ALS Schmiertechnik GmbH & Co. KG ▪ Martinsgasse 2 ▪ 71063 Sindelfingen, Germany ▪ Phone +49 7031/879392

1. Notes on instructions

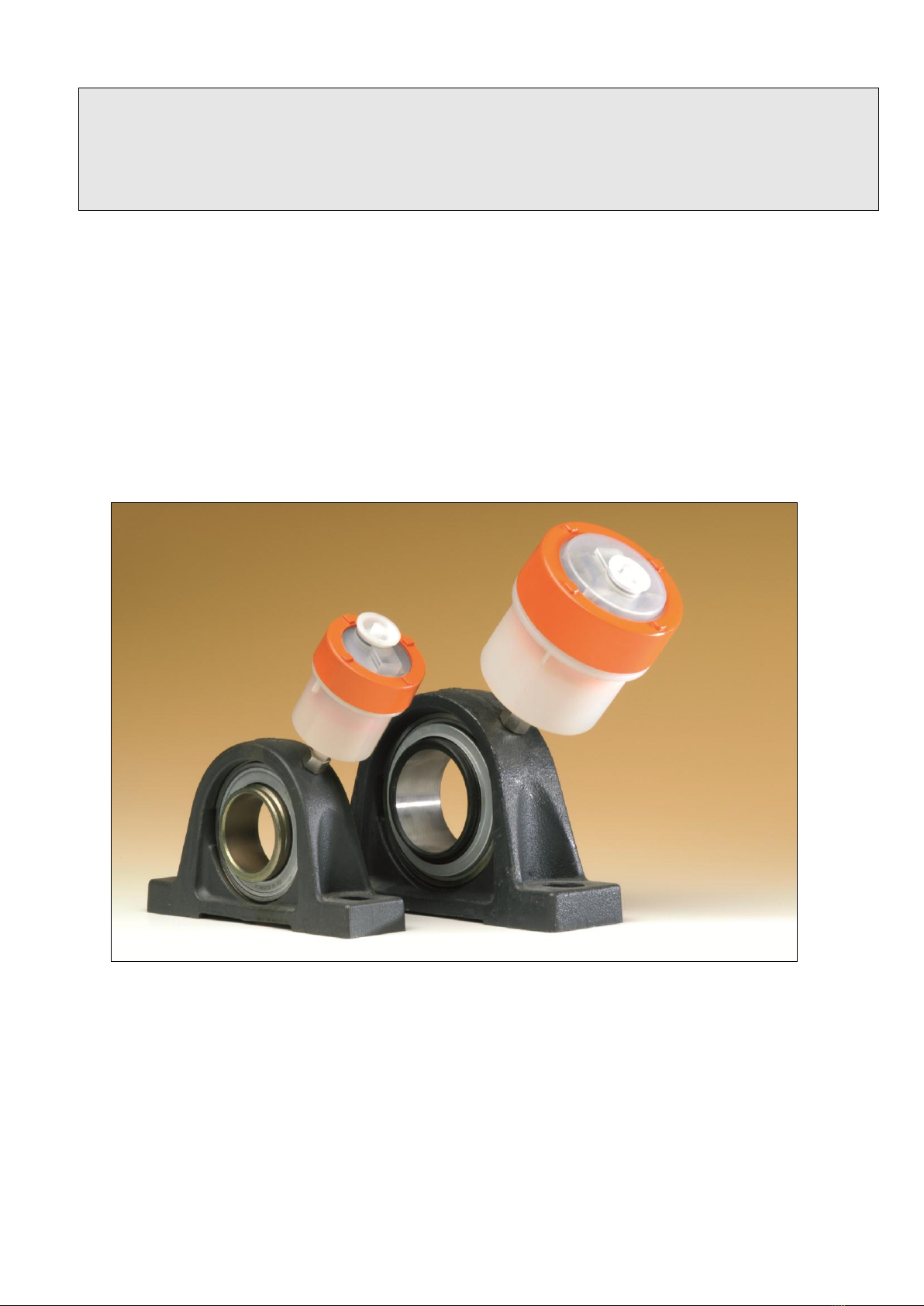

These instructions contain important information about the ALS Type 475 lubricant dispenser and are used for safely

working with the product. Here you can find technical information about the structure, application, installation and

disposal of the ALS lubricant dispenser. If you have further questions, please contact ALS Schmiertechnik GmbH &

Co. KG or a sales partner.

The following designations are used in these instructions:

–Type 475: 460 cm³ volume

2. Safety notes

These safety notes do not claim to be complete. If you have questions or problems, please contact ALS

Schmiertechnik. The ALS lubricant dispenser has been developed to take into account current, state-of-the-art

technology and recognized safety-related regulations. The following general safety and warning notes in these

instructions should be followed at all times to prevent potential property damage or personal injury.

• Please read through these instructions carefully before using the ALS lubricant dispenser.

• If the product is resold, the technical manual should always be included. The newest version can be downloaded

from the ALS website, http://www.als-info.com.

• The technical ALS manual is available in German and English. Resellers from countries speaking other

languages are obligated to translate the information into the respective language properly.

2.1 Use

• The ALS lubricant dispenser is a technical tool developed to counteract wear and friction on machine

components using targeted lubrication.

• The ALS lubricant dispenser contributes to the safety of maintenance personnel since dangerous system

and machine areas have to be visited substantially less often due to fact lubricant is supplied automatically.

• Proper use requires that these instructions, and Chapter 2 on safety notes in particular, are read and

followed.

• The ALS lubricant dispenser is a product as defined by Machinery Directive 94/9/EC.

• Installation, commissioning, operation and maintenance should be carried out by trained, qualified

specialists since fundamental mechanical knowledge, knowledge of associated specialized terminology and

knowledge of applicable standards, stipulations and accident prevention measures are necessary.

2.2 Warning and safety notes

The warning notes provide information about the risk of personal injury and property damage. Please pay particular

attention to sections that contain this symbol:

• Indicates a risk to personal well-being that may result in severe injuries.