3

WARNING: Engine exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to the State of California to cause

cancer and birth defects or other reproductive harm.

1. Foreword

This manual provides information and procedures to safely operate and maintain the model.

For your own safety and protection from injury, carefully read, understand and observe the

safety instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this manual or need an

additional copy, please contact our Corporation. This machine is built with user safety in

mind; however, it can present hazards if improperly operated and serviced. Follow operating

instructions carefully! If you have questions about operating or servicing this equipment,

please contact us.

The information contained in this manual was based on machines in production at the time

of publication. We reserves the right to change any portion of this information without notice.

All rights, especially copying and distribution rights are reserved.

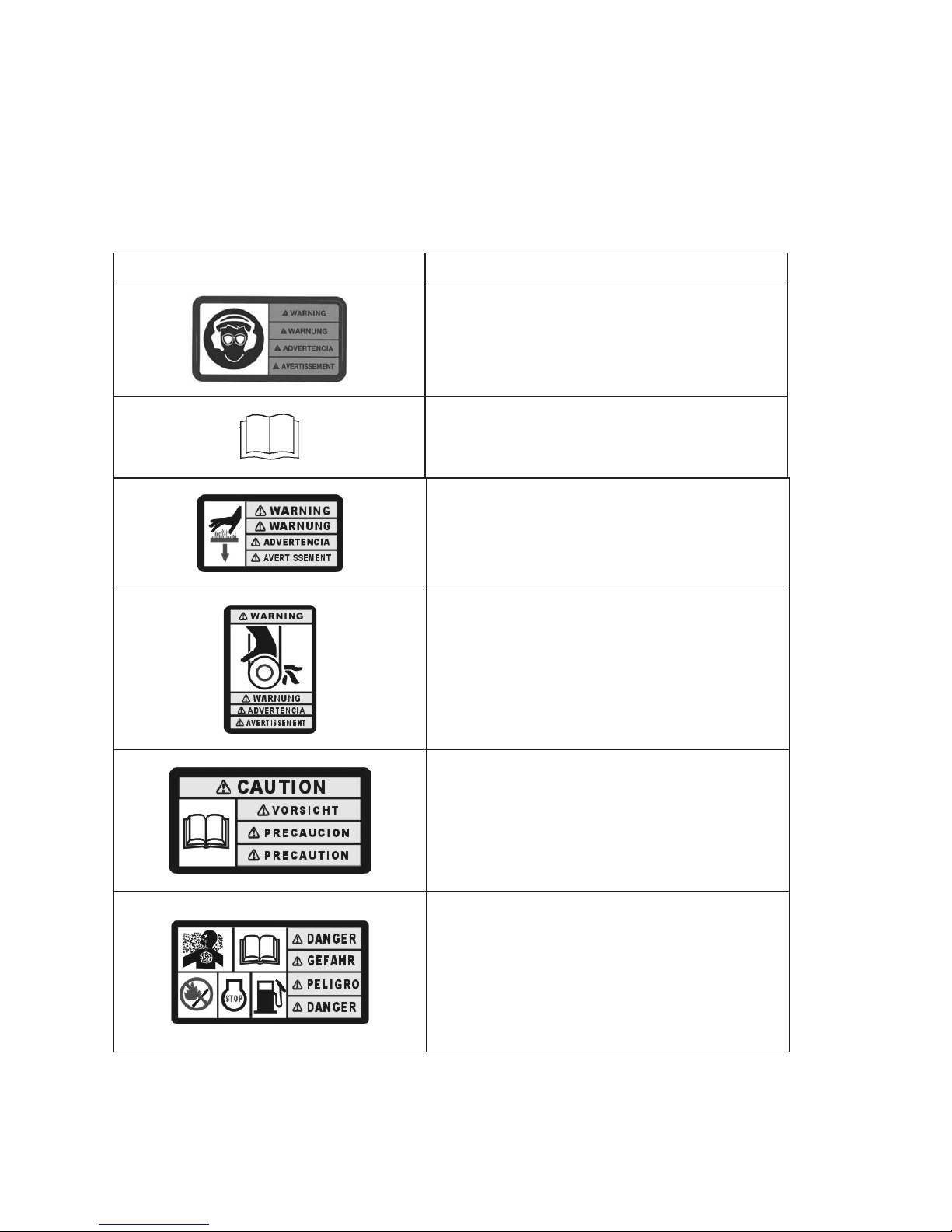

2. Safety Information

This manual contains DANGER, WARNING, CAUTION, and NOTE callouts which must be

followed to reduce the possibility of personal injury, damage to the equipment, or improper

service.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

CAUTION: Used without the safety alert symbol, CAUTION indicates a