Operating Instructions WFG-xx

Table of Contents

961-01244 rev9 3/14

Table of Contents

1 General Information ...........................................................................................................4

2 Technical Description ........................................................................................................5

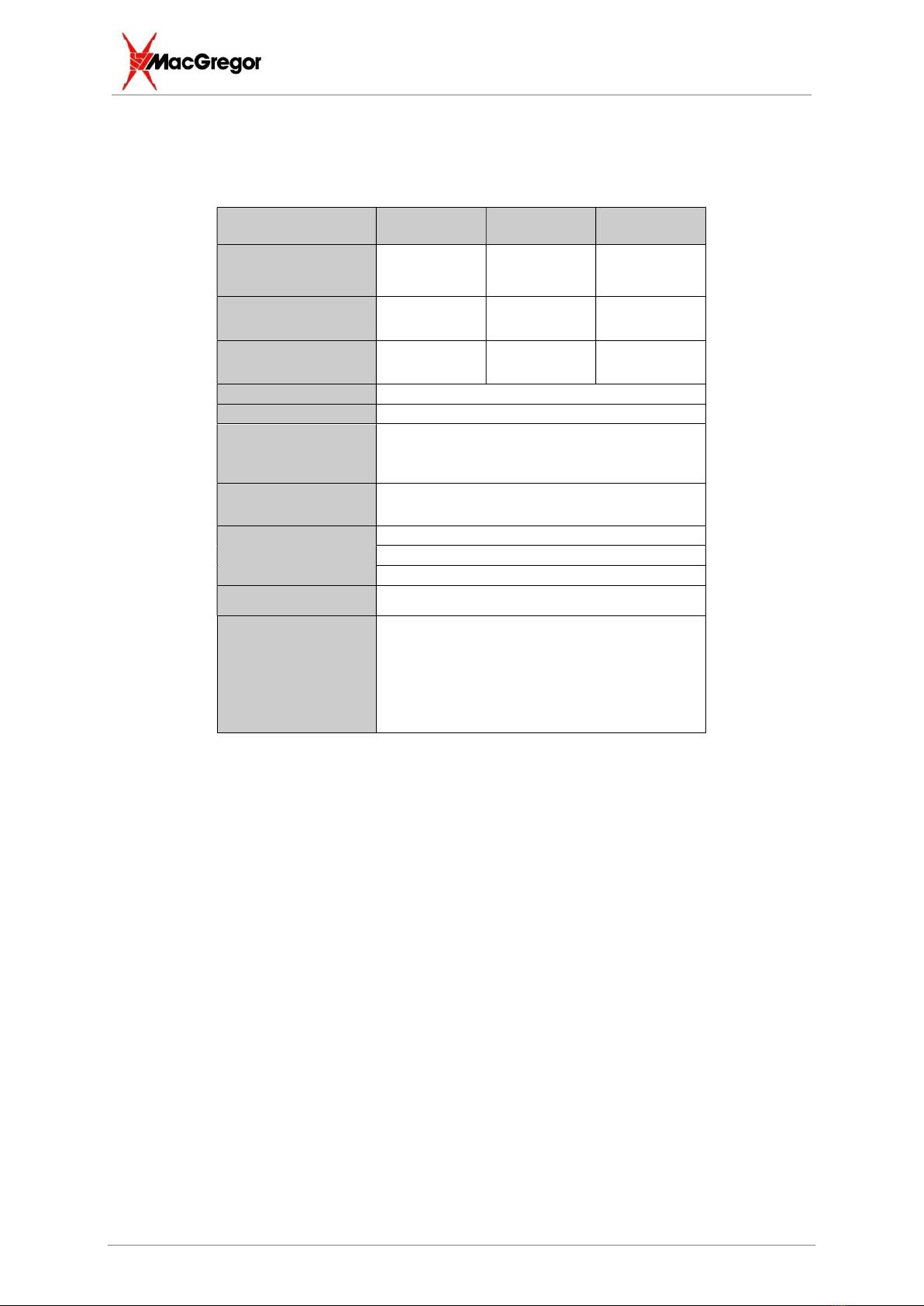

2.1 Technical Specification .....................................................................................................5

2.2 Introduction ........................................................................................................................6

3 Quick Start Guide ...............................................................................................................7

4 Storage ................................................................................................................................7

5 Wiring Information .............................................................................................................8

6 Battery Replacement .........................................................................................................9

7 Handling ..............................................................................................................................9

8 Manual Tare ........................................................................................................................9

9 System Description ........................................................................................................ 10

9.1 4 Digit LCD Display ......................................................................................................... 10

9.2 UNITS LED’s (Red) .......................................................................................................... 10

9.3 HOLD LED (Red).............................................................................................................. 10

9.4 FUNCTION BUTTONS ..................................................................................................... 10

9.4.1 UNITS ............................................................................................................................... 10

9.4.2 SET (POWER ON) ............................................................................................................ 10

9.4.2.1 To View Limits ................................................................................................................... 11

9.4.2.2 To Chamge the Set Point .................................................................................................. 11

9.4.2.3 To Change the Percentage ............................................................................................... 11

9.4.2.4 To Toggle Peak Hold Mode .............................................................................................. 11

9.4.3 HOLD ................................................................................................................................ 11

10 RS232 Data Link (Optional) ............................................................................................ 12

11 Analogue Output (Optional) ........................................................................................... 13

12 Index ................................................................................................................................. 14

12.1 Headword Index .............................................................................................................. 14