TABLE OF CONTENTS

SECTION 1, GENERAL INFORMATION ................................................................................................................................ 1

1.1 INTRODUCTION .......................................................................................................................................................... 1

1.2 RESTRICTION ON USE ................................................................................................................................................. 1

SECTION 2, TECHNICAL INFORMATION ............................................................................................................................. 2

2.1 SPECIFICATIONS.......................................................................................................................................................... 2

2.2 POWER RATINGS ........................................................................................................................................................ 3

2.3 MRO OUTPUT WATER QUALITY.................................................................................................................................. 3

2.4 TEMPERATURE CORRECTED MRO PRODUCTION RATES............................................................................................. 4

2.5 ENVIRONMENTAL/TRANSPORT CONDITIONS EXPECTED ........................................................................................... 4

SECTION 3, COMPONENTS AND SCHEMATICS ...................................................................................................................5

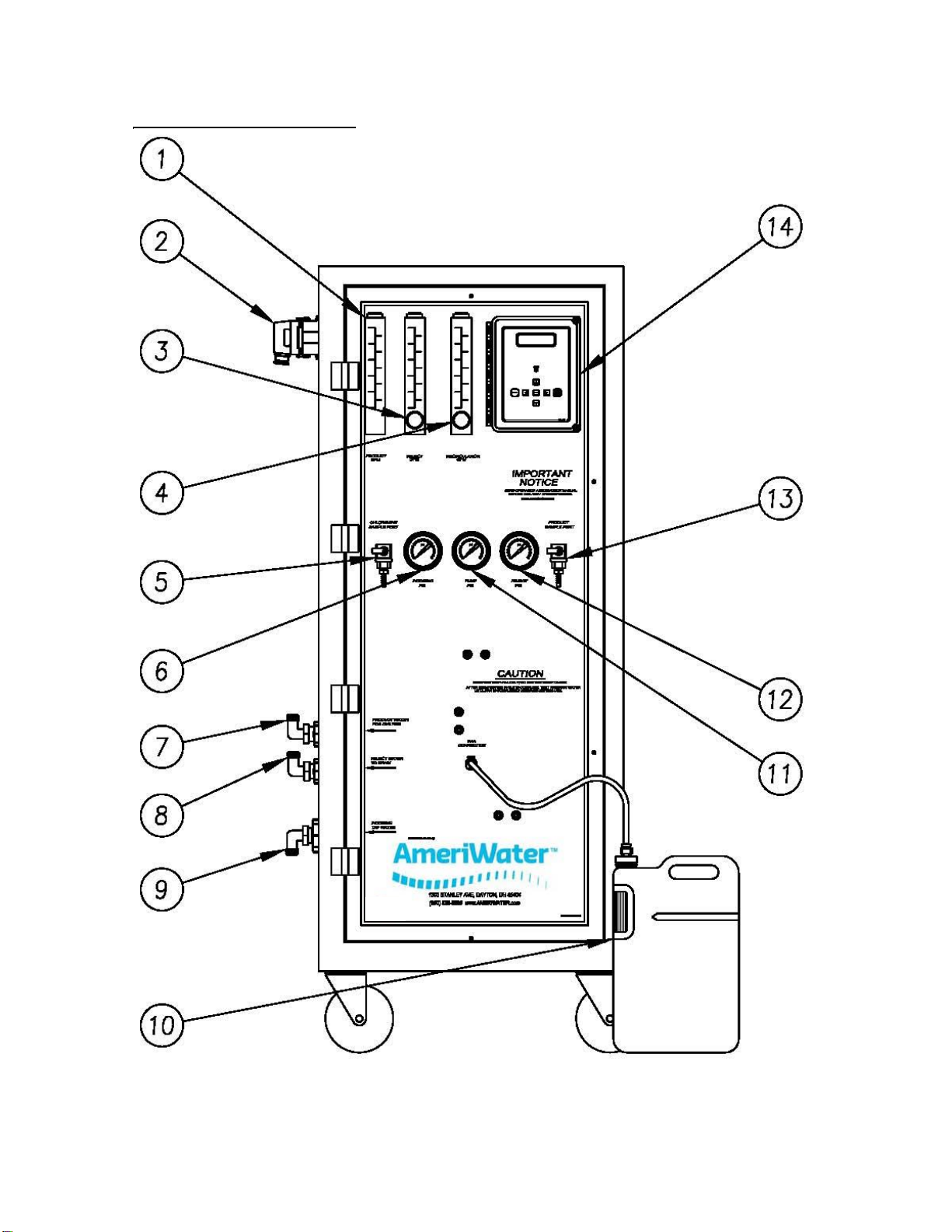

3.1 EXTERNAL FRONT VIEW.............................................................................................................................................. 5

3.2 INTERNAL REAR VIEW ................................................................................................................................................. 7

3.3 ELECTRICAL DIAGRAM, MRO2X, MRO3X, MRO4X &MRO5X...................................................................................... 9

3.4 FLUID DIAGRAM, MRO2X, MRO3X &MRO4X ........................................................................................................... 10

3.5 FLUID DIAGRAM MRO5X .......................................................................................................................................... 11

SECTION 4, MRO STARTUP & OPERATION....................................................................................................................... 12

4.1 CAUTION................................................................................................................................................................... 12

4.2 SAFETY FEATURES..................................................................................................................................................... 14

4.3 INITIAL STARTUP....................................................................................................................................................... 15

4.4 SYSTEM SHUTDOWN ................................................................................................................................................ 17

SECTION 5, DISINFECTING THE SYSTEM........................................................................................................................... 18

5.1 DISINFECTING THE SYSTEM ...................................................................................................................................... 18

5.2 DISINFECTING AN MRO AND “LARGE” LOOP SYSTEM............................................................................................... 23

5.3 AWORD ABOUT HYDROGEN PEROXIDE/PEROXYACETIC ACID ................................................................................. 24

5.4 MEMBRANE FLUSH FEATURE (AUTO FLUSH)............................................................................................................ 25

SECTION 6, MRO CONTROLLER ....................................................................................................................................... 26

6.1 FRONT PANEL CONTROLS AND INDICATORS ............................................................................................................ 26

6.2 CONTROLLER OPERATION ........................................................................................................................................ 27

6.3 CONTROLLER ADJUSTMENTS.................................................................................................................................... 30

6.4 STANDARD SETPOINTS ............................................................................................................................................. 33

6.5 TO DISPLAY OR CHANGE SETPOINTS......................................................................................................................... 35

SECTION 7, EXTERNAL WIRE INSTALLATION.................................................................................................................... 36

SECTION 8, MAINTENANCE ............................................................................................................................................. 37

8.1 MAINTAINING THE SYSTEM ...................................................................................................................................... 37

8.2PT401 ANTI-SCALANT ............................................................................................................................................... 38

8.3 MEMBRANE MAINTENANCE INSTRUCTIONS............................................................................................................ 38

SECTION 9, TROUBLESHOOTING AND REPAIR ................................................................................................................. 40

9.1 TROUBLESHOOTING CHART..................................................................................................................................... 40

9.2 CONTROLLER TROUBLESHOOTING ........................................................................................................................... 43

9.3 PUMP REPAIR ........................................................................................................................................................... 45

9.4 INSTALLING AREPLACEMENT PUMP ASSEMBLY ...................................................................................................... 45

9.5 SOLENOID TEST PROCEDURE .................................................................................................................................... 46

9.6 SOLENOID VALVE REPLACEMENT ............................................................................................................................. 47

SECTION 10, WARRANTY................................................................................................................................................. 47

SECTION 11 SPARE PARTS LISTING .............................................................................................................................. 48

ROUTINE REPLACEMENT ITEMS (NON-DURABLE COMPONENTS) ..................................................................................... 50