TLV PowerTrap GP14-B User manual

MODEL GP14-B

TYP GP14-B

MODÈLE GP14-B

GP14-B

INSTRUCTION MANUAL

Keep this manual in a safe place for future reference

EINBAU- UND BETRIEBSANLEITUNG

Gebrauchsanleitung leicht zugänglich aufbewahren

MANUEL D UTILISATION

Conserver ce manuel dans un endroit facile d'accès

Copyright (C) 2021 by TLV CO., LTD. All rights reserved.

PowerTrap

PowerTrap

PowerTrap

Deutsch

Français

English

Introduction

Thank you for purchasing the TLV PowerTrap. This product has been thoroughly

inspected before being shipped from the factory. When the product is delivered,

before doing anything else, check the specifications and external appearance to make sure

nothing is out of the ordinary. Also be sure to read this manual carefully before use and

follow the instructions to be sure of using the product properly.

If detailed instructions for special order specifications or options not contained in this

manual are required, please contact TLV for full details.

This instruction manual is intended for use with the model(s) listed on the front cover. It is

necessary not only for installation, but for subsequent maintenance, disassembly/reassembly

and troubleshooting. Please keep it in a safe place for future reference.

The English language instructions can be found on pages 2 – 35.

The contents of this manual are subject to change without notice.

Vorwort

Wir danken Ihnen für den Kauf von TLV PowerTrap. Dieses Produkt wurde nach

Fertigstellung sorgfältig geprüft und verließ unsere Fabrik vollständig und fehlerfrei. Wir

empfehlen Ihnen jedoch, gleich nach Erhalt den einwandfreien Zustand visuell zu

überprüfen und die Spezifikation mit Ihren Bestellunterlagen zu vergleichen. Sollten Sie

dabei Abweichungen von der Spezifikation oder sonstige Fehler feststellen, bitten wir Sie,

uns umgehend zu benachrichtigen.

Wenden Sie sich bitte an TLV für Optionen oder Sonderausführungen, die nicht in dieser

Einbau- und Betriebsanleitung enthalten sind.

Diese Anleitung kann nur für Installation, Betrieb, Wartung, sowie Ausbau und Zusam-

menbau der auf der Vorderseite angegebenen Typen benutzt werden. Wir empfehlen,

vor Einbau und Inbetriebnahme die Anleitung sorgfältig durchzulesen und an einem

leicht zugänglichen Platz aufzubewahren, damit sie im Bedarfsfall zu Rate gezogen

werden kann.

Die Einbau- und Betriebsanweisung auf Deutsch befindet sich auf den Seiten 36 – 69.

Wir behalten uns vor, den Inhalt dieser Betriebsanleitung ohne Ankündigung zu ändern.

Introduction

Nous vous remercions d’avoir choisi le TLV PowerTrap. Ce produit a été contrôlé

minutieusement avant de quitter l’usine. Toutefois, lors de sa livraison et avant toute chose,

nous vous conseillons de vérifier les spécifications et l’apparence externe du produit afin

de confirmer l’absence d’anomalie. Veuillez également lire ce manuel attentivement avant

d'utiliser le produit, et suivre les instructions afin de l'utiliser correctement.

Si vous avez besoin d’instructions détaillées pour des options non contenues dans ce

manuel ou pour des spécifications relatives à des commandes particulières, veuillez

contacter TLV pour plus de détails.

Ce manuel est destiné aux modèles énumérés sur la page de couverture. Il est non

seulement nécessaire pour l'installation, mais également pour tout entretien,

démontage/remontage et détection de problèmes ultérieurs. Nous vous recommandons

de le garder dans un endroit sûr pour de futures consultations.

Le manuel d’utilisation en français se trouve aux pages 70 – 103.

Le contenu de ce manuel est sujet à modifications sans préavis.

— 1 —

English

Contents

Safety Considerations………………………………………………....……....……....…….... 3

General Description…………………………….....……………............................................. 5

Operation……………………………………………………………………………….……............... 6

Specifications……………………………………………………………………………….……..... 7

Configuration……………………………………………………………………………….……....... 7

Installation……………………………………………………………………………….…….............

8

Open System Piping (Steam System Example) …………………………………………..........….... 8

Closed System Piping (Steam System Example)………………………………………..…….......... 9

Installation Procedure……………………………………………………………………………......... 10

Sizing the Condensate Receiver/Reservoir……………………………………………….…......... 14

Installing Several PowerTrap Units in Parallel …………………………………………………..... 17

Installation and Maintenance Space…………………………………………………..

18

Anchoring the Body ………………………………………………………………………………........

18

Maintenance Space ………………………………………………………………………………..…..

18

Operation and Periodic Inspection…………………..……........……..........…...........

19

Operation………………………………………………………….….….….….….….….……..….......

19

Periodic Inspection and Diagnosis………………………………………………………...….......….

20

Disassembly/Reassembly……………..……..........….................................................. 21

Replacement Parts …………………………………………………….............................................

22

Recommended Tools List for Disassembly/Reassembly……………………………….......….... 23

1. Removing/Reattaching the Body from / to the Cover…………………………………............ 24

2. Removing/Reattaching the Float …………………………………………………….……......... 25

3. Removing/Reattaching the Baffle………………………………………………………….......... 25

4. Removing/Reattaching the Snap-action and Lever Units…………………………….......…... 26

5. Removing/Reinstalling the Exhaust Valve and Exhaust Valve Seat …………………............ 27

5a. Checking/Adjusting the Gap between the Push Plate and Intake Valve

(Motive Medium)………………………………………………………………………………....... 28

6. Removing/Reinstalling the Intake Valve and Intake Valve Seat (Motive Medium)……......... 29

Troubleshooting………………………………..………...………...........……………..…….......30

Determining the Problem from the Symptoms ………………………………………………..........

30

Types of Failure and their Causes……………………………………………………………........… 31

Causes and Corrective Measures …………………………………………………………...............

32

Product Warranty……………..……..........…...........……………..……..........…................... 35

Service……………..……..........…...........……………..……..........…...........…………...............104

— 2 —

English

Safety Considerations

• Read this section carefully before use and be sure to follow the instructions.

• Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

• The precautions listed in this manual are designed to ensure safety and prevent equipment

damage and personal injury. For situations that may occur as a result of erroneous handling,

three different types of cautionary items are used to indicate the degree of urgency and the

scale of potential damage and danger: DANGER, WARNING and CAUTION.

• The three types of cautionary items above are very important for safety: be sure to observe all

of them as they relate to installation, use, maintenance and repair. Furthermore, TLV accepts no

responsibility for any accidents or damage occurring as a result of failure to observe these

precautions.

WARNING

Indicates an urgent situation which poses a threat of death or

serious injury

DANGER

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

Symbols

Indicates a DANGER, WARNING or CAUTION item.

CAUTION

WARNING

NEVER apply direct heat to the float.

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage to property and

equipment.

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions that may lead to serious accidents. Local regulations may

restrict the use of this product to below the conditions quoted.

Take measures to prevent people from coming into direct contact

with product outlets.

Failure to do so may result in burns or other injury from the discharge of

fluids.

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more).

Failure to do so may result in back strain or other injury if the object

should fall.

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the

product has cooled to room temperature.

Disassembling or removing the product when it is hot or under pressure

may lead to discharge of fluids, causing burns, other injuries or damage.

Safety considerations are continued on the next page.

Indicates that there is a potential threat of death or serious injury

— 3 —

English

CAUTION

Do not use excessive force when connecting threaded pipes to the

product.

Over-tightening may cause breakage leading to fluid discharge, which may

cause burns or other injury.

Be sure to use only the recommended components when repairing

the product, and NEVER attempt to modify the product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the discharge of

fluids.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which may

cause burns or other injury.

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

Take measures to ensure the proper handling, such as recovery or

dilution, of hazardous fluids discharged at product outlets.

Outflow of fluid or fluid leaks may lead to hazards such as flammable

conditions or corrosion, which may result in injury, fires, damage or

other accidents.

— 4 —

English

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations may

restrict the use of this product to below the conditions quoted.

CAUTION

・No flash steam discharge

・Small reservoir

・Use with vacuum equipment

possible

・Only one piece of equipment

possible per system

・Equipment has minimum height

requirement to ensure that

condensate flows naturally by

gravity (approx. 1 m (40 in))

・Collection of condensate from

multiple equipment possible

・Can be used where trap is lower than

receiver, such as equipment situated

near grade (providing there is

sufficient differential pressure)

・Separate steam trap required for

each piece of equipment

・Requires venting pipe to discharge

flash steam to atmosphere

System

Overview

Benefits

Notes

Type of System

General Description

Closed System Open System

Application

The PowerTrap is used to discharge liquid from vacuum-pressure or low-pressure areas to

high-pressure areas, or from lower to higher elevations.

The PowerTrap GP14-B has an integrated pumping function that can eliminate and pump out

condensate even if condensate cannot be discharged due to very low supply steam pressure

because of reduced load in the steam-using equipment (this phenomenon is referred to in this

document as ‘stall’).

There are two types of delivery systems (piping methods): the closed system and the open

system. The PowerTrap GP14-B you have purchased is a suitable model for both (for closed

system, please install a steam trap at the PowerTrap outlet).

Equip-

ment

Steam

Trap

Steam

Trap

Power

Trap

Equip-

ment

Receiver

Discharge to

Atmosphere

Condensate

Recovery

line

Condensate

Recovery

line

Venting

Pipe

Exhaust

Pipe

Overflow Pipe

Reservoir

Power

Trap

Condensate

Recovery

Line

Exhaust

Pipe

Equipment

Steam

Trap

— 5 —

English

Operation

(1) When condensate flows from the condensate inlet pipe through the inlet check valve into the

body of the unit, the air in the body escapes through the exhaust valve

(which equalizes the internal pump pressure to the pressure of the condensate source) and

the float rises, as shown in (1) below.

(2) When the float rises to its high level, the push rod on the snap-action unit rises quickly,

simultaneously closing the exhaust valve and opening the intake (motive medium) valve.

The pressure supplied by the motive medium causes the internal pressure in the unit to

become greater than the back pressure. The inlet check valve closes and the outlet check

valve is pushed open, thus discharging the condensate in the unit through the outlet pipe,

as shown in (2) below.

(3) As a result of the condensate in the unit being discharged, the water level in the unit drops

and the float descends. When the float reaches its low level, the push rod on the

snap-action unit moves down quickly, simultaneously opening the exhaust valve and closing

the intake (motive medium) valve and the status reverts to that shown in (1) below.

CAUTION Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

(1) Condensate Inflow (2) Condensate Discharge

Body

Exhaust Valve

[Open]

Exhaust Valve

[Close]

Intake Valve

(Motive Medium)

[Close]

Intake Valve

(Motive Medium)

[Open]

Inlet Check Valve

Inlet Check Valve

Float

Outlet Check Valve Outlet Check Valve

Cover

Condensate

Inlet Pipe

Condensate

Outlet Pipe

Push Rod

— 6 —

English

Specifications

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are PRESSURE

SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

** Valve No. is displayed for products with options. This item is omitted from the nameplate when

there are no options.

Motive Medium

Pressure Range

GP14-B (other than below)

GP14-B (Cast Iron in Europe)

0.03 - 1.4 MPaG

0.03 - 1.3 MPaG

0.3 - 14 barg

0.3 - 13 barg

5 - 200 psig

5 - 185 psig

Maximum Allowable

Back Pressure 0.05 MPa / 0.5 bar / 7 psi less than motive medium pressure used

(but not to exceed 1.05 MPaG / 10.5 barg / 150 psig)

Configuration

CAUTION Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations may

restrict the use of this product to below the conditions quoted.

CAUTION Use only under conditions in which no freeze-up will occur. Freezing may

damage the product, leading to fluid discharge, which may cause burns

or other injury.

Exhaust Outlet Exhaust Outlet

Motive Medium Inlet Motive Medium Inlet

Pumped Medium

Inlet Pumped Medium

Inlet

Snap-action Unit

Cover

Pumped Medium

Outlet

Pumped Medium

Outlet

Lever Unit

Cover Gasket

Cover Bolt

Body Float

Nameplate

Refer to the product nameplate for detailed specifications.

Nominal Diameter

Maximum Allowable Pressure*

Maximum Operating Pressure

Valve No.**

Model

Serial Number

Maximum Allowable Temperature* TMA

Maximum Operating Temperature TMO

Motive

Medium Inlet

Exhaust Outlet

Plug

Intake

Valve Unit

Exhaust Valve Unit

— 7 —

English

PowerTrap

Sv

Sm

Pm

Rm

Se

Sf

Ve

Vm

Km

Ci Ki Vi Vb Pb

Pi Sr

Q

Si So

St

Co Vo

Power

Trap

A

Installation

Open System Piping (Steam System Example)

CAUTION Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations may

restrict the use of this product to below the conditions quoted.

CAUTION Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

CAUTION Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

Necessity of installing a condensate receiver

It is necessary for storing condensate during pumping.

Condensate cannot enter the PowerTrap while condensate is being pumped.

NOTE: This sketch is for explanation purposes only and is not intended as an installation design.

— 8 —

English

Closed System Piping (Steam System Example)

NOTE: This sketch is for explanation purposes only and is not intended as an installation design.

In closed system applications, the motive medium must be compatible with the liquid

being pumped. If a non-condensable gas such as air or nitrogen is used as the motive

medium, please consult TLV for assistance.

Q

A

Pm

Pb

Si

So

Sr

Sm

Se

SP

Condensate Amount

Filling Head

Motive Medium Supply Pressure

Back Pressure

Condensate Inlet Pipe

Condensate Outlet Pipe

Condensate Recovery Line

Motive Medium Supply Pipe

Exhaust Pipe

Steam Trap on the Power Trap outlet

Sv

Dh

Ci

Co

Ca

La

Ki

Km

Pi

Vent Pipe

Condensate Reservoir

Condensate Inlet Check Valve

Condensate Outlet Check Valve

Check Valve for Air Vent

Air Vent (for Steam)

Condensate Inlet Strainer

Motive Medium Strainer

Equipment Pressure

Rm

St

Vi

Vo

Vm

Ve

Va

Vb

Motive Medium Pressure

Reducing Valve

Steam Trap on Drip Leg

Valve on Condensate Inlet Pipe

Valve on Condensate Outlet Pipe

Valve on Motive Medium Supply Pipe

Valve on Exhaust Pipe

Valve for Air/Gas Discharge

Blowdown Valve

Q

A

Pm

Pb

Si

So

Sr

Sm

Se

Sv

Sf

Dh

Ci

Co

Ki

Km

Rm

Pi

St

Vi

Vo

Vm

Ve

Vb

Condensate Amount

Filling Head

Motive Medium Supply Pressure

Back Pressure

Condensate Inlet Pipe

Condensate Outlet Pipe

Condensate Recovery Line

Motive Medium Supply Pipe

Exhaust Pipe

Vent Pipe

Overflow Pipe

Condensate Receiver

Condensate Inlet Check Valve

Condensate Outlet Check Valve

Condensate Inlet Strainer

Motive Medium Strainer

Motive Medium Pressure

Reducing Valve

Equipment Pressure

Steam Trap on Drip leg

Valve on Condensate Inlet Pipe

Valve on Condensate Outlet Pipe

Valve on Motive Medium Supply Pipe

Valve on Exhaust Pipe

Blowdown Valve

**If the pressure at the PowerTrap inlet exceeds the pressure at the PowerTrap outlet, make sure to install

a steam trap at the PowerTrap outlet. (Steam will blow if no steam trap is installed.)

Make sure the pipe between the PowerTrap and the steam trap is as short and thick as possible.

There should be no rise in piping between the PowerTrap and the steam trap.

Select the steam trap based on the pump discharge capacity of the PowerTrap. Consult TLV for details.

*

Ci

Vo

Km

Co

Steam-using

Equipment

Vm

Ve

Vi

Pb

Sm

Sv

Se

Si

So

Ki

Rm

St

Vb

Sr

Power

Trap

Va

Ca

La

Sp**

Condensate

Recovery

Line

Motive

Medium Motive Medium

Supply Pressure Pm

Pump

Exhaust

Back

Pressure

Temperature Controller

Air and Non-condensate

Gas Discharge

Filling

Head A

Equipment

Pressure

Steam for

Heating

Backflow

Water

Hammer

Prevention

Check Valve

Condensate

Reservoir Dh

When the rise in piping is 30 m (100 ft) or farther from the

PowerTrap, installation of check valve is recommended

for the prevention of return water hammer.

NOTE: Pipe the discharge to a

safe area such as a pit.

Condensate

Amount Q

Pi

— 9 —

English

Installation Procedure

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve opening/closing

should be carried out only by trained maintenance personnel.

(1) Pumped Medium:

• Fluids that can be discharged through the PowerTrap are limited to steam condensate,

water and non-flammable, non-toxic fluids with specific gravities 0.85 – 1.0. PowerTrap

that have been constructed for other specific fluids are not limited by this restriction.

(2) Motive Medium Supply Piping:

• The motive medium supply pipe diameter should be at least 20 mm ( ").

• Install a 40-mesh or finer strainer on the PowerTrap motive medium supply pipe, as close to

the PowerTrap as possible, while allowing sufficient space for maintenance of the strainer.

Strainers should be angled in the 3 or 9 o’clock positions for horizontal installations.

• See "Specifications" on page 7 for the maximum motive medium inlet pressure.

• For Open Systems: Steam, compressed air, nitrogen or other non-flammable, non-toxic

fluids may be used as the motive medium.

• For Closed Systems: Use steam as the motive medium. Except in special cases, do no use

non-condensable gases such as air or nitrogen.

• When the motive medium is steam, if the application will require that the equipment be shut

down (non-operating) for periods of 2 months or longer, install piping connecting the motive

medium supply line to the receiver/reservoir pipe, being sure to install a drip leg on the

motive medium supply line, and a steam trap in the drip leg (between where it branches to

go to the PowerTrap and where it enters the receiver/reservoir pipe). (See item [St] in the

drawings on pages 8 and 9.)

This measure is not necessary when the motive medium is compressed air or nitrogen.

(3) Pressure Reducing Valve on the Motive Medium Supply Piping:

• When the supply pressure of the motive medium is greater than the maximum operating

pressure of the PowerTrap, install a TLV COSPECT series pressure reducing valve. Make sure

that the motive medium pressure is lower than the maximum operating pressure of the

PowerTrap. Use good piping practices when selecting the installation location for COSPECT.

In this case, be sure to install a safety valve between the pressure reducing valve and the

PowerTrap.

• When the supply pressure of the motive medium is less than the maximum operating pressure

of the PowerTrap, if a pressure reducing valve is to be installed to slow the speed of the flow,

the installation of a safety valve is not required.

• Install the pressure reducing valve as far away from the PowerTrap as possible.

When the motive medium pressure is less than 0.5 MPaG (72.5 psig, 5 barg): at

least 3 m (10 ft)

When the motive medium pressure is 0.5 MPaG or greater (72.5 psig or greater, 5

barg or greater): at least 3 m + 1 m for every 0.1 MPaG (1 barg) over 0.5 MPaG (5 barg)

10 ft + 1 ft for every 4.5 psig over 72.5 psig)

• The pressure setting on the pressure reducing valve should be between 0.05 and 0.15 MPa

(7 – 20 psi, 0.5 – 1.5 bar) higher than the back pressure.

When the discharge capacity of the PowerTrap is insufficient for the set motive pressure,

increase this set pressure even further.

/

34

— 10 —

English

Figure 1: Open Systems Figure 2: Open & Closed Systems

* For Open Systems only

** For Closed Systems only

Vent Line

Equipment

When the

exhaust

piping is

3 m (10 ft.)

or more

Outlet

Pipe

Inlet

Pipe

Power

Trap

Pit Pit

Close to

Power

Trap

Pit

Exhaust

Piping Receiver

Overflow

Pipe

Steam

Trap

When the exhaust piping height exceeds 3 m (10 ft.)

Equipment

Receiver/

Reservoir

Power

Trap

Vent Line*

Overflow

Pipe*

Pit

Exhaust

Piping

Check

Valve

Pit

Inlet

Pipe

Outlet

Pipe

Steam trap**

When the

exhaust

piping is

3 m (10 ft.)

or more

Close to

Power

Trap

(5) Inlet and Outlet Piping

• Install a 40-mesh or finer strainer on the PowerTrap pumped medium inlet pipe.

The installation should be in a location that allows sufficient space for maintenance

of the strainer.

• Ensure that the inlet and outlet check valves are installed in the correct direction.

The check valve on the inlet pipe in particular should be installed right next to the PowerTrap.

• Only TLV check valves (CK3MG, CKF3MG) should be used; proper discharge capacity cannot

be guaranteed with other check valves.

(6) Valves on the Various Pipes

• In order to ensure the proper discharge capacity, use full bore ball valves or gate valves on

the pumped medium inlet and outlet lines as well as on the motive medium supply

and exhaust lines.

If it is necessary to reduce the velocity of the motive medium supply, a needle valve can be

used. However, be aware that the discharge capacity will be reduced. (Refer to

"Operation" (1) e) on pages 19 and 20).

• Install union or flanged joints between the valves and the PowerTrap to allow for easy

maintenance.

• Be sure to provide the necessary maintenance space for PowerTrap disassembly and repair

(see "Installation and Maintenance Space" on page 18).

(4) Exhaust Piping:

• The exhaust pipe diameter should be at least 25 mm (1").

• The exhaust pipe should be connected to the top of the receiver/reservoir.

• For Open Systems: If the GP exhaust line has to discharge to atmosphere, a sound level of

approximately 90 – 110dB may be emitted from the exhaust pipe discharge outlet for two

to three seconds. If soundproofing measures are necessary,

install a silencer. (If the exhaust line is connected to the condensate receiver, the sound

level will be below 60dB.)

• Make sure that the distance from the ground to the highest point on the exhaust pipe

(where it enters the receiver/reservoir) does not exceed 3 m (10 ft).

If it exceeds 3 m (10 ft) and steam is used as the motive medium, condensate must be

drained from the exhaust pipe in order not to obstruct the exhaust. Implement one of the

following countermeasures: (See the figures below.)

(a) For Open Systems only: Add a float-type steam trap to the exhaust pipe at a point just

above where the exhaust pipe exits the unit body. (Figure 1)

(b) For Open and Closed Systems: Add piping connecting the exhaust pipe to the

pumped medium inlet pipe between the reservoir and the strainer, being sure to install

a check valve on the piping to prevent backflow of condensate from the pumped

medium inlet pipe to the exhaust pipe. (Figure 2)

• For Closed Systems only: The exhaust pipe must be connected to the top of the reservoir.

— 11 —

English

To PowerTrap

To PowerTrap

Overflow Pipe

Condensate

Condensate

Loop Seal

There is a possibility of condensed hot water dripping from vent pipe outlet.

Make sure to extend to where people do not pass.

300 mm

(12 in)

Condensate

Receiver

1) 2)

Flash Steam

Flash Steam

Condensate

Receiver

Flash Steam

Vent Pipe Vent Pipe

Overflow Pipe

Pipe the discharge to a safe place such as a pit.

High temperature steam or hot water may splash.

NOTE: This sketch is for

explanation purposes only

and is not intended as an

installation design.

Examples of Overflow Piping for Open Systems

(7) Receiver/Reservoir Pipe and Filling Head.

• Please refer to “Sizing the Condensate Receiver/Reservoir” on pages 14 and 15.

The size and vent pipe aperture are determined by (a) the amount of any flash steam in the in-

flowing condensate (pumped medium) and (b) the amount of pumped medium held back while

the PowerTrap is discharging.

If the receiver is small, the flow of flash steam may cause condensate to flow out the vent pipe.

If the vent pipe size is small, the pressure in the receiver will rise, restricting the pumped

medium inflow.

Be sure to select a receiver/reservoir pipe of the correct size.

• The filling head represents the distance from the bottom of the PowerTrap (from grade)

to the bottom of the receiver/reservoir.

The standard filling head is 860 mm (36").

When an installation calls for a lower filling head, a filling head of less than 860 mm (36") is

allowable. However, the minimum filling head is 710 mm (30").

• For Open Systems:

- If venting flash steam to a high area, an overflow pipe must be installed to discharge

condensate to a safe area.

- Overflow pipe should be installed at the side of the receiver.

WARNING

・Be sure to install a vent pipe and an overflow pipe. Failure to install an

overflow pipe is dangerous, as condensate may spurt from the vent

pipe and could result in burns and other injuries.

・Pipe the vent pipe and the overflow pipe to a safe place such as a pit.

・Piping size of the overflow pipe should be the same or larger than

condensate inlet pipe.

— 12 —

English

(8) Velocity at Outlet Piping

The PowerTrap uses the motive medium supply pressure to push the pumped medium out

of the trap.

• The GP14-B can discharge approximately 30 liters (8 U.S. gal) of pumped

medium for each discharge operation.

• The amount of time required for each discharge operation will be between 3 and 30

seconds, depending on the back pressure and the motive medium pressure.

This means that the instantaneous flow through the pumped medium outlet pipe during the

discharge operation is between 4 and 40 metric tonnes (1,060 and 10,600 U.S. gal) per hour.

• When a flowmeter is to be installed in the pumped medium outlet piping, it should be

selected to reflect the intermittent operation and should be sized to accommodate the

maximum and minimum instantaneous flow.

Contact TLV for details.

(9) For Closed Systems:

• An air vent (for steam) [La] or valve for air discharge [Va] is required to discharge the initial air

in the equipment and the reservoir pipe or any gas generated in the system. In this case,

installing the check valve for air vent [Ca] will prevent air from being sucked in from the outlet

of the vent pipe [Sv]. This check valve must be installed when the pressure inside the piping

becomes negative. A valve for air discharge [Va] can be installed instead of the air vent (for

steam) [La] and check valve for air vent [Ca].

When releasing the initial air using a valve for air discharge, leave the valve for air discharge

[Va] slightly open until the PowerTrap has cycled 2 – 3 times. Close the valve for normal

operation.

• Refer to “(2) When flash steam is not involved” in “Sizing the Condensate Receiver/

Reservoir” for information on condensate reservoir sizing.

For more details, contact TLV.

Explanations for overflow piping for open Systems

1) If flash steam can be discharged from overflow pipe

Install overflow pipe and vent pipe separately.

2) If flash steam should not be released from overflow pipe (prevent flash steam release)

Install overflow pipe and vent pipe separately. For overflow pipe, install loop seal (approx.

300 mm (12 in)). Flash steam release from overflow pipe can be prevented since water

always accumulates at loop seal. Piping size should be the same or larger than condensate

supply pipe.

NOTE: • There is a possibility of rust becoming clogged and/or corrosion since water is

always present in the loop seal. The possibility is greater if the piping diameter is

too small (generally 25 mm (1 in) or smaller).

• If the loop seal becomes clogged, hot overflow water will blow from vent pipe.

Make sure to install vent pipe to lead to a safe place

• Do not install loop seal on the vent pipe

Contact TLV if neither 1) nor 2) above can be installed.

• For Closed Systems: An air vent for steam or a manual valve is required to discharge

the initial air in the equipment and the reservoir pipe or any gas generated in the system.

For positioning of the air vent or valve, see [Va] in the closed system drawing on page 9.

When releasing the initial air using a manual valve, leave the valve [Va] slightly open until

the PowerTrap has cycled 2 – 3 times.

— 13 —

English

Sizing the Condensate Receiver/Reservoir

When selecting the receiver/reservoir for the

PowerTrap, select from among the following 3 conditions:

①When large quantities of flash steam are involved

(For open systems using steam)

a) Determining the amount of flash steam:

Amount of flash steam Fs = Q x(hd’ - hh’) / r

Fs : amount of flash steam (kg/h) (lb/h)

Q : amount of condensate (kg/h) (lb/h)

hd’: specific enthalpy (kJ/kg) (Btu/lb) of saturated condensate at

condensate inlet set pressure (Pi)

hh’: specific enthalpy (kJ/kg) (Btu/lb) of saturated condensate at

condensate receiver set pressure (Ph)

r : specific enthalpy (kJ/kg) (Btu/lb) vaporization (latent heat of

steam) at condensate receiver set pressure (Ph)

b) Determine the vent pipe diameter according to the amount of flash steam in Vented

Receiver Table - 1 shown on the next page.

c) Determine the overflow pipe diameter (Dop, refer to the figure below).

NOTE: The overflow pipe diameter should be at least as large as the condensate inlet pipe

diameter (Dcip, refer to the figure below).

d) Determine the minimum condensate receiver diameter (Dcr, refer to the figure below) by

selecting the largest value among those from (i), (ii), and (iii) based on a condensate receiver

length of 1 m (3.3 ft).

( i ) is the overflow pipe diameter multiplied by 3 or more.

(ii) is the minimum receiver diameter according to the amount of flash steam in Vented

Receiver Table - 1 shown on the next page.

(iii) is the minimum receiver diameter according to the amount of condensate in Vented

Receiver Table - 2 shown on the next page.

NOTE: Receiver length can be reduced by 50% when the motive pressure (Pm) divided by the

back pressure (Pb) is "2" or greater. (When Pm ÷ Pb≥2)

Pi Qi

Ph

Flash Steam

Condensate

Receiver

×

— 14 —

English

25

50

75

100

150

200

300

400

500

700

800

1000

1100

1400

1500

Receiver

Diameter

mm (in)

(Length: 1 m)

Flash Steam

up to ~

kg/h

Flash Steam

up to ~

lb/h

Receiver

Diameter

in

(Length: 3.5 ft)

Vent Line

Diameter

in

Vent Line

Diameter

mm (in)

50

75

100

200

300

400

600

800

1000

1400

1600

2000

2200

2800

3000

3

4

4

6

8

8

10

12

14

16

18

20

20

22

24

1

1

2

2

3

4

4

6

6

8

8

8

10

10

10

(3)

(4)

(5)

(6)

(8)

(8)

(10)

(12)

(14)

(16)

(18)

(20)

(20)

(22)

(24)

80

100

125

150

200

200

250

300

350

400

450

500

500

550

600

(1)

(2)

(2)

(3)

(3)

(4)

(5)

(5)

(6)

(8)

(8)

(8)

(10)

(10)

(10)

25

50

50

80

80

100

125

125

150

200

200

200

250

250

250

Vented Receiver Table - 1

(For atmospheric, open system installations)

/

12

/

12

Amount of

Condensate

kg/h

Receiver

Diameter

mm (in)

(Length: 1 m)

(3)

(4)

(5)

(6)

(8)

(10)

80

100

125

150

200

250

Vented Receiver Table - 2

(For atmospheric, open system installations)

1000 or less

1500

2000

3000

6000

10000

Amount of

Condensate

lb/h

Receiver

Diameter

in

(Length: 3.5 ft)

3

4

5

6

8

10

2200 or less

3300

4400

6600

13000

22000

NOTE: When amount of flash steam and condensate are between two values in the table, select

the larger value (one line below).

— 15 —

English

Condensate

Reservoir

Pi

PowerTrap

②When flash steam is not involved

(For closed systems)

Determining the reservoir diameter and

length based on the amount of Condensate:

300 or less

400

500

600

800

1000

1500

2000

3000

4000

5000

6000

7000

8000

9000

10000

Amount of

Condensate

(kg/h)

Reservoir Diameter (mm) & Length (m)

Reservoir Diameter (in) & Length (ft)

500 or less

700

1000

1200

1500

2000

3000

4000

5000

6000

7000

8000

9000

10000

12000

14000

16000

18000

20000

Amount of

Condensate

(lb/h)

40

1.2m

1.5

2.0

50

0.7

1.0

1.2

1.5

2.0

80

0.5

0.6

0.8

1.0

1.5

2.0

100

0.5

0.7

1.0

1.3

2.0

150

0.6

0.9

1.2

1.4

1.7

2.0

200

0.5

0.7

0.8

1.0

1.2

1.3

1.5

1.7

250

0.5

0.6

0.7

0.8

0.9

1.0

1

3.0 ft

4.0

5.5

2

2.0

2.5

3.5

4.5

3

1.0

1.5

2.0

2.5

3.5

4.5

6.5

4

1.0

1.5

2.0

3.0

4.0

5.0

5.5

6.5

6

1.5

2.5

2.5

3.0

3.5

4.0

4.5

5.0

6.0

6.5

8

1.5

1.5

2.0

2.5

2.5

3.0

3.5

4.0

4.5

1.5

10

1.5

1.5

2.0

2.5

2.5

3.0

1.5

NOTE: Reservoir length can be reduced by 50% when the motive pressure (Pm) divided by the

back pressure (Pb) is "2" or greater. (When Pm ÷ Pb≥2)

③When there are small quantities of flash steam and a large amount of condensate

(E.g., open systems pumping large amounts of super-cooled condensate)

Consult the sizing tables in sections ①and ②above.

Select the condensate receiver size based on the larger of ①and ②.

Select the vent pipe diameter and overflow pipe diameter from ①.

Reservoir Table

(For equalized, closed system installations)

/

12

— 16 —

English

Pumped Medium Return Line

Pumped Medium Inlet Pipe

Pumped Medium

Exhaust Pipe

Filling Head A

Motive

Medium

Supply

Motive

Medium

Supply

Motive

Medium

Supply

Overflow Pipe

Medium Return

(Main Line)

Vent Pipe

Exhaust Pipe Manifold

Exhaust Pipe

Exhaust Pipe

TLV

Power

Trap

TLV

Power

Trap

TLV

Power

Trap

Receiver

Installing Several PowerTrap Units in Parallel

Refer to the figure below as a general guide for the piping when several PowerTrap units are to be

installed after the same pumped medium inlet pipe.

The size of the pumped medium inlet pipe, return line and exhaust pipe manifold is determined by

the number of PowerTrap units installed.

When specifications exist separately from the instruction manual, follow the specifications.

NOTE: This sketch is for explanation purposes only and is not intended as an installation design.

40 mm (1 in)

50 mm (2 in)

65 mm (2 in)

65 mm (2 in)

80 mm (3 in)

80 mm (3 in)

100 mm (4 in)

100 mm (4 in)

125 mm (5 in)

125 mm (5 in)

125 mm (5 in)

150 mm (6 in)

200 mm (8 in)

200 mm (8 in)

200 mm (8 in)

Number of

PowerTrap

Units Installed

Pumped Medium

Inlet Pipe Size Pumped Medium

Return Line Size

Exhaust Pipe

Manifold Size

Overflow

Pipe Size Vent Pipe

Size

/

12

/

12

/

12

2

3

4

5

6

See the Vent

Line Diameter

column in

Table-1 on

page 15

Determine

overflow pipe size

according to

“Sizing the

Condensate

Receiver/Reservoir”

on page 14

— 17 —

English

( )

/

34

( )

/

316 ( )

/

3 16

(1 )

/

14

/

18

(1 ) /

18

(1 )

(3 )

/

5 16

100

29 29315.5 5.5

19

(1 )

/

916

( )

/

18

20

( )

/

13 16

20

( )

/

13 16

3.2

40

( )

/

13 16 ( )

/

13 16

(2 )

/

38

20 2060

C10C10

C10C10

( )

/

34

19

( )

/

34

19

(2 )

/

916

( )

/

916

(1 )

/

916

/

38

( ) 65

1510 40

PowerTrap

(1 )

/

916

/

15 16

(10 )

/

34

(5 )

/

716

(11 )

/

716

/

58

(9 )

/

716

(14 )

/

316

(31 )

/

12

(31 )

/

12

(~78 )

/

34

(~78 )

/

34

~268

Installation and Maintenance Space

Anchoring the Body

Maintenance Space

The maintenance space shown in the figure below should be provided to enable disassembly,

inspection and replacement of the PowerTrap.

40

( )

/

13 16

21

( )

/

13 16

20

(10 )

/

916

173

138

290

800

800

~2000

~2000

240

360

Anchor Bolt with nut

M16, 2 pcs.

(Customer

Supplied)

Hex Bolt with Nut

M16 x 50 mm, 2 pcs.

( "-11UNC x 1 ")

included with

Anchor Fixture Set)

Unit: mm (in)

Unit: mm (in)

Anchor Fixture Set included in the package.

Fixture is designed so that the body can be moved

backwards (opposite direction to the cover).

Failure to use fixtures or use of other than those

provided may prevent mobility of the body, and

inhibit maintenance.

(Consisting of two anchor brackets and two hex

bolts with nuts)

(Suitable Anchor Bolt Size: M16)

(Bolt Holes in Product Body: ø19)

Anchor fixture set:

Anchor fixture ×2

Hex bolt (M16) ×2

Hex nut (M16) ×2

Washer (Diameter: 16)×2

— 18 —

English

Table of contents

Languages:

Other TLV Water Pump manuals

Popular Water Pump manuals by other brands

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 811/2B3-B Installation, operation, and maintenance manual with parts list

Star

Star HSPJ100 user manual

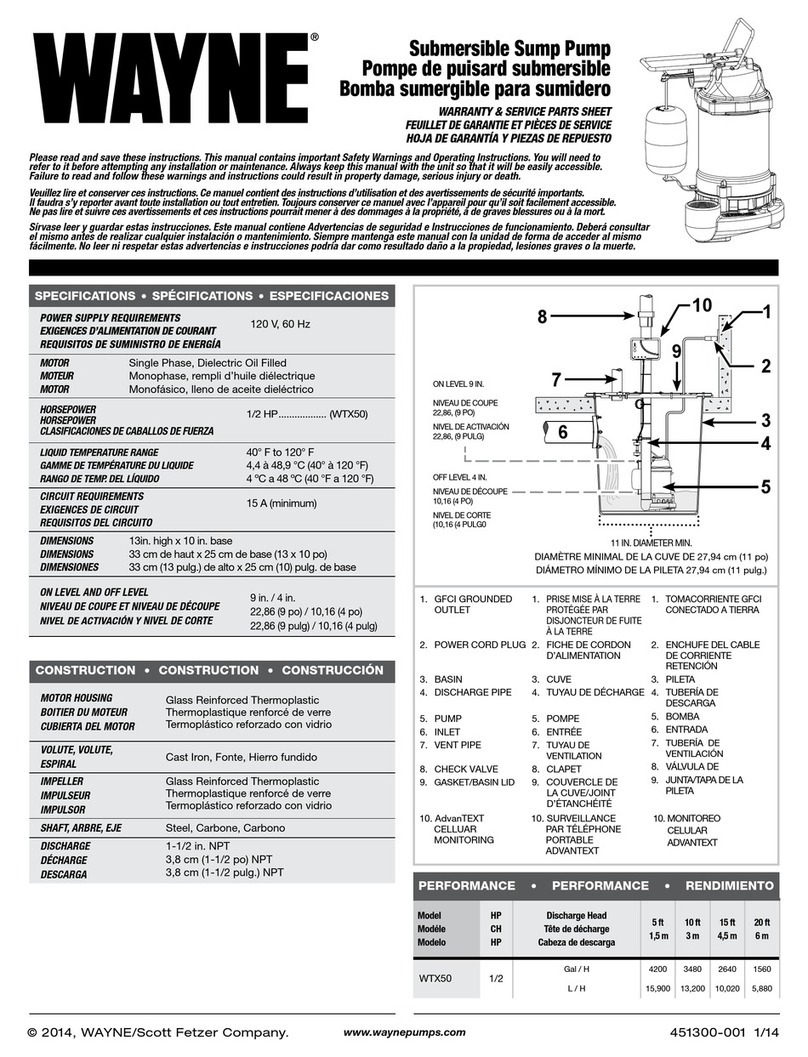

Wayne

Wayne WTX50 Warranty & service parts sheet

Gardena

Gardena 4000/5 eco operating instructions

CET

CET PFP-11HPHND-EM-HP Instruction handbook

Pfeiffer Vacuum

Pfeiffer Vacuum DUO 3 operating instructions

fluid-o-tech

fluid-o-tech DGD Series instruction manual

Ingersoll-Rand

Ingersoll-Rand 650484-X Operator's manual

Enerpac

Enerpac EAM-1000 Series instruction sheet

Alentec & Orion

Alentec & Orion 52510 user manual

SKF

SKF EPB-Pump-ECO Original operating and maintenance instructions