2. Forbestresults, cuttape at a slight diagonal,

join ends together with splicing tape on the glossy side

and trim off any excessive width.

E rasing Recorded Material-

When the Play-Record knob (3) is in the "Record"

position, the erase head is automatically in operation,

erasing any previous recording before a new one is

made. You may erase material no longer needed,

without recording, by moving the Play-Record knob

(3) to "Record" on turning the "Volume" control knob

to the minimum volume position just before the record-

er shuts off. Onetrack is erased at a time, To erase

the second track, reverse the reels and repeat the

above operation.

To Use Recorder As A Public Address System-

Plug microphone cord into I'Mic. or Phonoil re-

ceptacle. Turn Play-Record controlto I'phono-record"

position. Be sure microphone is far enough away from

speaker to avoid feedback squeal. Volume may be ad-

justed with Volume eontrol. Mikeand/or radio-phono

can be simultaneously used for blending of special

effects in public address use with Ampro Dual - Input

Mixer, No. 133.

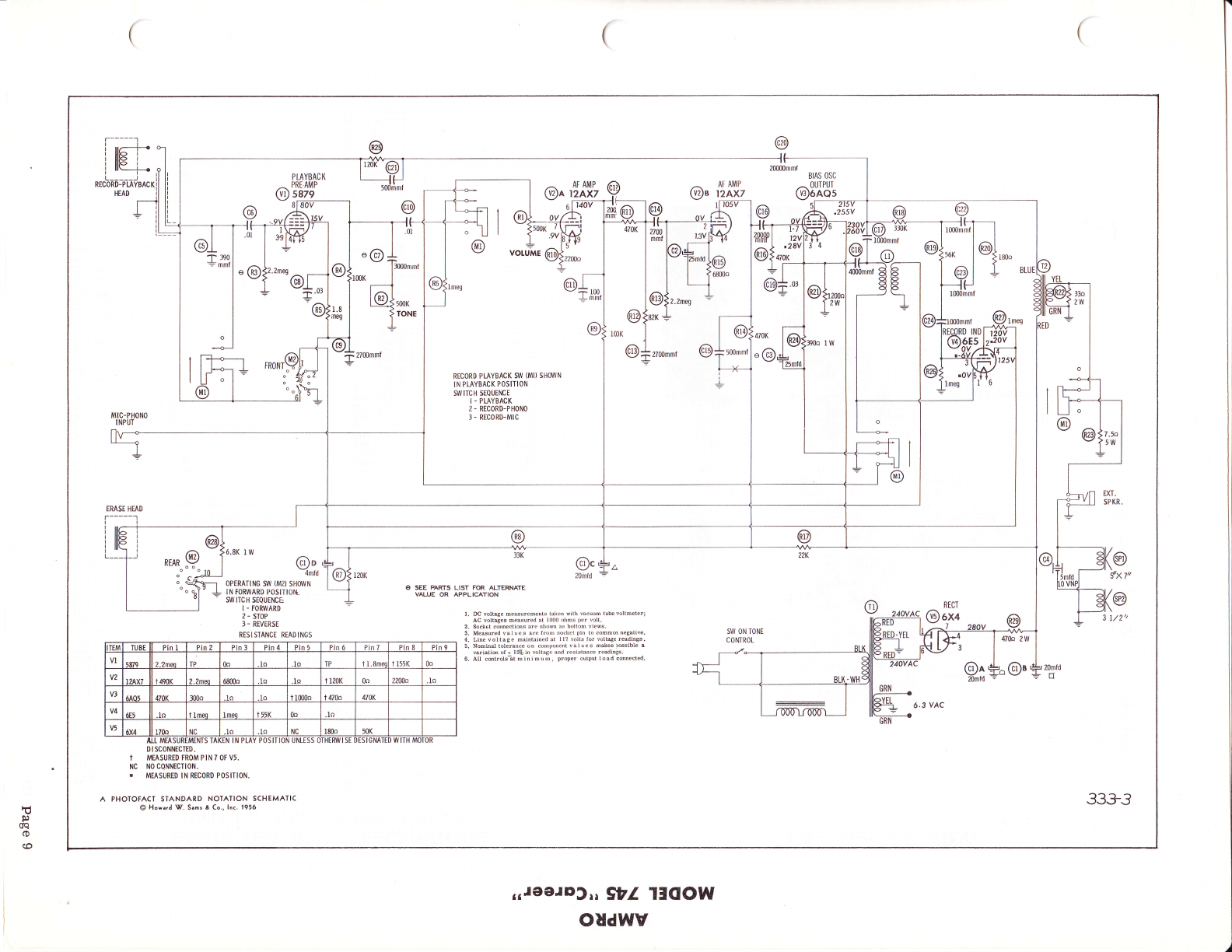

ELECTRICAL ADJUSTMENTS

Erase Head Adjustment-

I, Loosen screws located on the left side of

erase head and raise or lower head and tilt head as

required in order to obtain minimum output.

2. Then loosen screw (32A) and rotate position-

ing block for minimum output.

3. Tighten screw (32A) and rotate positioning

block for minimum output.

4, Checkfor oppositetrackerasure if excessive,

head is set too low.

Record Head Adjustment-

The record head is mounted on a pivoted plate

which is held in place by two filister head screws

(32B) located at opposite corners of the plate. Tight-

ening or loosening the screw on the left (viewed from

operating position) rocks the pivoted plate thereby

changing the angular relationship between the gap and

thetapeand increasing or decreasing the compression

oI the spring located under the head of the opposite

mounting screw. In order to make an adjustment,

threadtherecorder with pre-recorded 1 mil alignment

tape or a good recorded tape on the machine.

Connect an output meter across the terminals of

the elliptical speaker. Switch recorder to "play" po-

sition and set the volume control to the 12 o'clock po-

sition. Rotate the screw which secures the left side

of the plate in order to obtain maximum output from

the pre-recorded material. Make a rough adjustment

at a tape velocityof 3. ?5 inches per second the switch

to ?.50 inches per second for final adjustment.

NOTE: Watch out for a false peak you may find 3

peaks - be sure to adjust for strongest peak.

Page 4

Erase Current-

Disconnect the ground lead at the erase head

terminal and insert a 10 ohm non-inductive resistor.

Qonnect a VTVM across the resistor. Switch to

record and note voltage. Correct voltage will be ap-

proximately 0,4-0. 5 volts indicating an erase current

of approximately 40-50 ma.

Bias Current-

Disconnect lead from record head. Insert 100

ohm non-inductive resistor between red lead and re-

cord head terminal and connect VTVM acrossl00 ohm

resistor. Turnvolume control to low volume position.

Switchtorecord and measure voltage across resistor.

Voltage shouldbe "0.40 - 0,45" volts which is equiva-

lent to a current of "0.40 - 0.45 ma. If bias is not

within these limits adjust slug in oscillator coil to

obtain correct current.

MECHANICAL ADJUSTMENTS

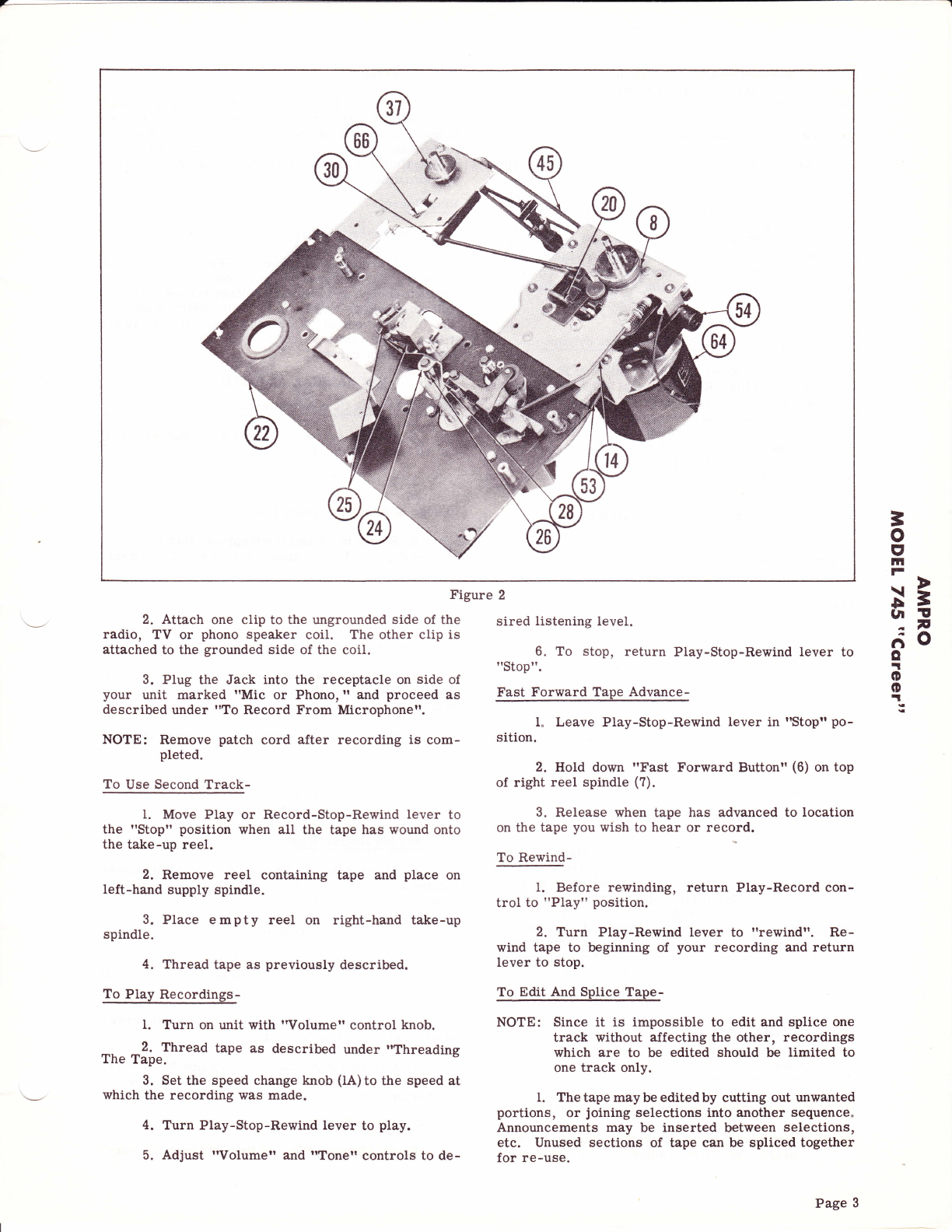

Erase Interlock Cam Adjustment-

l. Loosen set screw slightly so that cam (34)

can be turned on control shajt.

2. Turn shaft to maximum clockwise t'Playt'

position. Rotate cam so that flat surface is parallel

to edge of interlock spring (35).

3. Press in on interlock spring, then turn con-

trol shaft in order to expose setscrew. Tighten set-

screws.

Rewind-Play Or Record Cam (29) Adjustment-

1. Turn control shaJt to maximum counter-

clockwise (Play or Record) position.

2. Loosen setscrews in cam. Rotate cam so

thatcamflatis parallel to flat surface of pad actuating

arm (24).

3. Raise or lower cam (29) as required in order

to locate top face of cam in the same plane as top of

arm (24). Tighten setscrews.

4. Place light film of "Lubriplate" on surface

of cam which comes in contact with arm (24).

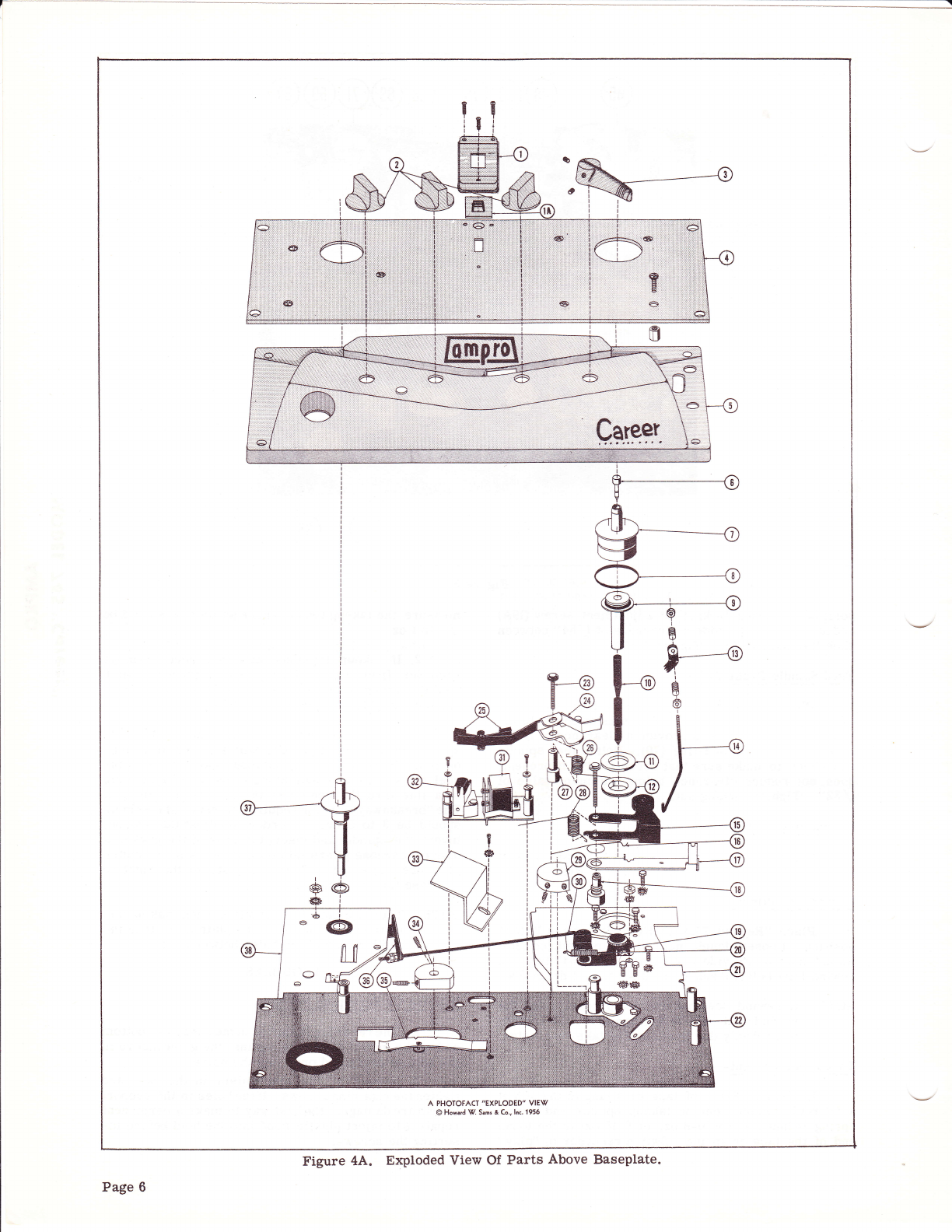

Disassembly Instructions-

1. Take outthe four Phillips filister head screws

located at the corners of the panel (5). Loosenthetwo

allen setscrews in the "Rewind-Play or Recordl knob

(3) and remove the knob. Puli off the other three

knobs (2). Lift off the control panel (5).

2. Removethreephillipsoval head screws which

hold speed change control cover (l) in place and lift off

cover.

3. Take out ten phillips oval head wood screws

which hold metal panels to case.

4. Loosen cable clamp which holds line cord to

back of carrying case. Standrecorder on end and pull

mechanism out of case.

Takeup Brake Adjustment-

Place "Rewind-Play or Recordtt knob in [Playtt

t-