For more information please call

your Account Manager or 1-800-BAKERS-1.

Headquarters

AMF Bakery Systems

2115 West Laburnum Avenue

Richmond, Virginia 23227

1-800-225-3771 or 804-355-7961

FAX: 1-804-342-9724

www.amfbakery.com sales@amfbakery.com

European operation

West Park Ring Road

Leeds LS16 6QQ England

Tel.: 1132-787110

Fax: 1132-741415

08/2002

22-N-AB

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.

Moulder / Panner

section

• Easily removable endless transfer belt 18'' wide.

•Delrin transfer plate and stainless steel adjustable plow.

•Stainless steel adjustable curling mat.

•D.C. variable speed, removable stainless steel rotary flour

sifter with automatic cut-off.

• Fixed speed easily removable endless moulder belt 20'' wide

(cantilever frame design).

• Easily removable endless “motorized” pressure board belt

19'' wide. (Adjustable at both ends, with floating action).

•New design “insert style” U.H.M.W. dough guides, supplied

with 4 different thicknesses (1/2'', 3/4'', 1'', 1-1/4'').

• Stainless steel Sanigrid drop chain assembly (15'' wide X 22''

long) with manual adjustable dough guides.

• Double loaf detection device.

• Two-position discharge (straight or angle drop) to adapt

“optional” hand twist table section.

• Stainless steel sliding catch pan.

• Manual adjustable pan guides (min. 7'' - max. 19'').

•A.C. variable speed dual strand plastic table-top pan

conveyor.

•Magnetic pan indexer (belt type) with soft start drive system

and SLC 5/03 processor (Elev. 21-3/4'' ± 1'').

• Complete Moulder/Panner section is all timing belt driven

(without chains and sprockets).

ULTRA ‘’S’’ CROSS GRAIN

•Stainless steel type 304 frame (sanitary design).

•Special slanted infeed conveyor with Teflon® coated dough

guides and adjustable flattener roller (Elev. 61'' ± 1'').

•Easily removable endless infeed belt 12'' wide.

•D.C. variable speed, removable stainless steel rotary flour

sifters with automatic cut-off.

•Fixed speed 17'' wide, adjustable sheeting rolls driven

by a 1-1/2 H.P. motor (top front sheeting roll is grooved).

•Baked Teflon® coated sheeting roll scrapers.

•A.C. variable speed, easily removable endless sheeter belt

14'' wide, driven by a 3/4 H.P. motor (Elev. 39-1/4'' ± 1'').

•Lexan® guard over sheeting rolls with safety switches.

•Stainless steel sliding catch pan.

•Adjustable legs.

•Stainless steel side covers with safety sensors.

•U.H.M.W. sheeter belt scraper with stainless steel catch pan.

•Complete Sheeter sector is all timing belt driven

(without chains and sprockets).

•AMF dough spacer with D.C. controls.

•Third set of sheeting rollers with independent drive.

•Extra stainless steel Sanigrid drop chains:

• 12-1/2'' x 22'' LG • 11'' x 22'' LG • 9-1/2'' x 22'' LG

•Pressure board equipped with new air operated lifting device.

•A.C. inverters on the following:

- Dough spacer

- Flour sifters

- Sheeter rolls

- Transfer belt

- Moulder make-up belt

• AMF hand twisting table with magnetic pan indexer.

Sheeter Section

Electrical

Specifications

Options

•Nema 4 remote control panel with the following:

- Allen Bradley starters

- D.C. controls for flour dusters

- A.C. inverters (2) for sheeter belt and pan conveyor

- Allen Bradley SLC 5/03 processor

- Main disconnect switch

- Relays, terminal block, wiring

•Nema 4 operator panel mounted to moulder frame with the

following:

- Allen Bradley push-buttons and alarm message display

- Potentiometers for flour sifters, sheeter belt and pan

conveyor

- Safeties

- Emergency stop

- Red Lion display to indicate fault messages.

•CAD electrical wiring.

•Solid stainless steel construction.

•Magnetic pan indexer (belt type) with soft start drive system.

•Table/flattener roll and multiple roller drop gate assemblies.

•Belt type loading section from AMF Moulder/Panner:

belt conveyor is raised vertically while hand twister is not in

use, in order to permit operator to see the actual panning

operation, and correct a possible “double”.

•Added safeties and guards.

•Electrical control panel.

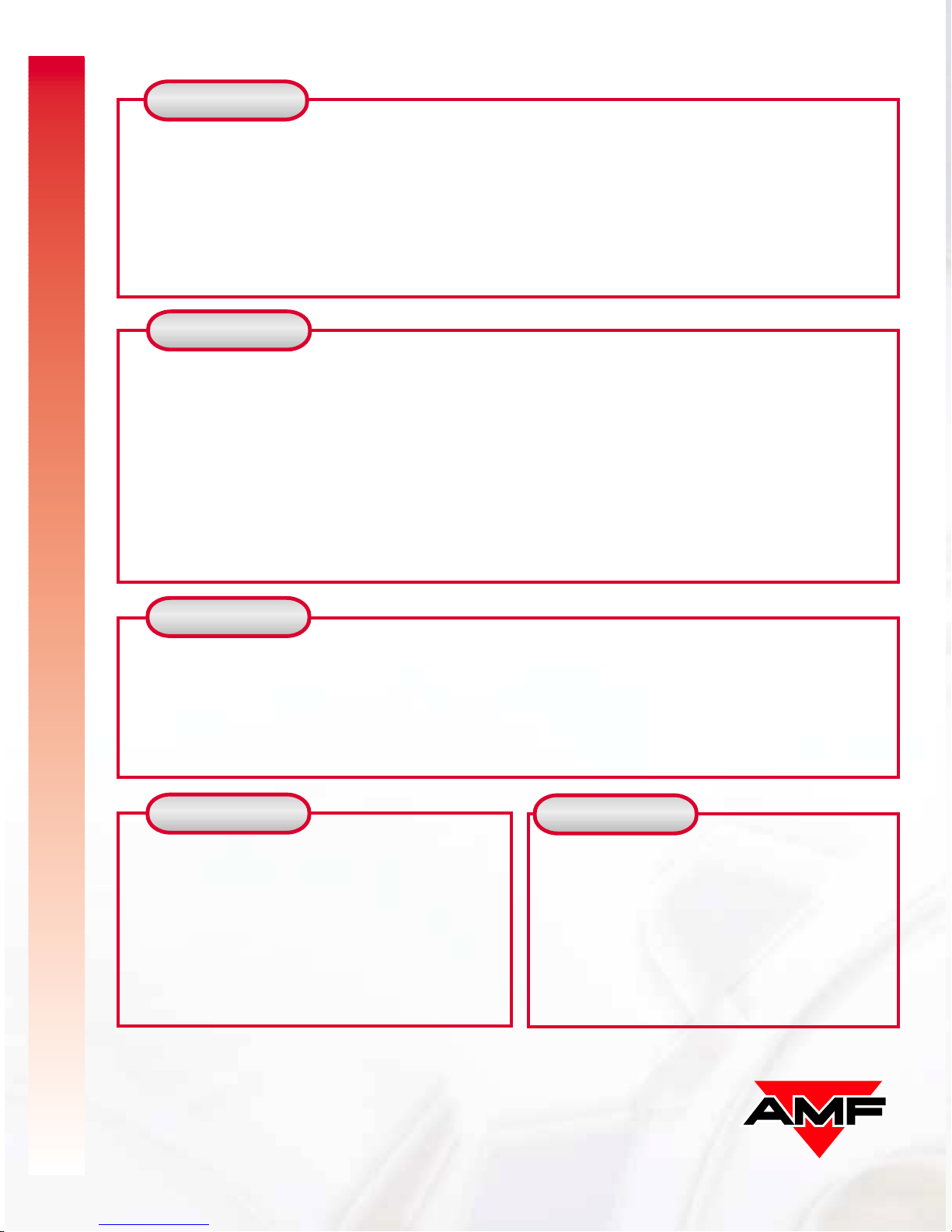

Options Hand

Twisting section

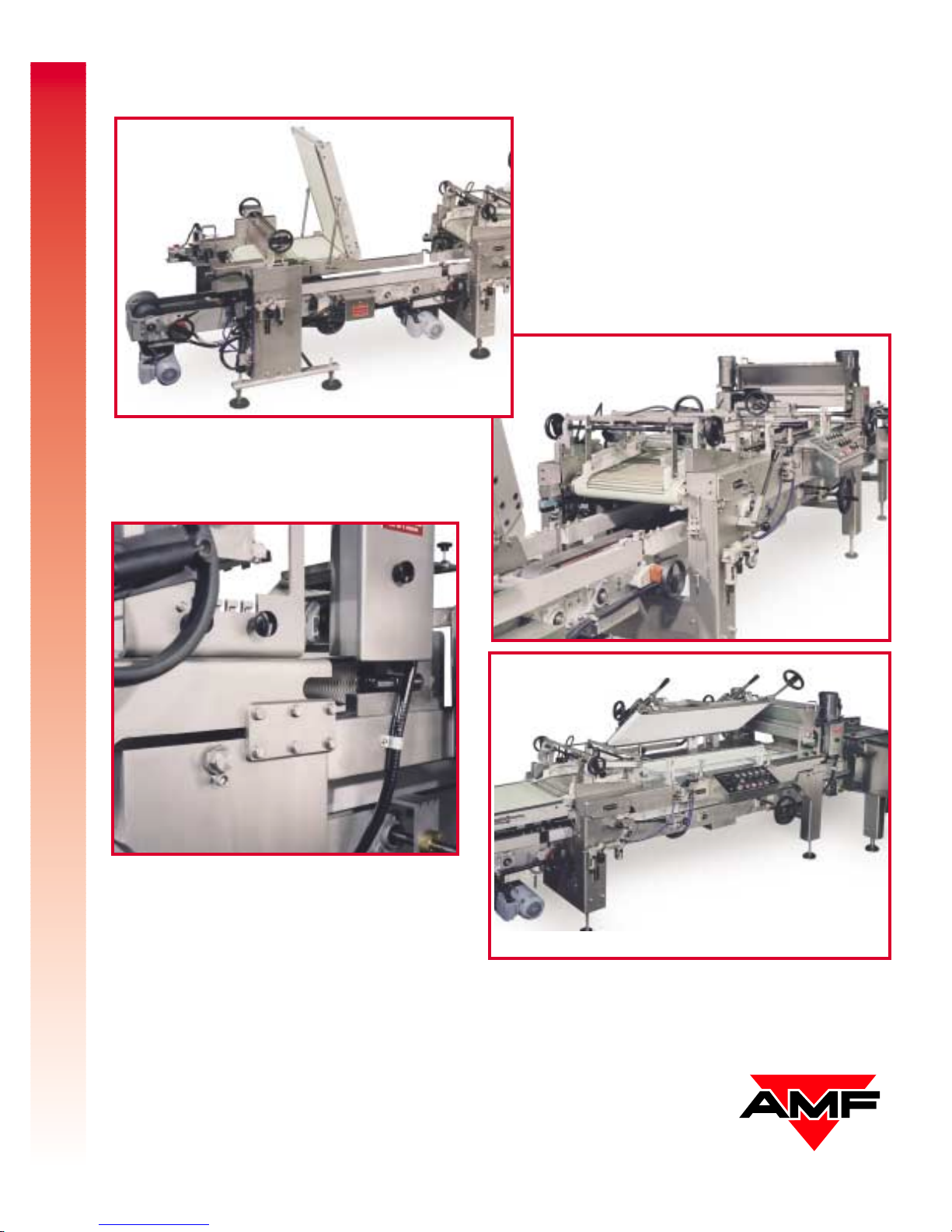

ULTRA ‘’S’’

CROSS GRAIN

SHEETER/MOULDER/PANNER

• 110 loaves/minute 18 to 24 oz.

• Pan size up to 19’’ wide

• Reliable performance

Shown with optional

Dough Spacer

Shown with optional

Handtwist Table