Contents

1-GENERAL REMARKS...................................................................................................................................................6

1-1 Power source features.......................................................................................................................................6

1-2 Functional principle............................................................................................................................................ 6

1-3 Output characteristics........................................................................................................................................ 6

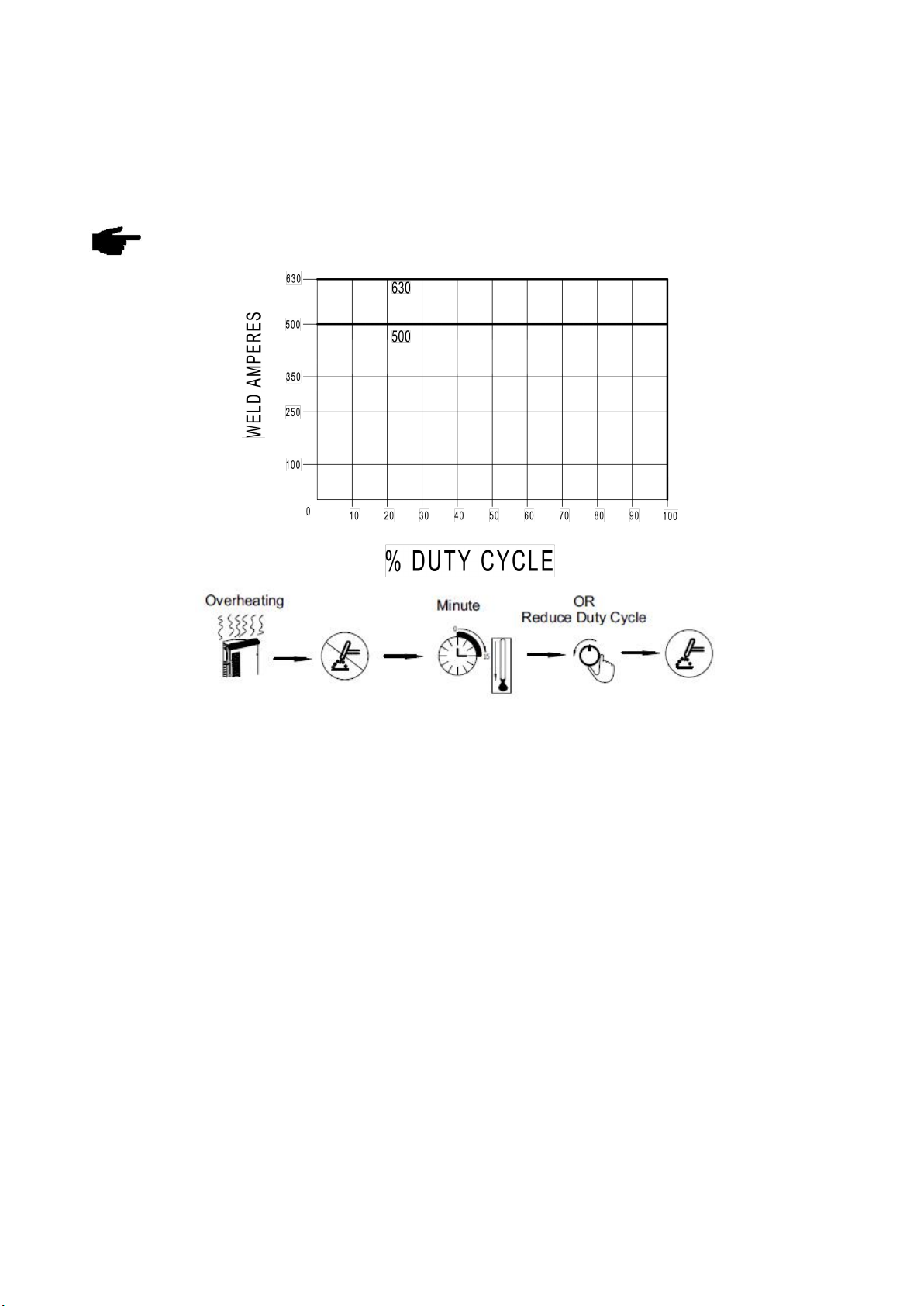

1-4 Duty cycle............................................................................................................................................................ 7

1-5 Applications......................................................................................................................................................... 7

1-6 Warning label...................................................................................................................................................... 8

2-VERSIONS BRIEFS...................................................................................................................................................... 8

3-BEFORE COMMISSIONING........................................................................................................................................9

3-1 Utilization for intended purpose only............................................................................................................... 9

3-2 Machine installation rules.................................................................................................................................. 9

3-3 Power source connection.................................................................................................................................. 9

3-4 Welding cables instruction................................................................................................................................ 9

4-SYSTEM INSTALLATION.......................................................................................................................................... 11

4-1 System components........................................................................................................................................ 11

4-2 Installation......................................................................................................................................................... 11

5-AMIG 500/630 PD........................................................................................................................................................ 14

5-1 Interface............................................................................................................................................................. 14

5-2 Control panel.....................................................................................................................................................15

5-3 Sub menu.......................................................................................................................................................... 19

5-4 Job mode........................................................................................................................................................... 22

5-5 Technical data...................................................................................................................................................24

5-6 Disassembly and reassembly.........................................................................................................................25

6- WIREFEEDER.............................................................................................................................................................27

6-1 Features.............................................................................................................................................................27

6-2 Interface............................................................................................................................................................. 27

6-3 Control panel.....................................................................................................................................................29

6-4 Structure............................................................................................................................................................ 31

6-5 Installation and operation................................................................................................................................ 32

6-6 Technical data...................................................................................................................................................32

6-7 Dimension..........................................................................................................................................................33

6-8 Spare parts........................................................................................................................................................ 33

7-TROUBLE SHOOTING............................................................................................................................................... 35

8 –CARE AND MAINTENANCE................................................................................................................................... 38