Altronic CDM-2100 User manual

Operating Manual

CDM-2100

Dierential Pressure Monitor

Form CDM-2100 OM 3-21

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 2

TABLE OF CONTENTS BY SECTION PAGE

1.0 OVERVIEW....................................................................................................................... 3

2.0 CDM−2100 PANEL .......................................................................................................... 3

3.0 CDM−2100 DISPLAY MODULE ........................................................................................ 3

4.0 MOUNTING THE PANEL .................................................................................................. 3

5.0 WIRING............................................................................................................................ 4

6.0 KEYPAD DESCRIPTION.................................................................................................... 4

7.0 UNDERSTANDING THE HOME SCREEN........................................................................... 4

8.0 INITIAL CONFIGURATION................................................................................................ 5

9.0 RS−485 COMMUNICATIONS ......................................................................................... 10

10.0 MODBUS REGISTER LISTS ............................................................................................ 11

TABLE OF FIGURES

FIG. 1 MOUNTING DIMENSIONS ............................................................................................ 16

FIG. 2 WIRING DIAGRAM, CUSTOMER CONNECTIONS........................................................... 17

FIG. 3 FLOW CHART ............................................................................................................... 18

FIG. 4 CDM−2100 SYSTEM DIAGRAM..................................................................................... 19

FIG. 5 RS−485 COMMUNICATIONS: PC HOOK−UP................................................................. 20

FIG. 6 RS−485 COMMUNICATIONS: MULTIPLE SLAVE UNITS................................................ 20

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 3

1.0 OVERVIEW

1.1 The CDM-2100 control panel consists of the DSG-1611DUPS instrument, wiring

terminals, and fuse installed in an industrial enclosure.

1.2 The CDM-2100 controller is a dedicated electronic microprocessor-based system

designed to sense dierential pressure across a single catalyst element. A front

mounted keypad serves as the user interface for all required system configuration.

A backlit 128 x 64 character graphic display shows system status, programmed

controller parameters and channel labels. The controller provides complete

supervisory and alarm annunciation capability dedicated to monitoring and

protecting catalyst elements indicating when internal pressures have risen above

manufacturers limits.

In conjunction with the CDM-2100 controller, a highly accurate, low pressure

inches of water column dierential pressure transmitter is used. When each port

of the dierential pressure transmitter is placed across the catalyst element,

it sends an electronic signal back to the CDM-2100. This signal represents the

amount of pressure drop across the catalyst element.

2.0 CDM-2100 PANEL

2.1 The panel contains all the necessary hardware and provides the wiring interface

to an external sensor. Conduit openings at the bottom of the enclosure provide

access for supply power, sensor and other necessary wiring.

3.0 CDM-2100 DISPLAY MODULE

3.1 The CDM-2100 display module provides for monitoring the catalyst dierential

pressure. The output of the CDM-2100 instrument provides a 4-20mA signal

representing the incoming pressure, and alarm outputs as discrete contacts.

3.2 The keypad is a sealed membrane unit containing MENU/ESC, UP, DOWN and

ENTER keys, used to navigate through channel status and description and to

edit the setpoints.

3.3 The LCD has a Home Screen that displays a Status Line, along with the catalyst

dierential pressure in inH2O.

3.4 The keypad and display are used to navigate through channel status and

descriptions, view screens, and to view or edit the system’s configuration.

Pressing the MENU/ESC key advances the display to the menus. All menu

adjustments are saved in non-volatile EEPROM memory by pressing the ENTER

key. The EEPROM memory retains the current configuration during normal

operation, after engine shutdown and a system power-down.

3.5 The CDM-2100 has serial communications compliant to Modbus RTU standard

and uses RS-485 for its hardware communication format.

4.0 MOUNTING THE PANEL (FIG. 1)

4.1 Mount the control panel(s) to a post or to a suitable flat surface so that the

display is at a convenient viewing height. NOTE: Avoid mounting the panel

with the LCD display facing direct

sunlight. The display operating

temperature range is -31°F to +176°F

(-35°C to +80°C). The panel(s)

should be mounted within 10–20

feet of the engine, the fuel solenoid

valve and sensors.

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 4

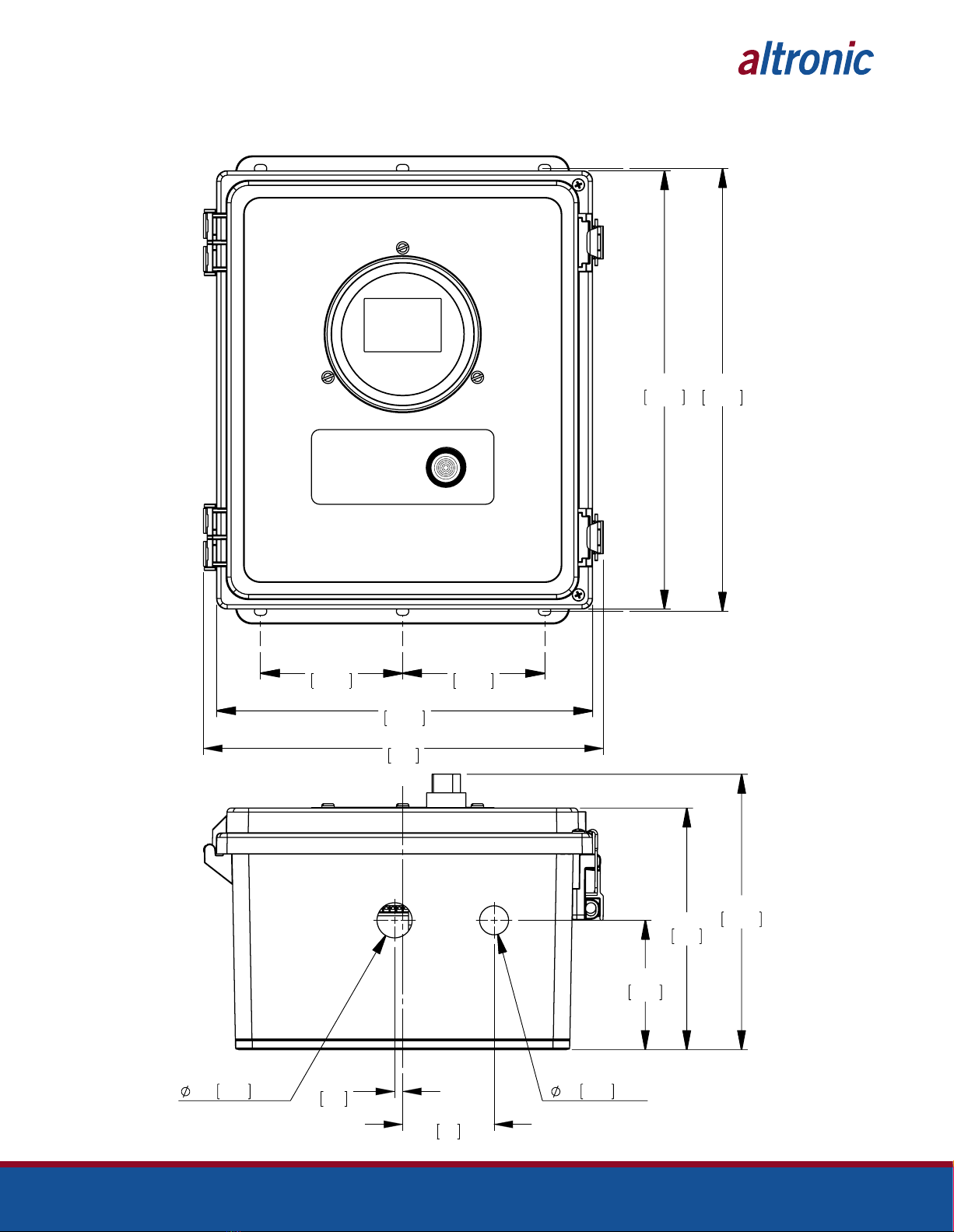

5.0 WIRING (SEE WIRING DIAGRAM, FIG. 2)

5.1 Wire Cable Assembly 693158-XX, where XX may be -60, -120, -360 (which

represents the cable length in inches) cabling, into the panel. This assembly

contains the wiring for the connection to the dierential pressure transmitter.

Feed the cable through the bottom of the panel and connect each wire to its

appropriate position on the terminal strips. Separate power wiring must be routed

to the panel, and must follow guidelines published by the NEC and local authority.

6.0 KEYPAD DESCRIPTION

6.1 The CDM-2100 gauge features a four-key front keypad which is used to view or

change the setpoint values, configure and calibrate the gauge. The front panel

keys are MENU/ESC, ENTER, and , (up and down arrow keys).

6.2 MENU/ESC

The MENU/ESC key is used to enter the main menu and to return to the home

screen at any time. If the MENU/ESC key is used to return to the home screen

prior to pressing the ENTER key, changes are not stored in the memory and do

not take eect.

6.3 ENTER

The ENTER key is used throughout the menu to proceed through the

configuration and to accept the data to be saved. Throughout configuration

when a change has been made and is to be saved to memory, press ENTER and

the display will read SAVED, and the new data or configuration will be stored in

the nonvolatile memory.

6.4 AND

The up and down arrow keys are used to scroll through the selections in the

menu and to increase or decrease values during configuration and calibrations.

Values can be changed incrementally using individual key presses or more

rapidly by holding the key down.

7.0 UNDERSTANDING THE HOME SCREEN

7.1 The CDM-2100 is considered in the HOME SCREEN when measuring and

displaying monitored data. The gauge displays up to a 5-digit numeric value

in 0.5” numbers, units of measure, the monitored point label, and a graph if

enabled. If a setpoint is configured and its value is exceeded, the output switch

turns on and the display will indicate SW1 LO, SW1 HI, SW2 LO or SW2 HI (low,

or high setpoint and switch 1 or 2 has tripped).

When the displayed reading exceeds the upper limit of the gauge (110% of

range), the display will read INPUT SIGNAL IS HI OUT OF RANGE, and if

configured, its high output switch will activate. If the displayed reading exceeds

the lower limit of the gauge, the display will read INPUT SIGNAL IS LO OUT OF

RANGE, and if configured, its low output switch will activate.

NOTE: All furnished drawings and

instructions assume (–) ground DC

system. In the case of a floating

ground, or (+) ground DC system,

please contact Altronic Factory for

support.

DIFFERENTIAL

12.0mA inH20

0

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 5

8.0 INITIAL CONFIGURATION

8.1 The CDM-2100 is pre-configured for measuring the dierential catalyst pressure

using the Altronic dierential pressure transmitter. All of the basic labels and

configuration are already complete for the user to start monitoring. However,

there are site specific parameters that should be updated. This section will guide

the user through the minimum screens required to set-up the controller. A more

detailed description of all user parameters is provided in section 10.

This system is shipped with factory default settings. Upon power-up a splash

screen displays: DSG-1611DUPS, the firmware Rev. Level, and date.

Once the arrow cursor is adjacent to the line to be changed, pressing the ENTER

key changes the icon to é. Now the up and down arrow keys can be used to

change the selection. Once the desired change is made, pressing the ENTER key

saves the change and returns the arrow cursor.

Press the MENU key to enter into the main system menu.

The up and down arrow keys can be used to move the cursor down to the

PREVIOUS MENU. Pressing ENTER then returns the display to the main menu.

Move the cursor adjacent to SETPOINTS and press ENTER.

CHANNEL 1

UNITS psi

FILTER 254

~SETPOINTS

CONFIGURE

CALIBRATE

RESET

PREVIOUS MENU

ENTER

An LED is tied to the output of Switch 2, such that when a fault occurs the LED

will illuminate. According to the manufacturer of the catalyst there will be an end

of life pressure. Switch output 2 should be set such that the LED indicator will

alert someone visually before the end of life pressure of the catalyst. Optionally

Switch 1 is wired to terminals, and can be configured to operate an external relay

or digital input to notify a control system of the elevated catalyst pressure.

CHANNEL 1

~HI 6in H2O

LO 0in H2O

HYST 3 SEC

PREVIOUS MENU

NOTE: The splash screen can be

displayed at anytime from a home

screen by pressing both the up and

down arrow keys together.

UNITS inH2O

FILTER 254

~SETPOINTS

CONFIGURE

CALIBRATE

RESET

COMMUNICATIONS

SECURITY

ENTER

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 6

Press ENTER again to change the cursor to the éicon. Use the UP and DOWN

arrow buttons to make the desired setpoint changes. The procedure is repeated

to change the first setpoint value.

8.2 HYSTERESIS

Hysteresis can be used when the output switch is configured as non-latching

to prevent the output switch from oscillating or turning on and o around the

setpoint. The hysteresis is implemented as a time, in seconds, that begins

when the sensor input value returns to within the setpoint value limits. When

the input value returns to within the setpoint value limits, the hysteresis timer

starts and the switch stays tripped for the configured hysteresis time. If during

the hysteresis time the setpoint is violated again, the hysteresis timer starts

over. The hysteresis value can be set from 0 to 99 seconds. To set the hysteresis

value, point to HYST and press the ENTER key. Use or to increase or

decrease the hysteresis time and press ENTER to save the new value.

CHANNEL 1

HI 6in H2O

LO 0in H2O

~HYST. 9 SEC.

PREVIOUS MENU

8.3 SETPOINTS

The SETPOINTS menu allows the user to set a setpoint value for Low and

High, and set the hysteresis value for each channel.

REFER TO SECTION 8 FOR DETAILS ON SETPOINTS

8.4 CALIBRATE

The gauge is calibrated at the factory and should not require additional

calibration. However, calibration can be performed in the field many times

over the life of the gauge. Each channel is calibrated separately to the type of

input transducer selected. The calibration mode is used to calibrate the zero

and span values. Calibration can be performed from the front keypad without

disassembling the gauge. A calibrator or simulator capable of outputting the

correct signal for the type of transducer selected for that channel is required

to provide a calibration reference.

CHANNEL 1

CALIBRATE:

~FULL CAL

TWEAK LO ONLY

TWEAK HI ONLY

RECALL FACT CAL

PREVIOUS MENU

8.4.1 CALIBRATION PROCEDURE

Connect the appropriate calibrator or simulator (for thermocouples use the

proper type of thermocouple extension wire) to the gauge for channel 1 or 2,

follow the hook-up drawing for that sensor type. Be sure that the sensor type

and the engineering units of the calibrator match the type and engineering

units of the instrument before performing a calibration.

NOTE: During calibration, the unit

allows 2 minutes between keystrokes

to change or save a new calibration.

If 2 minutes lapse without a keystroke,

the device will automatically return

to the home screen with the previous

values. The new calibration information

is saved only if the ENTER key is

pressed and the display reads SAVED.

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 7

To calibrate the gauge, select CALIBRATE from the channel 1 or 2 menu

and press the ENTER key. Select FULL CAL and press ENTER. The display

will read SET LO POINT ON CALIBRATOR AND PRESS ENTER. Adjust the

calibrator/simulator at or near zero or a very low reading and press ENTER;

the display will show SAMPLING, then ADJUST LO POINT TO MATCH

CALIBRATOR. Use the or arrow keys to increase or decrease the display

reading to match the setting of the simulator and press ENTER. The display

will show SET HI POINT ON CALIBRATOR AND PRESS ENTER. Adjust the

simulator at or near the span value of the transducer or a very high reading

and press ENTER; the display will show SAMPLING, then ADJUST HI POINT

TO MATCH CALIBRATOR. Again use the or arrow keys to increase or

decrease the display reading to match the simulator and press ENTER. The

display will read CALIBRATION VALUES SAVED!. The gauge will return to the

home screen with the new calibration values stored in memory.

8.4.2 The CDM-2100 gauge has a feature that allows a slight adjustment of either

the zero or span values individually. This type of calibration can be used

to “tweak” the readout to match that of a known value without actually

performing a formal calibration procedure. This adjustment is independent for

each channel and must be performed on that individual channel. Please note

that this type of adjustment will invalidate calibration settings from the FULL

CAL procedures.

TWEAK LO ONLY

To make a small adjustment on the zero calibration value of the gauge, enter

the calibration mode by selecting CALIBRATE and press ENTER; select

TWEAK LO ONLY from the menu and press ENTER. The display will show

SET LO POINT ON CALIBRATOR AND PRESS ENTER. Adjust the calibrator/

simulator at or near zero or a very low reading and press ENTER; the display

will show SAMPLING, then ADJUST LO POINT TO MATCH CALIBRATOR.

Use the or arrow keys to increase or decrease the display reading to

match the calibrator and press ENTER. The display will read CALIBRATION

VALUES SAVED!. The gauge will return to the home screen with the new zero

calibration value stored in memory.

TWEAK HI ONLY

To make a small adjustment on the span calibration value of the gauge, enter

the calibration mode by selecting CALIBRATE and press ENTER; select

TWEAK HI ONLY from the menu and press ENTER. The display will show

SET HI POINT ON CALIBRATOR AND PRESS ENTER. Adjust the calibrator/

simulator at or near the desired span value and press ENTER; the display

will show SAMPLING, then ADJUST HI POINT TO MATCH CALIBRATOR.

Use the or arrow keys to increase or decrease the display reading to

match the calibrator and press ENTER. The display will read CALIBRATION

VALUES SAVED!. The gauge will return to the home screen with the new span

calibration value stored in memory.

8.4.3 RECALL FACTORY CAL VALUES

The user can at any time during the life of the gauge reinstate the factory

calibration values for channel 1 or 2 independently. Select CALIBRATE from

the CHANNEL 1 or CHANNEL 2 menu and press ENTER; select RECALL

FACTORY CAL and press ENTER. The next screen will display the type and

range for which the selected channel’s input is currently configured. Select

APPLY to confirm or CANCEL to decline and press ENTER. If APPLY is

selected, the display will show CALIBRATION VALUES SAVED!. The gauge will

return to the home screen with the factory default calibration values stored in

memory. If CANCEL is selected, the gauge will retain the current calibration

values. Press the ESC key to return to the home screen.

The calibration values only, will return to the factory default; all other settings will

remain unchanged. If the transducer type or range is incorrect, press the MENU/

ESC key to abort saving incorrect factory cal values. Configure the gauge for the

desired input sensor type and range and then recall the factory cal values.

8.5 RESET

The reset selection in the menu is used to reset the min/max reading for

channel 1 or 2 independently. To perform a reset, select either channel 1 or 2

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 8

from the menu, use or to scroll to RESET and press ENTER. The display

will show RESET!. A reset can also be performed by sending a reset command

via the RS-485 Modbus RTU communications register.

8.5.1 MIN/MAX READING

Use the or arrow key to point to MIN/MAX READING and press ENTER;

The display will show RESET!. RESET resets both the min and max readings to

the current reading.

CHANNEL 1

RESET:

~MIN/MAX READING

PREVIOUS MENU

8.6 COMMUNICATIONS

8.6.1 The CDM-2100 gauge is part of a system that has been carefully designed to

easily interface to popular computers, terminals, programmable controllers

and Altronic instruments. Modbus RTU is the protocol used in the CDM-

2100. A Modbus register list with register numbers and descriptions of

each register can be found in section 10.0. The serial communications are

compliant to the Modicon Modbus RTU standard and uses RS-485 for its

hardware communication format. To view or adjust the communication

parameters, select COMMUNICATIONS from the main menu and press

ENTER. Throughout the menu use the or arrow keys to make a selection

and press ENTER to save the changes.

FOR DETAILED COMMUNICATIONS INFORMATION SEE SECTION 9.0.

COMMUNICATIONS

~NODE: 1

BAUD: 9600

PREVIOUS MENU

8.6.2 NODE

The node number gives each gauge on the communications port an identity.

Any node number from 1 to 99 can be used. Use the up and down arrow keys

to select a node number and press ENTER to save.

8.6.3 BAUD — Select the required baud rate and press ENTER to save.

SEE SECTION 9.3 FOR AVAILABLE BAUD RATES.

8.7 SECURITY

8.7.1 The security feature allows for a user to lock the gauge to secure chosen areas

of the menu from being changed. There are several individual areas in the menu

system that can be protected as well as two layers of protection. The menus

that can be protected are the CONFIGURATION menu settings, the SETPOINT

values, the ability to make changes via modbus COMMUNICATIONS, and

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 9

CALIBRATION protection. When protection is ON, the user is able to view the

menu values but not able to change them. If an attempt is made to change the

values and the ENTER key is pressed when protection is on, the display will read

PASSWORD PROTECTED! ENTER PASSWORD. This prompts the user to enter

the password. If the correct password is entered, the requested configuration

values can be changed.

To set or change a password, select SECURITY from the main menu and press

ENTER. If the password is set to 000, the security menu will be available without

entering the password. If the password is any number but 000, the proper

password must be entered to enter the security menu. Each of the security

selections can be turned ON or OFF individually. Use the or arrow key to

point to the item to be protected and press ENTER, the éarrow will change to

é. Use the or key to select either ON or OFF and press ENTER. The display

will show SAVED and the change will be saved to memory. When a menu item is

protected, the display will read ON, not protected will show as OFF. To enter a

password, point to PASSWORD and press ENTER. Use the or arrow key to

increase or decrease each of the 3-digit password numbers and press ENTER.

The display will show SAVED and the change will be saved to memory. Any

number from 000 to 999 can be used. Please note that Autoscan, Units, Filter

Values, and R eset cannot be locked out by security protection. Please note that

SECURITY protects both channels.

8.7.2 CONFIGURATION PROTECTION:

When set to ON, prevents the user from changing items in the CONFIGURE

menu. Items protected are TYPE (input sensor type), GAUGE LABEL, and

BARGRAPH.

8.7.3 SETPOINT PROTECTION:

When set to ON, prevents the user from changing the items in the SETPOINTS

menu. All setpoint values and configurations can be read but not changed.

8.7.4 COMMUNICATIONS PROTECTION:

When set to ON prevents the user from changing the Modbus registers via the

serial communications. User can read, but not write data. If the user attempts

to perform a write, the error message INVALID FUNCTION CODE will be sent.

8.7.5 CALIBRATION PROTECTION:

When set to ON, prevents user from changing calibration values.

8 .7. 6 P A S S W O R D :

The password is the second level of protection. When PASSWORD is selected,

the user will be prompted to enter a 3-digit password. To enter a password,

point to PASSWORD and press ENTER, the first digit will be underlined. Use

the or arrow key to increase or decrease that digit from 0 to 9 and press

ENTER. The next digit will be highlighted, use the same procedure to continue

to enter a 3-digit password and press ENTER to save. Any number from 000 to

999 can be used. The default password is 330.

With a password in memory, and the security screen is accessed, the

message PASSWORD PROTECTED! ENTER PASSWORD will appear. If the

proper password is entered, the security screen will be displayed and changes

will be allowed. To gain access to the protected menus without having to enter

a password, turn protection OFF. If the incorrect password is entered, the

display will return to the menu denying access to the protected menu.

SECURITY:

CONFIG PROT ON

SETPNT PROT ON

COMM PROT ON

CAL PROT ON

~PASSWORD 000

PREVIOUS MENU

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 10

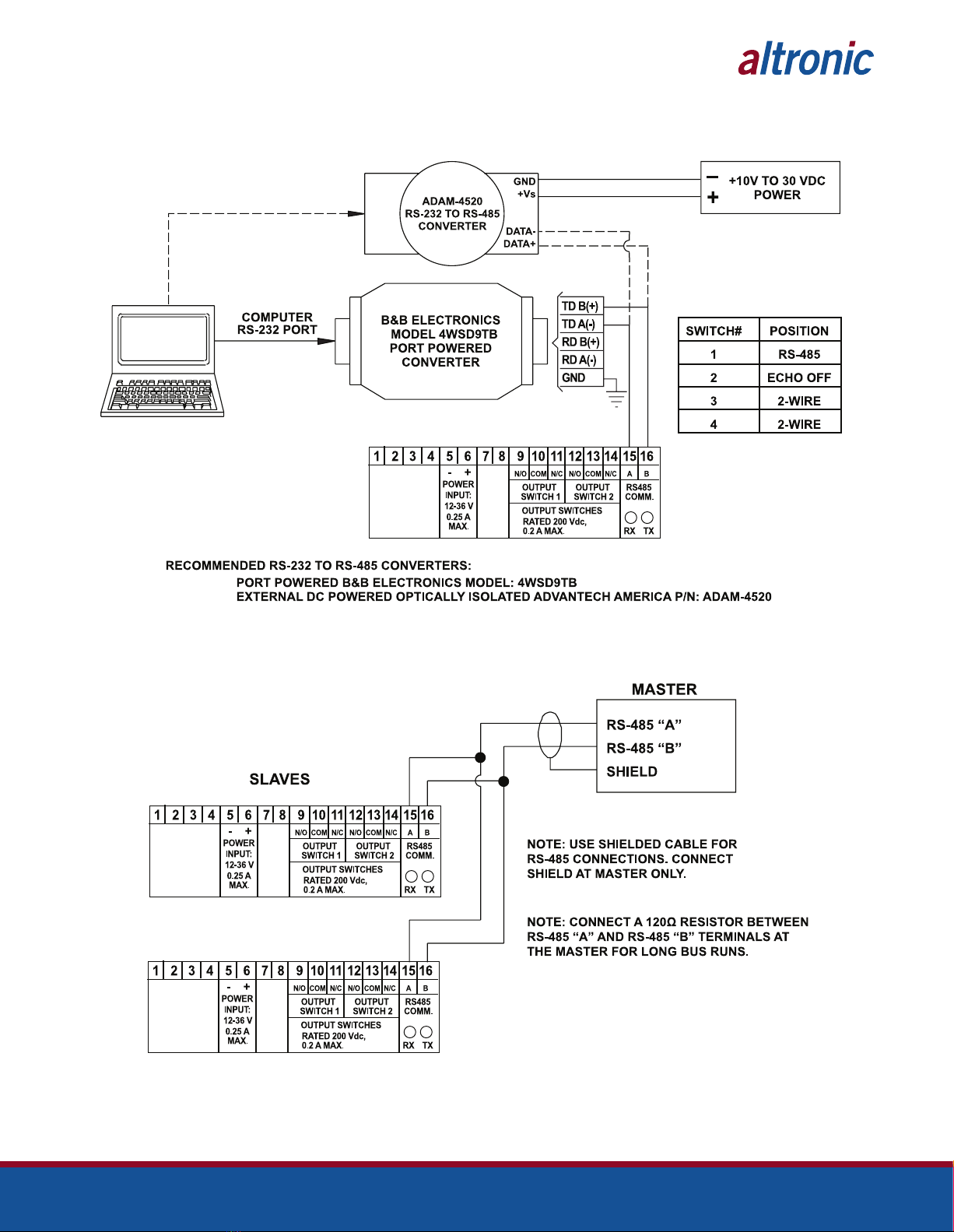

9.0 RS-485 COMMUNICATIONS

The CDM-2100 gauge is part of a system that has been carefully designed to

easily interface to popular computers, terminals, programmable controllers and

Altronic instruments. The gauge communicates in the Modbus RTU protocol.

9.1 MASTER/SLAVE OPERATION:

The gauge’s RS-485 communication system is designed as a master/slave

system; that is, each unit responds to its own unique address (node number)

only after it is interrogated by the master (computer). One master and up to 32

slaves can communicate in the system. The units communicate with the master

via a polling system. The master sends a command and only the polled slave

responds. The slave modules can never initiate a communications sequence. A

simple command/response protocol must be strictly observed.

9.2 NODE NUMBER:

The node number is used in the system to identify the desired slave unit being

polled. The node number can be any numeric value from 1 to 99 although

only 32 devices can be served on a single communications port. This number

range (1 to 99) is allowed so that if device grouping by function or application

is desired, it can be implemented using the first digit as the group or engine

number and the second as the unit number. For example, 53 could be used to

identify the number 3 slave unit mounted on engine number 5.

9.3 BAUD RATE:

Baud rates available are 9600, 19200, 38400, 57600, 115200.

9.4 HALF-DUPLEX OPERATION:

The RS-485 system employed uses two wires for communication and cannot

send and receive data at the same time over the same two wires making it a

half-duplex system. When the master is in the transmit mode, the slave is in the

receive mode and vice-versa.

9.5 ELECTRICAL OPERATING RANGE:

RS-485 is a communications standard to satisfy the need for multi-dropped

systems that can operate at high speeds over long distances. RS-485 uses a

balanced dierential pair of wires switching from 0 to 5 volts to communicate

data. RS-485 drivers can handle common mode voltages from -7 to +12

volts without loss of data, making them an excellent choice for industrial

environments.

9.6 COMMUNICATIONS PARAMETERS:

The following must be set by the master to communicate with the slaves:

Baud Rate: 9600 (DEFAULT) others available, see section 10.3

Data Bits: 8

Stop Bits: 1

Parity: None

9.7 COMMUNICATIONS WIRING:

The RS-485 wiring diagram illustrates the wiring required for multiple slave

unit hookup. Note that every slave unit has a direct connection to the master.

This allows any one slave unit to be removed from service without aecting

the operation of the other units. Every unit must be programmed with a unique

address or node number, but the addition of new units or nodes can be in

any order. To minimize unwanted reflections on the transmission line, the bus

should be arranged as a trunk line going from one module to the next. Random

structures of the transmission line should be avoided. Special care must be

taken with long busses (500 feet or more) to ensure error-free operation. Long

busses must be terminated with a 120 ohm resistor between the terminals

marked RS-485 A and RS-485 B at the master only. The use of twisted pair

shielded cable will enhance signal fidelity and is recommended. To prevent

ground loops, the shield should be connected to the shield terminal at the

master only.

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 11

9.8 RX, TX INDICATORS:

RX and TX (receive and transmit) LEDs on the back of the gauge indicate when

the unit is receiving or transmitting data.

9. CONNECTING TO A PC:

When connecting the gauge to the RS-232 port on a PC, an RS-232 to RS-485

converter must be used for the communication interface.

9.10 LOADING:

RS-485 uses a balanced dierential pair of wires switching from 0 to 5 volts to

communicate data. In situations where many units (32 max.) are connected

together on a long run, voltage drop on the communications leads becomes a

major problem. Voltage drops on the RS-485 minus lead appear as a common

mode voltage to the receivers. While the receivers are rated to a maximum

voltage dierence of ±7 volts, -7 V to +12 V, a practical system should not have a

voltage dierence exceeding ±3 volts under normal conditions. The wire gauge

used for the connections, therefore, limits the maximum number of units or

the maximum length of wire between units in each application. The following

formula can be used as a guideline to select the appropriate wire gauge.

For 18 AWG wire No. of units = (4000)/(ft. of wire used)

For 20 AWG wire No. of units = (2500)/(ft. of wire used)

For 22 AWG wire No. of units = (1600)/(ft. of wire used)

10.0 MODBUS REGISTER LISTS

The maximum number of registers that can be read at one time is limited to 32.

The maximum number of booleans that can be read at one time is limited to 256.

All communications are at 9600 baud (default), see section 9.3 for other speeds

8 Data bits, No Parity, 1 Stop bit (9600 8N1).

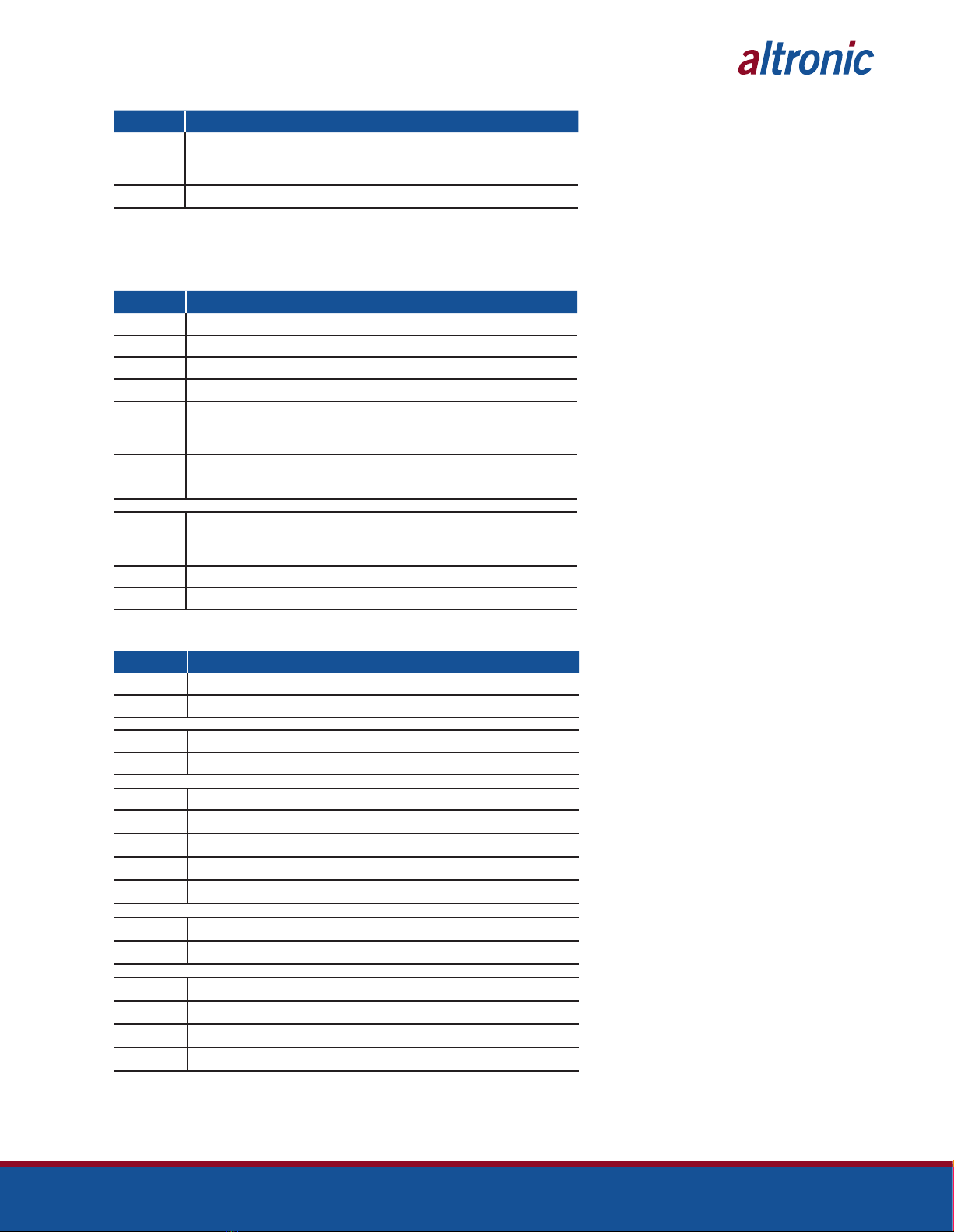

10.1 00000 SERIES REGISTERS

ADDRESS DESCRIPTION OF FUNCTION

00001 PROTECT CONFIGURATION 0=OFF 1=ON

Protect configuration from being changed by keypad

00002 PROTECT SETPOINT 0=OFF 1=ON

Protect setpoints from being changed by keypad

00003 PROTECT COMMUNICATIONS 0=OFF 1=ON

Protect against ModBus writes

00004 PROTECT CALIBRATION 0=OFF 1=ON

Protect against changing calibration values

00005 DISPLAY LOOP 0=OFF 1=ON

Display loop value on home screen

00006 RESET MIN/MAx 1=RESET

Reset MIN/MAx readings

00008

00016

RESERVED

00017 SWITCH 1 RESET 1=RESET

00018 SWITCH 1 STATE 0=SHELF 1=FAILSAFE

00019 SWITCH 1 TYPE 0=NON-LATCH 1=LATCHING

00020

00024

RESERVED

00025 SWITCH 2 RESET 1=RESET

00026 SWITCH 2 STATE 0=SHELF 1=FAILSAFE

00027 SWITCH 2 TYPE 0=NON-LATCH 1=LATCHING

NOTE: The maximum number of units

connected in a system is 32.

NOTE: All temperatures are stated

in 0.1 DEG. Kelvin (for universal

compatibility). Therefore a register

value of 2730 is 273.0° K, which is 0°

C, or 32° F.

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 12

ADDRESS DESCRIPTION OF FUNCTION

00028

00047

RESERVED

00048 Config Override – Allow ModBus to override Channel Configuration

10.2 10000 SERIES REGISTERS

The node number is the address of the controller being contacted. This number

is programmed by the terminal program and can be viewed or edited in the menu

screen. A two digit number from 01 to 99 can be used.

ADDRESS DESCRIPTION OF FUNCTION

10001 CHANNEL 1 signal OK 1=OK

10002 LOOOR – Channel signal low out of range 1=LOOR

10003 HIOOR – Channel signal hi out of range 1=HOOR

10004 TCOPEN – Channel thermocouple open 1=TCOPEN

10005

10016

RESERVED

10017 SWITCH 1 FAULT HI

10018 CHANNEL 2 signal hi out of range 1=HOOR

10020

10024

RESERVED

10025 SWITCH 2 FAULT HI

10026 SWITCH 2 FAULT LO

10.3 30000 SERIES REGISTERS

ADDRESS DESCRIPTION OF FUNCTION

30001 CHANNEL STATUS – same as 10001–10016

30002 SWITCH STATUS – same as 10017–10032

30004 Analog Value (float msw)

30005 Analog Value (float lsw)

30010 Ambient Temp. DEGK (float msw)

30011 Ambient Temp. DEGK (float lsw)

30012 Current Loop (4-20ma,400=4mA, 2000=20mA)

30013 SWITCH 1 Hi Hysteresis Timer (0.1 increments)

30014 SWITCH 1 Lo Hysteresis Timer (0.1 increments)

30016 SWITCH 2 Hi Hysteresis Timer (0.1 increments)

30017 SWITCH 2 Lo Hysteresis Timer (0.1 increments)

30019 CHANNEL 1 MAX (float) (msw)

30020 CHANNEL 1 MAX (float) (lsw)

30021 CHANNEL 1 MIN (float) (msw)

30022 CHANNEL 1 MIN (float) (lsw)

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 13

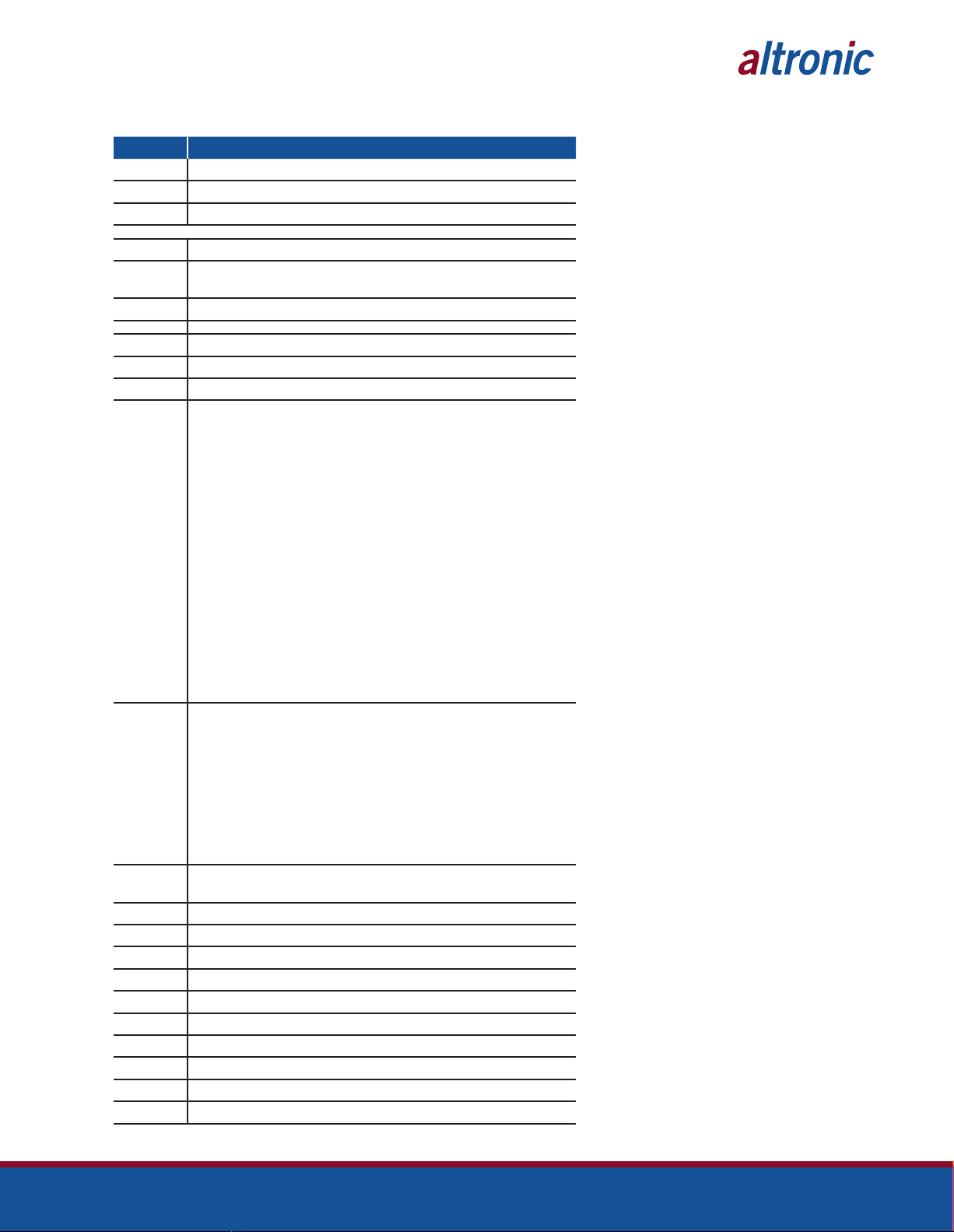

10.4 40000 SERIES REGISTERS

ADDRESS DESCRIPTION OF FUNCTION

40001 Coils 001-016

40002 Coils 017-032

40003 Coils 033-048

40005 Node Number 1-99

40006 Baud rate Index

0=9.6k 1=19.2k 2=38.4k 3=57.6k 4=115.2k

40007 Security Password 000-999

40009 RESERVED

40010 RESERVED

40011 Lag Filter Gain (1-255)

40012 SENSOR TYPE

CUSTOM

0=Custom

PRESSURE SENSORS

256=15psi 257=25psi 258=50psi 259=100psi

260=300psi 261=500psi 262=1000psi 263=2000psi

264=5000psI 265=10000psi 266=Custom Pressure

TEMPERATURE SENSORS

512=JTC 513=KTC 514=DEG1 515=DEG2

516=Custom Temperature

VIBRATION SENSORS

Velocity 768=1ips 769=2ips 770=Custom Velocity

Acceleration 1024=10g 1025=20g 1026=50g

1027=Custom Acceleration

PERCENT

1280=0–100% (0-55Vdc) 1281=Custom Percent

VOLTAGE

1536=0-5Vdc 1537=±160mVdc 1538=±80mVdc

1539=Custom Voltage

40013 Units Index (class specific)

PRESSURE SENSORS

0=psi 1=psig 2=psia 3=Kpa 4=bar 5=mbar

6=inH2O@20C 7=inHg 8=mmH2O 9=mmHg

10=kg/cm2 11=torr

TEMPERATURE SENSORS

0=Kelvin 1=Celsius 2=Fahrenheit

VIBRATION SENSORS

Velocity 0=in/s 1=mm/s 2=cm/s

Acceleration 0=G 1=ft/s/s 2=m/s/s

40014 A/D Voltage Range

0=5V 1=±160mV 2=±80mV

40015 SENSOR MAX (float) (msw)

40016 SENSOR MAX (float) (lsw)

40017 SENSOR MIN (float) (msw)

40018 SENSOR MIN (float) (lsw)

40019 Range HI (float) (msw)

40020 Range HI (float) (lsw)

40021 Volt HI (float) (msw)

40022 Volt HI (float) (lsw)

40023 Range LO (float) (msw)

40024 Range LO (float) (lsw)

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 14

ADDRESS DESCRIPTION OF FUNCTION

40025 Volt LO (float) (msw)

40026 Volt LO (float) (lsw)

40027 Zero Band (float) (msw)

40028 Zero Band (float) (lsw)

40029 Custom Decimal Place (0-4)

40030 Label Index 0=NONE 1=CUSTOM

40031 Custom Label (char. 1:2)

40032 Custom Label (char. 3:4)

40033 Custom Label (char. 5:6)

40034 Custom Label (char. 7:8)

40035 Custom Label(char. 9:10)

40036 Custom Label (char. 11:12)

40037 Custom Label (char. 13:14)

40038 Custom Label (char. 15:16)

40039 Custom Unit Label Index 0=NONE 1=CUSTOM

40040 Custom Unit Label (char. 1:2)

40041 Custom Unit Label (char. 3:4)

40042 Custom Unit Label (char. 5:–)

40043 CHANNEL 1 Bargraph type

0=O

1=Single bar between low and high

2=Increasing bars between low and high

3=Single bar between setpoints for switch 1

4=Increasing bars between setpoints for switch 1

5=Single bar between setpoints for switch 2

6=Increasing bars between setpoints for switch 2

40044 Bargraph Hi (float) (msw)

40045 Bargraph Hi (float) (lsw)

40046 Bargraph Lo (float) (msw)

40047 Bargraph Lo (float) (lsw)

40048

40054

RESERVED

40092

40098

40099 SWITCH 1 Setpoint Type

0=O

1=High On

2=Low On

3=High and Low On

40100 SWITCH 1 Hysteresis Time 1-99s

40101 SWITCH 1 Setpoint Hi (float) (msw)

40102 SWITCH 1 Setpoint Hi (float) (lsw)

40103 SWITCH 1 Setpoint Lo (float) (msw)

40104 SWITCH 1 Setpoint Lo (float) (lsw)

40105 SWITCH 1 Setpoint Dierential (float) (msw)

40106 SWITCH 1 Setpoint Dierential (float) (lsw)

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 15

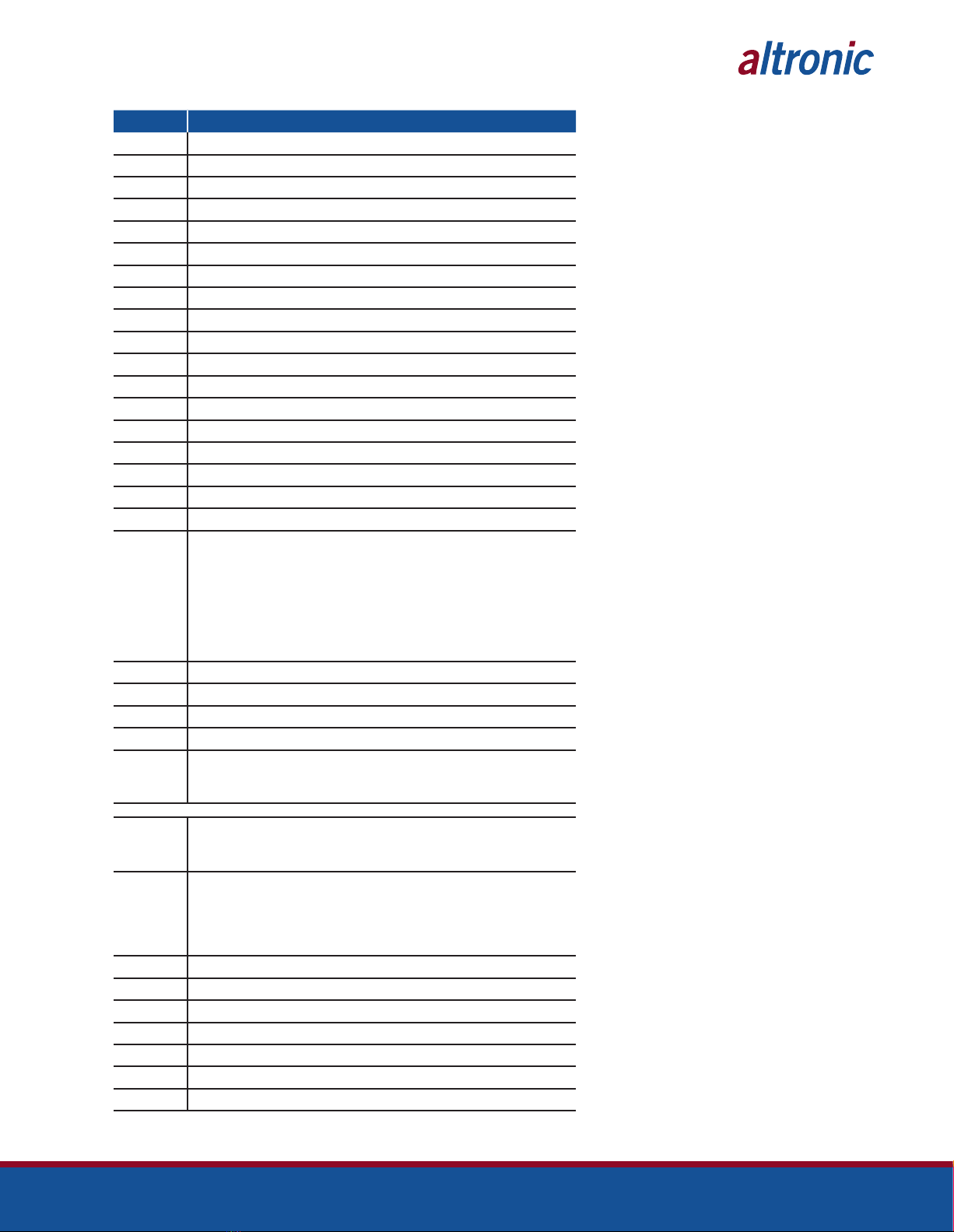

ADDRESS DESCRIPTION OF FUNCTION

40099 SWITCH 2 Setpoint Type

0=O

1=High On

2=Low On

3=High and Low On

40108 SWITCH 2 Hysteresis Time 1-99s

40109 SWITCH 2 Setpoint Hi (float) (msw)

40110 SWITCH 2 Setpoint Hi (float) (lsw)

40111 SWITCH 2 Setpoint Lo (float) (msw)

40112 SWITCH 2 Setpoint Lo (float) (lsw)

40113 SWITCH 2 Setpoint Dierential (float) (msw)

40114 SWITCH 2 Setpoint Dierential (float) (lsw)

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 16

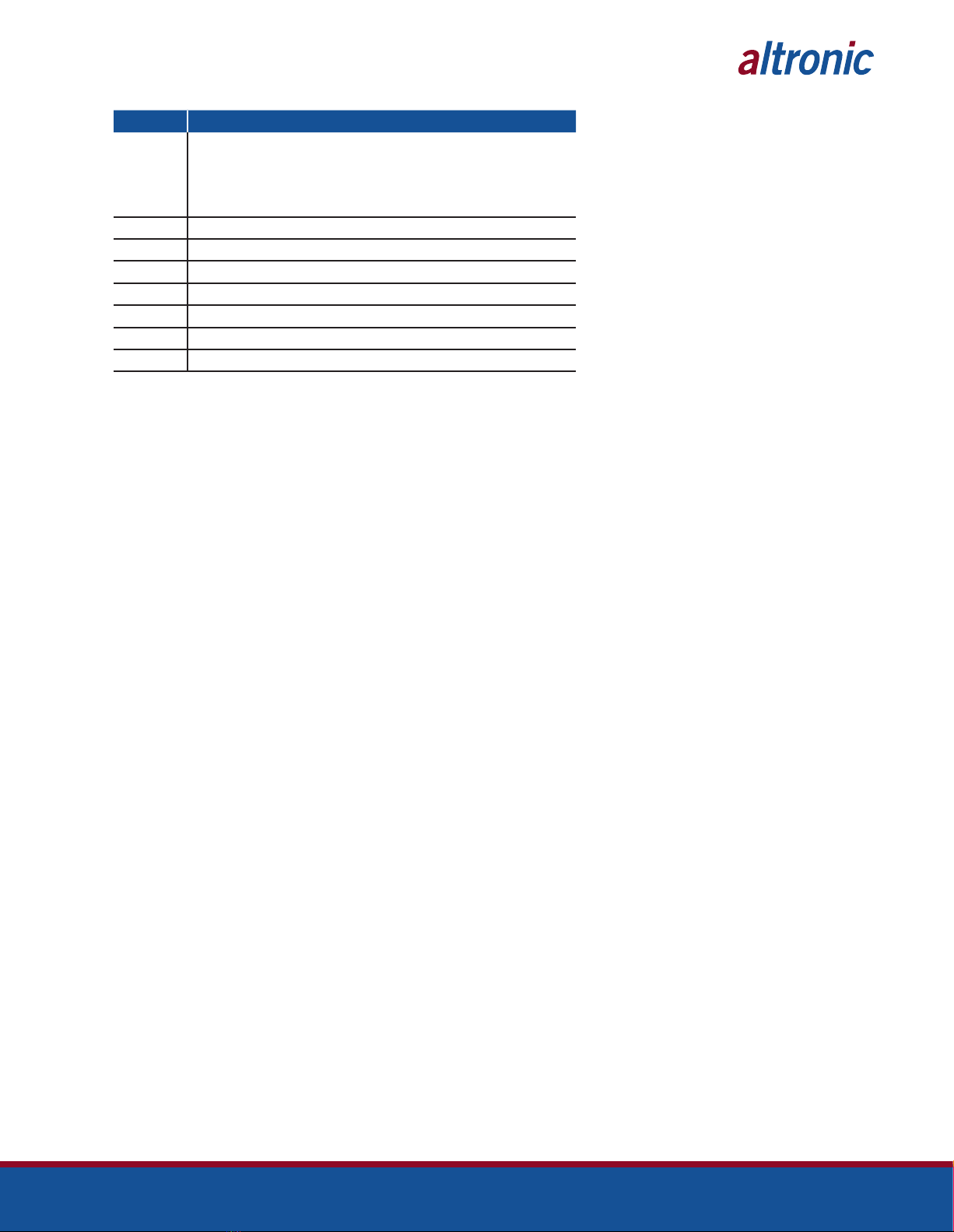

FIG. 1 MOUNTING DIMENSIONS

13.21

335.5

11.34

287.9

12.05

306

13.34

338.9

4.28

108.8

4.28

108.8

3.90

99.1

7.28

185

8.30

210.8

.24

6.2

2.76

70

.88 22.2

THRU

1.06 26.9

THRU

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 17

FIG. 2 WIRING DIAGRAM, CUSTOMER CONNECTIONS

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 18

FIG. 3 FLOW CHART

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 19

FIG. 4 CDM−2100 SYSTEM DIAGRAM

CDM-2100 OM 3-21

All rights reserved © ALTRONIC, LLC 2021 20

FIG. 5 RS−485 COMMUNICATIONS: PC HOOK−UP

FIG. 6 RS−485 COMMUNICATIONS: MULTIPLE SLAVE UNITS

Table of contents

Other Altronic Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

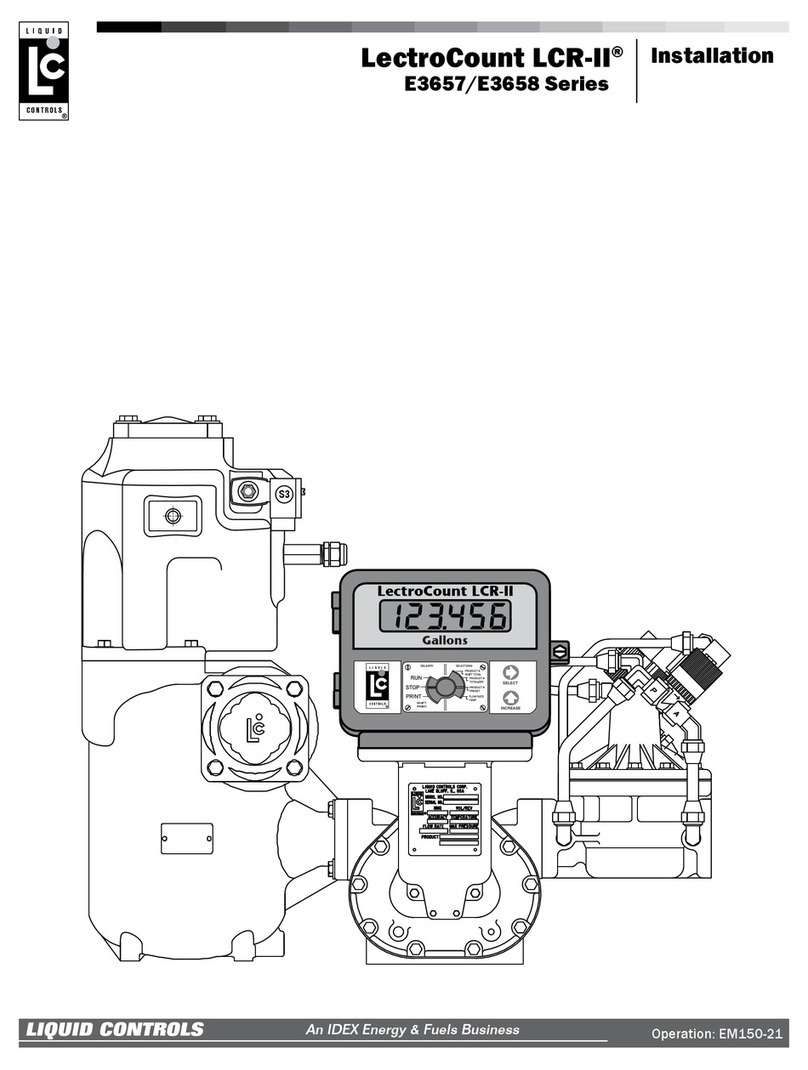

Liquid Controls

Liquid Controls LectroCount LCR-II E3657 Series Installation

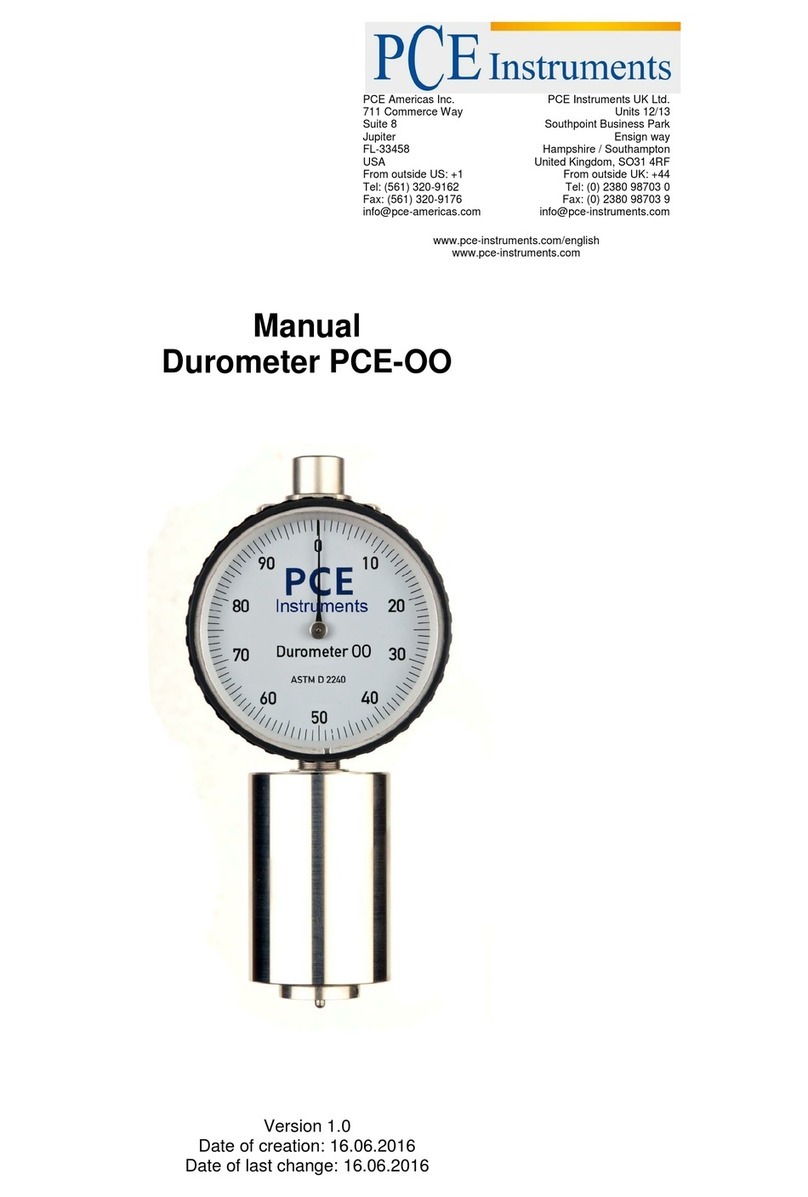

PCE Instruments

PCE Instruments PCE-OO user manual

Panasonic

Panasonic LH2H preset quick start guide

barfield

barfield CT12A instruction manual

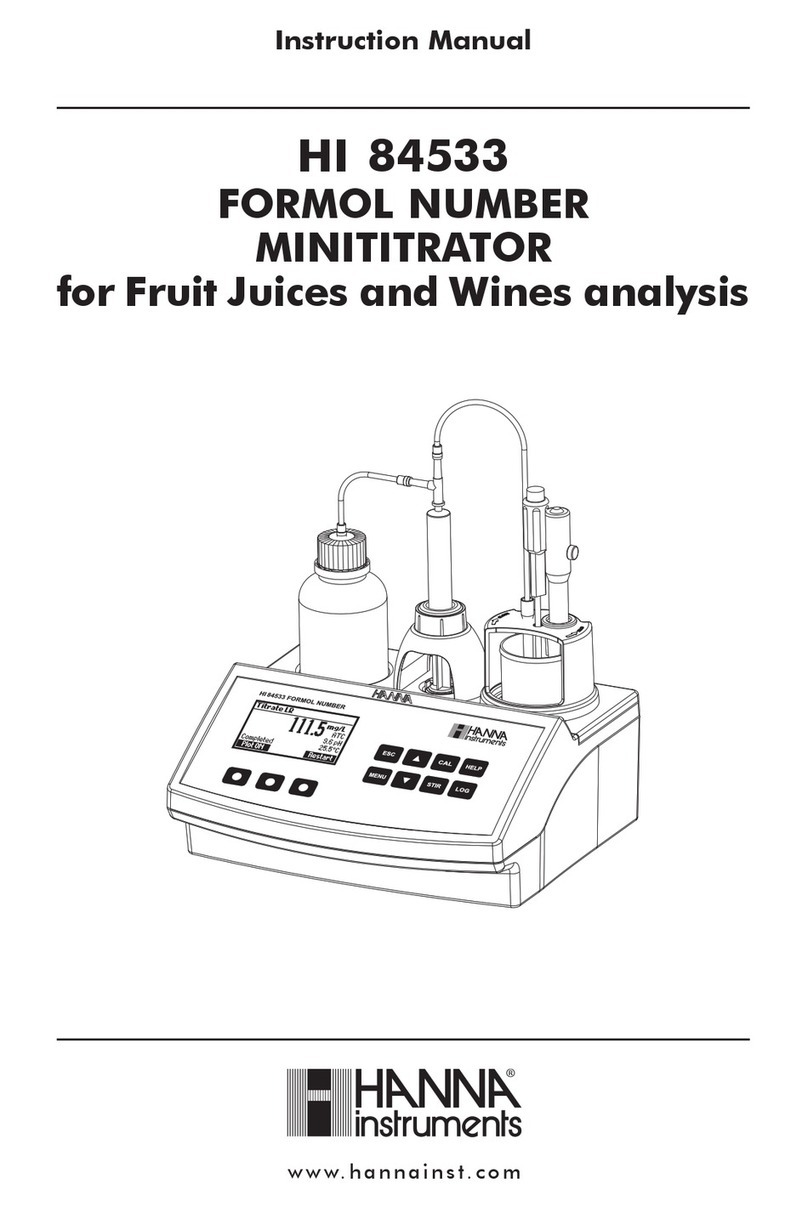

Hanna Instruments

Hanna Instruments HI 84533 instruction manual

Pulsar

Pulsar 22 user manual