RRAM-MCT/E12-XX

3/40 rram-mcte12-xx_g_en_100

Contents History of revisions.........................................................................................5

Related documentation...................................................................................5

Used symbols.................................................................................................5

1. Introduction..........................................................................................6

2. Technical parameters..........................................................................7

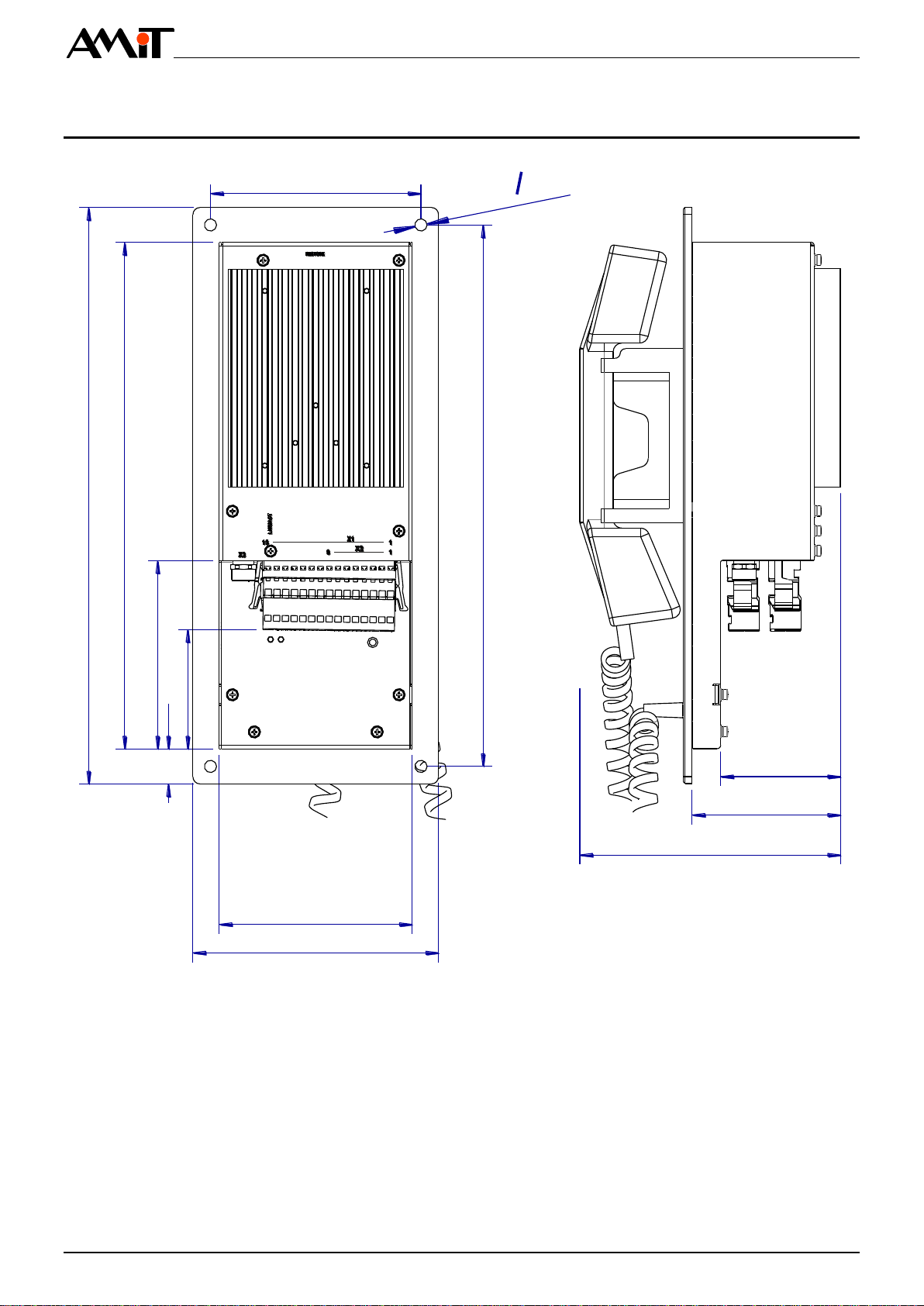

2.1. Dimensions...................................................................................................10

2.2. Design of front panel ....................................................................................11

2.3. Recommended drawing symbol ...................................................................12

3. Product marking ................................................................................13

4. Conformity assessment ....................................................................15

4.1. Other tests....................................................................................................16

5. Power supply......................................................................................17

6. Ethernet...............................................................................................18

6.1. Ethernet line state indication ........................................................................19

7. UIC interface.......................................................................................20

7.1. UIC line state indication................................................................................20

7.2. UIC interface functions.................................................................................21

7.2.1 UIC interface hardware functions .................................................................23

8. Inputs/outputs....................................................................................24

8.1. Digital input...................................................................................................24

8.2. Audio input ...................................................................................................24

8.2.1 Front audio input...........................................................................................24

8.2.2 Rear audio input...........................................................................................25

8.3. Power audio outputs.....................................................................................25

8.3.1 Rules for connecting loudspeakers...............................................................26

8.3.2 Wiring examples...........................................................................................26

8.4. Relay............................................................................................................29

9. Indications and settings....................................................................30

9.1. System LEDs................................................................................................30

9.2. Factory setting..............................................................................................31

10. Phone handset ...................................................................................32

11. Mounting and installation rules........................................................33

11.1. Mounting apertures.......................................................................................34

11.2. Installation rules............................................................................................35

12. Ordering information and completion .............................................36

12.1. Ordering Information.....................................................................................36

12.2. Completion ...................................................................................................36

12.3. Connectors...................................................................................................36

13.Packing ...............................................................................................37

14. Storing.................................................................................................38