10 Pub. No. 18-HE56D1-3

Field Upgrade Guide

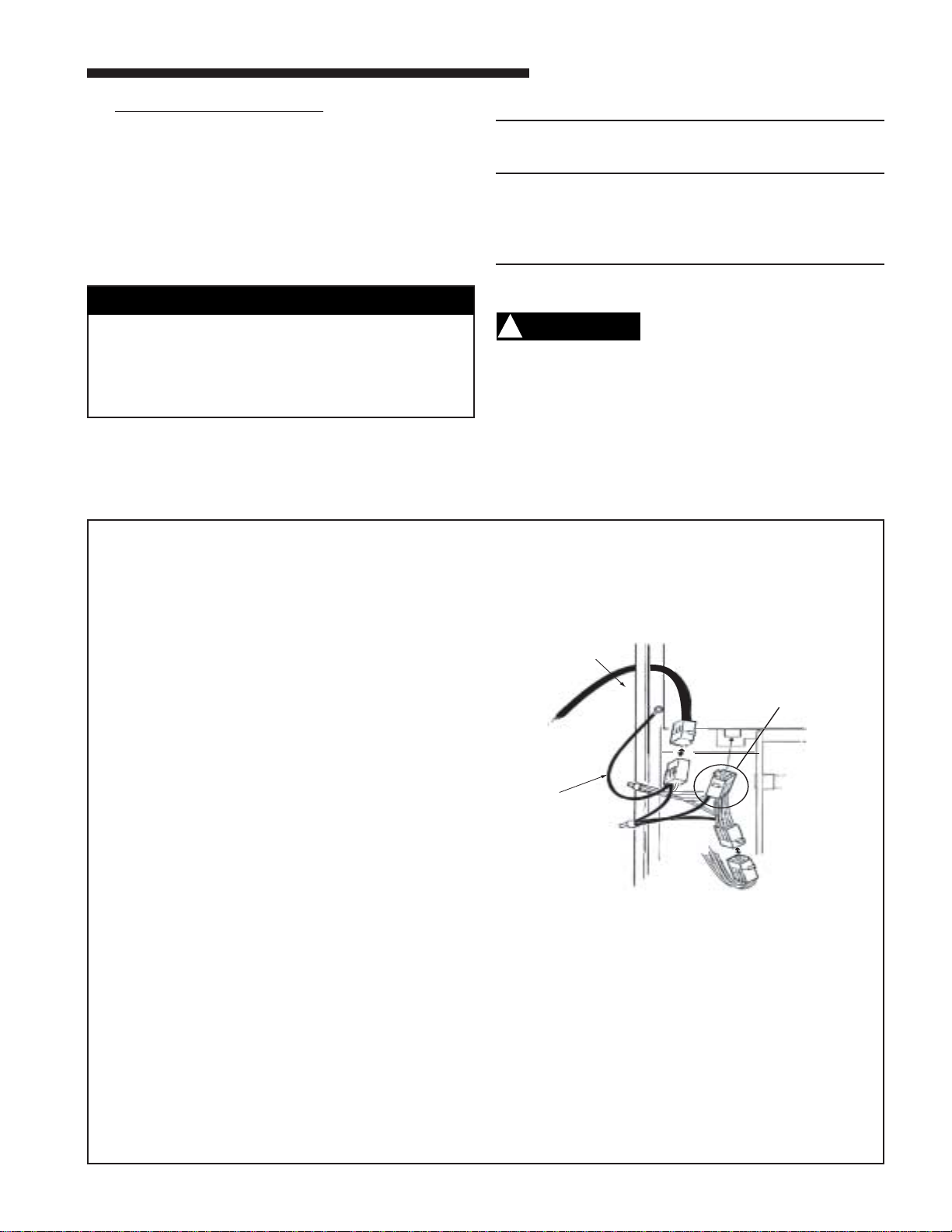

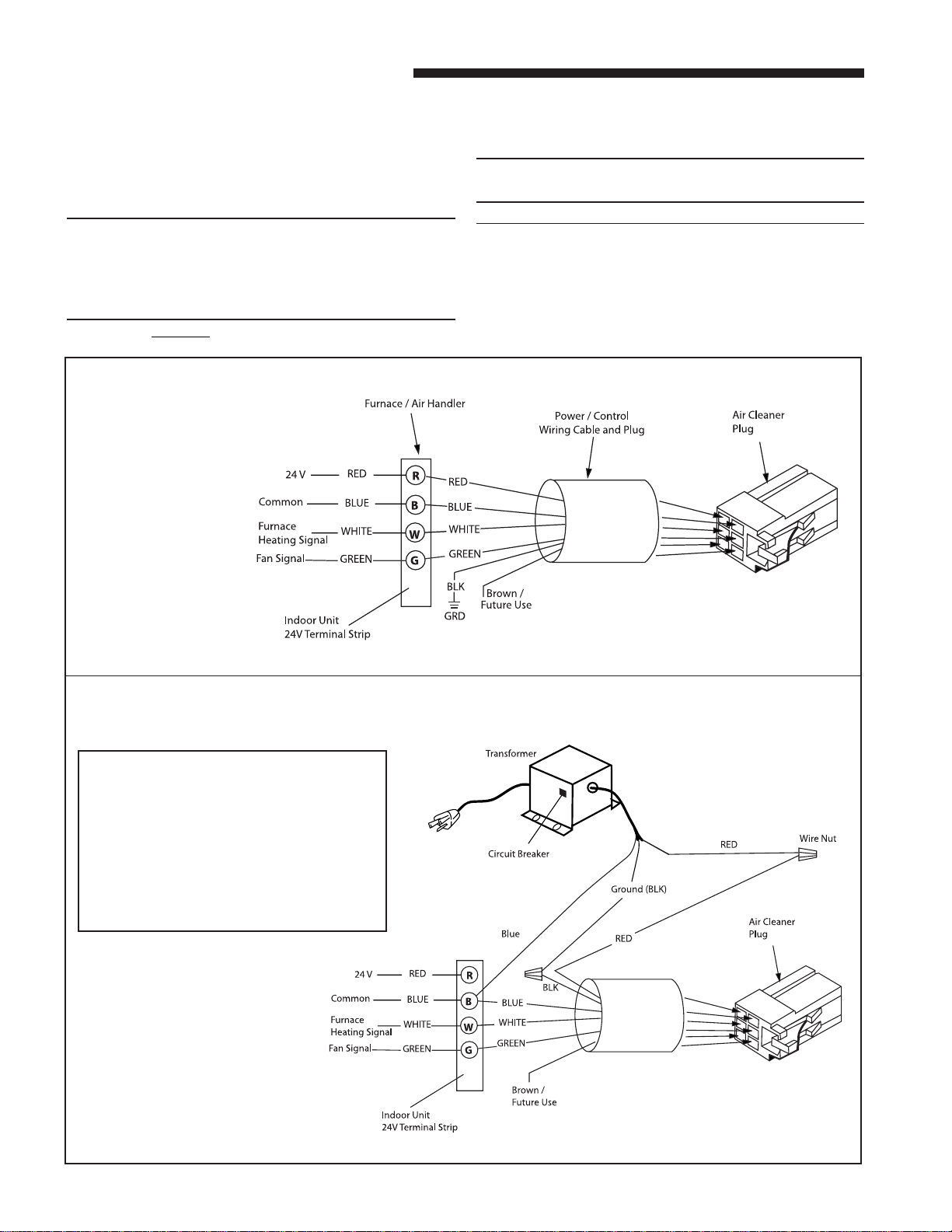

CELL CLEANING SETTING (Fig. 17)

One or more of the YELLOW LED’s will come on indicating

the COLLECTION CELL cleaning time setting. Repeatedly

press the RESET button to cycle through the time options for

the COLLECTION CELLS cleaning cycle until the desired

setting is displayed. Press the POWER button once to accept

that setting and move to the power settings.

Fig. 17 YELLOW LED COLLECTION CELL SETTING

2 Month 4 Months 6 Months* 9 Months

G1

G2

G3

Y3

Y4

R1

R2

R3

Y2

CLEAN

DIRTY

G1

G2

G3

Y3

Y4

R1

R2

R3

Y2

CLEAN

DIRTY

Y1

G1

G2

G3

Y3

Y4

R1

R2

R3

Y2

CLEAN

DIRTY

Y1 Y1

G1

G2

G3

Y3

Y4

R1

R2

R3

Y2

CLEAN

DIRTY

Y1

*Factory Setting

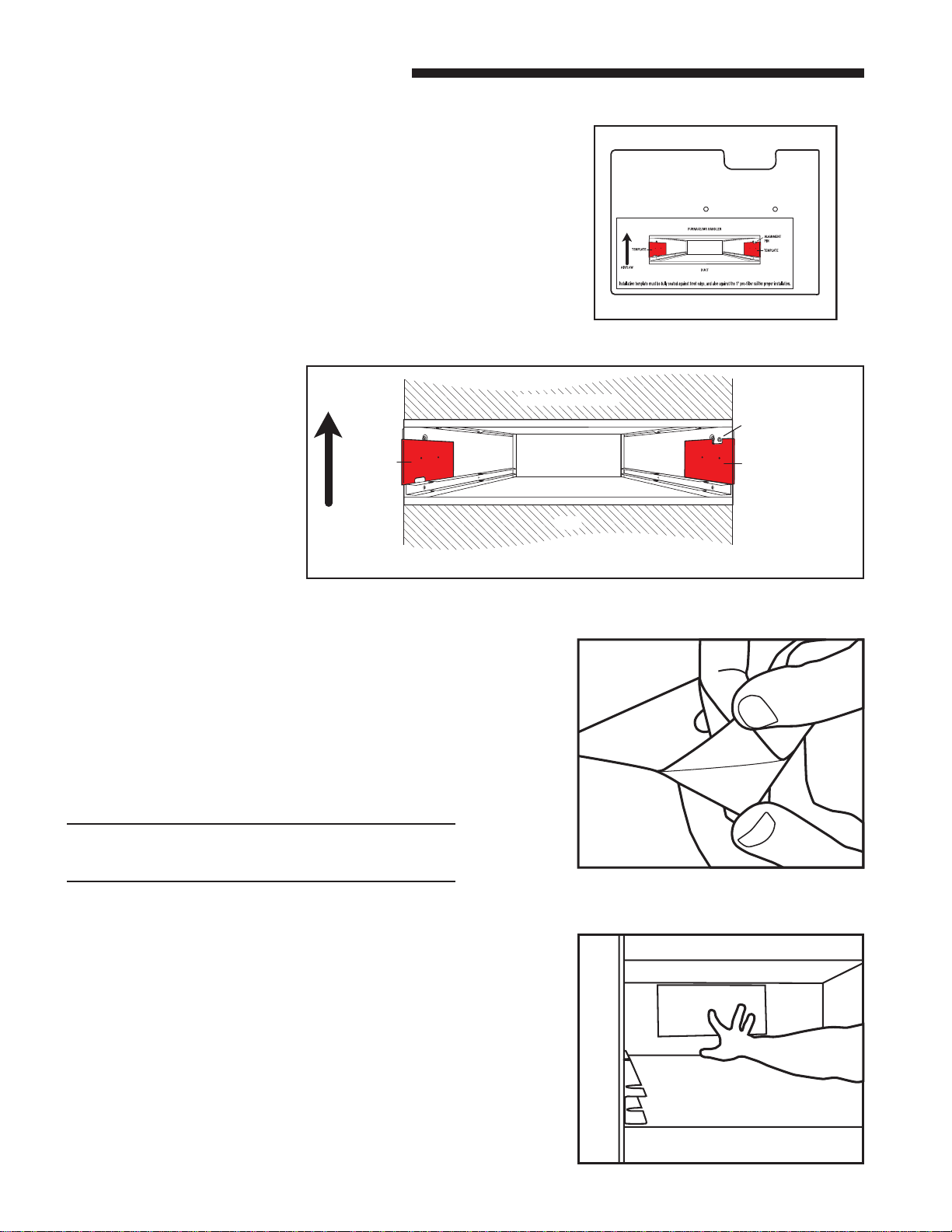

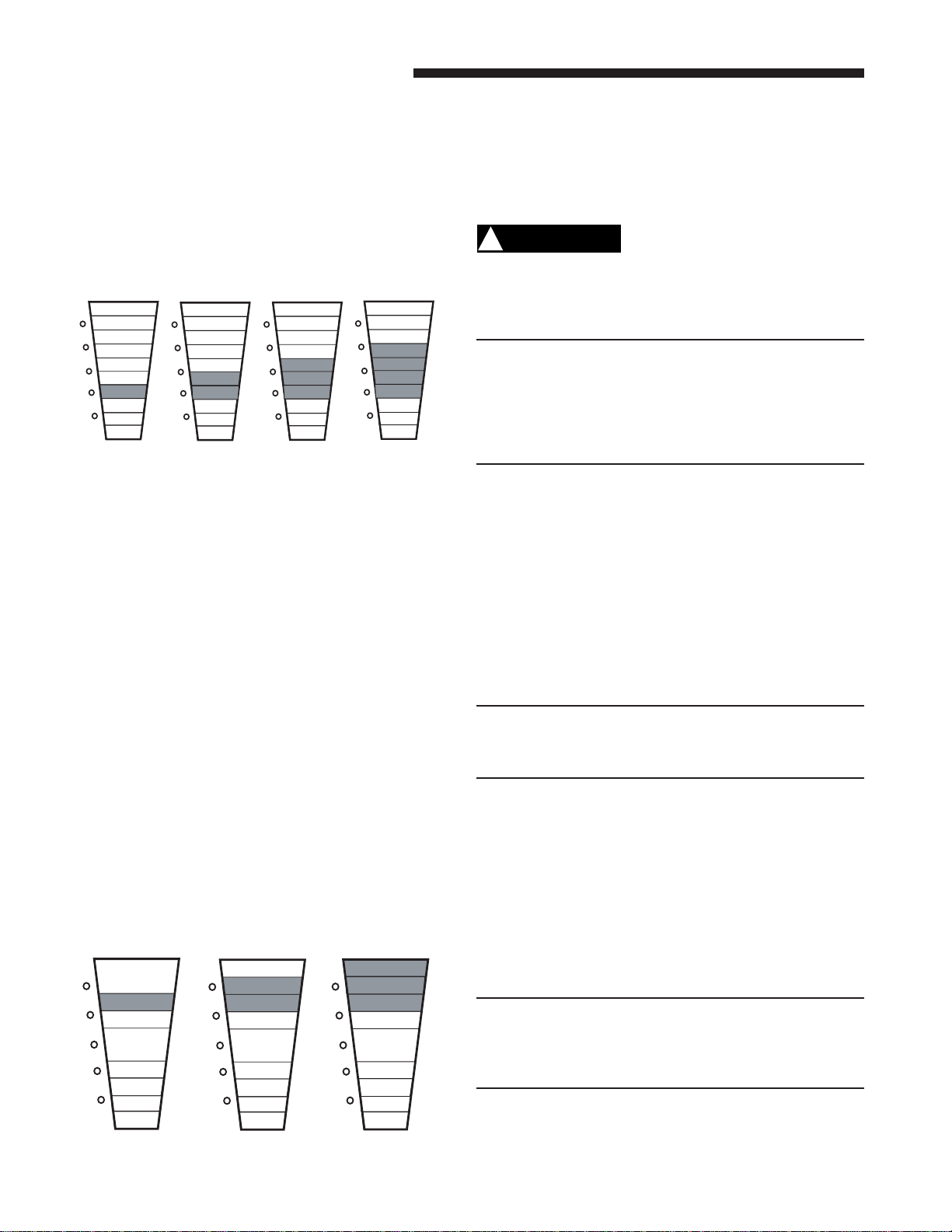

FIELD CHARGER POWER LEVEL

The RED LED lights are used to set the power level of the

FIELD CHARGER for maximum, medium, or minimum. The

number of illuminated RED LED lights indicates the current

setting. The factory setting is for maximum.

Lower settings will reduce the slight sound emitted by the

unit with minimal loss of air cleaning efficiency, if desired.

Lower settings will also further reduce the very low ozone

produced by the air cleaner. The U.S. Food and Drug

Administration recommends indoor ozone concentrations

should not exceed 50 parts per billion. Your air cleaner will

contribute only 5 parts per billion at the factory setting and

can be reduced to 3 parts per billion at the minimum setting.

FIELD CHARGER POWER LEVEL SETTINGS

One or more of the RED LED lights will illuminate. To

change the power level setting, press the RESET button

until the desired setting is indicated.

To save your new settings and exit the Set-Up mode, press

and hold BOTH the POWER and filter RESET buttons for a

minimum of 5 seconds.

Fig. 18 RED LED POWER LEVEL SETTINGS

Minimum Medium Maximum*

G1

G2

G3

Y1

Y3

Y4

R1

R2

R3

Y2

CLEAN

DIRTY

G1

G2

G3

Y1

Y3

Y4

R1

R2

R3

Y2

CLEAN

DIRTY

G1

G2

G3

Y1

Y3

Y4

R1

R2

R3

Y2

CLEAN

DIRTY

*Factory Setting

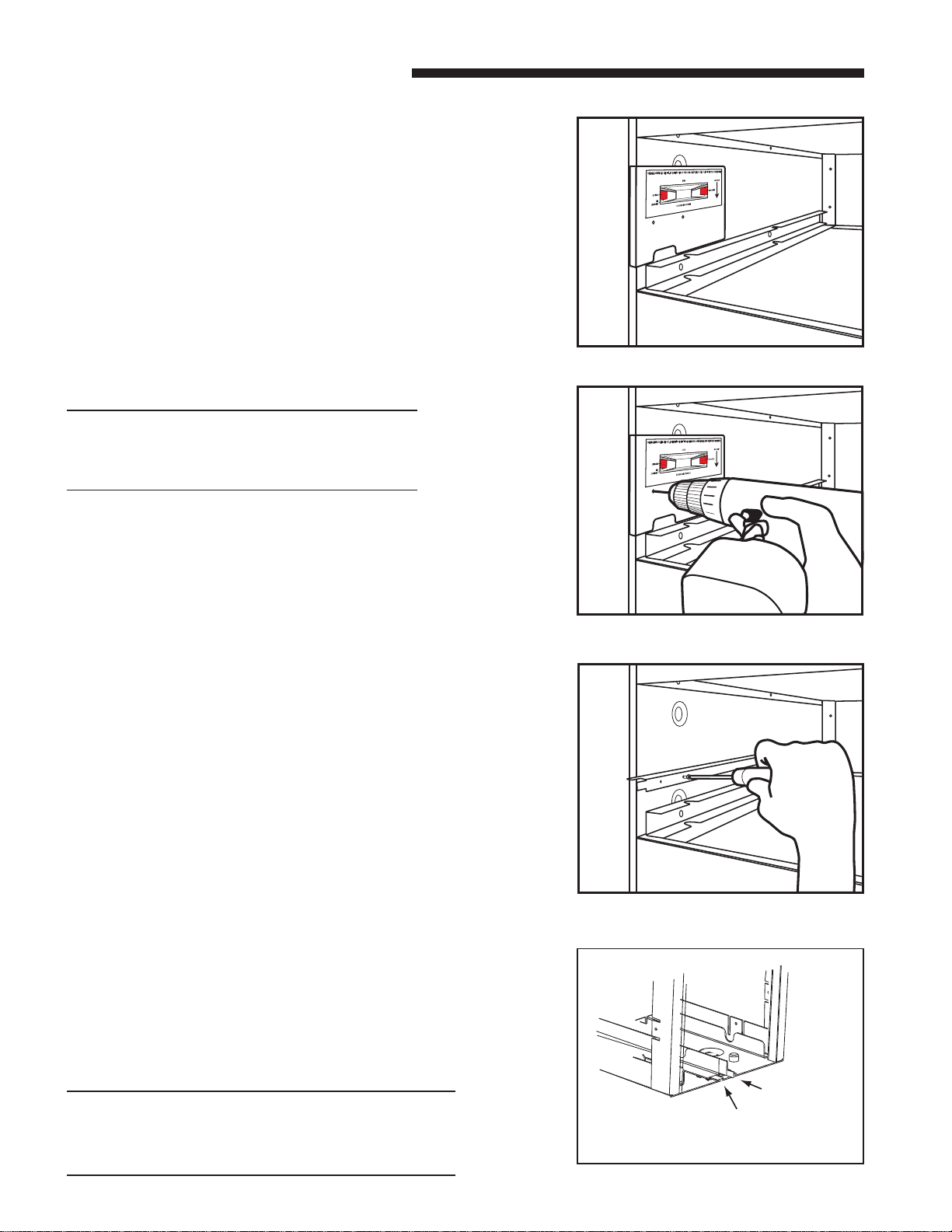

MAINTENANCE

For maximum efficiency the COLLECTION CELLS and PRE-

FILTER should be inspected and cleaned on a regular basis.

The FIELD CHARGER should only be removed and cleaned

annually by an authorized service professional.

CAUTION

!

High Voltage is present within the air cleaner for operation.

Beforeremovingthedoor,turnthepoweroffandwaitatleast

15 seconds to allow voltage to discharge.

NOTE: Before cleaning the coil or ducts in the air handler

or furnace, remove the COLLECTION CELLS, FIELD

CHARGER, and PRE-FILTER from the air cleaner.

Chemicals used during the cleaning of the air handler,

furnace, or ductwork can damage the air cleaner

components and degrade the performance of the air

cleaner.

CLEANING

1. Turn the air conditioning system off at the thermostat.

2. Turn off power to the air cleaner by pushing and holding the

POWERbuttonforthreeseconds. TheLED'swillremainon

until the voltage has discharged and it is safe to remove the

door. This requires approximately 15 seconds. Do not

remove the door until all lights are off.

3. Disconnect the power/control cable if required to place the

door in a secure location.

PRE-FILTER CLEANING

The PRE-FILTER can be vacuumed or washed to clean. The

PRE-FILTER should be completely dry before re-installing.

NOTE: Do not replace the plastic PRE-FILTER with a metal

type PRE-FILTER. A metal PRE-FILTER will cause

reduction in efficiency and potential failure of the

electronics in the air cleaner

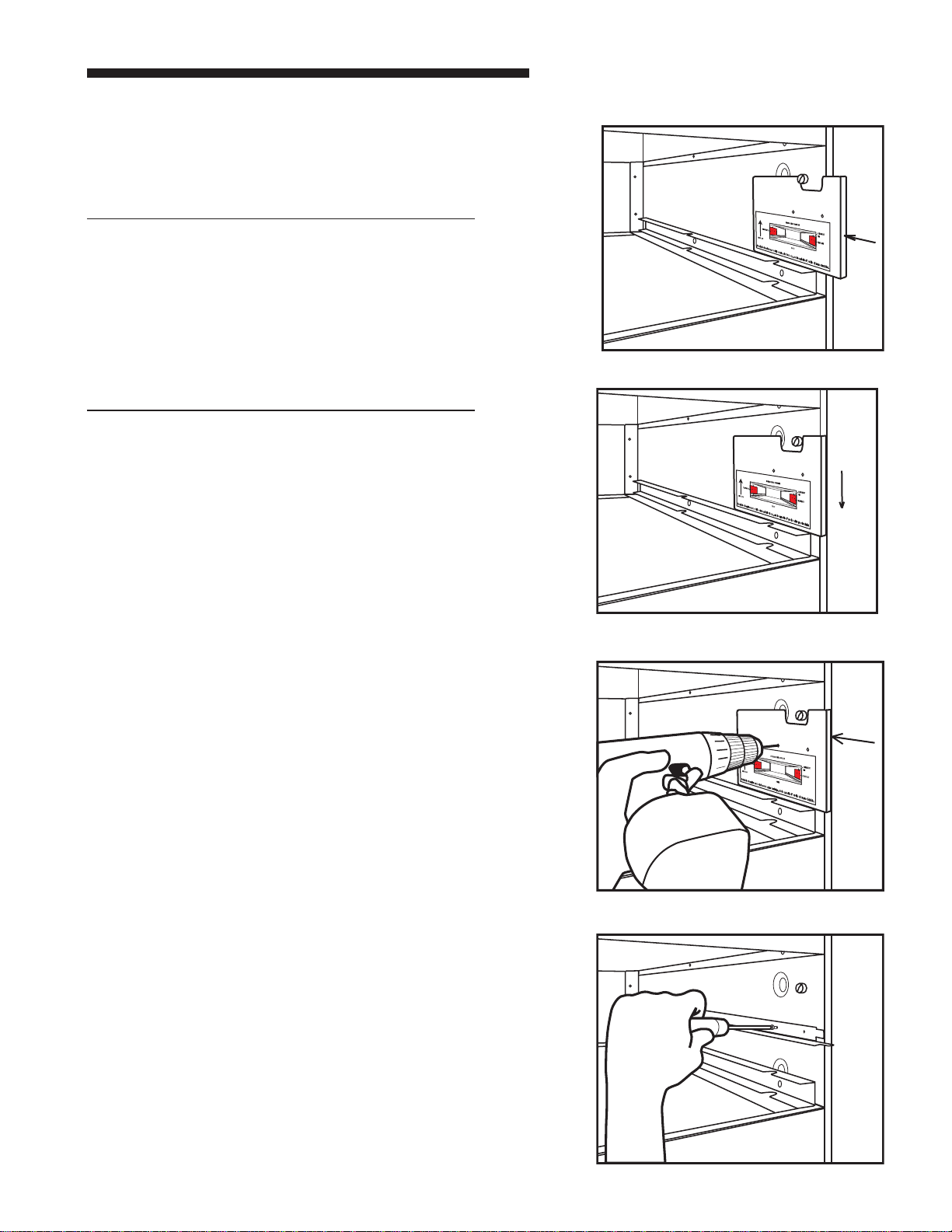

COLLECTION CELL CLEANING

The COLLECTION CELLS can be cleaned either by

vacuuming (recommended method) or by washing.

VACUUM CLEANING

Vacuum both sides of the COLLECTION CELLS to clean.

WASHING

Use low-pressure water spray, such as a sink sprayer or

garden hose to clean the cells. Some residue may require

warm water to be removed.

• DO NOT USE SOAP OR DETERGENT IN CLEANING THE

COLLECTION CELLS.

• DO NOT IMMERSE THE CELLS COMPLETELY IN WATER.

• DO NOT PLACE THE CELLS INTO A DISHWASHER TO

CLEAN

.

Slightly tap the COLLECTION CELLS to remove water

retained in the filter. Allow the COLLECTION CELLS to dry

before re-installing.