A. Cigarette lighters, pilot lights and any other source of ignition can create an explosion when active during a sanding

session. All sources of ignition should be extinguished or removed entirely if possible from the work area.

B. Work areas that are poorly ventilated can create an explosive environment when certain combustible materials are in the

atmosphere, i.e., solvents, thinners, alcohol, fuels, certain nishes, wood dust and other combustible materials. Floor

sanding equipment can cause ammable material and vapors to burn. Read the manufacturer’s label on all chemicals

used to determine combustibility. Keep the work area well ventilated.

C. Spontaneous combustion or an explosion can occur when working with sanding dust. The sanding dust can self-ignite

and cause injury or damage. Sanding dust should be disposed of properly. Always empty the sanding dust into a metal

container that is located outside of any building(s).

D. Remove the contents of the dust bag when the bag is 1/3 full. Remove the contents of the dust bag each time you nish

using the equipment. Never leave a dust bag unattended with sanding dust in it.

E. Do not empty the contents of the dust bag into a re.

F. Hitting a nail while sanding can cause sparks and create an explosion or re. Always use a hammer and punch to

countersink all nails before sanding oors.

3

EN

DANGER: Failure to read the Owner’s Manual prior to operating or servicing your American Sanders machine could result in injury to

you or to other personnel; damage to the machine or to other property could occur as well. You must have training in the

operation of this machine before using it. If you or your operator(s) cannot read English, have this manual explained fully

before attempting to operate this machine.

DANGER:

DANGER:

DANGER:

DANGER:

WARNING::

WARNING::

WARNING::

WARNING::

Operating partially assembled sanding equipment could result in injury to the operator or bystander and could cause damage

to the equipment or to other property.

A. Do not operate this equipment unless it it fully assembled and all guards, doors and covers are secured.

B. Keep all fasteners tight.

C. Keep all adjustments within manufacturers specications.

This sanding equipment requires a supply of electricity. Improper use could result in electrical

shock or re.

A. Connect only to an electrical source matching what is shown on the equipment nameplate.

B. Do not use this sanding equipment on an ungrounded electrical circuit. Consult an electrician if you suspect the circuit is

not properly grounded.

C. Do not use this sanding equipment with a damaged electrical cord. Inspect before each use.

D. Avoid striking the elelctrical cord with the abrasive. Always lift the electrical cord over the sanding equipment.

E. Do not use the electrical cord to move the sanding equipment.

F. Disconnect the electrical source before servicing this equipment.

Bodily injury could occur if power is applied to the equipment with the power switch already in the “ON” position. Always

check to assure that the power switch is in the “OFF” position before connecting power supply.

WARNING: Risk of explosion. Floor sanding can result in an explosive mixture of ne dust and air. Use oor sanding machine only in a

well-ventilated area free from any ame or match.

CAUTION: Maintenance and repairs performed by unauthorized personnel could result in damage or injury. Maintenance and repairs

performed by unauthorized personnel will void your warranty. Servicing of this unit must always be referred to an authorized

American Sanders distributor.

CAUTION: Use of this equipment to move other objects or to climb on could result in injury or damage. Do not use this equipment as a

step or furniture. Do not ride on this equipment.

CAUTION: Damage could occur to the equipment if not properly kept in a dry building for storage. Store the equipment in a dry building.

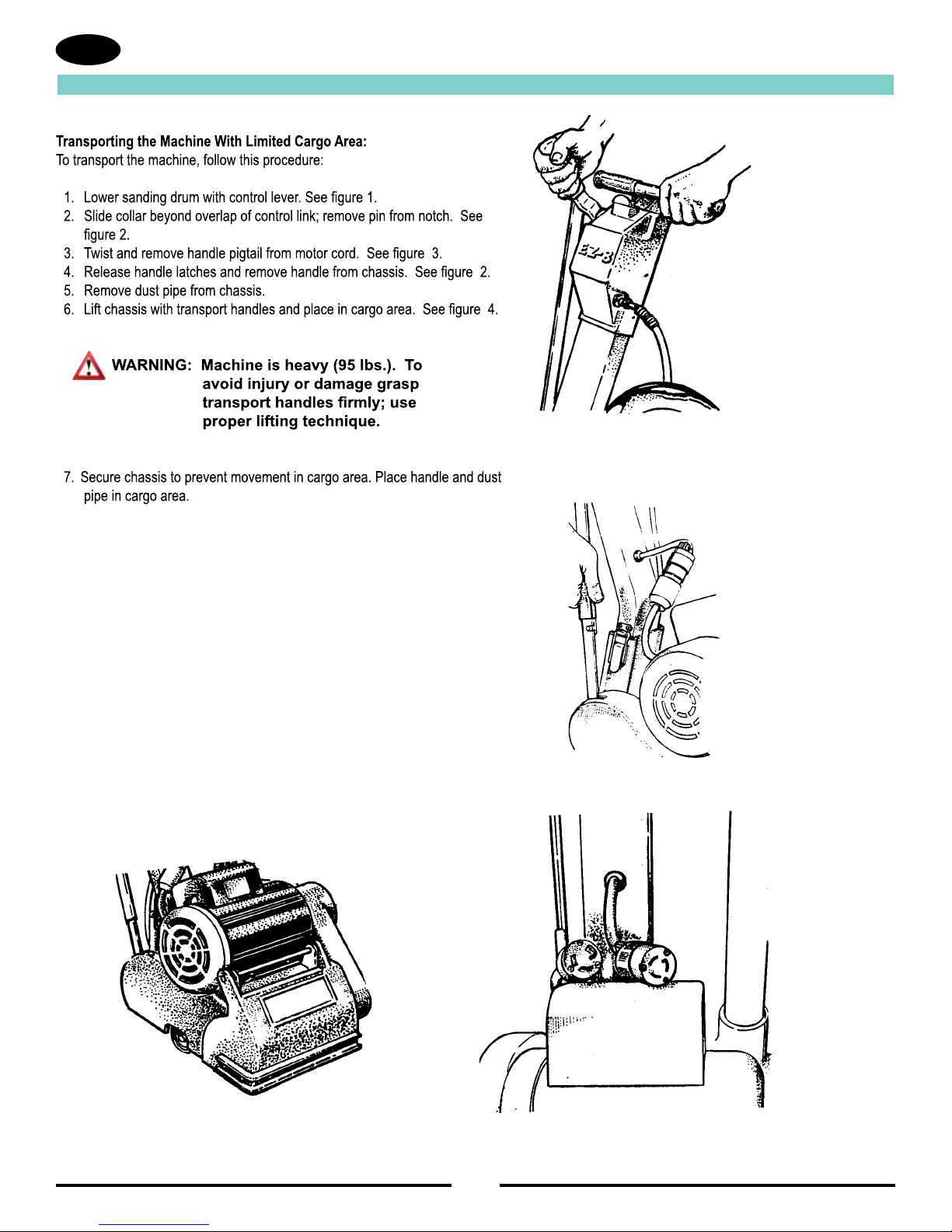

CAUTION: The equipment is heavy. When transporting the equipment, remove the motor. Get help to lift the equipment and motor.

CAUTION: Serious damage to the oor can occur if the sanding equipment is left running in one spot while the sanding drum is in

contact with the oor. To avoid damage to the oor, feather cut in at a normal sanding rate. Do not dwell while lowering or

raising the contact wheel. Always sand at a constant rate.