www.americantorchtip.com

No. Part No. Description

124CT-37-S Nozzle, Coarse Thread, 3/8” I.D.

24CT-50-S Nozzle, Coarse Thread, 1/2” I.D.

24CT-62-S Nozzle, Coarse Thread, 5/8” I.D.

24CT-75-S Nozzle, Coarse Thread, 3/4” I.D.

No. Part No. Description

414-23 Contact Tip .023” 0.6mm

14-30 Contact Tip .030” 0.8mm

14-35 Contact Tip .035” 0.9mm

14-40 Contact Tip .040” 1.0mm

14-45 Contact Tip .045” 1.2mm

14-52 Contact Tip .052” 1.3mm

14-116 Contact Tip .062” 1.5mm

No. Part No. Description

544-3545-15 Liner Assy., 15’ .035-.045”

44-116-15 Liner Assy., 15’ .062”

44-564-15 Liner Assy., 15’ 5/64”

44-3545-25 Liner Assy., 25’ .035-.045”

44-116-25 Liner Assy., 25’ .062”

44-564-25 Liner Assy., 25’ 5/64”

44N-3545-1 Nylon Liner Assy., 15’ .035-.045”

44N-116-15 Nylon Liner Assy., 15’ .062”

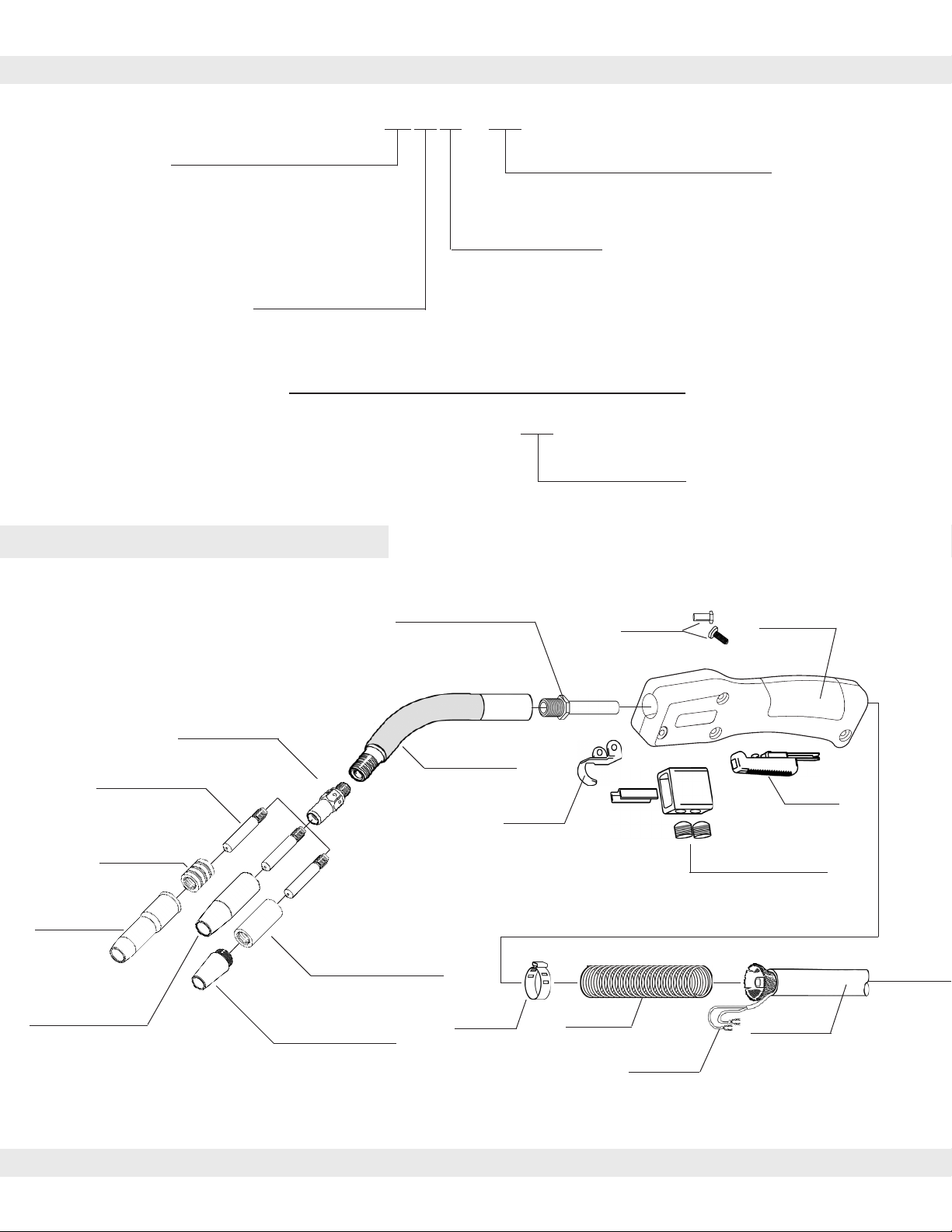

Gun Assembly - Rear

No. Part No. Description

223-37 Nozzle, Self Insulated, 3/8” I.D.

23-50 Nozzle, Self Insulated, 1/2” I.D.

*23-62 Nozzle, Self Insulated, 5/8” I.D.

23-75 Nozzle, Self Insulated, 3/4” I.D.

23T-37 Nozzle, Tapered Self Ins. 3/8” I.D.

324A-50 Nozzle, Adjustable, 1/2” I.D.

24A-62 Nozzle, Adjustable, 5/8” I.D.

24A-75 Nozzle, Adjustable, 3/4” I.D.

24A-37-SS Nozzle, Short Stop, 3/8” I.D.

24A-50-SS Nozzle, Short Stop, 1/2” I.D.

24A-62-SS Nozzle, Short Stop, 5/8” I.D.

* Standard Nozzle with gun

Cone Nut Connector Cone

Power Pin

Mount

Pin (Lincoln)

Pin (Tweco #4)

Conduit Liner

Power Pin O-Ring

64-8202 STD O-Ring

64-8309 Miller O-Ring

Liner Set Screw

64-8203

63-6302 63-6301

64-8208

See Chart for Part #’s

64-8211T

Pin (Miller)

64-8311T

64-8411T

Liner O-ring

64-9001

Guide Cap

64-8303 (.035-1/16)

64-8304 (5/64-3/32)

Unicable Assembly Spring Guard

See Chart for Part #’s

Control Plug

Connector

64-7909

63-6502

Mounting Screw

64-6501

Housing & Screws

63-6101

Outer Jacket

Clamp

63-7902

Handle

64-6106

Lead Extension Lead Extension

64-8404 (Spade) 64-8306 (Miller)

64-8403 (Lincoln)