4

(spray) products are being used or where oxygen is being

administered.

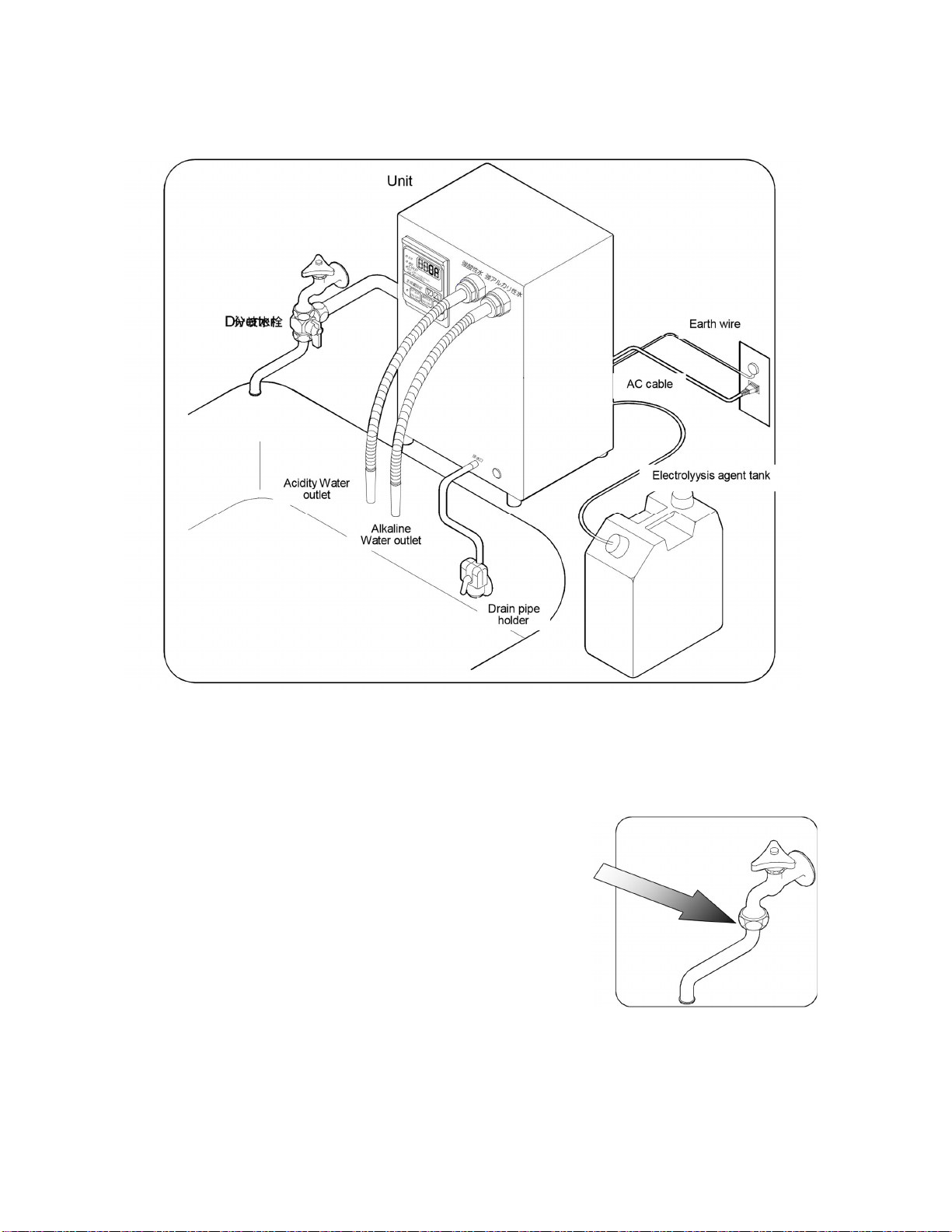

(18) Connect this unit to a properly grounded outlet only.

(19) Do not place a kink into the AC cord.

(20) Do not unplug by pulling the AC cord.

(21) Do not wash the unit by water or other liquids.

(22) Do not pour water into the unit.

(23) Do not set the unit in an unstable place or an inclined place.

(24) Do not install the unit near a fire source, direct sun-

light, in a freezing zone, a dirty place, a wet place or where

corrosive gas is present.

(25) Do not use the unit in a closed area since gases such as

hydrogen and chloride are generated while electrolysis is in

operation. Please use the unit in a well-ventilated place and

keep out of close proximity of a fire source.

(26) Do not directly inhale gas in the electrolyzed liquid stored

tank.

DANGER: To reduce the risk of electrocution:

WARNING: To reduce the risk of burns, electrocution, fire, or injury to

person:

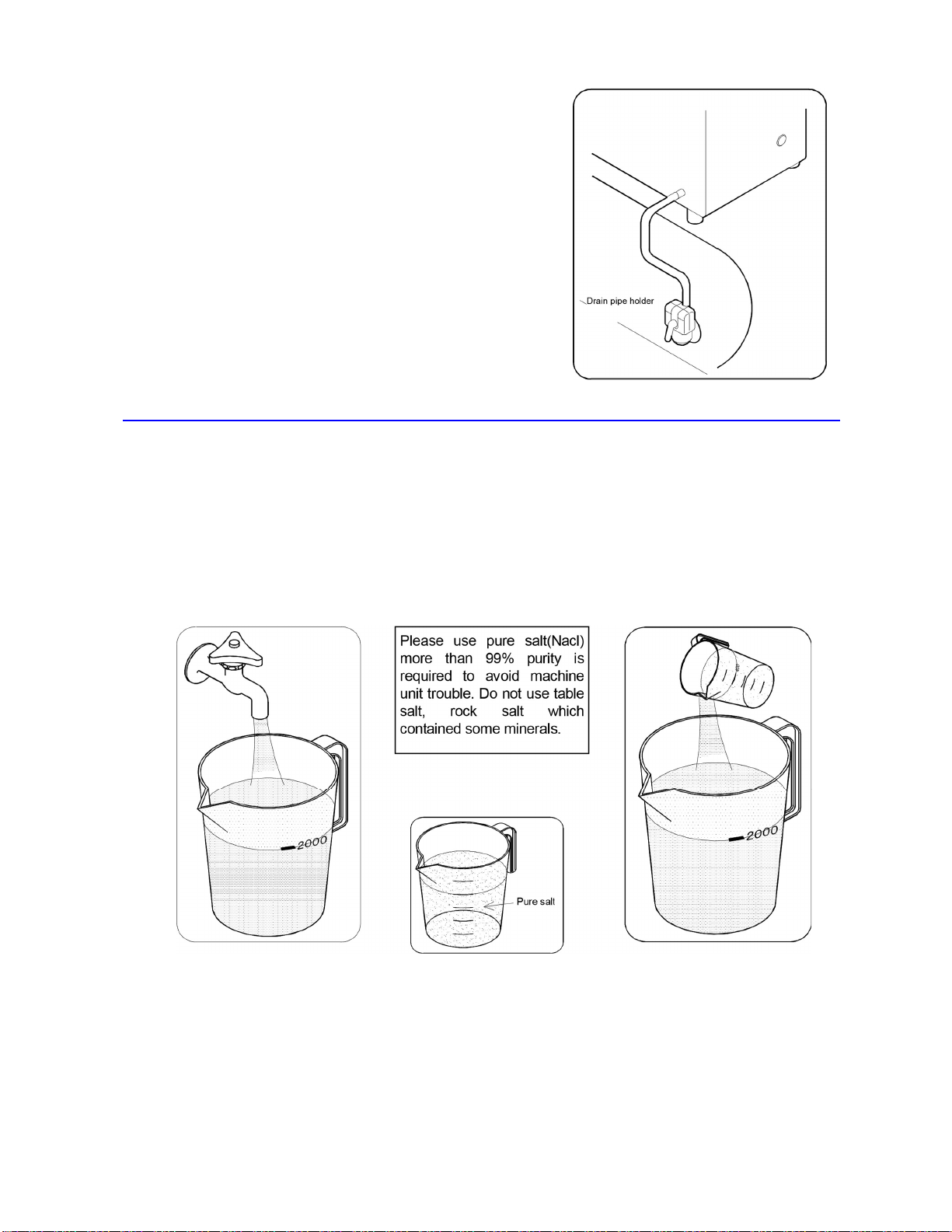

(1) The water to be used in this unit should be suitable for

drinking.

(2) Do not use salty water, underground water, dirty water, high

hardness water and rust water to avoid the unit from damage.

(3) Please consult your doctor when electrolyzed water

comes into contact with one’s eye.

(4) Please consult your electrical contractor when electric

work is required.

(5) Do not use hot water more than 40 centigrade.

(6) Do not close any water outlet.

(7) Do not use extra tubing for electrolysis agent tank.

(8) Do not place any heavy items onto the unit.

(9) Do not use any inappropriate containers for holding of the acidic