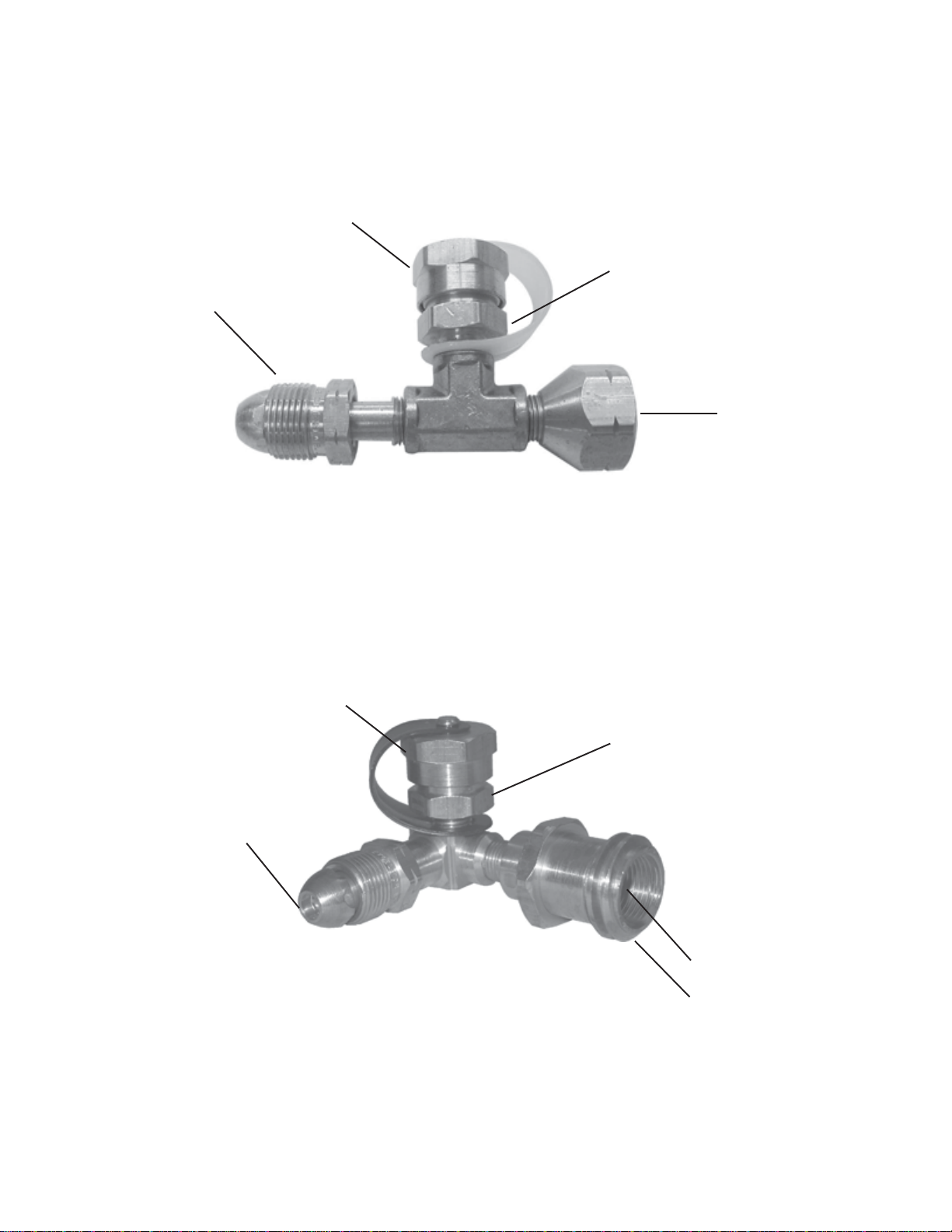

It will be necessary to move the existing POL fitting on your regulator away from the vapor withdrawal

valve far enough to place the Flow-Longer tee between them. If the Flow-Longer is being installed on

an RV’s ASME tank, this may also require moving the regulator cover.

Thread the male POL fitting on the Flow-Longer tee, into the vapor withdrawal valve. Turn this left-

hand nut counter-clockwise to tighten, but before tightening, position the fitting’s top outlet port for best

access. Use a 7/8 inch wrench to tighten the POL nut into the vapor withdrawal valve.

Flow Longer Tee- Thread the male POL fitting attached to the pressure regulator or pigtail hose, into the

female POL fitting on the Flow-Longer tee.Again, turn the left-hand POL nut counter-clockwise. Two

(2) wrenches are required to tighten this connection properly, but before tightening, besure to orient your

pressure regulator in its original position. It is important not to break the factory seal on the threaded inlet

and outlet connections on the Flow-Longer tee. Use one wrench to securely hold the Flow-Longer

female fitting while tightening the male POL nut with a second wrench. Prevent rotating the Flow-

Longer tee while tightening this connection.

Flow Longer Plus Tee–Can follow same installation instructions as above orcan be used with a standard

Type I connection, by turning the plastic nut onto the male threads clockwise until hand tight. Do not use

tools to make this connection.

If you installed the Flow-Longer tee on an RV’s ASME tank, securely fasten the pressure regulator and

its accompanying low-pressure outlet hose to the vehicle, to avoid possible damage or loosening due to

“over the road” vibration. Depending upon the particular layout of your vehicle’s LP-Gas container

compartment, it may be necessary to have an LP-Gas dealer or RV service technician fabricatebrackets

or supporting hardware.

LEAKAGE CHECKS for the Flow-Longer tee:

After allconnections are tightened securely,the installation must bechecked for leaks.Make sure all gas appliances

are off, and then turn the LP-Gas vapor withdrawal valve counter-clockwise to its full open position. Using an

ammonia-free soap, prepare a soapy water solution and check for leakage at all the connections from the valve up

to and including the low-pressure outlet of the regulator. If a leak is found at one of the POL connections, tighten

it until the bubbles stop. If however, leakage is found at a pipe thread connection at the Flow-Longer tee, or at the

pressure regulator, close the cylinder valve immediately and contact your LP-Gas dealer.

WARNING: An LP-Gas leak, if ignited, could result in fire, explosion, severe personal injury, property damage,

or death. Matches, candles, or other sources of open flame must NEVER be used to test for leaks.

DOUBLE CYLINDER INSTALLATIONS:

If your double cylinder installation has an automatic changeover regulator, the indicator arrow of the

changeover must point at the cylinder to which the tee is connected to assure an uninterrupted supply of gas

to the tee.As long as there is gas in the cylinder to which the tee is connected, the tee will function regardless

of which cylinder the arrow points to. However, if the cylinder to which the tee is connected is emptied, the

automatic regulator will not allow gas to flow to the tee if the arrow points to the opposite cylinder. If the

cylinder to which the tee is connected is empty and the arrow is pointed to the empty cylinder, the gas

pressure to the tee will be reduced to approximately 10 to 15 psi. While this pressure is sufficient for most

portable appliances, it may not be suitable for appliances having larger BTU requirements. Also, some

regulatorsonportableappliancesfunctiondifferentlywithlessthanfullcylinderpressure.Anemptycylinder