Amphenol Network Solutions

All rights reserved. 12.06.19 147728-6 A0

509.926.6000 –amphenol-ns.com

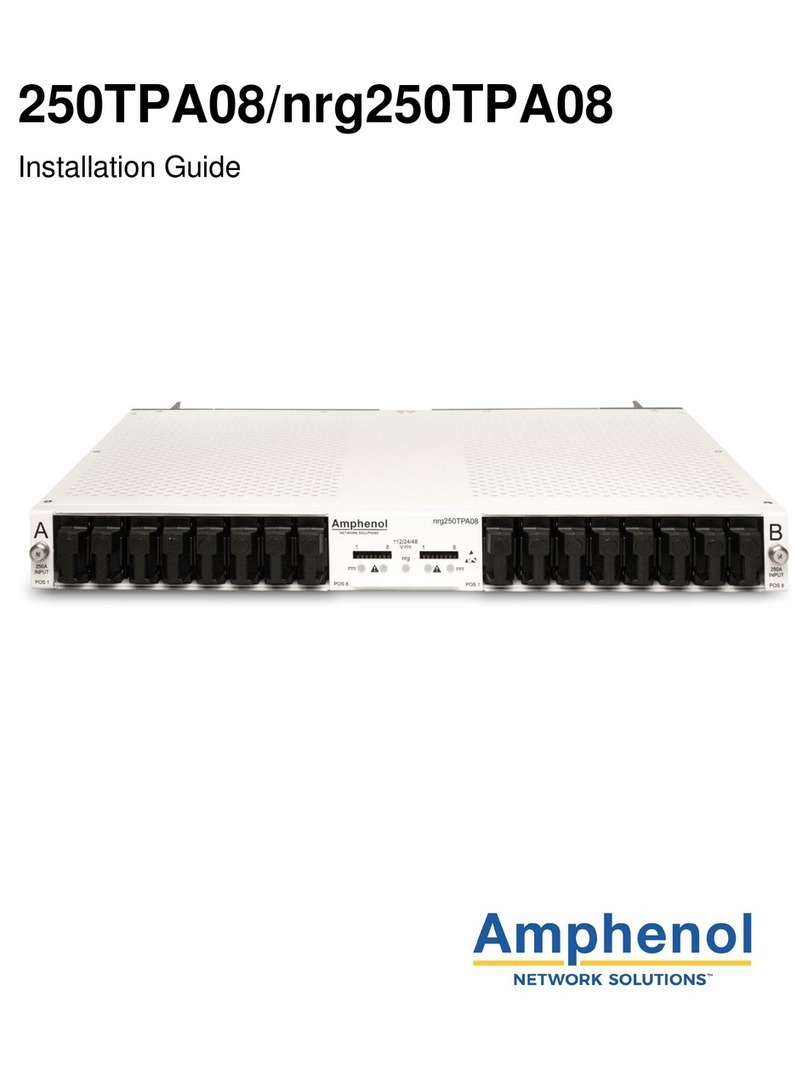

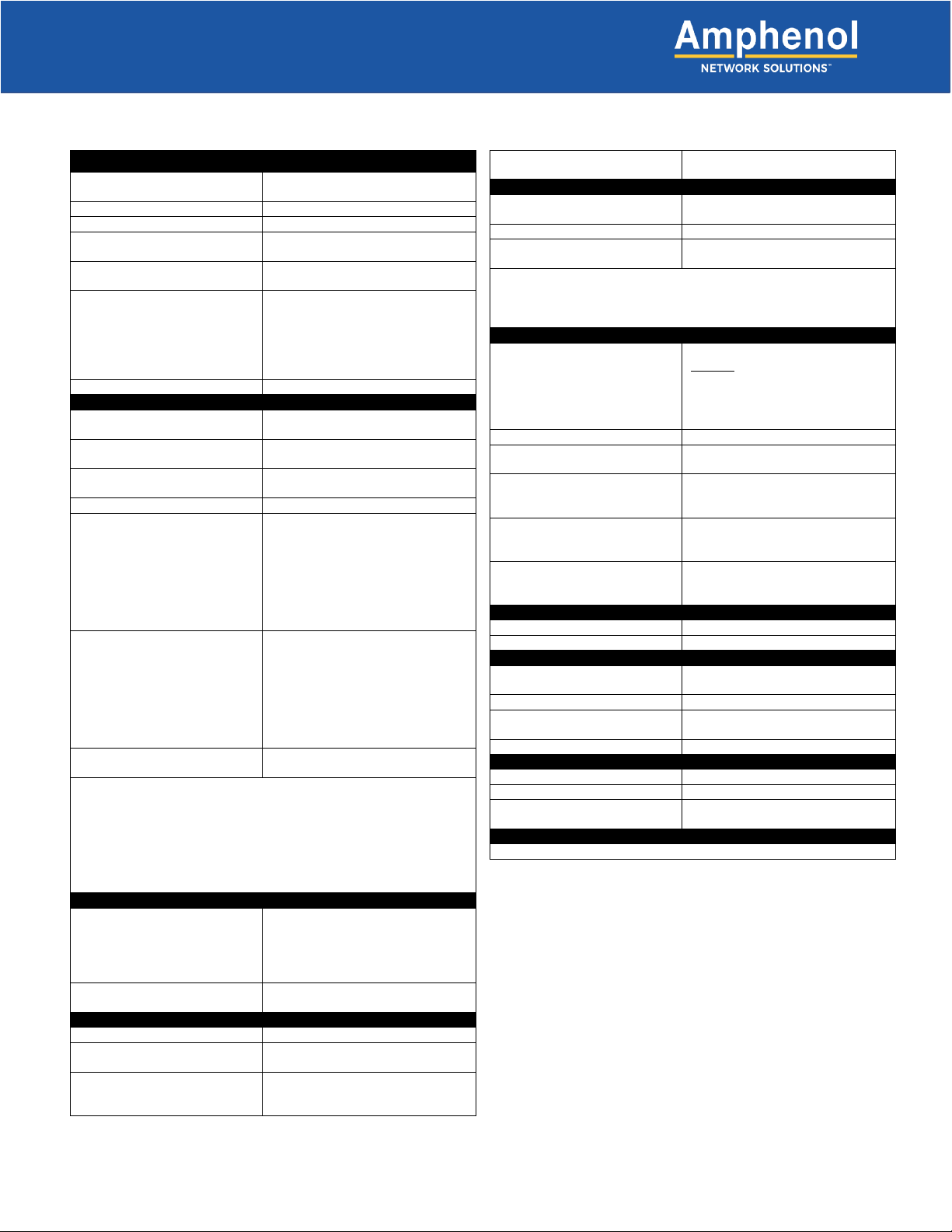

Voltage range, nominal voltage

-40V to -60V, nominal

-48V VDC

Maximum input load rating

Short circuit withstand rating

Nominal power loss at full load

Less than 7W per side @ 28,000W

full load (600A x -48V)

Percentage of full power

dissipation at nominal voltage

Input terminal studs (with nuts,

flat washers and spring

washers) for dual-hole

compression lugs

•3/8-16 studs on one-inch centers

per terminal (max. lug width of

1.94-in. [49.2 mm] per pair)

•Torque nut (using 9/16-in. or 15

mm wrench) to 150-in.lb (~17

N•m), max.

Max. output circuit breaker or

fuse holder

Single-pole: 100A

Double-pole: 175A

Max. output load –continuous

Single-pole: 80A

Double-pole: 140A

Minimum short circuit interrupt

rating

Output terminal studs (with

KEPS nuts and washers) for

dual-hole compression lugs

•1/4-20 studs on 5/8-in. centers

(max. lug width of 0.625-in. [15.8

mm] for a BATT terminal and

0.70-in. [17.7 mm] for a RTN

terminal).

•Torque bolts (using 7/16-in. or 12

mm wrench) to 50-in./lb (5.5

N•m), max.

•#10 AWG (min.) for a 25A single-

pole interrupter to #2 AWG

(max.) for a 100A single-pole

interrupter

•#2 AWG (min.) for double-pole

interrupters from 100A to 175A

•2/0 AWG (min.) for triple-pole

interrupter

Carling, symmetrical alarm

breakers**

*Amphenol Network Solutions suggests avoiding use of different types

of circuit breakers in the same load center. Alarm contacts may vary

among interrupter manufacturers and may incapacitate the alarm

system

**Circuit breakers for this load center are designed and manufactured

by Airpax Corporation and Carling Industries to meet the Amphenol

Network Solutions symmetrical pin specifications. Order circuit

breakers only from Amphenol Network Solutions

Earth GND terminal bolts (with

washers) for dual-hole

compression lug

•Two pairs of 1/4-20 threaded

holes on 5/8-in. centers

•Torque bolts (using 7/16-in. or 12

mm wrench) to 50-in./lb (5.5

N•m), max.

#2 AWG (min.) for any input

interrupt device 400A or more

Removable 6-pin connector with

screw down terminal

Dry Form-C contacts (1A @ 30

VDC; 0.5A @ 60 VDC; 0.3A @ 125

VAC)

@24V: 72mA (1.73W)

@48V: 147mA (7.06W)

0 to -19.99V: ±0.3V

-20V to -60V: ±0.1V

Voltage measurement range

0 to -19.99V: ±0.3V

-20V to -60V: ±0.1V

NOTE:

•Voltage measurement may be slightly different than at input terminal

blocks due to the voltage drop within the panel.

•Sensors are factory calibrated and do not require user adjustment.

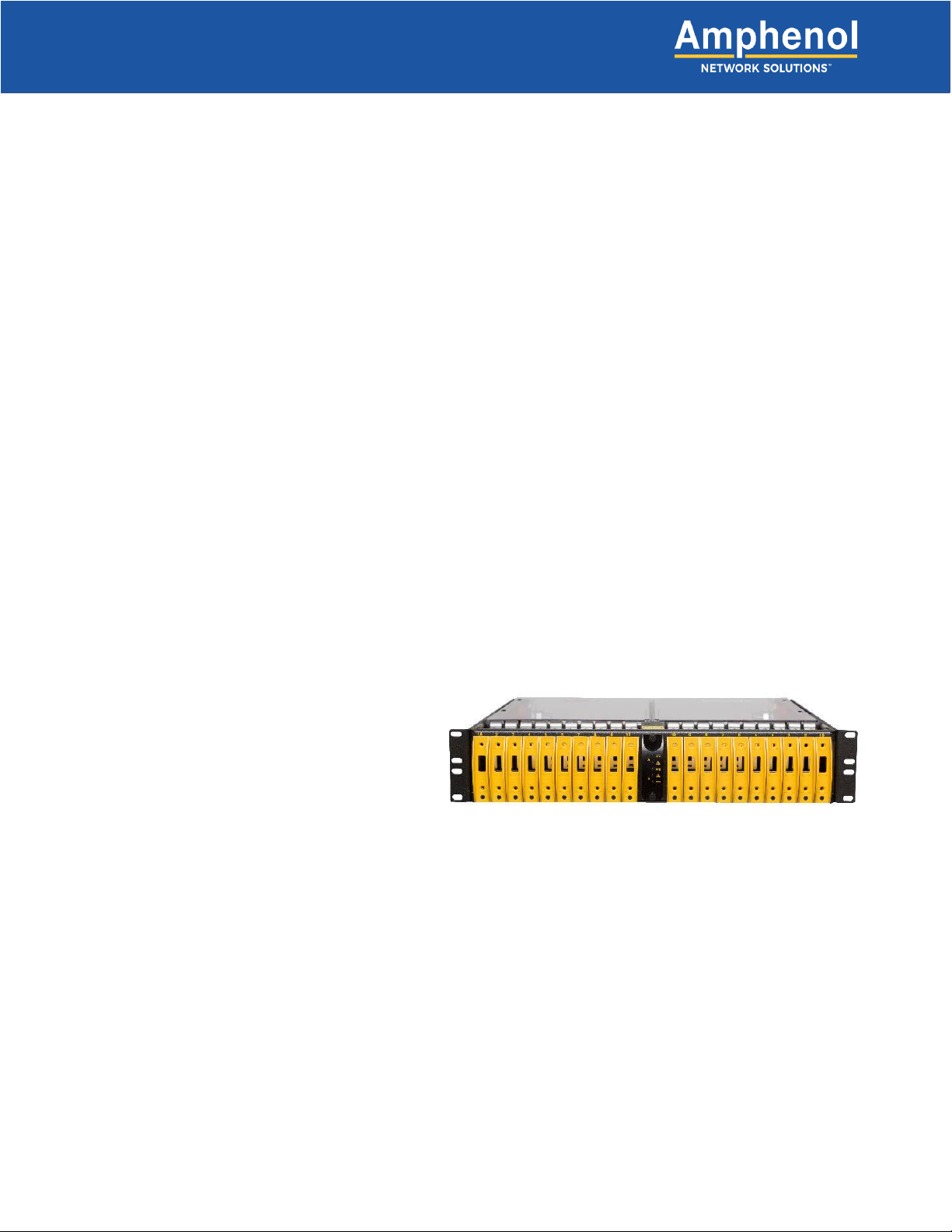

nrgNET sensor and alarm card

power

(via nrgNET cabling connection

to an nrgCONTROL-BT

controller)

-48 VDC nominal

*NOTE: The nrg600BT10 &

nrg600BT20S chassis’ MUST BE

connected to an nrgCONTROL-BT

controller via nrgNET cabling and

LED Alarm Indicators to function

nrgNET data communication

Removable 5-pin connector with

screw down terminals

nrgNET connector functions

nrgNET IN from the nrgCONTROL

or nrgSMART panel, nrgNET OUT

to next in-line nrgSMART panel

LED Alarm Indicators

(requires nrgNET & controller

for power)

A/B bus power

A/B fuse alarms

nrgNET Comms active

Proprietary nrgNET used to

communicate between panels and

controller

19”L x 15”W x 3.5”H

(483 mm x 305 mm x 88 mm)

Weight, without packaging and

accessories

-10°C (14°F) to 53°C (127°F)

0 to -19.99V: Alarm

-20V to -60V: Normal

Standard one-year warranty on all parts.