%

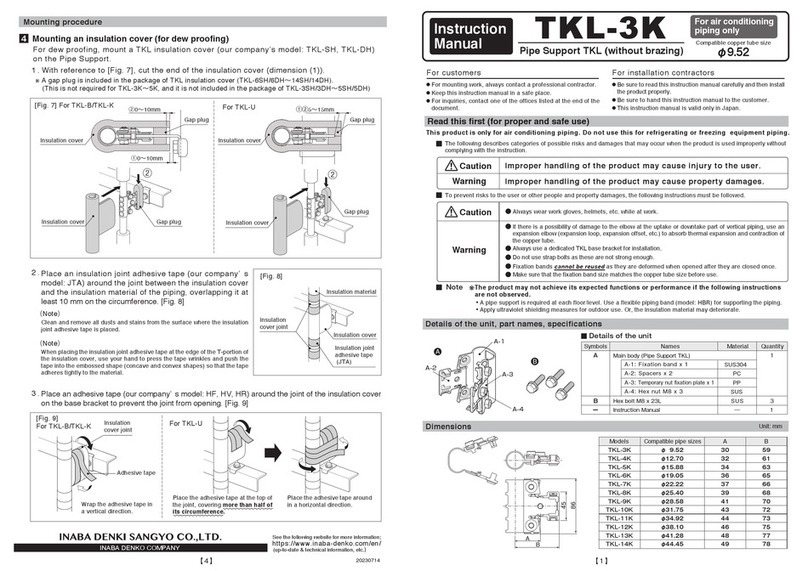

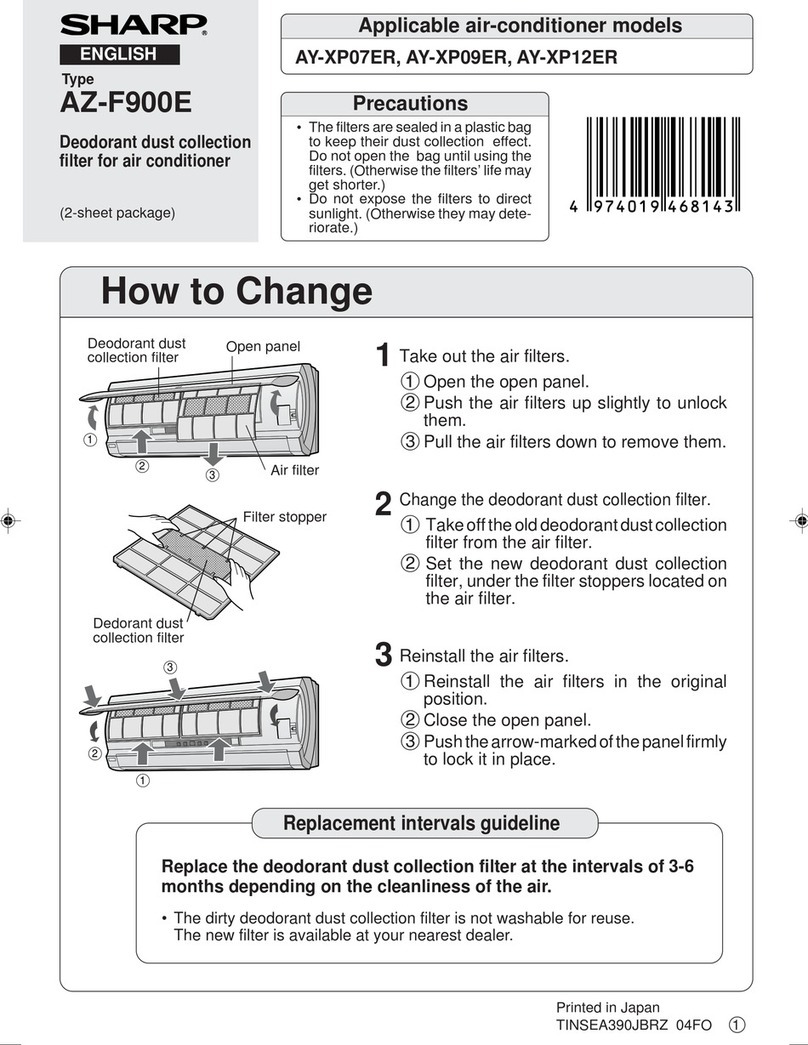

(Drawing15)

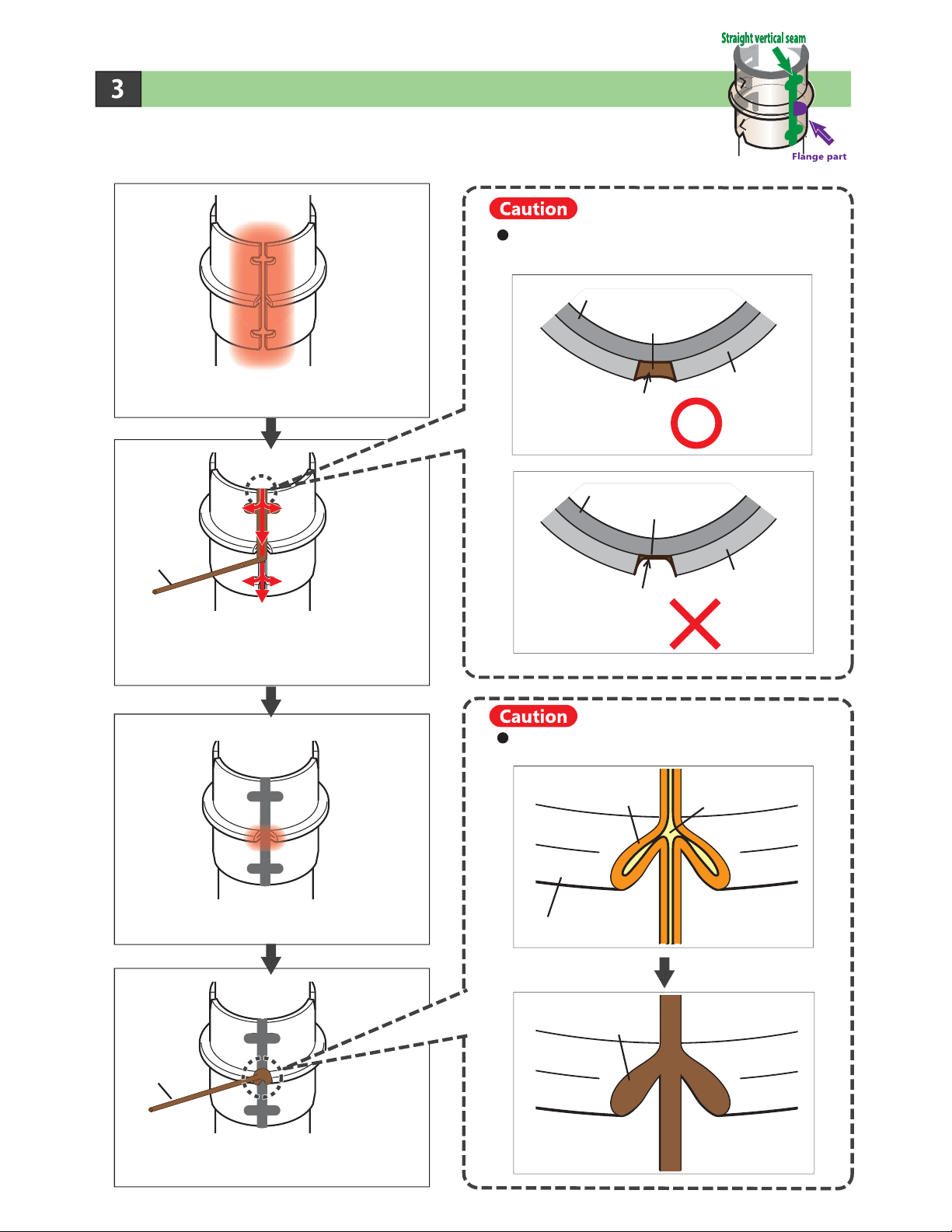

Entire circumference

of bottom edge

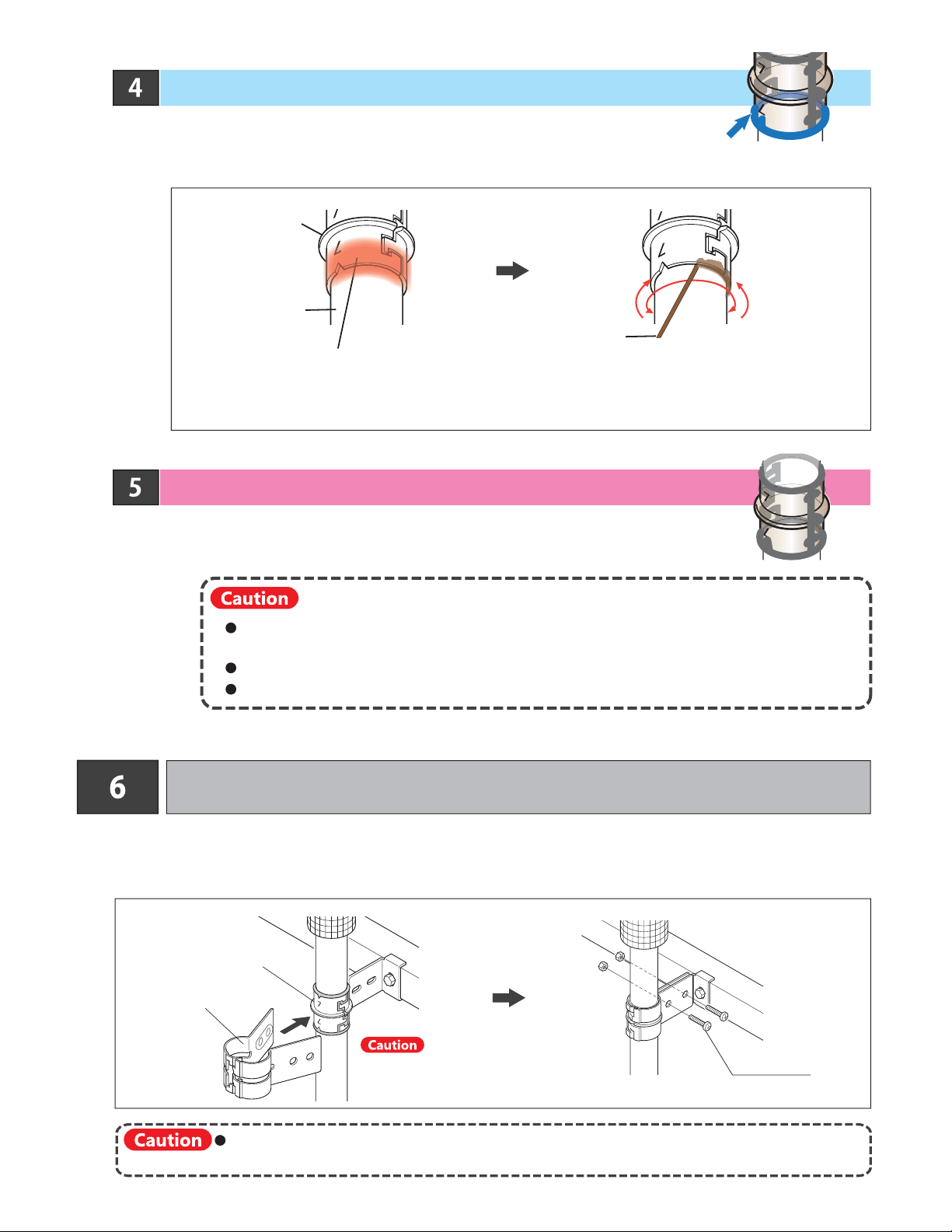

Apply the filler rod to the weld area

clockwise and counterclockwise to ensure

that the gap is completely filled with brazing

material.

Braze entire circumference of bottom edge.

(Drawing 15)

Pipe Support

Ferrule

Copper pipe

Brazing material

Ensure that entire surface of weld area

is properly heated.

Check brazing condition again after completion of

brazing work.

Check for integrity of brazing material on all brazed surfaces of ferrule.

Cool down brazed ferrule assembly with damp cloth.

Filled brazing material may flow downwards when heat is applied to an adjacent section,

In this case, rebraze affected part.

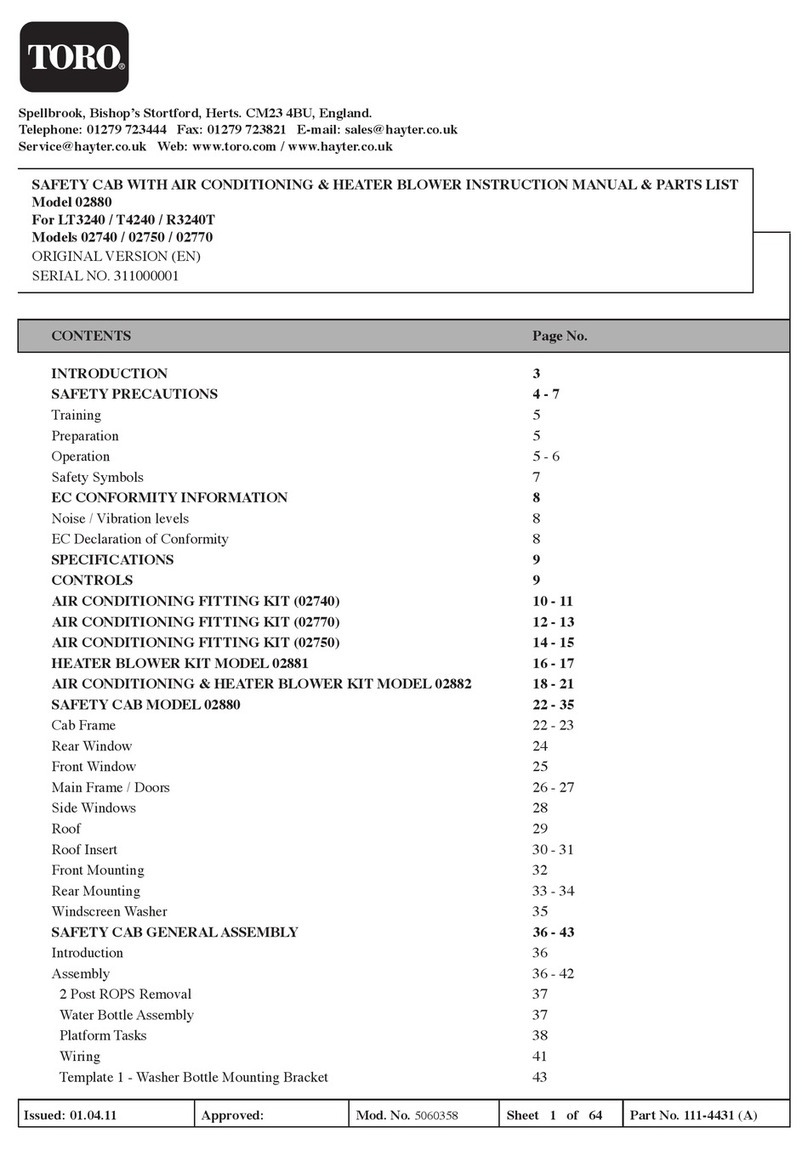

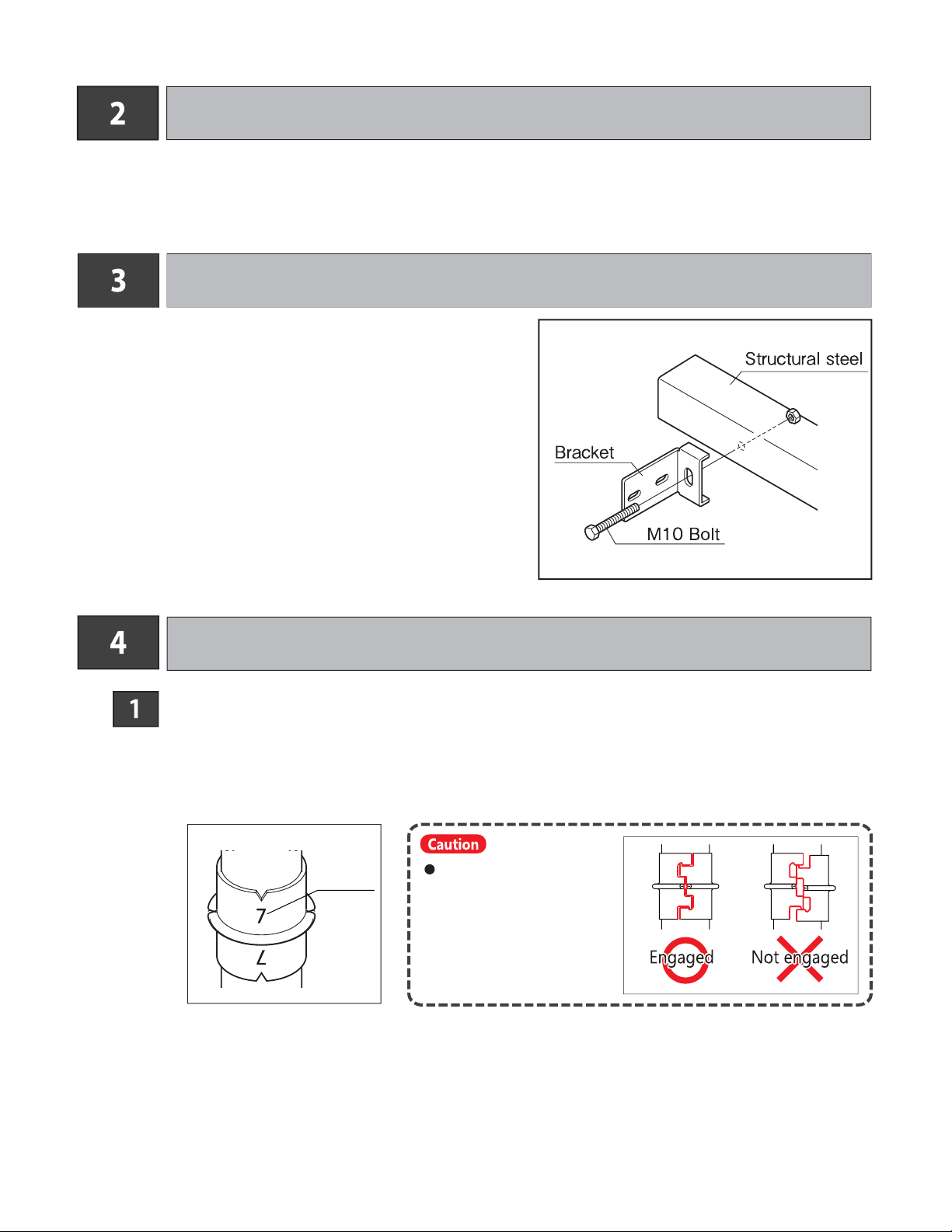

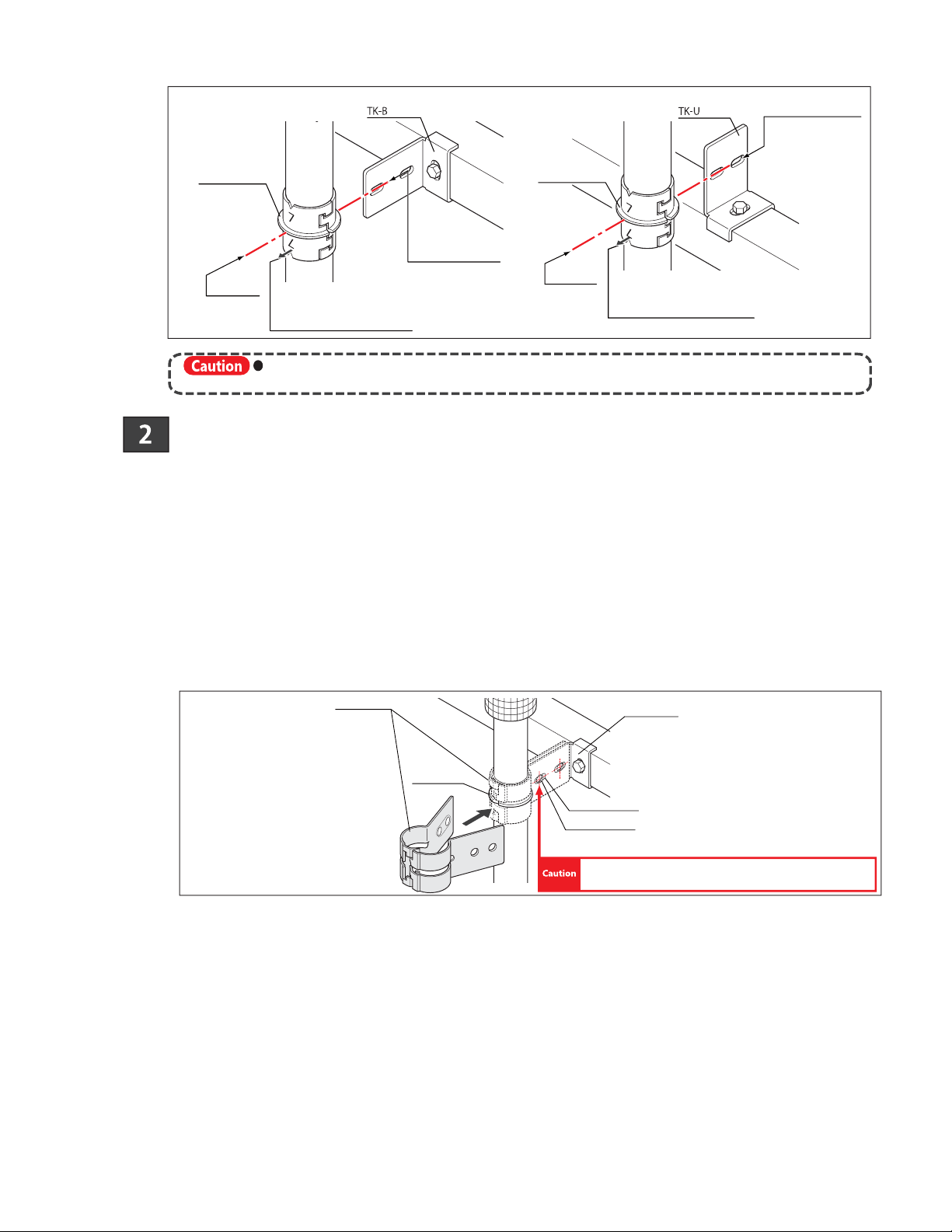

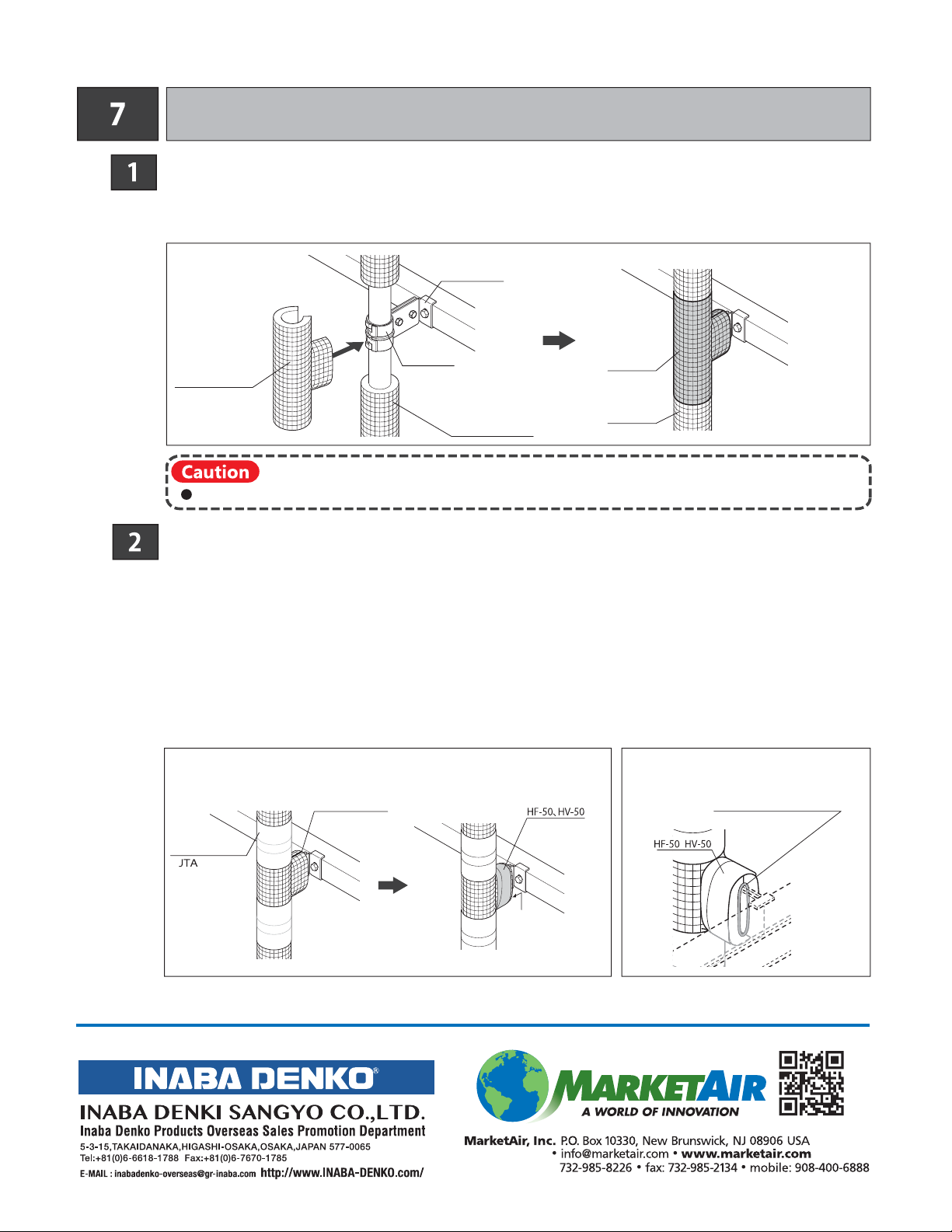

After cooling ferrule, attach fixing clamp around ferrule and attach

to mounting bracket (drawing 16).

Pipe Support Ferrule

(Drawing16)

IF fixing clamp is attached to ferrule before it is sufficiently cooled, damage to painted

surface of clamp may occur.

Confirm that pipe ferrule has cooled down

sufficiently after brazing. M6 bolt enclosed

Fixing Clamp

& '()

& '()& '()

"#