............................................................................................................................5

2.11 Over Temperature Protection.........................................................................................................................5

2.12 Ventilation.......................................................................................................................................................5

2.13 Paralleling Diode............................................................................................................................................. 5

2.14 Reverse Polarity Protection............................................................................................................................ 5

3CONVERTER SHELF FEATURES ..................................................................................................................................... 6

3.1 Module Locking Bar.......................................................................................................................................... 6

3.2 Site (Chassis) Ground ...................................................................................................................................... 6

3.3 DC Input............................................................................................................................................................ 6

3.4 DC Output.........................................................................................................................................................7

3.5 Alarm Cable/Relays.......................................................................................................................................... 7

4INSPECTION.................................................................................................................................................................. 8

4.1 Packing Materials ............................................................................................................................................. 8

4.2 Check for Damage............................................................................................................................................8

5INSTALLATION .............................................................................................................................................................. 9

5.1 Safety Precautions............................................................................................................................................ 9

5.2 Tools Required ................................................................................................................................................. 9

5.3 Shelf Preparation/Mounting............................................................................................................................10

5.4 Module Insertion/Removal..............................................................................................................................10

6WIRING AND CONNECTIONS ........................................................................................................................................ 11

6.1 Safety Precautions..........................................................................................................................................11

6.2 Site (Chassis) Ground .................................................................................................................................... 11

6.3 DC Input..........................................................................................................................................................11

6.4 DC Output.......................................................................................................................................................12

6.5 Alarm (Relay) Outputs ....................................................................................................................................12

7INITIAL STARTUP ........................................................................................................................................................ 13

7.1 Normal Mode of Operation .............................................................................................................................13

7.2 Reverse Polarity Protection............................................................................................................................13

8MAINTENANCE............................................................................................................................................................ 14