Hardware — Small Bag (A) Contains:

1. Cable Plug / Qty. 1

2. 1/2” Cap Bolt with Nylon Insert / Qty. 2

3. Belleville asher / Qty. 1

4. Strips of Velcro / Qty. 1

5. 5/16” x 1/2” Hex Head Bolt / Qty. 6

6. 3/8” heel Bolt / Qty. 1

7. 5/16” Flat asher and Anti-Rotate Bracket

Base Bolts — Large Bag (B) Contains:

1. 3/8” - 16 X 6-1/2” Hex Head Bolt / Qty. 2

2. 3/8” - 16 Hex Nut / Qty. 2

3. 3/8” - 16 Hex Nylon Loc Nut / Qty. 4

4. 3/8” - 16 X 5” Hex Head Bolt / Qty. 2

5. 3/8” - 16 Flat asher / Qty. 2

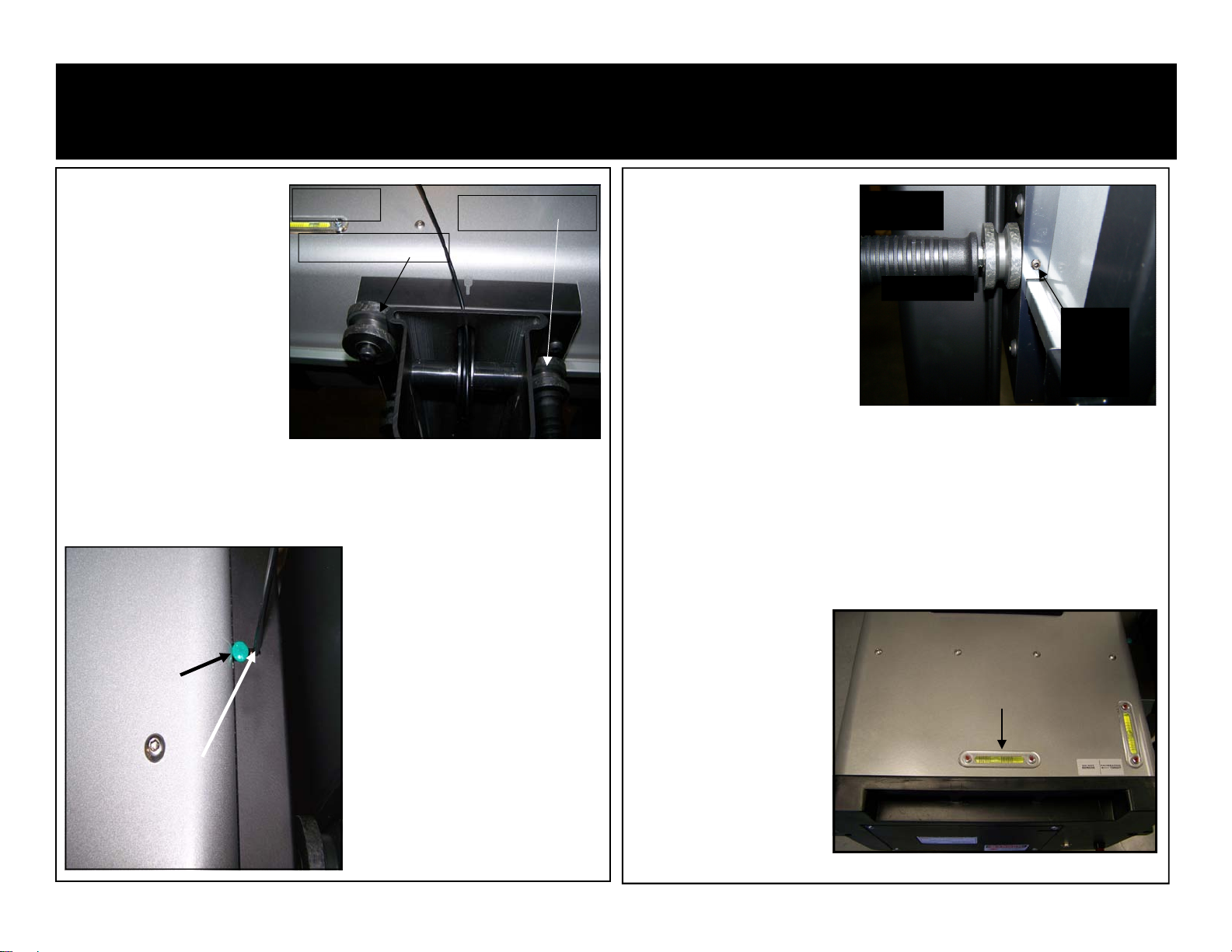

Box 2 - Boxed Base & Hardware

Box 2 contains the following: heels (3), Brake

Handle (1), T-Base Front (1), T-Base Rear (1)

Mast Cover (1), Charger (1), Small Bag A (1),

Large Bag B (1), heel & Cam Mount (1), Shaft

(1), Mast Support Column (1), & Anti-Rotate

Bracket (1), as shown in Figure 1 below.

Box 2

Boxed Base & Hardware Kit

Note: Some omponents are shipped inside T-Base legs.

Unpacking & Inspection

UPON receipt open the boxes and check contents for

any shipping damage. If necessary, notify carrier of dam-

age and make a claim through the carrier. Check the

oxes for the following content:

Box 1 — Vision II Pro Head contains: (1) Vision II

Pro Head Manual; (1) arranty Card; (1) Transit (1)

Bundle of Laser Targets; (1) Vision II Pro Head As-

HEADLIGHT

Laser

Sti kers

G2 Transit

Laser

Targets

Vision II Pro Head

Box 1

Warranty Card

Manual

BOX 3 — The Counterweight is secured in the middle of the Mast

with two cardboard inserts. The inserts will need to be removed from

each end. Use caution when removing the inserts to prevent the

Counterweight from falling out. It may be necessary to hold the

Counterweight Cable to prevent the Counterweight from sliding out

of the mast.

NOTE: Counter weight is VERY heavy; use aution.

Remove 4’ sections of track (3 — 4’ sections of track).

Corrugated

Insert

Alignment Tra k

Prote tive Bags

Corrugated Insert

Mast Box

Mast with Counterweight

Box 3

Vision II Pro Optical Headlamp Aimer Unpacking & Inspection 1.1

Page 5 of 28

Wheels (3)

Charger

Brake Handle

Small

Bag (A)

Figure 1

Cam &

Wheel Mount

Large

Bag (B)

Mast

Support

Column

Shaft

Anti-Rotate

Bra ket

Mast

Cover

T-Base Front

T-Base Rear

Wheels (3)

Charger

Brake Handle

Small

Bag (A)

Figure 1

Cam &

Wheel Mount

Large

Bag (B)

Mast

Support

Column

Shaft

Anti-Rotate

Bra ket

Mast

Cover

T-Base Front

T-Base Rear