Supervisor 5000 Installation Instructions

Contents. ......................................................................................................................................................................... 2

ETL Certication. ............................................................................................................................................................. 2

Safety Precautions. ......................................................................................................................................................... 3

Safety Icons..................................................................................................................................................................... 3

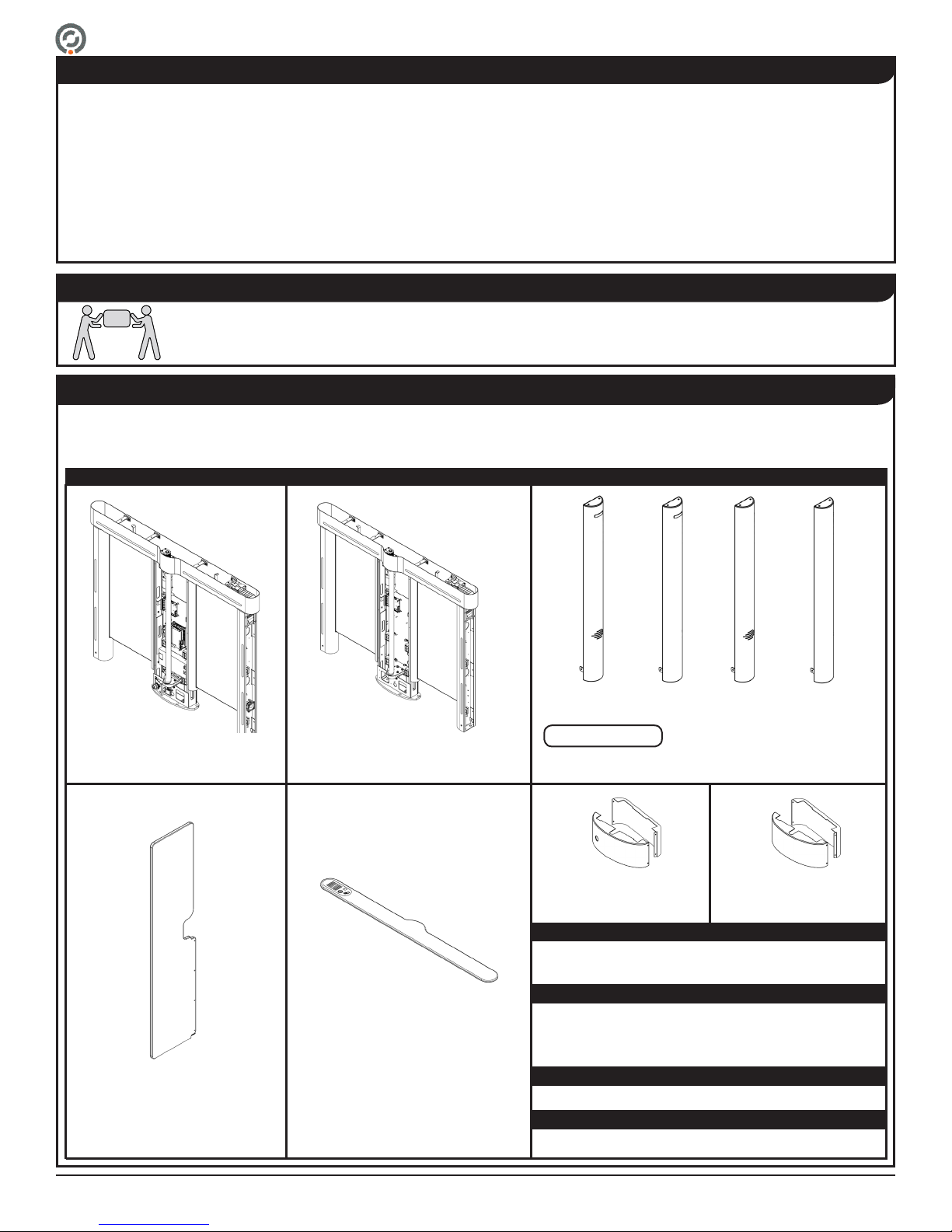

Installation Tools. ............................................................................................................................................................. 4

Uncrating. ........................................................................................................................................................................ 4

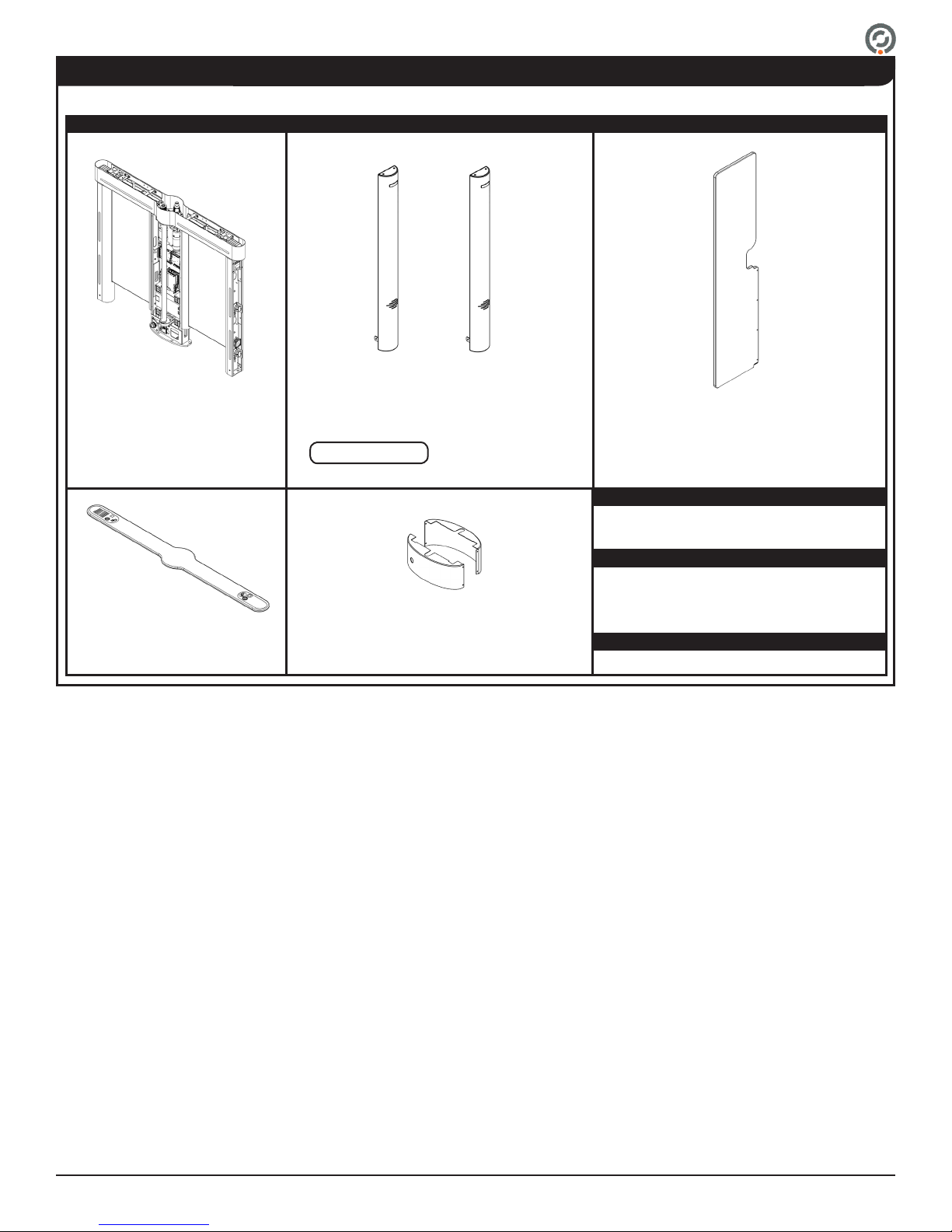

Parts List.......................................................................................................................................................................... 4

Introduction...................................................................................................................................................................... 6

Before You Begin............................................................................................................................................................. 8

Slab Requirements. .................................................................................................................................................. 8

Space Requirements. ............................................................................................................................................... 8

Conduit Requirements. ............................................................................................................................................. 9

Electrical Requirements. ........................................................................................................................................... 9

Environmental Requirements.................................................................................................................................... 9

Communication Requirements................................................................................................................................ 10

Internal Card Reader Installation Requirements (Optional). ................................................................................... 10

Barcode Reader Requirements (Optional).............................................................................................................. 10

User Training........................................................................................................................................................... 10

Pre-Installation Checklist. ....................................................................................................................................... 10

Pre-Installation Instructions. ...........................................................................................................................................11

Cabinet Panel Removal. ..........................................................................................................................................11

QA Checkpoint Shim Removal.................................................................................................................................11

Baseplate Installation (Optional). ............................................................................................................................ 12

Installation Instructions.................................................................................................................................................. 13

Anchoring the Turnstile. .......................................................................................................................................... 13

End Cover Installation............................................................................................................................................. 14

Internal Card Reader Installation. ........................................................................................................................... 15

Wiring Instructions......................................................................................................................................................... 16

Primary Power......................................................................................................................................................... 16

Crossover Cable Connection. ................................................................................................................................. 16

I/O Control Board (13-0328 Rev. F). ....................................................................................................................... 17

Conguring Passage Modes. ........................................................................................................................................ 19

Ethernet Communication (Optional). ............................................................................................................................. 21

Barrier Installation.......................................................................................................................................................... 21

Post-Installation Functions Check. ................................................................................................................................ 23

Finish the Installation..................................................................................................................................................... 28

Cabinet Lid Installation............................................................................................................................................ 28

Cabinet Panel Installation. ...................................................................................................................................... 29

Base Cover Installation. .......................................................................................................................................... 29

Post-Installation Checklist. ............................................................................................................................................ 30

Troubleshooting............................................................................................................................................................. 31

Appendix A - Setting the Home Position........................................................................................................................ 32

Appendix B - 36" Single Lane - Plan, Elevation & Footprint Drawing............................................................................ 33

Appendix C - 28" & 36" Baseplate Dimensions. ............................................................................................................ 34

Appendix D - External DC Power Supply Installation (Optional). .................................................................................. 35

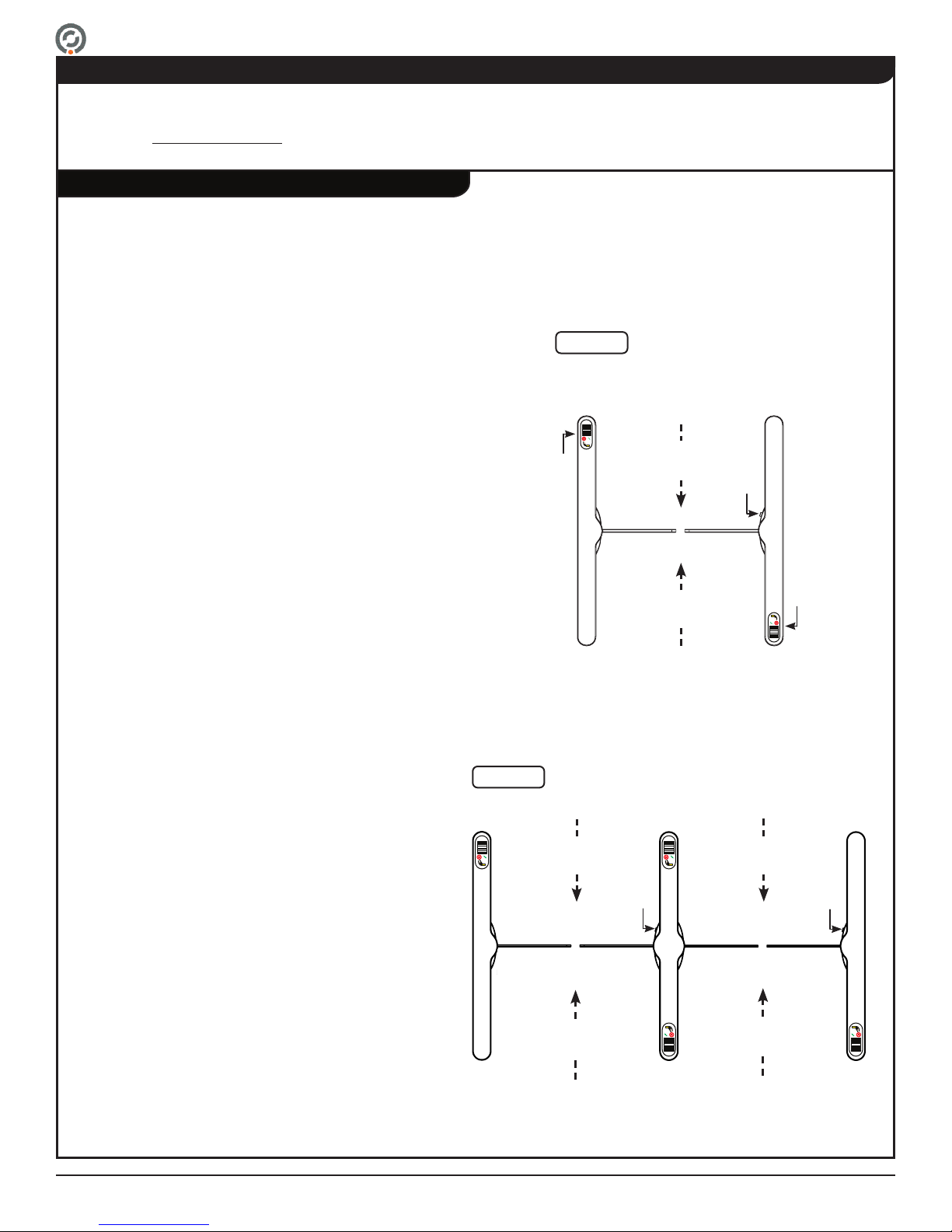

Appendix E - Multi-Lane Conduit Requirements. .......................................................................................................... 40

Appendix F - Crossover Cable Connection Diagrams................................................................................................... 41

Revision History............................................................................................................................................................. 42

Contents

This product is fully certied by a nationally recognized testing laboratory to UL 2593 and

CSA C22.2 #247. Unauthorized modication to this product in any way is prohibited.

ETL Certication