A. Overview..........................................................................................................................................2

1、Use and structural features..................................................................................................... 2

2、Technical parameter................................................................................................................ 2

B. Electric wiring and installing........................................................................................................... 3

1、Installing.................................................................................................................................. 3

1.1 The installation of the connecting pipe of spark detectors..............................................3

1.2 The installation of the metal detector..............................................................................3

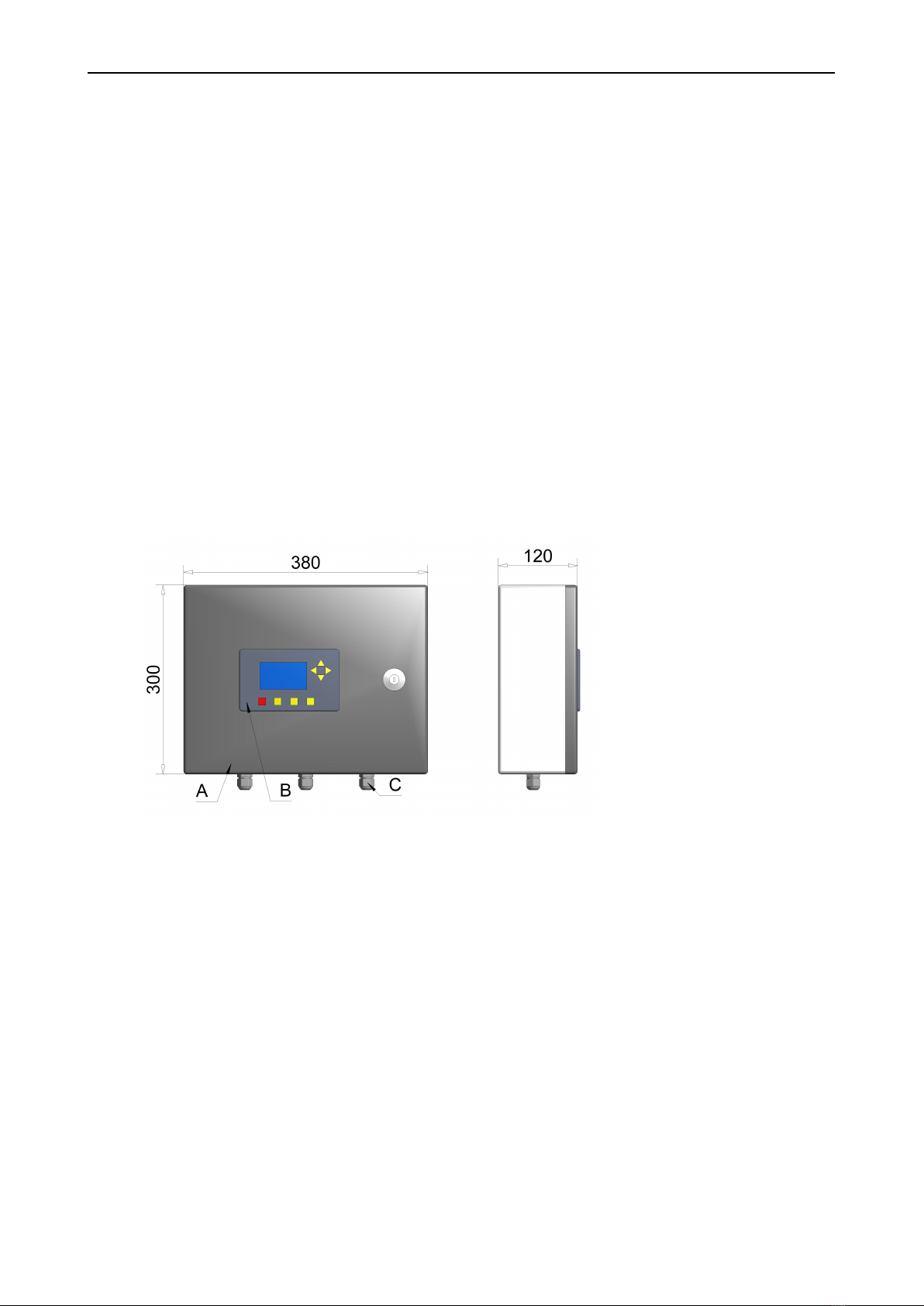

1.3 The installing of control box............................................................................................. 4

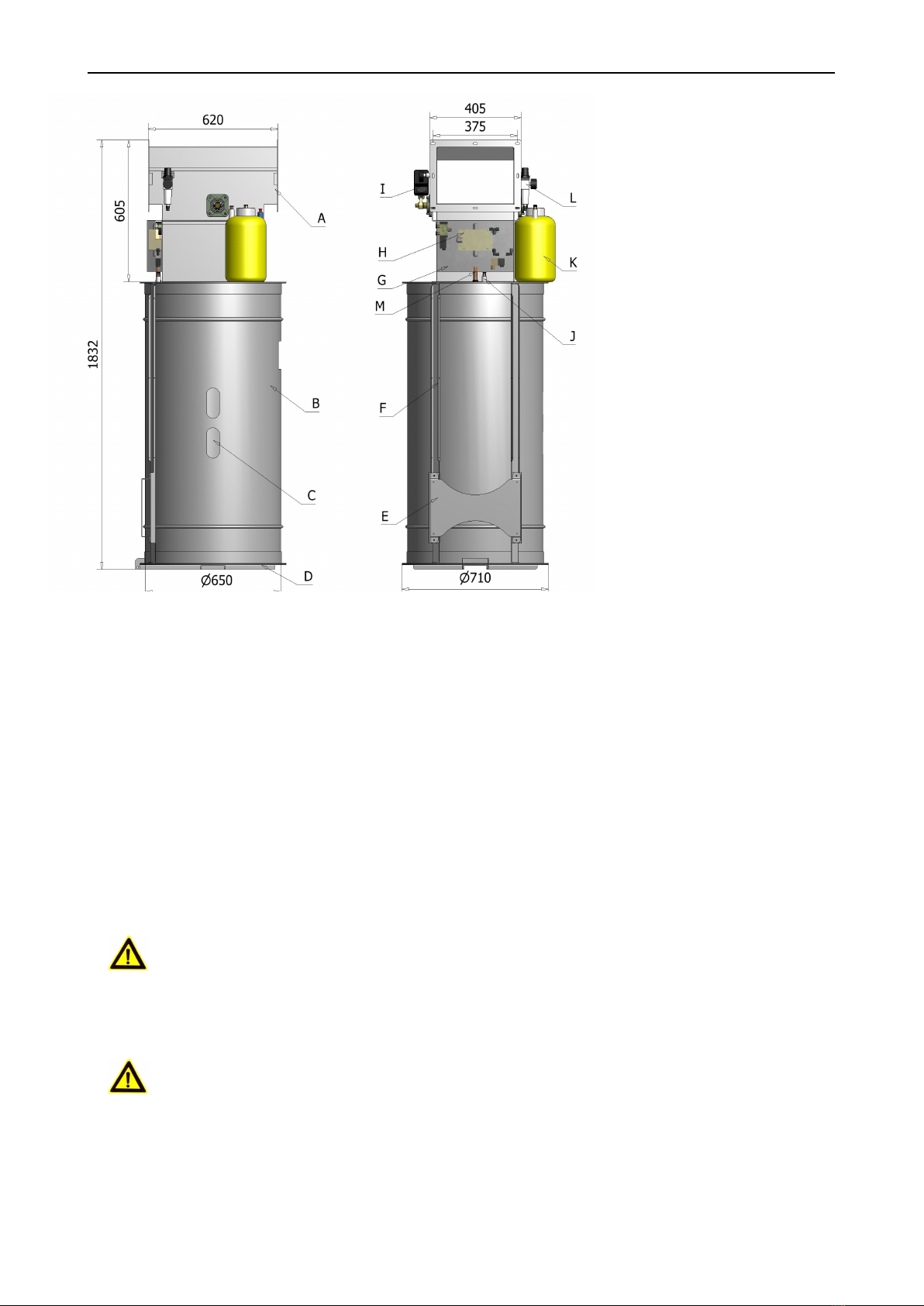

1.4 The installing of actuator unit.......................................................................................... 4

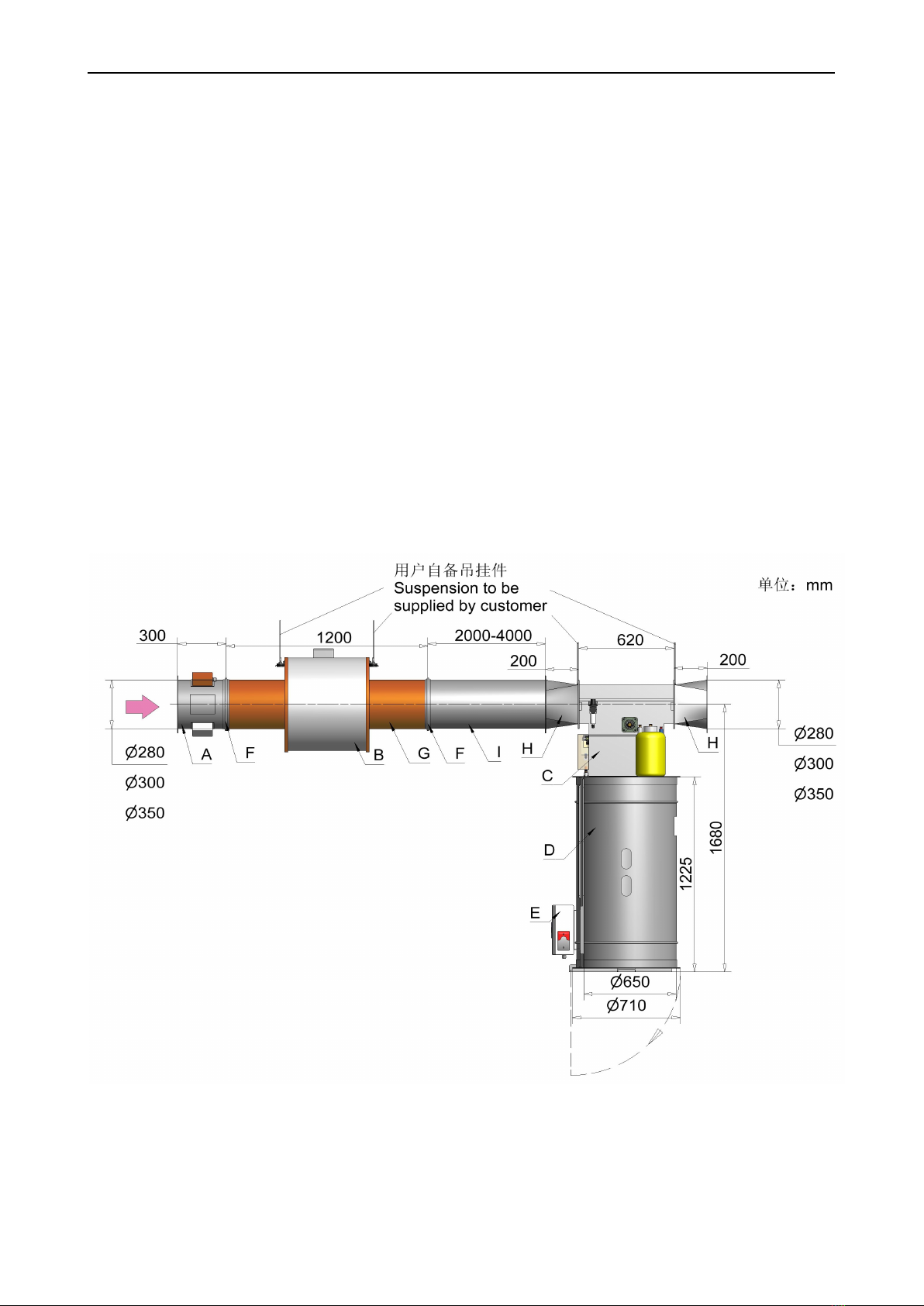

1.5 The standard installation.................................................................................................. 6

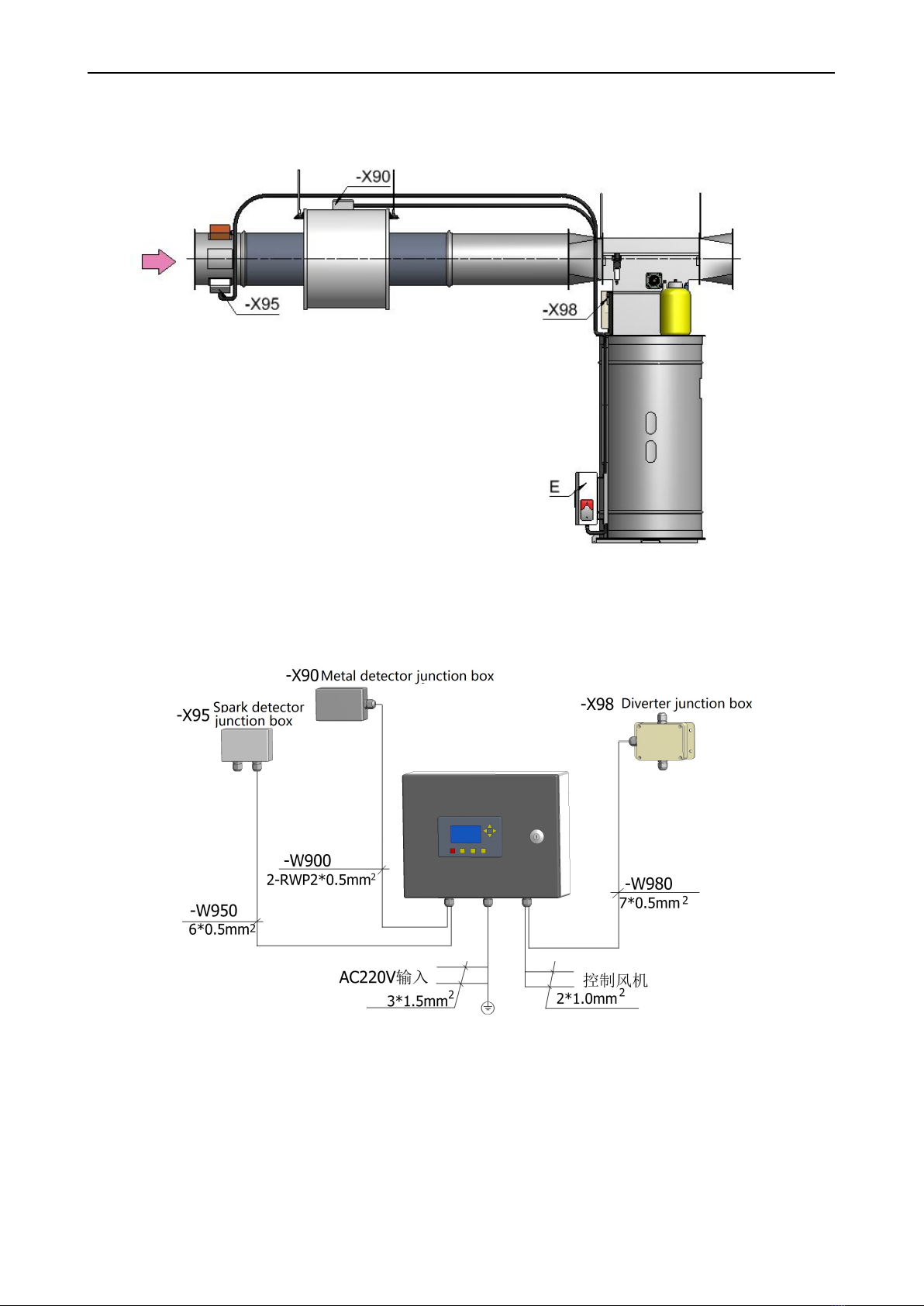

2.Electric wiring.......................................................................................................................... 7

2.1 Electric wring - J0 of the control box................................................................................ 8

2.2 Electric wring – J13 of the control box............................................................................. 9

2.3Electricwiringofthemainboard to themetaldetector........................................................... 9

2.4Electric wiring of the main board to the spark detectors............................................... 10

2.5 Electric wiring of the control box to the diverter...........................................................10

2.6 Earthing and safety.........................................................................................................11

C. Using of the control panel............................................................................................................. 11

1、The instruction of LCD Displayer and function of the control panel.....................................11

1.1 Explanation of the panel................................................................................................ 11

1.2 Explanation of the keys.................................................................................................. 13

2、Parameter setting.................................................................................................................. 14

2.1 Real time setting.............................................................................................................14

2.2 System setting................................................................................................................ 15

2.3 Function setting..............................................................................................................15

2.4 History............................................................................................................................ 17

2.5 Communication setting.................................................................................................. 18

3、Communication protocol.......................................................................................................18

3.1 10-bit character frame(for ASCII)..............................................................................18

3.2 Communication protocol ASCII mode:........................................................................... 18

3.3 Functions........................................................................................................................ 19

3.4 Address list..................................................................................................................... 19

D. Debugging and usage maintenance..............................................................................................20

1、Fire alarm simulation test......................................................................................................20

2、Metal diverting function test and adjustment...................................................................... 20

3、Maintenance and inspections............................................................................................... 21