2

Document Index.

1 Installation Requirements

1.1 Health & Safety

1.2 Model definitions

1.3 Technical Details

2 Commissioning Instructions

3.1 Tools Required

3.2 Commissioning Chart

3 Servicing Instructions

3.1 Tools required

3.2 Burner Description

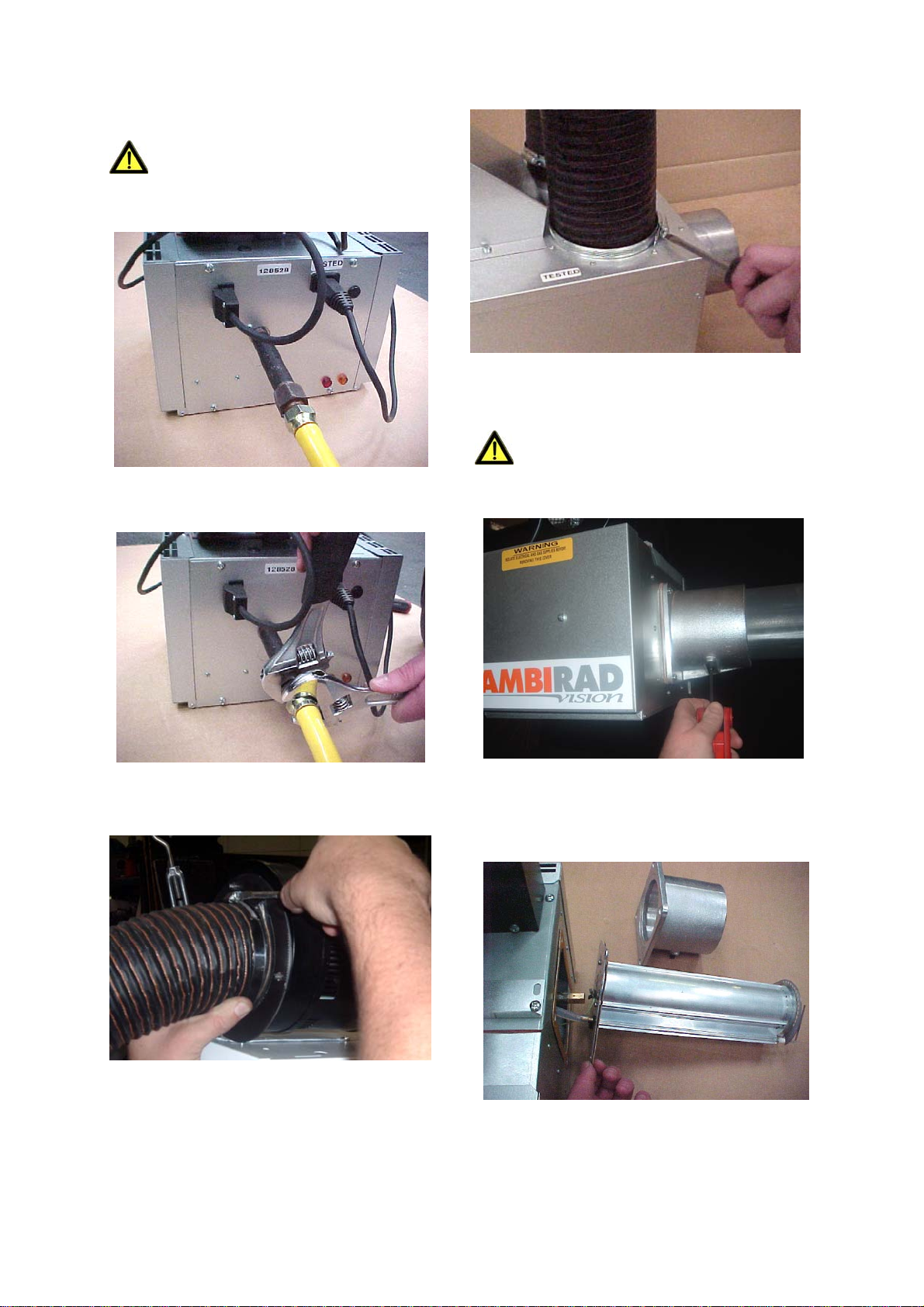

3.3 Burner Removal

3.4 Burner Gas Injector Servicing

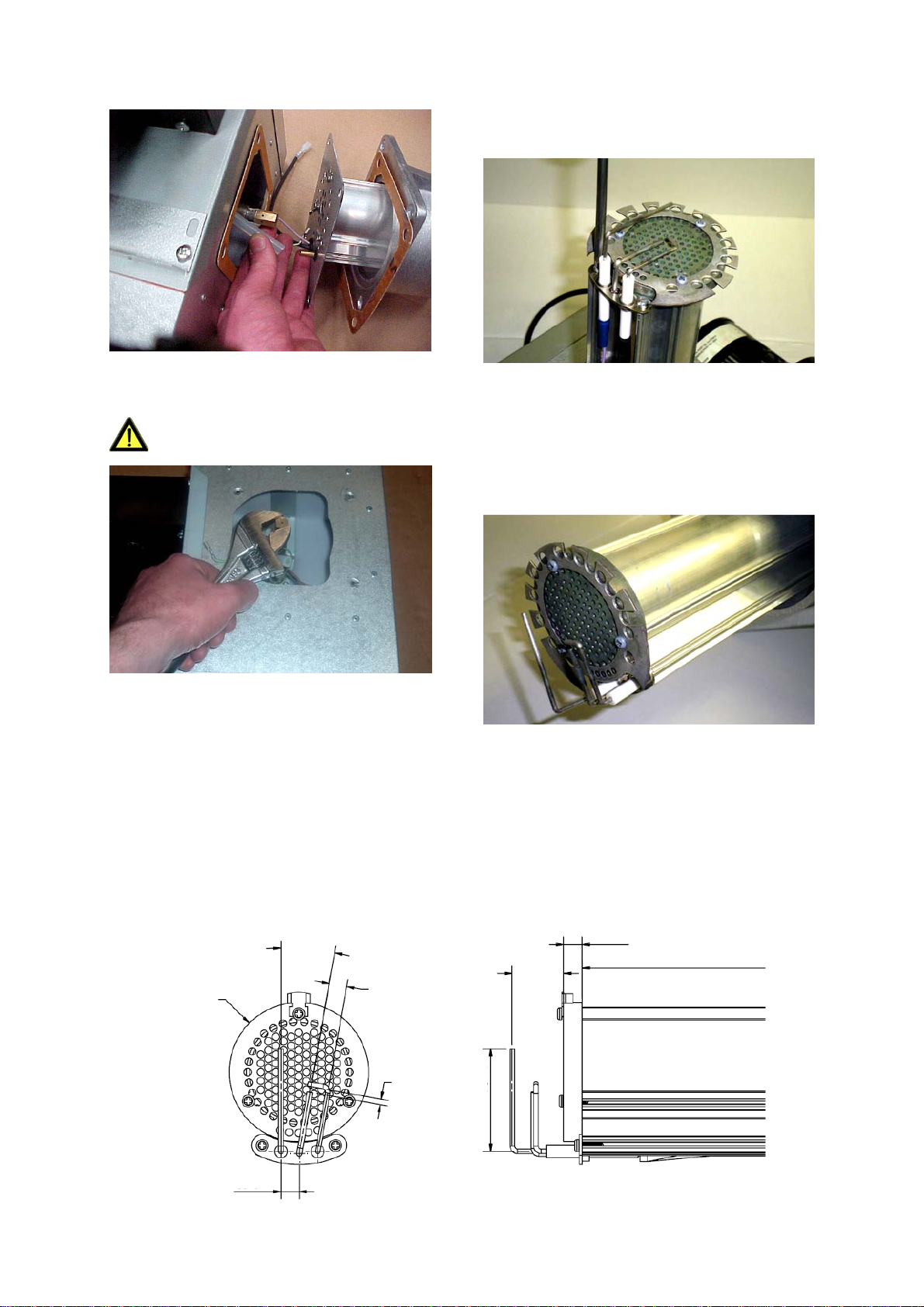

3.5 Burner Head and Electrode Servicing

3.6 Combustion Fan Assembly

3.7 Radiant Tube Servicing

3.8 Heat Exchanger Servicing

Introduction. and attention is required to ensure that working

at height regulations are adhered to at the

mounting heights specified.

PLEASE READ this document prior to

installation to familiarise yourself with the

components and tools you require at the various

stages of assembly.

All Dimensions shown are in mm unless

otherwise stated.

The manufacturer reserves the right to alter

specifications without prior notice.

Welcome to the new range of high efficiency

AmbiRad Vision radiant tube heaters. Local

regulations may vary in the country of use and

it is the installers responsibility to ensure that

such regulations are satisfied.

All installation, assembly, commissioning and

service procedures must be carried out by

suitable qualified competent persons

appropriate to the statutory regulations in the

country of use.

When assembling, installing, commissioning

and servicing is undertaken on radiant tube

heaters specified in these instructions, due care

3.9 Reflector Servicing

3.10 Inspection of Flue

3.11 Re-commissioning after Service

4 Spare Parts

5 Fault Finding Guide

6 Replacing Parts

6.1 Burner Controller Replacement

6.2 Air Pressure Switch Replacement

6.3 Gas Valve Replacement

7 User and Operating Instructions

7.1 To Start Heater

7.2 To Switch off Heater

7.3 Routine Maintenance Between Service Intervals

7.4 Frequency of Servicing

1. Installation Requirements.

Isolate any electrical supply to the

heater and controller before proceeding.

relevant British Standards and Codes of

Practice by a qualified installer. Isolate all

electrical supplies to the heater & controller

before proceeding.

For your own safety we recommend the use of

safety boots and leather faced gloves when

handling sharp or heavy items. The use of pro-

tective eye wear is also recommended.

1.2 Model Definitions

VSXUT = Ambirad Vision High efficiency U

Tube heater with painted powered burner, deep

profile stainless steel reflector and end caps,

reflector canopy and end caps in Aluzink

1.1 Health and Safety

AmbiRad heaters must be installed in

accordance with the relevant provisions of the

Gas Safety (Installations and Use) Regulations

1998. Due account should also be taken of any

obligations arising from the Health and Safety

at Works Act 1974 or relevant codes of prac-

tice. In addition the installation must be carried

out in accordance with the current IEE wiring

regulations (BS 7671:2001), BS 6896:2005

(Industrial & Commercial) and any other