WARNINGS

Carefully read all instructions and review all illustrations before installing. Failure to observe these warnings

could result in a fire, electric shock, or personal injury.

Table should be built in the room it is intended to be used in. Use two people when flipping or moving the

table.

Ensure there are no obstacles above or below the table that would prevent movement. All cords must be of

appropriate length to accommodate the table’s full range of heights.

Keep unsupervised children away from this height adjustable table. Ensure children understand the dangers

of operating this table without supervision.

Keep electrical components away from liquids. Components to be opened by professional technicians only.

Use this table indoors only.

This table is designed for a 10% duty cycle, meaning, for every minute of operation the table should be allo-

wed to rest for 9 minutes.

In the event of a power outage, or if any cord is unplugged, an initialization is required. See step 12 for initi-

alization steps.

Do not sit or stand on table’s base or worksurface. Weight rating is 180 lbs including worksurface. Do not

exceed.

Page 2 Of 10

1430119200 Rev D

09/2020

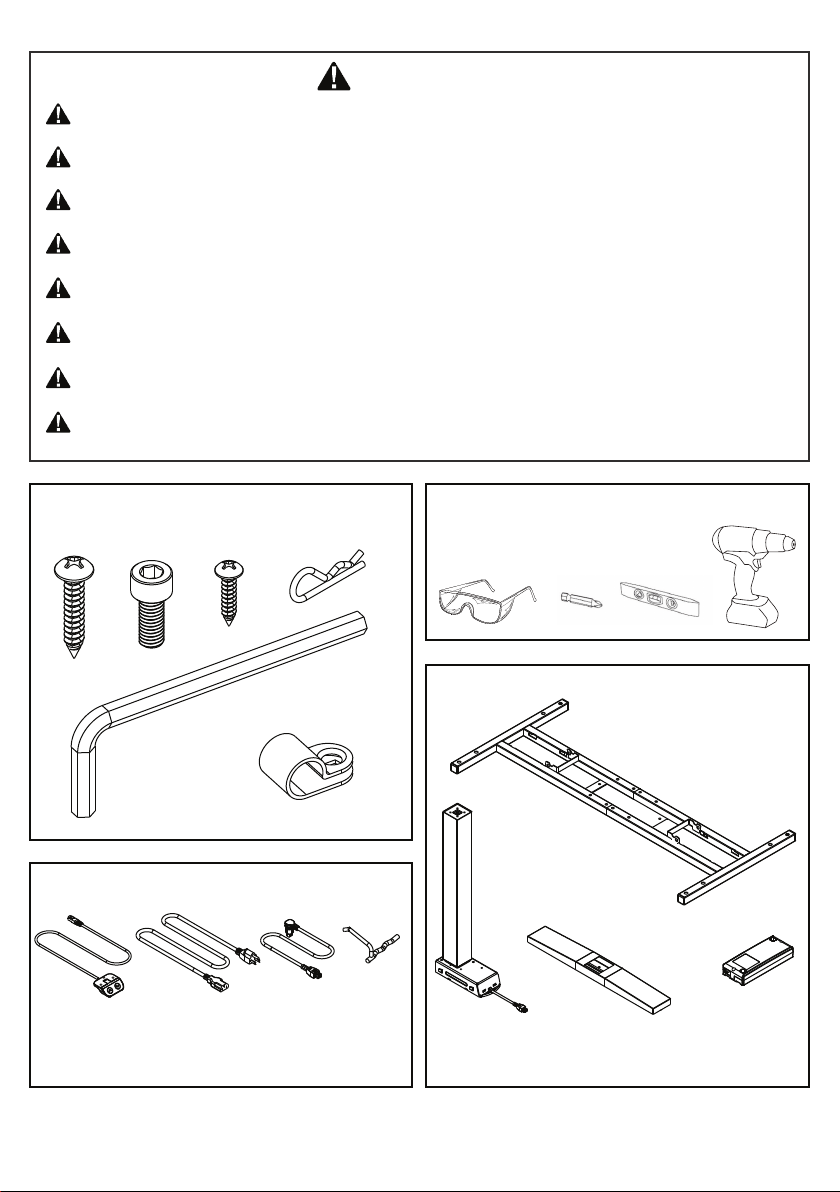

Included Hardware / Tools Other Tools Required

14x M5x25 8x M6x15 13x M3.5x15 2x Cotter Pin

#2 Phillips

Allen Wrench 5mm

10x Cable Clips

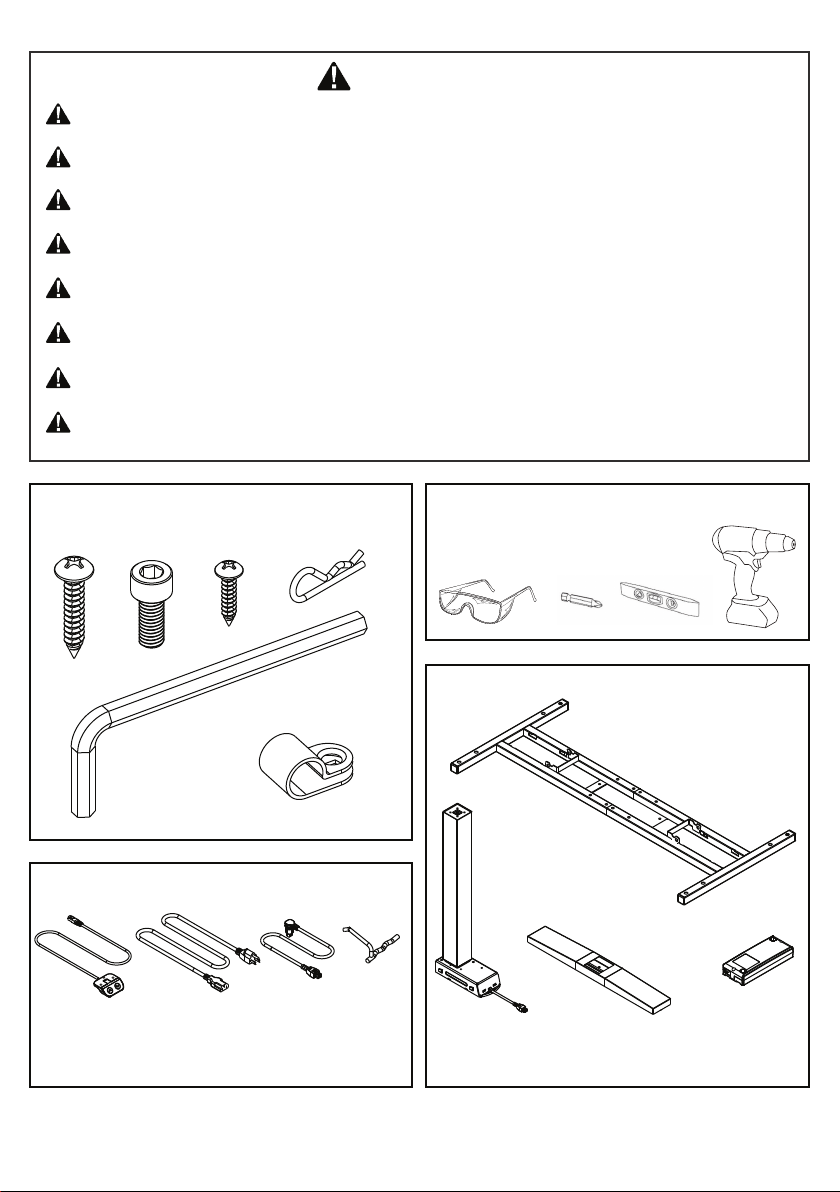

Frame Assembly

2x Column

2x Feet Control Box

Keypad Power Cable

2x Cam

Lever

2x Motor

Cable