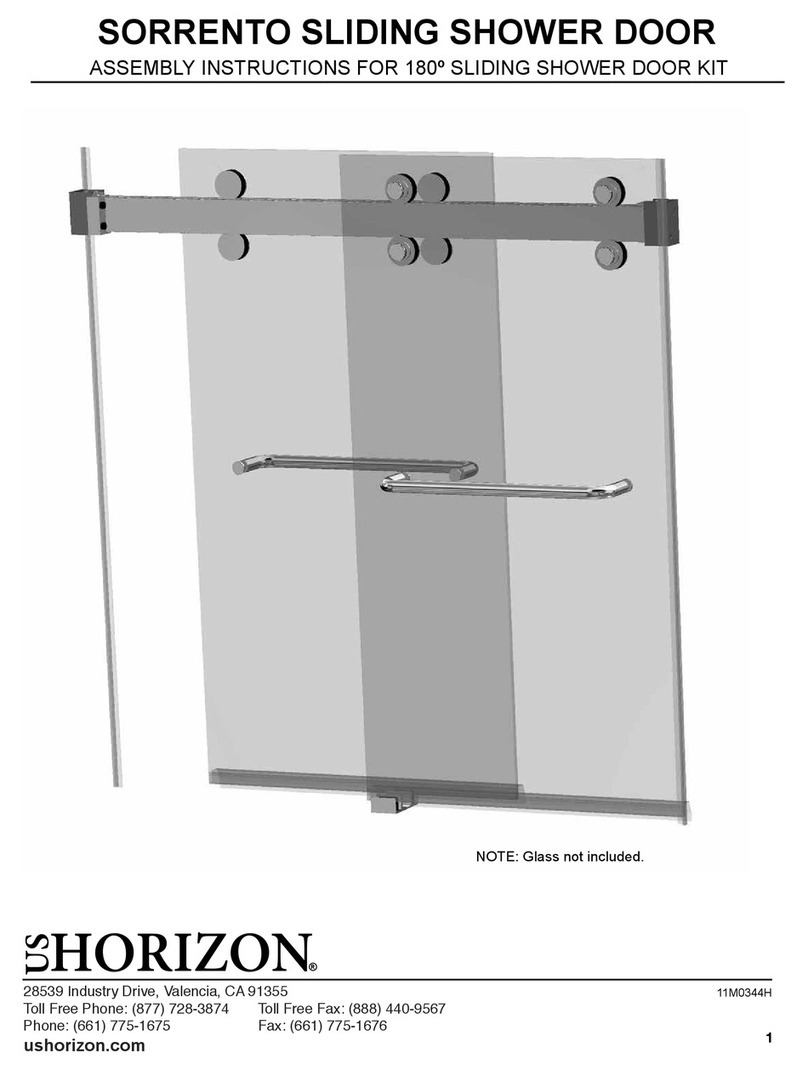

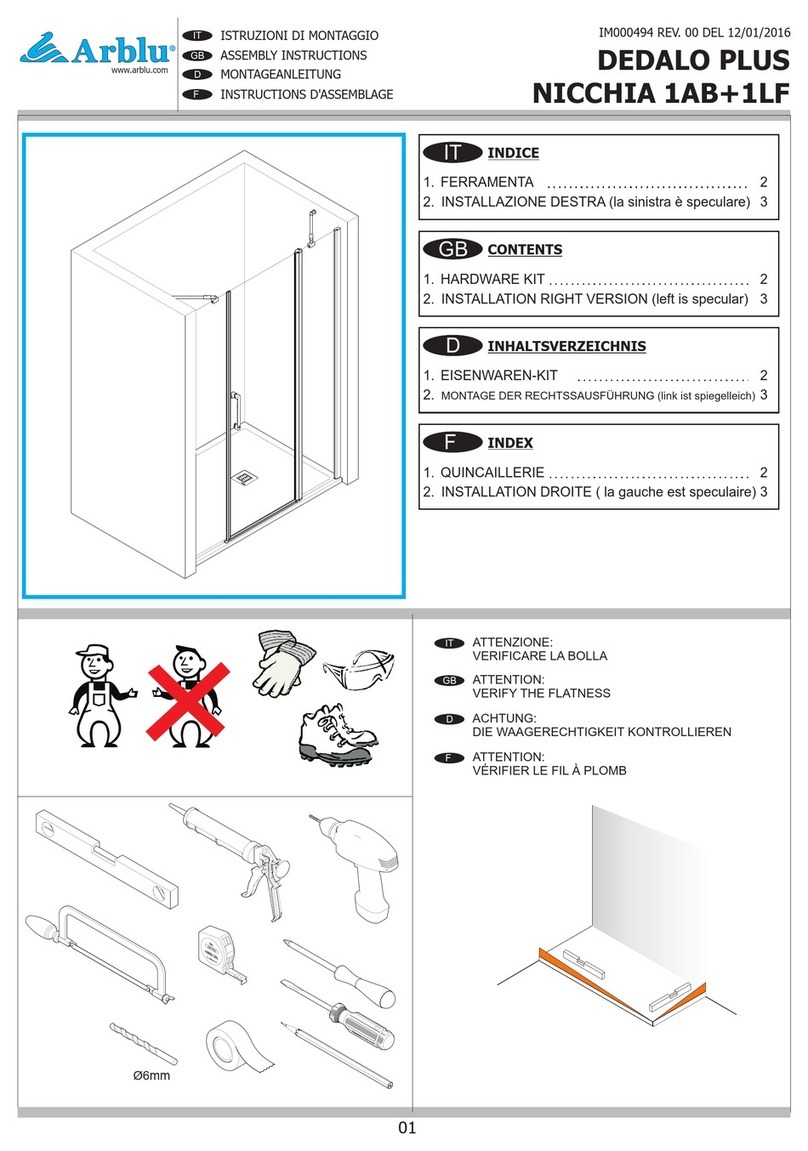

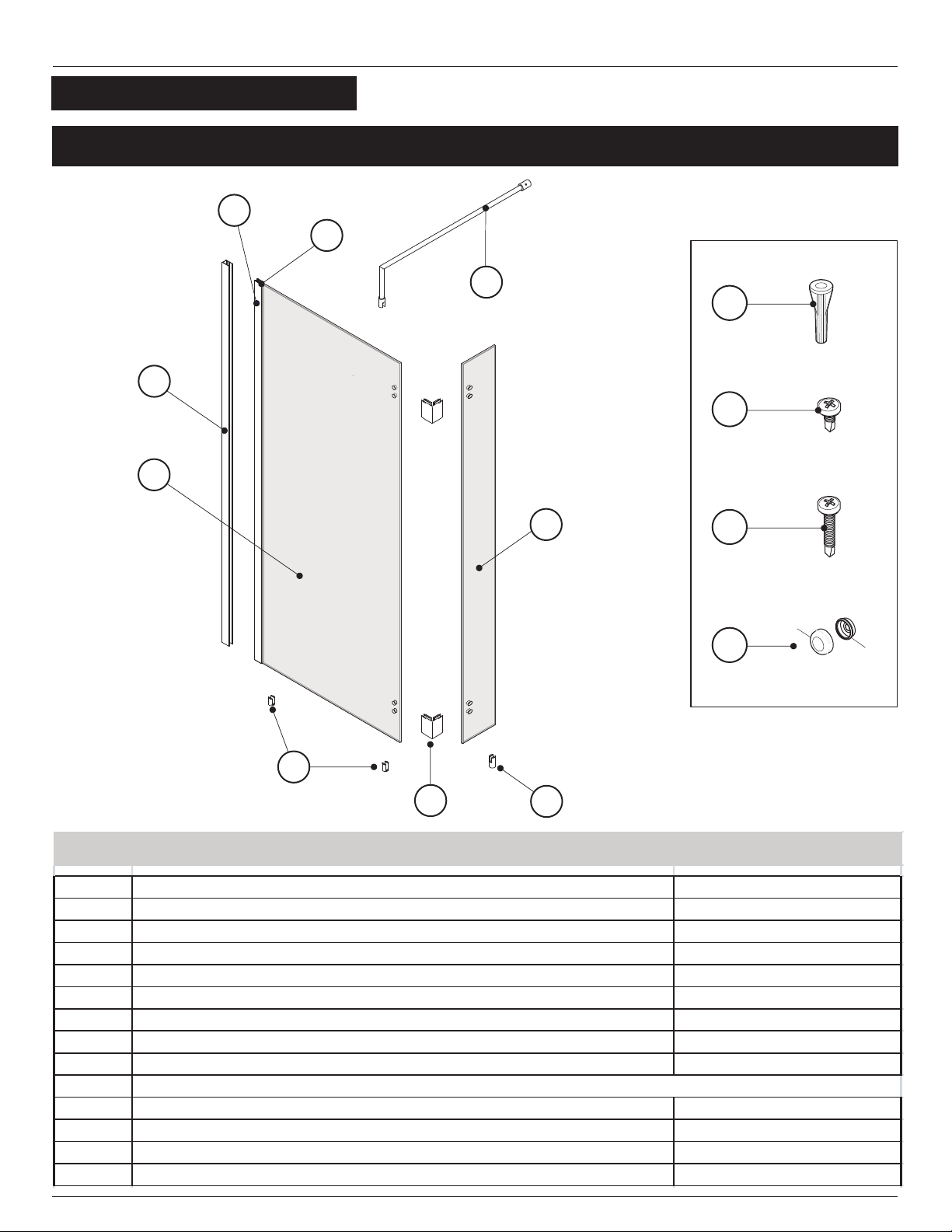

INSTRUCTION MANUAL

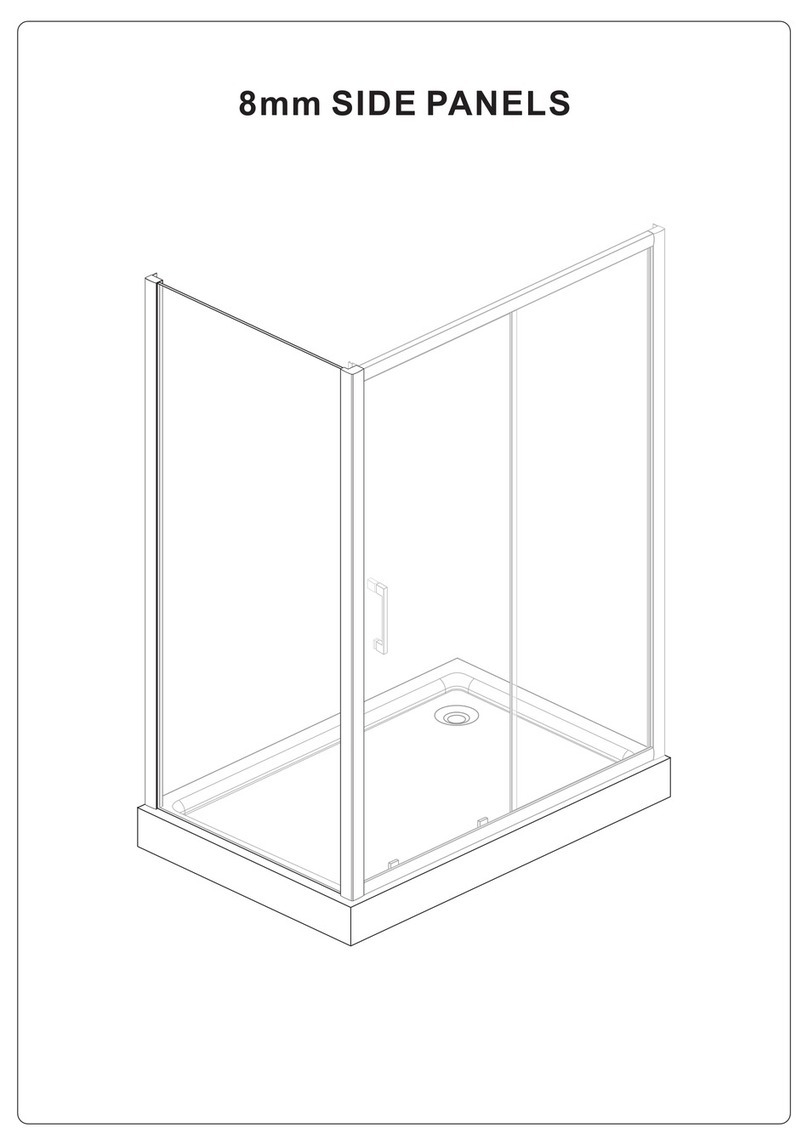

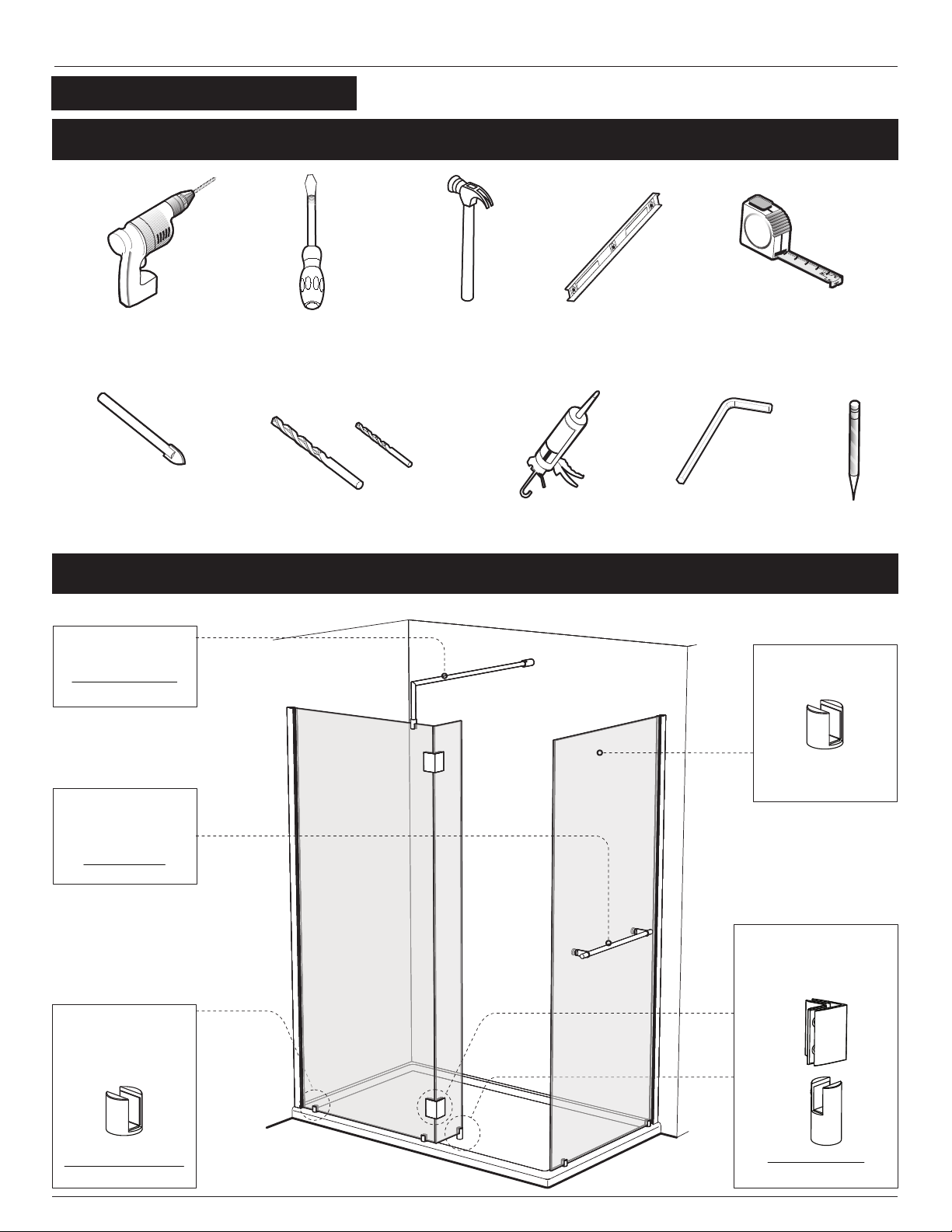

1RETURN PANEL INSTALLATION

1a. Using a measuring tape, mark the

center of the threshold of the base.

1b. Using the marking established in the

previous step, run a second line up the

wall. Use a level to ensure verticality of

this line.

1c. Place the wall jamb (1) onto the wall

while ensuring that the wall jamb holes

align themselves onto the line running

up the wall. Moreover , the side holes of

the wall jamb should face the interior of

the shower . Proceed to drilling, using a

1/8½drill bit, through the wall using the

wall jamb holes as a reference.

1d. Insert a drop of silicone into each hole

made in the previous step. Following

that, insert an orange wall plug (10.1)

into each hole and from there the wall

jamb can be repositioned and

permanently fastened using #8-1 1/4

Self drilling screws (10.3).

1a

1b

1d

1

1

10.1

10.3

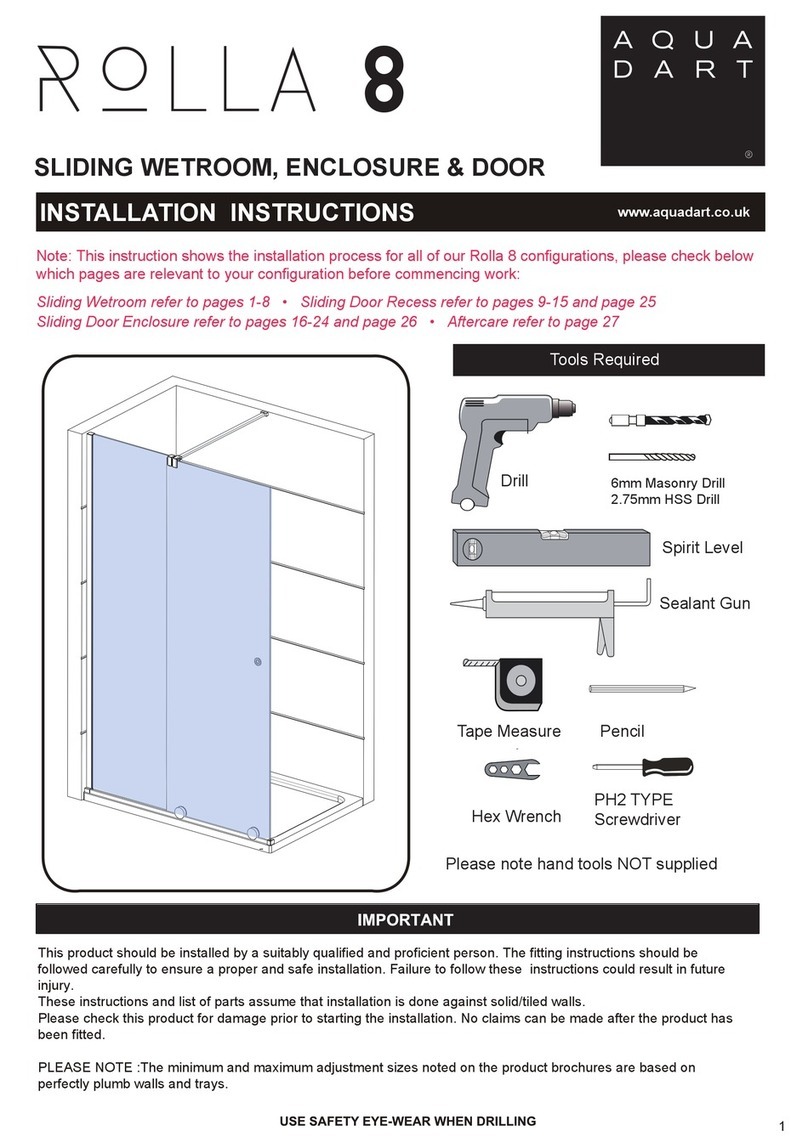

THIS INSTALLATION PROCEDURE APPLIES FOR

ALL RETURN PANELS INSTALLATION

REGARDLESS QUANTITY OR ADITTIONAL

FIXTURE AS TOWEL BAR.

7

1c

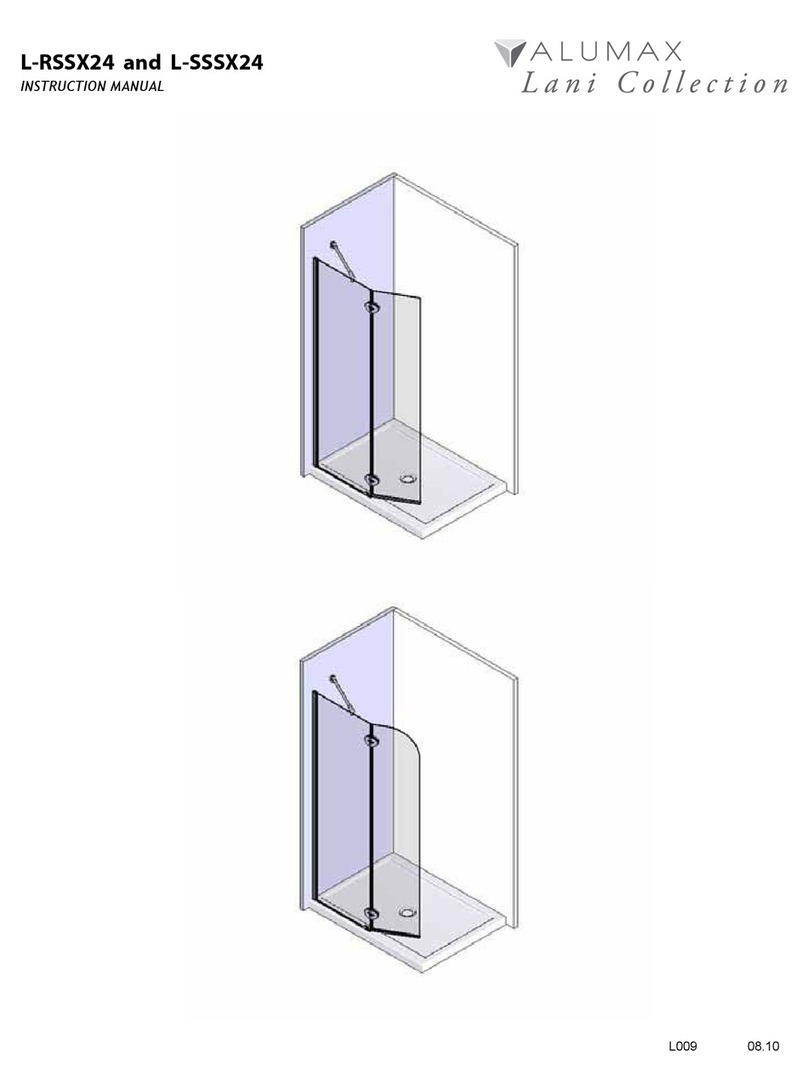

FRONT PANEL

203X, 313X, 313TBX

INSTALLATION