Thanks for using new models AMP series of high performance metal & spark diverter produced

by Jiangsu Ampeon Electronic Engineering Co., Ltd. AMP series products are manufactured with

high quality units, materials and with the utilization of latest microcomputer technology. Jiangsu

Ampeon Electronic Engineering Co., Ltd. continuously practices the design and innovation of the

product and provides excellent products with professional attitude. Furthermore, it responds to the

customers with professional service and benefits each other with the customers.

The manual provides cautions about the installing, parameter setting, troubleshooting and daily

maintenance of metal & spark diverter to the user. In order to assure the proper installing and usage

of the product, please read this manual in detail before installing. Please keep the manual well and

give it to the operator of the machine.

Welcome to visit the website of Jiangsu Ampeon Electronic Engineering Co., Ltd. :

www.ampeon.cn. The website provides the download of the operation instructions and technical BBS

The following are the cautions that need special attention:

1. First please carry out the delivery inspection and check whether there is damage caused by

2. After unpacking, please compare with the packing list and check the type, specification and

components of the product. If it does not conform to your order documents or if you have any

questions regarding the product, please contact to the dealer or the service office of our

3. Jiangsu Ampeon Electronic Engineering Co., Ltd. provides services of the three guarantee

period 18 months from the delivery date.

4. Troubles due to lightening strike, water invasion and obvious artificial miss or damage etc.

are not in the range of repair guarantee.

5. Metal & spark diverter series products are important products of the fore-spinning procedure

in cotton spinning mill. But the users in cotton spinning mill should also take integrated

measures in fire protection equipments, selection of material, management regulations etc. to

assure the safety production.

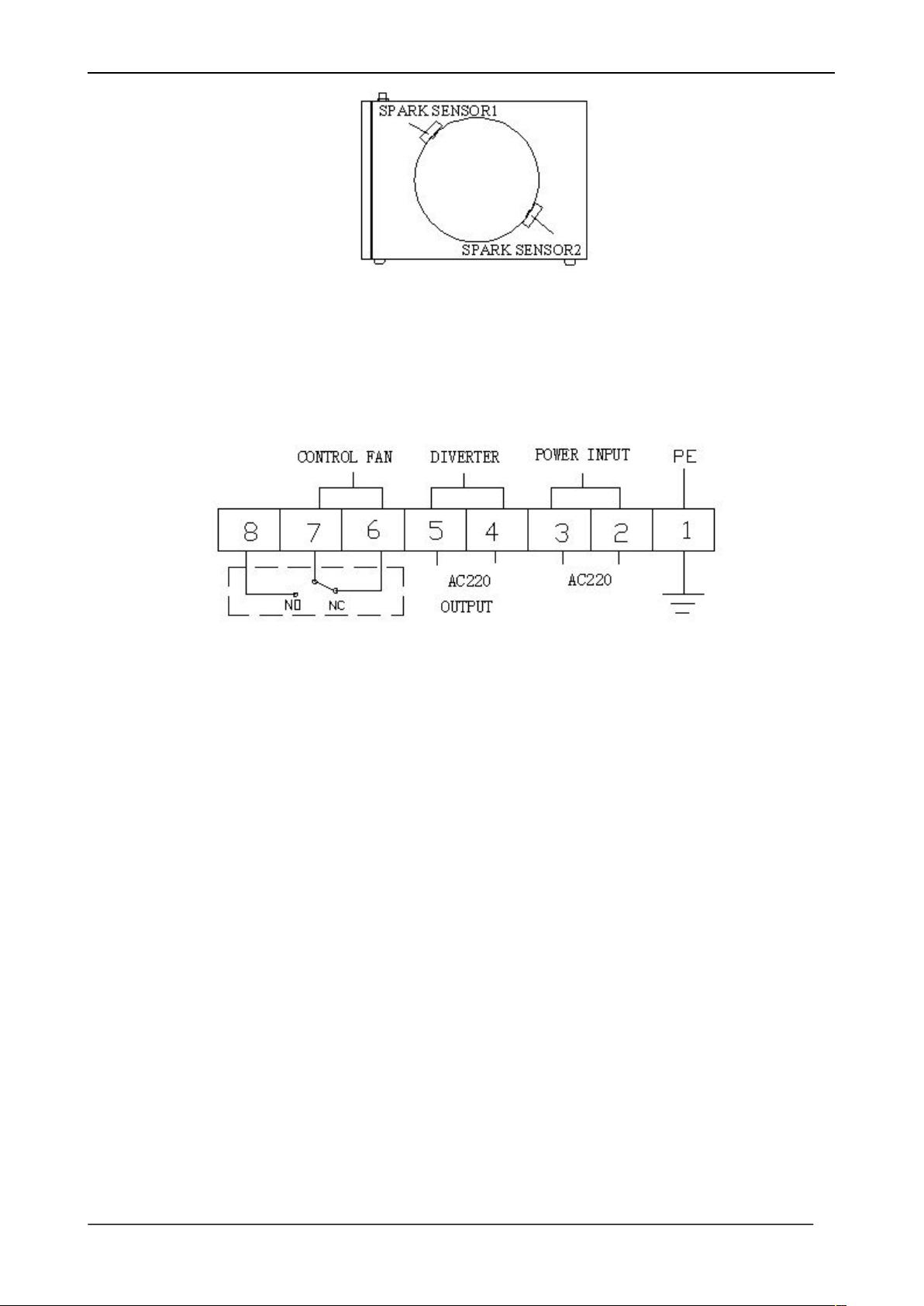

1. The power supply must first be shut down before the electric wiring.

2. Wiring, repairing & maintenance of the machine should be carried out by electric

3. Do not carry out compression test toward the inner components because the semiconductor

units are easy to be broken down by the high voltage and are easy to damage.

4. The circuit board CMOS integrated circuit is apt to static electricity damage. So you should

take the static electricity prevention measure before touching the circuit board with hand.

5. As the machine is installed to the pipe in high place, installing personnel should take safety

measures. Suspending or bracket should be solid to prevent the machine from dropping down.

6. Select safety area to install the equipment, prevent the high temperature & direct shinning and

avoid humidity and splashing of the water drops.