©Copyright Amkus Rescue Systems, Inc. 2016 LAR-001 May 31, 2016 Rev00

DANGER Understand manual before use. Operating AMKUS Rescue Systems without understanding

the manual, receiving proper training, and using appropriate personal protective equipment is

a misuse of AMKUS equipment. This manual does not fully address safety. Additional safety

information is published in AMKUS Safety Manual LAA-001. Obtain safety information at

www.amkus.com/

©Copyright Amkus Rescue Systems, Inc. 2016 LAA-001 April 15, 2016 Rev00

DANGER Understand manual before use. Operating AMKUS Rescue Systems without understanding the

manual, receiving proper training, and using appropriate personal protective equipment is a

misuse of AMKUS equipment. Obtain safety information at www.amkus.com/

This Safety Manual is intended to familiarize rescue workers and maintenance personnel with the safety messages of AMKUS

Rescue Systems, including powered rescue tools (rams, cutters, spreaders, combination tools), power units (electric or gasoline

driven), and powered rescue tool components (cable assemblies, hose assemblies, hose reels, etc.). The safety messages in this

publication supersede safety information appearing in AMKUS publications prior to April 2016.

This manual is intended for use with manuals published by manufacturers of prime movers (engines, electric motors, and pumps)

used in AMKUS power units.

This manual does NOT address operation or servicing of AMKUS Rescue Systems. Only competent rescue tool repair technicians

are quali¿ ed to repair AMKUS equipment. This manual should be available to all personnel involved with AMKUS equipment.

SAFETY MANUAL for AMKUS

RESCUE SYSTEMS

AMKUS RESCUE SYSTEMS

www.amkus.com 4201 Montdale Drive, Valparaiso, IN 46383-4098 USA

800-592-6587 • 219-548-5000 • Fax 630-515-8866

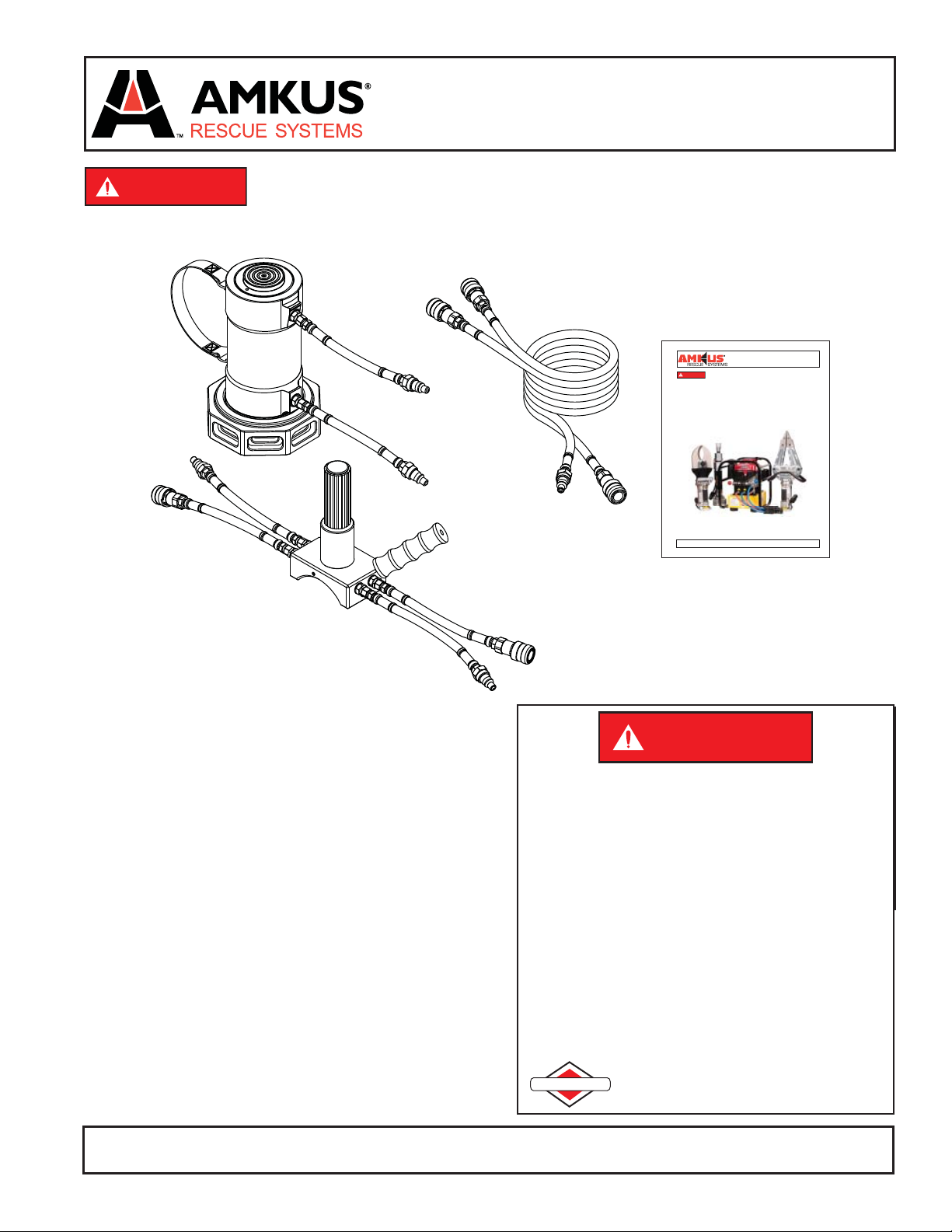

AMK-100R LIFTING JACK

User Information Manual

AMKUS RESCUE SYSTEMS

www.amkus.com 4201 Montdale Drive, Valparaiso, IN 46383-4098 USA

800-592-6587 • 219-548-5000 • Fax 219-476-1669

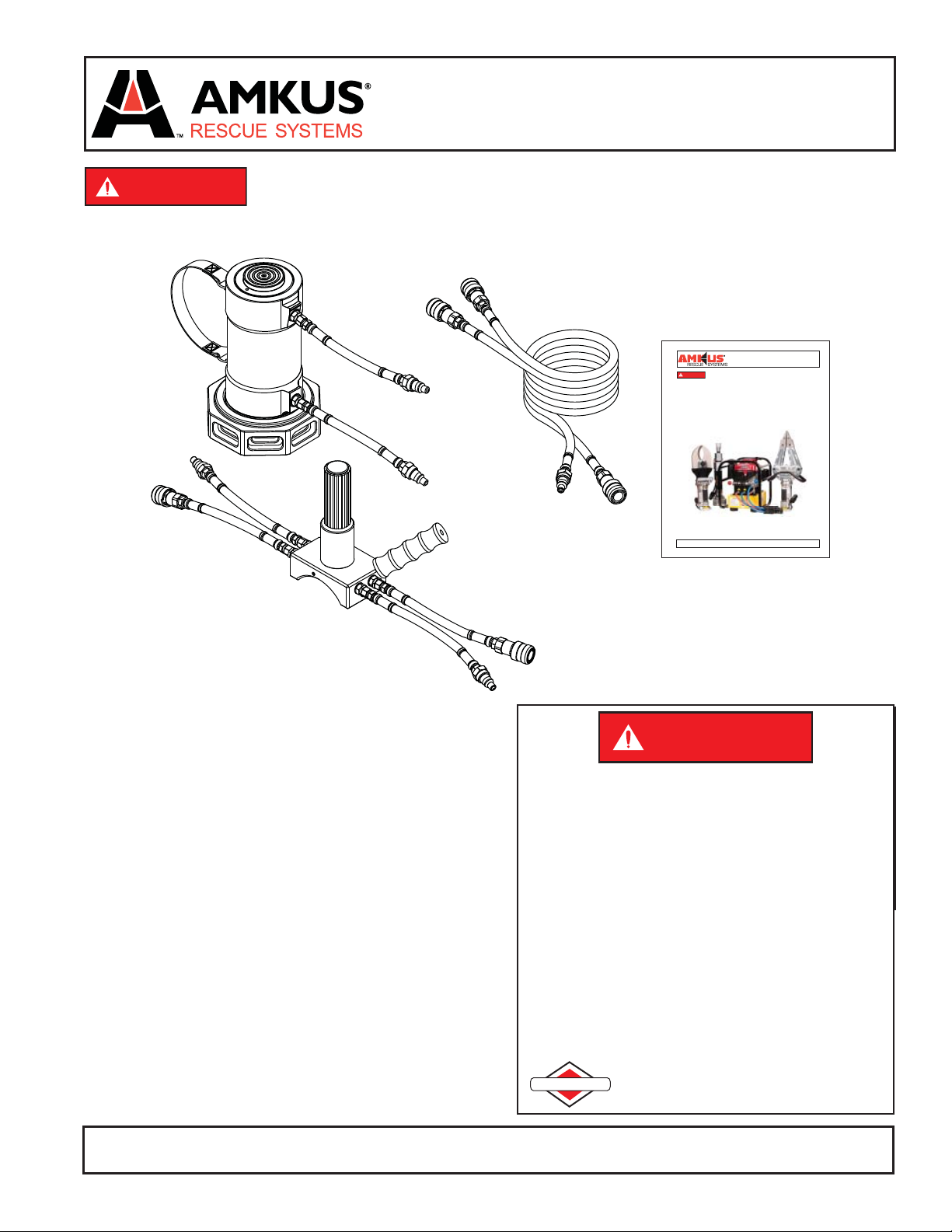

DANGER

PERSONAL RESPONSIBILITY CODE

The member companies of FEMSA that provide emergency response

equipment and services want responders to know and understand the

following:

1. Firefi ghting and Emergency Response are inherently dangerous activities

requiring proper training in their hazards and the use of extreme caution

at all times.

2. It is your responsibility to read and understand any user’s instructions,

including purpose and limitations, provided with any piece of equipment

you may be called upon to use.

3. It is your responsibility to know that you have been properly trained in

Firefi ghting and /or Emergency Response and in the use, precautions, and

care of any equipment you may be called upon to use.

4. It is your responsibility to be in proper physical condition and to maintain

the personal skill level required to operate any equipment you may be

called upon to use.

5. It is your responsibility to know that your equipment is in operable

condition and has been maintained in accordance with the manufacturer’s

instructions.

6. Failure to follow these guidelines may result in death, burns or other

severe injury.

FEMSA

Fire and Emergency Manufacturers and Service Association

P.O. Box 147, Lynnfi eld, MA 01940 • www.FEMSA.org

Thank you for choosing AMKUS Rescue Systems. Read this User

Information Manual thoroughly. If you have any questions, please

contact your local dealer or AMKUS Rescue Systems.

Please complete the tool registration form included with your

equipment and return it to AMKUS Rescue Systems. You may also

register your equipment on-line at www.amkus.com.

The serial number for your tool is identifi ed on the product label

which is located on the cylinder of the tool. Please have the

serial number available if you need to contact your local dealer or

AMKUS Rescue Systems.