2

Contents

ModelIdentification .................................................2

Asure™ExtendedServicePlan ..............................2

ImportantSafetyInformation.......................................3

ALLAPPLIANCES..................................................4

SELF-CLEANINGOVEN.........................................4

SURFACECOOKINGUNITS ..................................4

OVEN .....................................................................4

VENTILATIONHOOD ..............................................4

InCaseofFire ........................................................5

Precautions ............................................................5

Installation..................................................................5

Packing Material .....................................................5

RangeLocation .......................................................5

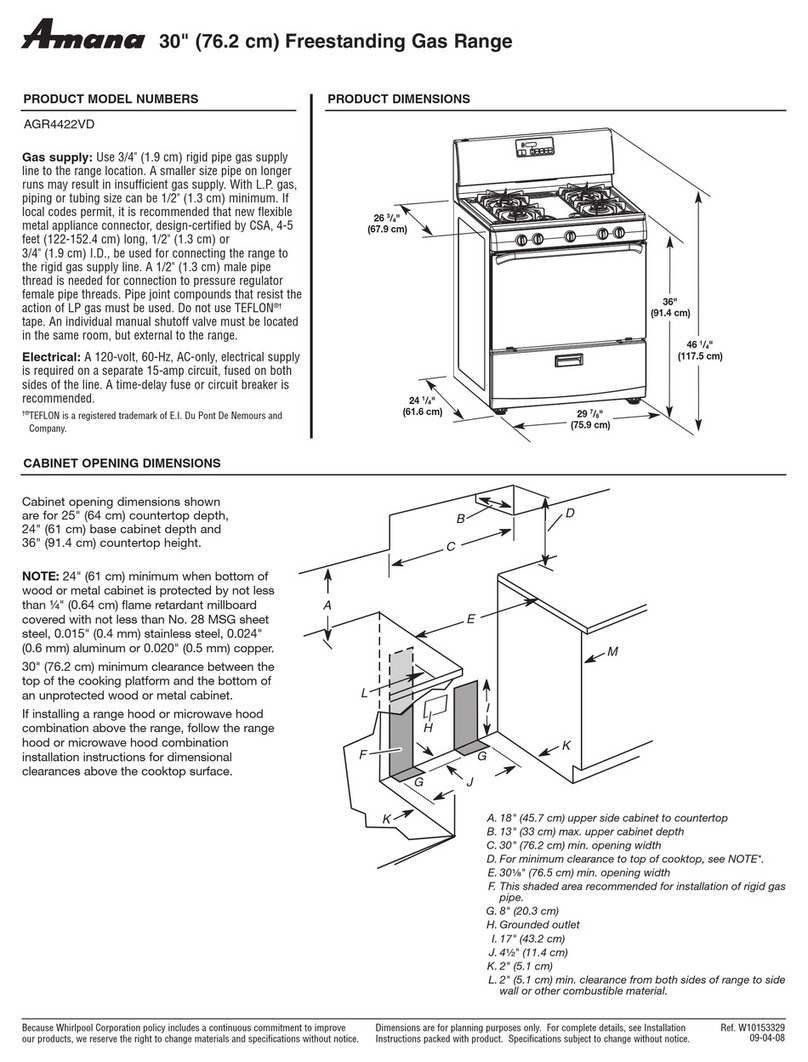

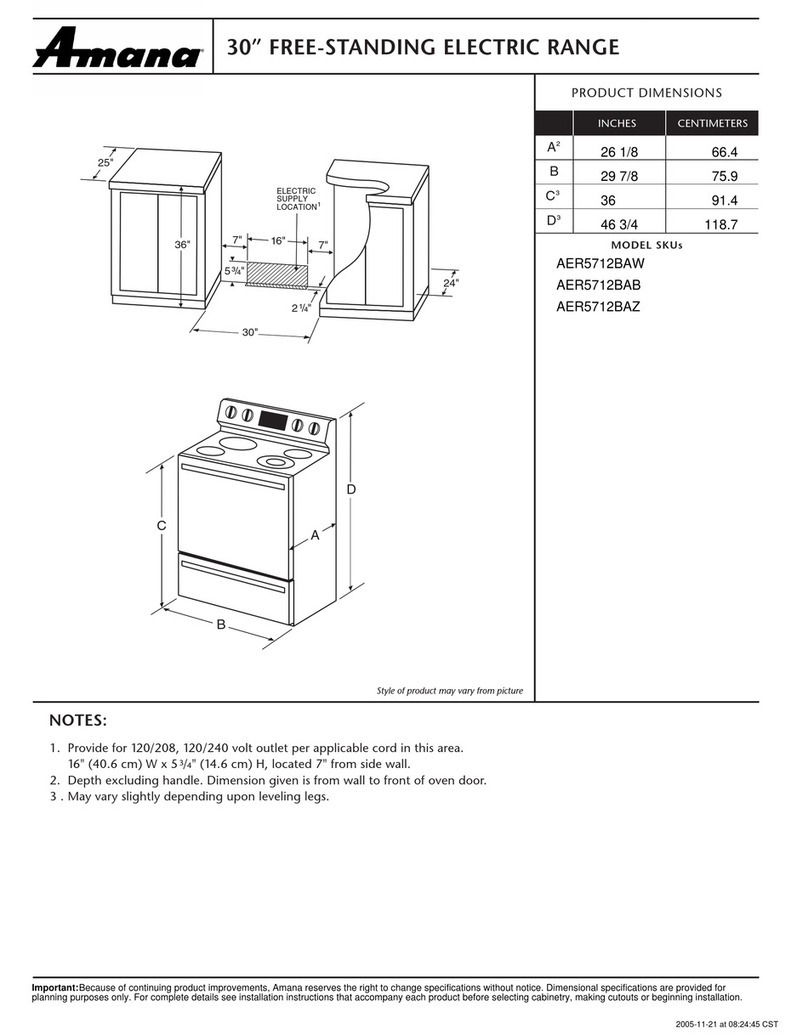

MinimumClearancestoCombustibleSurfaces .......6

StandardCabinet and CounterTop

Heightand Depth ....................................................6

CounterTopOpening...............................................6

BackguardKit .........................................................7

CounterTop Front Edge ..........................................7

IrregularCabinet and CounterTopHeights...............7

ElectricalConnectionRequirements .......................8

ElectricalConnectionClearance .............................8

GasConnection Requirements................................8

GasSupplyLocation...............................................8

ConvertingforUse with NaturalGas

orPropaneGas.......................................................9

GasSupplyPressure..............................................12

GasConnection ......................................................12

PressureRegulatorLocation ...................................13

TestingforGasLeaks .............................................13

SealOpenings ........................................................13

Anti-tipBracket Installation .....................................14

LevelRange ............................................................14

Removaland ReplacementofRange .......................14

PlacingBurnerCaps ...............................................15

AdjustingSurfaceBurnerFlame..............................15

AdjustingSurfaceBurnerLowFlameSize ..............16

AdjustingOven Burner Flame..................................16

BroilerFlame ..........................................................16

Operation

OperatingSurface Burners ......................................17

OperatingSurfaceBurner during aPowerFailure ....17

OvenLight...............................................................17

ElectronicOven Control

ElectronicOvenControlPads .................................18

OvenSignals...........................................................18

SafetyFeatures ......................................................18

QuickReferenceInstructions ..................................19

Baking ....................................................................19

TimedBaking..........................................................20

DelayedBaking.......................................................20

Broiling ...................................................................21

Self-Cleaning...........................................................21

DelayedSelf-Cleaning .............................................22

Child Lock Out ........................................................22

CookingGuide

Utensils ..................................................................23

OvenRackPlacement ............................................23

PanPlacement .......................................................23

BakingGuide ..........................................................24

BroilingGuide .........................................................24

PoultryRoastingGuide ...........................................25

BeefandPorkRoastingGuide ................................25

CareandCleaning

Cleaning..................................................................26

RemovingOvenDoor ...............................................27

ReplacingOven Light Bulb ......................................27

RemovingStorageDrawer .......................................28

ReplacingBurner Caps ...........................................28

ReplacingDripPans ...............................................28

BeforeCalling forService

AdjustingOvenTemperature....................................29

CommonQuestions ................................................29

ServiceTonesandCodes........................................29

Warranty ....................................................................30

Model Identification

Completeenclosedregistrationcardandpromptlyreturn.

If registration card is missing, call Consumer Affairs

Departmentat1-800-843-0304 inside U.S.A.

319-622-5511outsideU.S.A.WhencontactingAmana,

provideproduct information. Find productinformationon

ratinglabellocatedon oven frame behind front of storage

drawer. French translation islocatedonoutside right edge

ofstoragedrawer.Recordthe following:

ModelNumber: ______________________________

ManufacturingNumber: ________________________

SerialorS/NNumber: _________________________

Dateofpurchase:_____________________________

Dealer’snameandaddress: ____________________

__________________________________________

__________________________________________

Keepacopy of sales receipt for futurereferenceor in

case warranty service is required. Any questions or to

locateanauthorized servicer,call 1-800-NAT-LSVC

(1-800-628-5782)inside U.S.A. 319-622-5511outside

U.S.A.Warranty service must be performedby an

authorizedservicer.Amanaalsorecommendscontacting

anauthorizedservicer if service is required afterwarranty

expires.

Asure™ Extended Service Plan

Amanaofferslong-termservice protection for this new

range. Asure™ Extended Service Plan is specially

designedto supplement Amana’s strong warranty.This

plancoversparts, labor,andtravelcharges.Call 1-800-

528-2682for information.