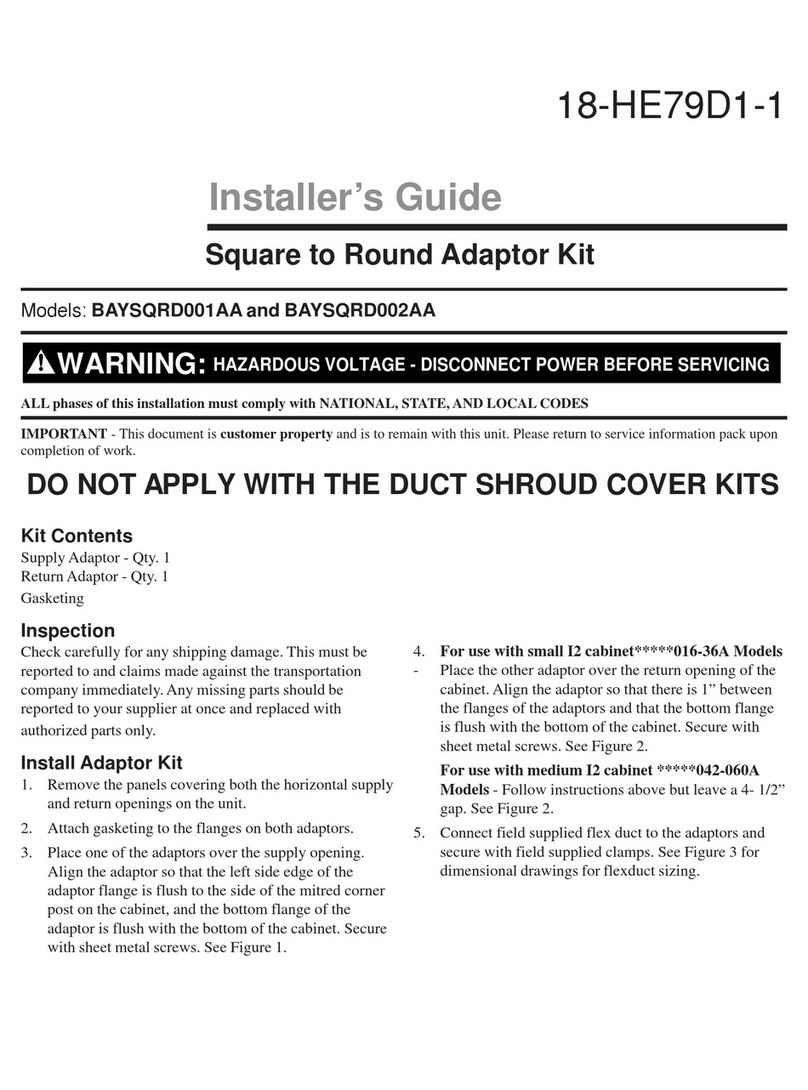

Model:

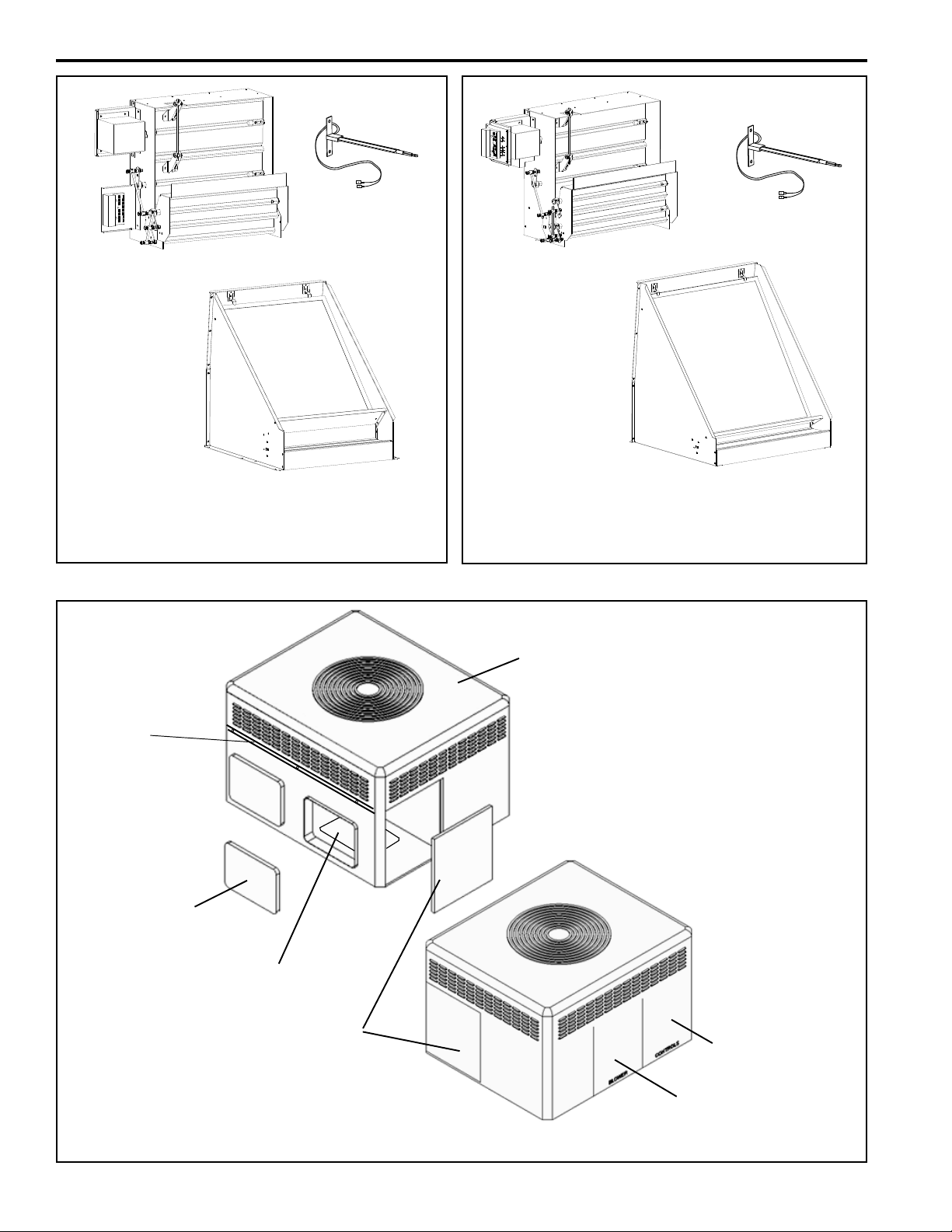

BAYECON101A

BAYECON102A

BAYRLAY004A (Relay required in WC* Units)

Down Discharge Economizer and Rain Hood

Used with:

2/4TC*,WC*,YC*,DC* *018-036A

2/4TC*,WC*,YC*, DC* *042-060A

Inspect Contents

You must report damage and make claims to the transporta-

tion company immediately. Report missing parts to your sup-

plier immediately and replace with authorized parts only.

3. Install Economizer Assembly

Note: You must first install the filter rack per the instruc-

tions provided and then install the economizer.

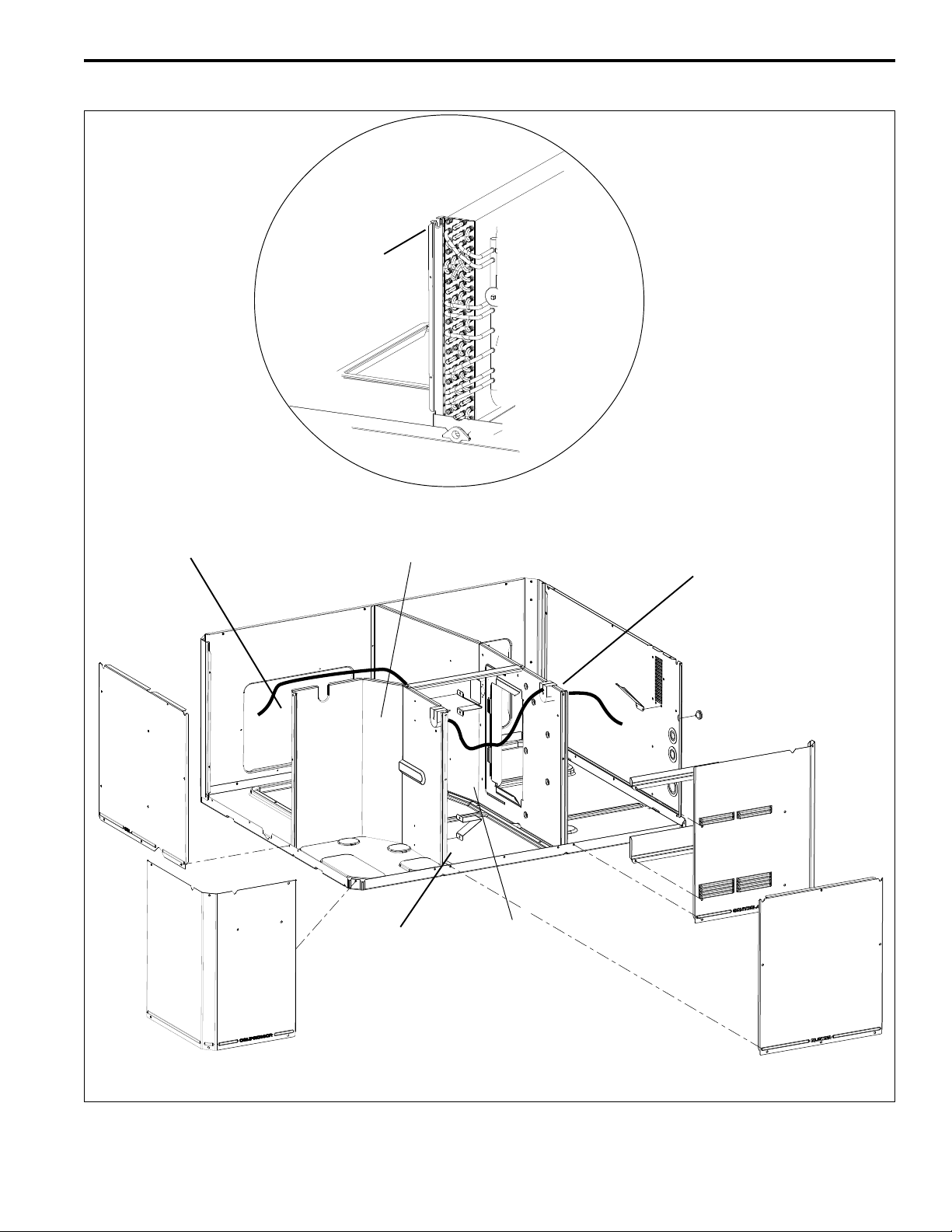

2. Swing the return air damper section down so that it rests

on the bottom of the unit. The economizer will sit

completely over the return air opening in the bottom of

the unit. See Figures 5 on page 4. Screw the economizer

assembly together with one assembly screw in the side of

the economizer. Tighten the linkage rod between the

return air dampers.

3. Insert 2 screws through the holes in the front face of the

unit and into the matching attachment holes in the econo

mizer assembly. See Figure 6 on page 4.

4. Insert a screw through the pre-punched hole in the side

flange of the return air damper and into the mating hole

in the economizer assembly and tighten. See Figure 5 on

page 4.

18-HE39D8-7

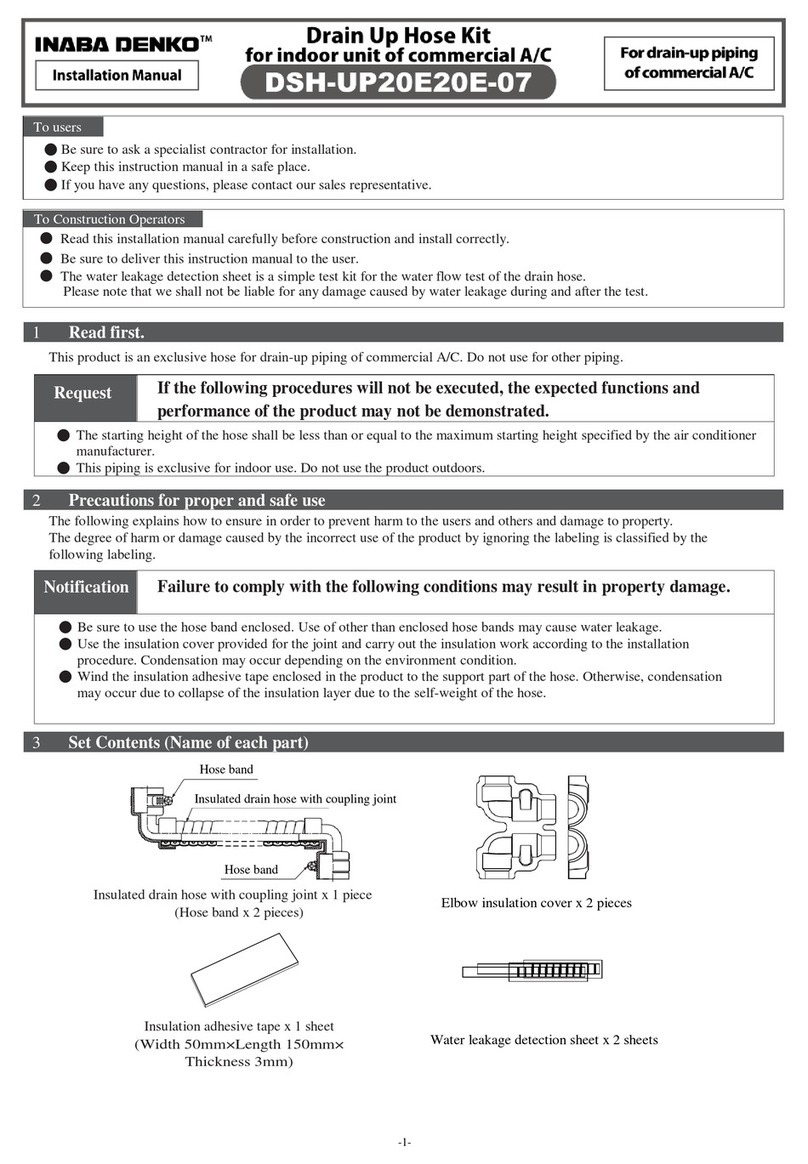

Identify Economizer Kit Contents

Refer to Figures 1 and 2 on page 2 to identify the kit

contents.

Install Economizer Kit

General

The economizer is a multi-damper design. It is installed in the

return air stream and is connected to the unit low voltage sup-

ply through wire leads. The economizer is fully accessible

through the Coil access panel.

Important: The Economizer installation requires that you first

install an air filter rack ordered separately. Use:

BAYFLTR101A for 2/4YC*, WC*, TC*, DC* *018-3036A

BAYFLTR201A for 2/4YC*, WC*, TC*, DC* *042-3060A.

1. Remove Power

Disconnect and verify that power is off.

2. Remove Access Panels

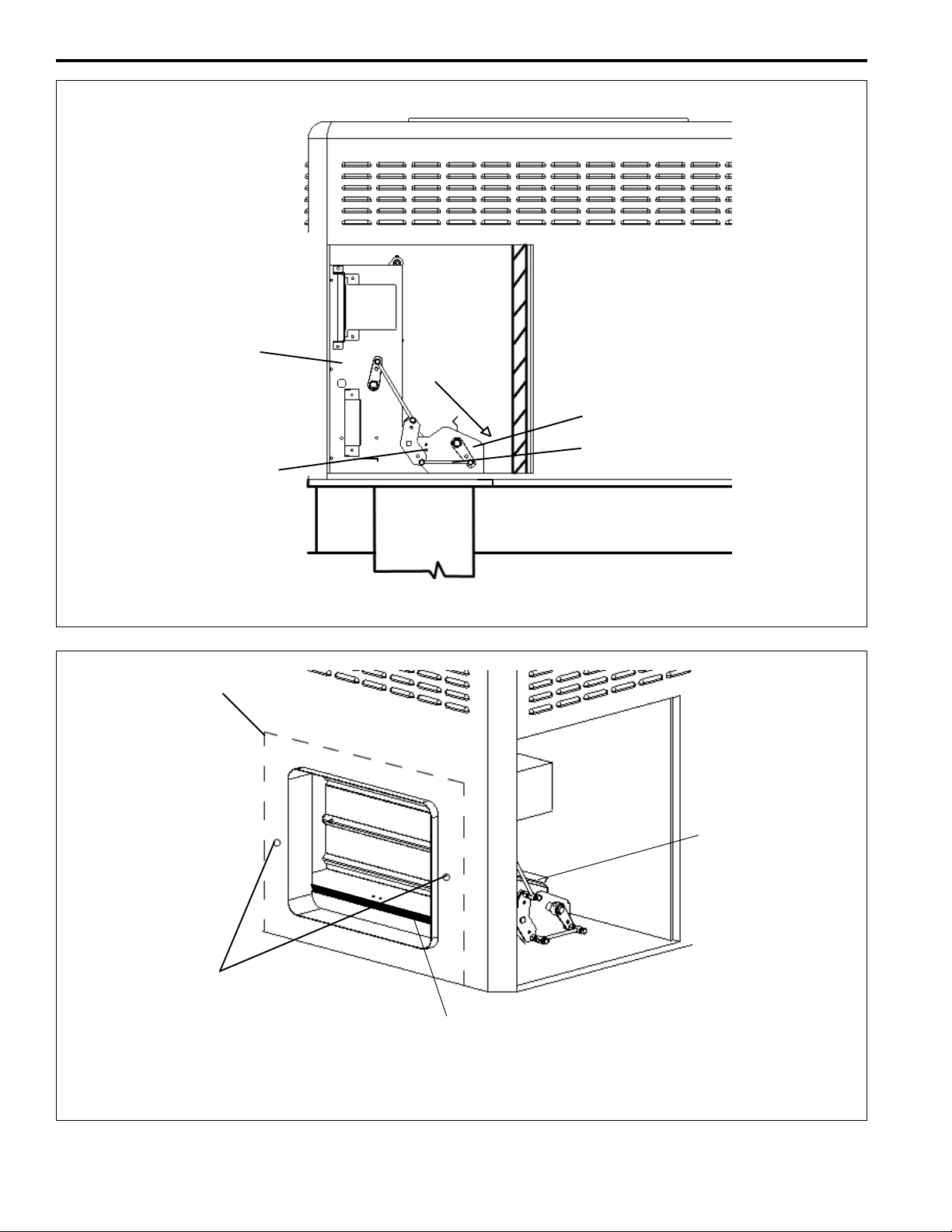

Remove these four (4) access panels (see Figure 3, page 2):

• Control/Heat access panel

• Blower access panel

• Coil access panel

• Horizontal Return Air panel (discard or store)

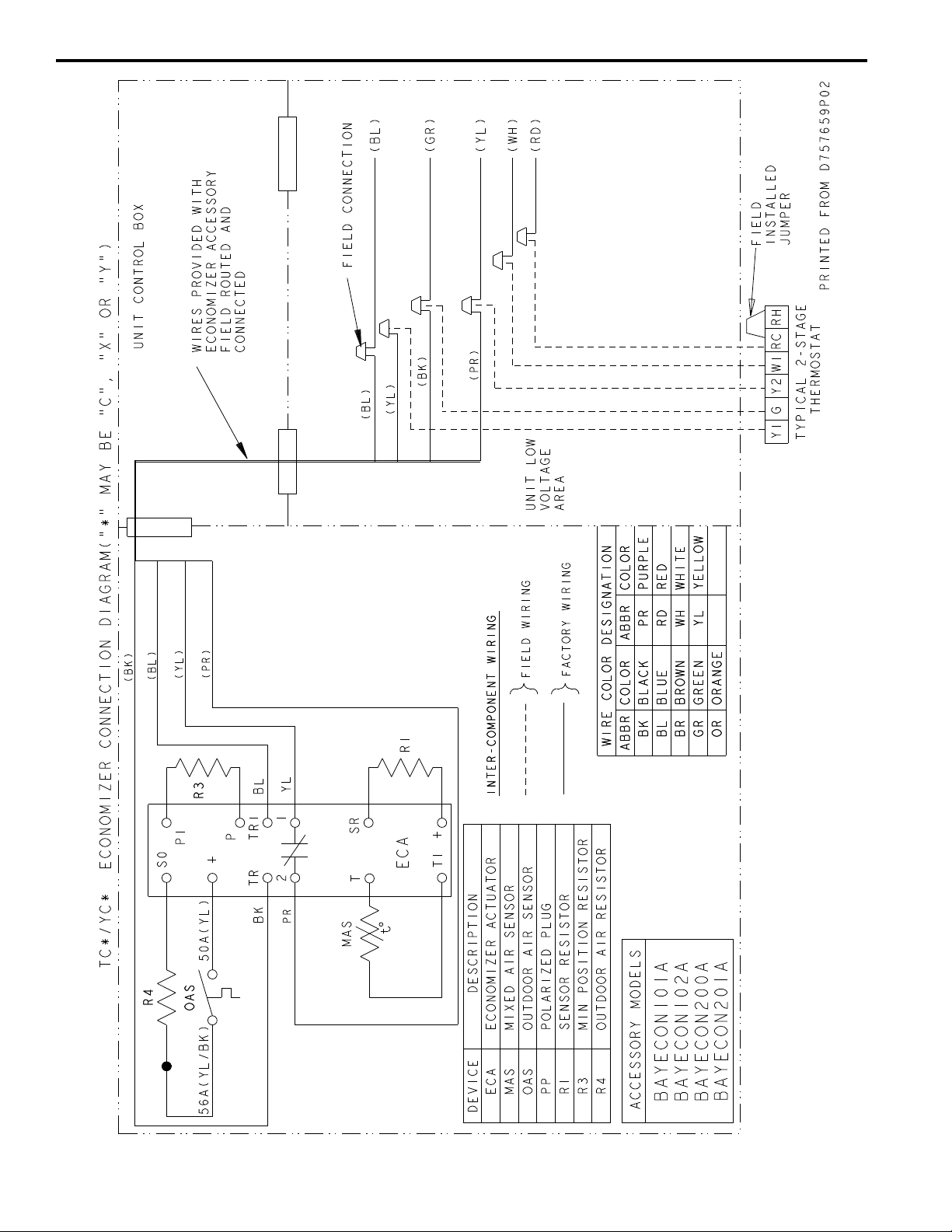

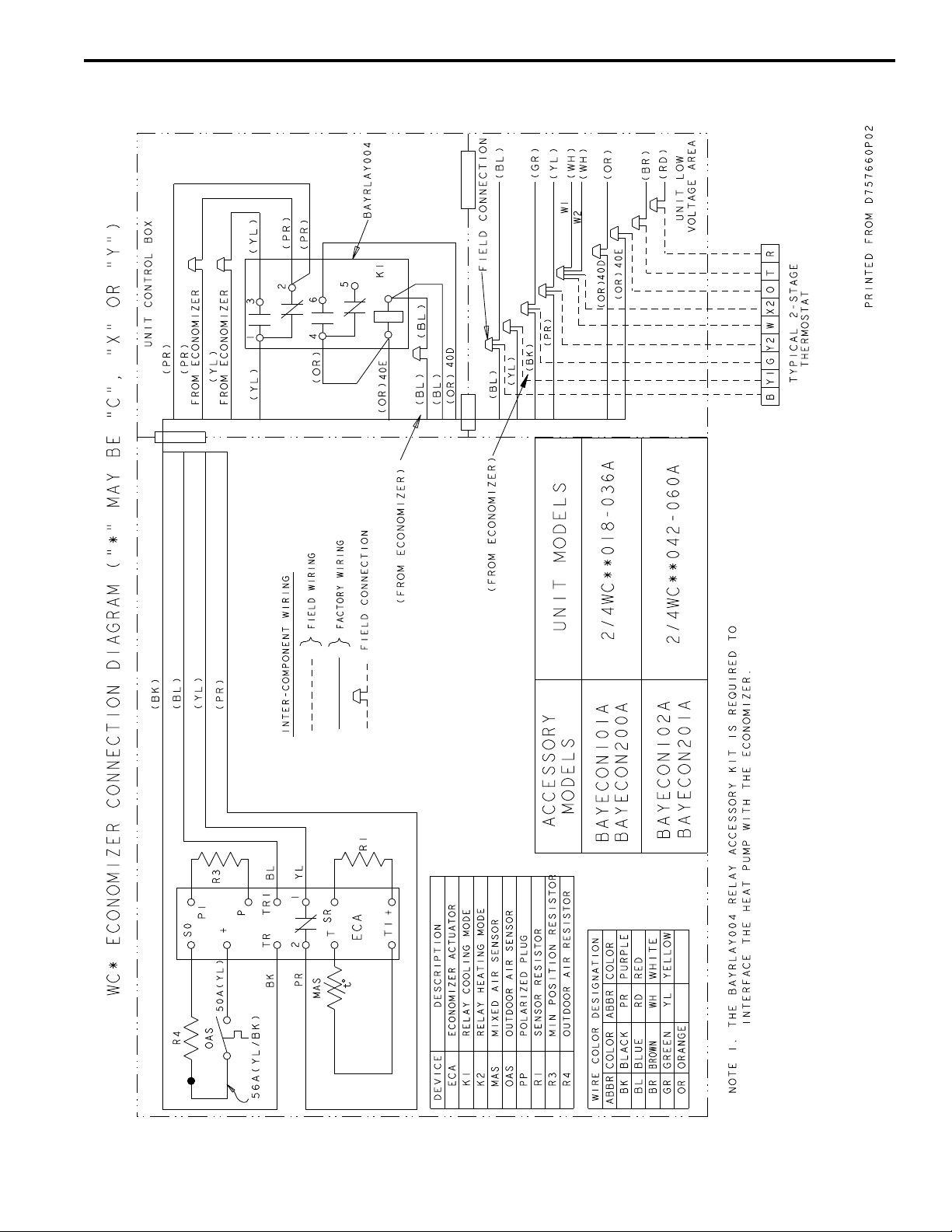

When the economizer is installed in WC* models, relay

accessory kit BAYRLAY004A is required. Refer to the drawing

on page 9 to make your relay wiring connections in the Control

Box.

Installer’s Guide

ALL phases of this installation must comply with NATIONAL, STATE AND LOCAL CODES

IMPORTANT — This Document is customer property and is to remain with this unit. Please return to service

information pack upon completion of work.

HAZARDOUS VOLTAGE - DISCONNECT POWER BEFORE SERVICING

WARNING:

ELECTRIC SHOCK HAZARD

OPEN AND LOCK OUT ALL UNIT DISCONNECTS PRIOR TO

ACCESSORY INSTALLATION OR UNIT MAINTENANCE, TO

PREVENT INJURY OR DEATH FROM ELECTRICAL SHOCK OR

CONTACT WITH MOVING PARTS.

SAFETY HAZARD

DO NOT REMOVE END COVERS FROM ECONOMIZER AC-

TUATOR; THE SPRING-RETURN ASSEMBLY MAY RELEASE

AND CAUSE PERSONAL INJURY.

WARNING

!

!

WARNING

Use care when inserting the economizer in the return air com-

partment, to prevent damaging the foil faced insulation.

CAUTION

!

1. The economizer ships with the return air damper folded

up to allow the assembly to fit through the Coil opening

in the side of the unit, see Figures 1 and 2 on page 2.

Insert the economizer assembly into the unit through the

Coil access panel opening. See Figure 4 on page 3.