- 7 - v.10182019 PN 400-111

pressure. Increase pressure by turning clockwise, decrease pressure by

turning counter-clockwise.

o Ball Valve – Used to shut off gas to the line, also includes a check valve to

prevent backflow into the regulator

o Tank Fitting Nut – Connects the regulator to the CO2tank. Be sure that

there is a washer in place between the tank and regulator. Do not reuse

this washer, it should be replaced every time you change your CO2tank.

• Gas Line – Delivers CO2from the regulator to your keg

o Gray ball lock fitting connects to IN post on your keg.

• Product Line – Delivers beer to your glass

o Party faucet – Squeeze handle down while pointing spout into glass. Be

sure to open completely when pouring, otherwise your beer will come out

foamy.

o Black ball lock fitting – Connects to OUT post on your serving keg.

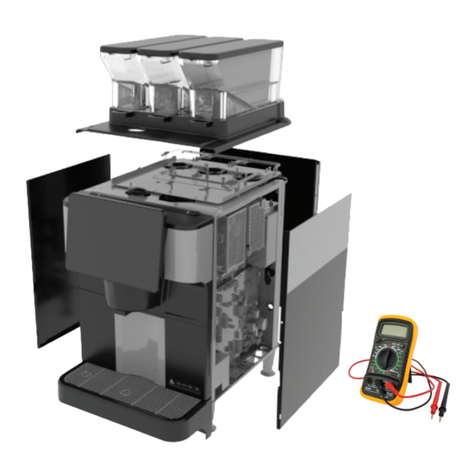

• Keg

o Keg Body

o Keg Lid – Is sealed in place with the locking

bale. The ring can be pulled to open the

pressure relief valve to release pressure from

the keg. The gray pressure relief valve should

be in place when carbonating and serving, not

the red FastFermentation valve.

o Keg Posts – IN and OUT, connect to your ball

lock fittings. Be sure to orient these correctly.

o Dip Tubes – The long should go on the OUT

location, the short should be on IN. Make sure

that the long dip tube is centered on the

bottom of the keg when assembling.

o Poppet valves – Seal the keg posts when the ball locks are not

in place. Make sure that these are assembled correctly with

the wide end of the spring pointing down and the black seal

at the topmost position.

o O-Rings – There are four different sizes of O-rings in your keg:

§ The largest O-ring seals the keg lid

§ The second largest O-rings are for the keg posts

§ The slightly smaller O-rings seal the dip-tubes

§ The smallest O-rings seal your poppet valves