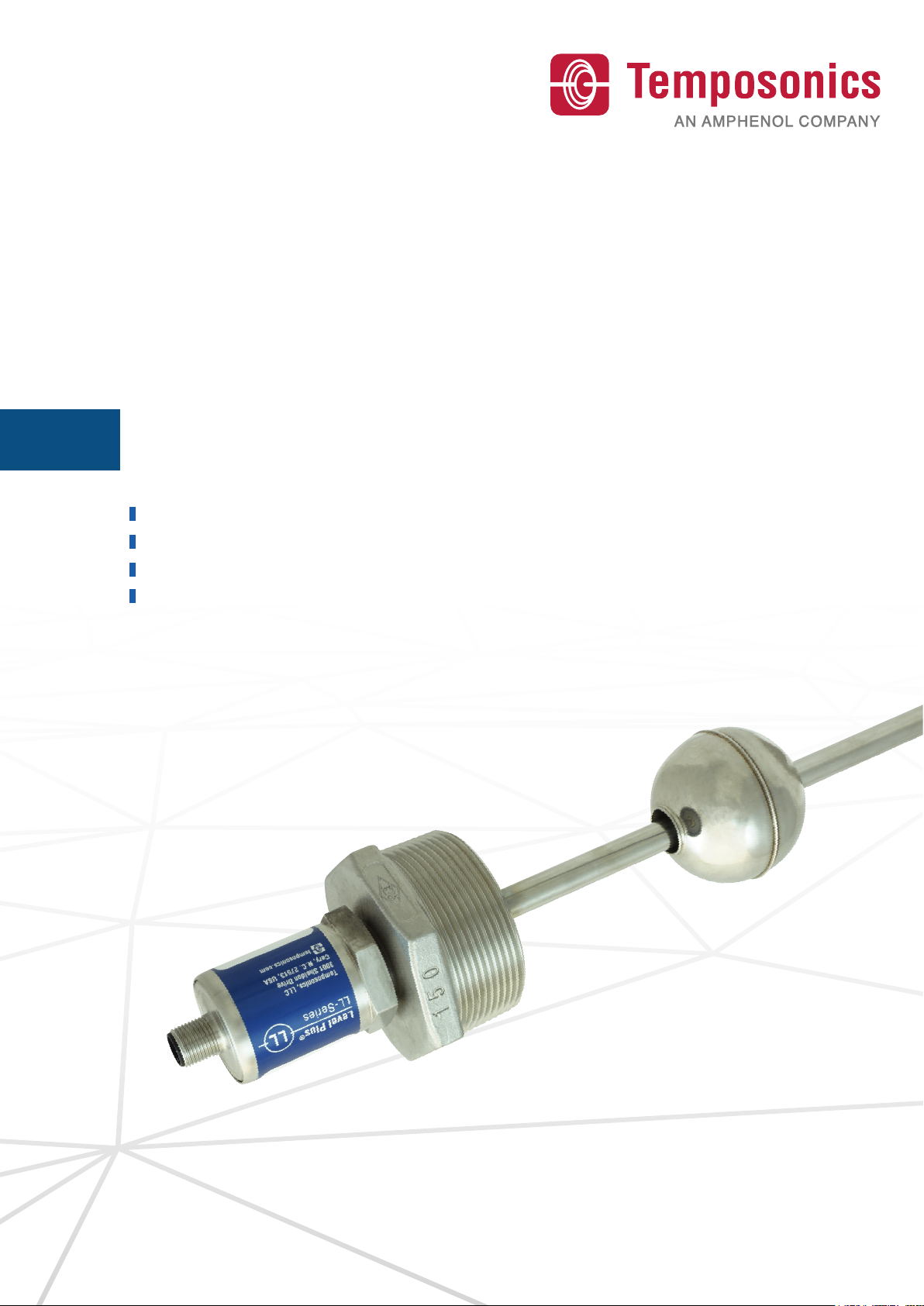

Level Plus® LLE

Operation Manual

I7 I

5. Product overview

The Level Plus LLE satisfies the demand for an accurate and robust

liquid level transmitter for general purpose applications. The LLE can

provide product level and/or interface level in a compact mechanical

design. There is no requirement for scheduled maintenance or

recalibration for the expected 10 year life of the sensor. Set it and

Forget it.

The LLE liquid level transmitter can be mounted on most tanks

offering NPT and RF flanged connections from 3/4 to 6 inches. The

LLE also offers a variety of outputs including analog, CANbus, SSI and

IO-Link. Included in the model number is the selection of float, cable,

and stop collar options. The single model offers everything needed for

level measurement in a variety of applications.

Applications

• Hydraulic Reservoir

• Industrial Printers

• Firefighting Airplanes

• Waste Management

• Generators

• Process Tanks

• Skids

Features

• Product and Interface Level

• No scheduled maintenance or recalibration

• Inherent Accuracy +/- 0.5 mm

• IP69K

• 100 g Shock/15 g Vibration

5.1 Components

The Level Plus®LLE liquid level transmitter consists of four main

components; a base model, float, adaptor, and optional temperature

measurement. Varying the components of the transmitter allows the

transmitter to be customized to almost any application.

Base Model

The base model of the LLE consist of the housing, 3/4” NPT threads,

M12 connector, and either a 7 mm or 10 mm pipe. The drawing of the

base model is shown in section 5.7 Technical Drawing.

Floats

LLE transmitters offer numerous floats for different applications such

as stainless steel for both product level and interface level. To be able

to accurately detect the interface level there needs to be a difference

of at least 0.05 in specific gravities between the product and interface

liquids. For detailed information about floats, refer to the ‘Accessories

Catalog’, (Temposonics Part # 551103).

For assistance with selecting a specific float for your application,

please contact Technical Support with the following information:

• Specific gravity of liquid(s) being measured

• Process temperature

• Process opening size

• Vessel pressure

Adaptor

The LLE is available with multiple adapters to allow for mounting of

the standard 3/4” NPT fitting into larger openings. Available adapters

include NPT fittings from 1” to 4”, ANSI flanges from 1” to 6”, SAE 5

bolt adapters, and custom flanges.

Temperature Measurement

The LLE offers an optional temperature measurement for analog

outputs models with a direct RTD output from a PT100 Class A RTD.

The RTD is located at 2" from the tip of the pipe for order lengths less

than 20" and at 10% of order length for all other lengths.

Accessories

Temposonics also offers a series of displays, housings, converters,

and other accessories, please refer to the ‘Accessories Catalog’,

(Part#551103).

5.2 Accuracy

For magnetostrictive transmitters inherent accuracy is measured

in terms of non-linearity. Non-linearity is a measurement of any

imperfections in the waveguide that are reflected in the linearity of

the transmitter’s output. Temposonics tolerances reflect a maximum

non-linearity of +/- 0.5 mm. Temposonics is able to achieve such

strict tolerances by manufacturing all of its own waveguide from a

proprietary alloy and testing 100% of all transmitters before shipping.

5.3 Warranty

Important:

Contact Technical Support or Customer Service for assistance if

you suspect that the transmitter is not working correctly. Technical

support can assist you with troubleshooting, part replacement, and

Returned Material Authorization (RMA) information if required.

All Level Plus®transmitters come with a two year limited warranty

from the factory shipment date. An additional extended warranty can

be purchased. A Return Materials Authorization (RMA) number is

required and must accompany any transmitter returns. Any unit that

was used in a process must be properly cleaned in accordance with

OSHA standards, before it is returned to the factory. A Material Safety

Data Sheet (MSDS) must also accompany the transmitter that was

used in any process.

The Temposonics obligation is limited to repair or replacement of any

defective part of the unit. No warranty can be provided for defects

that are due to improper use or above average stress of the product,

as well as for wear parts. Under no circumstances will Temposonics

accept liability in the event of offense against the warranty rules, no

matter if these have been assured or expected, even in case of fault or

negligence of the company.