IMPORTANT SAFEGUARDS

Read these instructions carefully and retain them for future use. If this

product is passed to a third party, then these instructions must be included.

Before First Use

•Check for transport damage.

Before beginning assembly of product, make sure all parts are present. Compare

parts with package contents list. If any part is missing or damaged, do not attempt

to assemble the product.

Estimated Assembly Time (New installation): 30 minutes (or longer if installing

new sump pit).

Always use handle to lift pump. Never use power cord to lift

pump. To avoid skin burns, unplug and allow timefor the pump to cool after

periods of extended use.

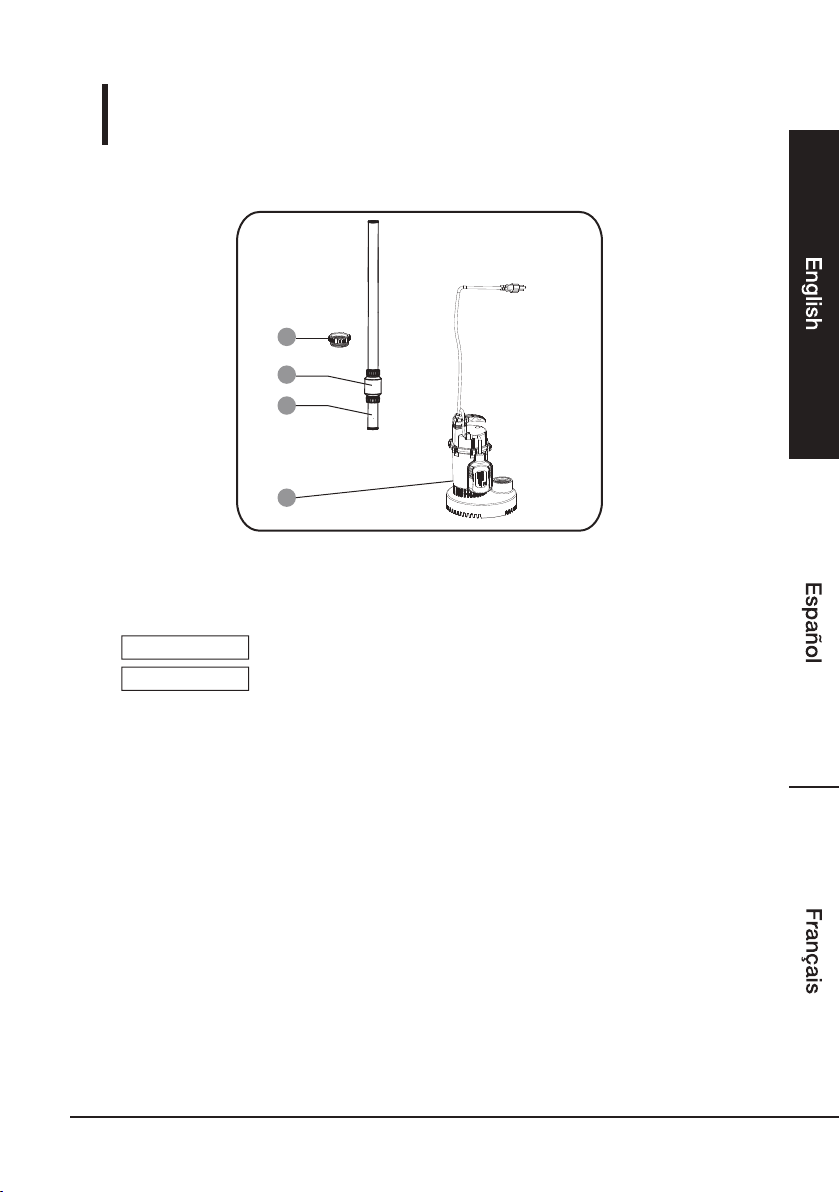

Materials Required for Assembly (not included): Flexible connector, Check valve,

GateValve,PVC pipe, PVC elbow, Thread Tape, PVC Purple Primer, and PVC Cement

Tools Required for Assembly (not included): Wrench, Phillips screwdriver

Risk of suffocation! Keep any packaging materials away

from children – these materials are a potential source of danger,

e.g. suffocation.

DANGER

When using the product, basic safety precautions should always be followed to reduce

the risk of injury including the following:

• Connect the pump DIRECTLY to a grounded, GFCI outlet.

Always disconnect the pump from its power source before installing,

inspecting, maintaining, or repairing.

Do not stand in water when the pump is connected.

•

Do not disassemble the motor housing. The motor has NO repairable internal parts,

and disassembling may cause oil leakage or dangerous electrical wiring issues.

•

Do not allow children to operate tool and keep children away from the work area.

•

Always use handle to lift pump. Never use power cord to lift pump. To

avoid skin burns, unplug and allow time for the pump to cool after periods of extended

use.

•

5

WARNING

WARNING