1. Carefully remove the programmer from the shipping carton and remove all packaging

materials. Inspect the equipment for any physical damage that may have occurred during

shipment.

NOTE: If there is any shipping damage, save all packing

material and contact the shipping representative to file a damage

claim. Do not return the instrument to AMI unless prior

authorization has been received.

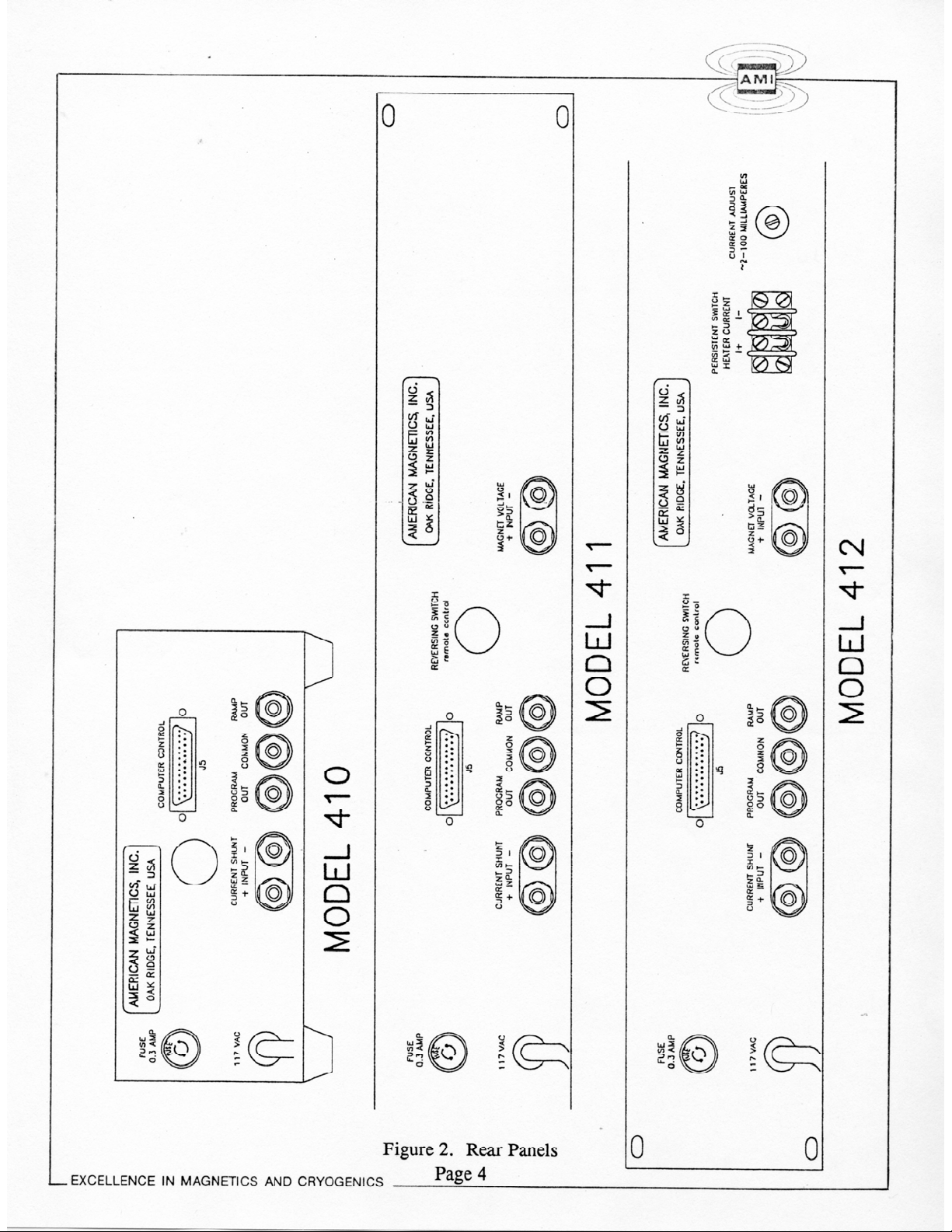

2. Install the Model 410 programmer on a flat secure surface or install the Model 411, 412

programmer in a 19 inch rack by securing the front panel to the cabinet rails with

mounting hardware supplied by the cabinet manufacturer. It is recommended to support

the rear of the instrument in some fashion.

3. If the programmer and power supply were purchased as part of a console, they should

already be wired together prior to shipment. In any event, the wiring should be checked

prior to applying power to the equipment.

4. Figure 3 depicts a typical system configuration consisting of a superconducting coil,

energy absorber (optional), power supply and programmer.

5. A suitable power supply for operating your system should be available.

NOTE: The power supply is part of the feedback loop for the

programmer and therefore the noise and stability of the system is a

function of the quality of the power supply. The ideal power supply

has zero phase shift, a voltage control mode where 1 volt input

produces 1 volt output, has zero current ripple and would be much

slower than the programmer time constant (0.1 millisecond,

typically). Some switching power supplies may be too noisy for this

application. AMI recommends the Hewlett-Packard Model 6259B

or Model 6260B, as modified by AMI for use with superconducting

magnets, where an extremely quiet and stable linear power supply

is required. AMI also recommends the Power Ten Model 10100, as

modified by AMI, in applications where more power supply noise

can be tolerated. The modifications performed on these power

supplies includes an output rectifier to protect the power supply

from damage due to transfer of the stored energy in the

superconducting magnet back to the supply.

NOTE: An energy absorber should be installed in a system

where it is important to ramp the magnet down at the maximum

rate (i.e. the shortest time). The magnet discharge rate is

determined by the voltage across the magnet according to the

equation V=L*dI/dt and without an energy absorber, the discharge

voltage is determined by the IR drop in the system power supply

cables and many be as low as 0.1 volt. Since the inductance is

Page 5