7

INTRODUCTION

The ACDC-400 Clamp-On meter is an average responding autoranging 400 Amp

/ 600 V clamp meter. The features include AC / DC voltage, AC / DC current,

Resistance, and Continuity tests.

This Instrument’s display also contains an analog bar graph.

OPERATION

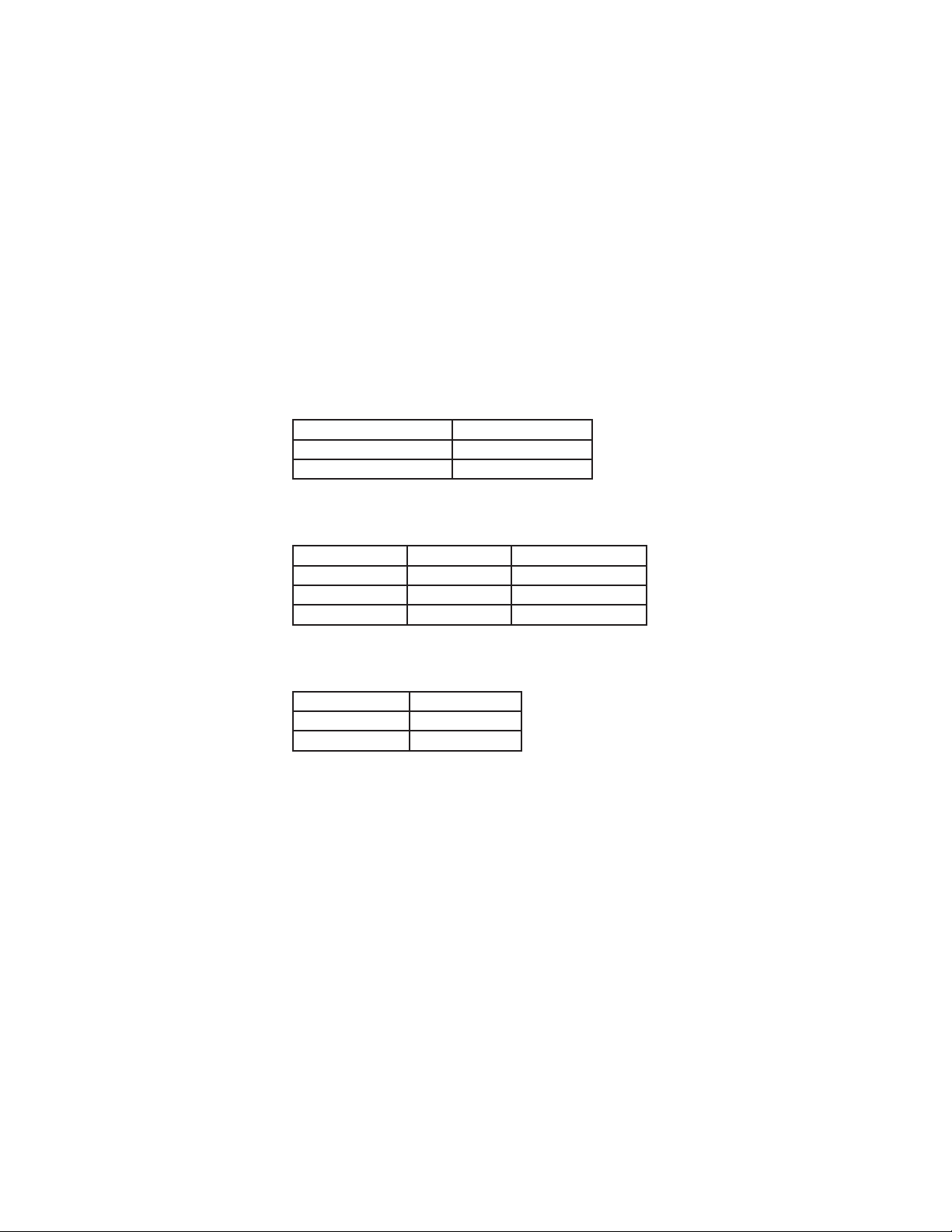

Alignment marks (see Fig. 2)

Place conductor within the jaws at the intersection of the indicated marks as close

as possible to maximize the accuracy of the reading.

Auto Power Off function

In order to save battery life, your clampmeter powers down automatically after

approximately 30 minutes of inactivity. You can turn it back on by turning the

function selector switch to OFF and back to a measuring function. The instrument

does not power down while in MAX MIN mode. You can disable Auto Power Off by

pressing and holding the ZERO button while turning the meter ON.

R-H Range selection

Press R-H button < 1 second, to enable/disable manual range selection.

Backlight function (�)

Press Backlight button more than 1 second, enable/disable Backlight. To use the

backlight in the ‘Autoranging’ mode, press and hold the R-H button for more than

2 seconds.

D-H function (DATA HOLD)

Freezes the reading present on the LCD at the moment the button is pressed.

To use this button feature, set up the meter for the type of measurement and

range desired. Connect the test leads or clamp jaws to the circuit/component to

be measured, then press Hold. The LCD reading will freeze and display “.” You

may now remove the test leads and the reading will not change until you press D-H

again.

ZERO button: Relative display function

The ZERO mode displays the difference between the actual reading and a reference

value. It may be used with any function or range; however, the range must be

set manually. To make a relative measurement first establish a reference value

by measuring a value and then pressing the ZERO button after the reading has

stabilized. This stores the measured value as the reference and sets the display to

zero. The meter subtracts the reference value from subsequent measurements and

displays this difference as the relative value. Measurement values greater than

the reference value will be positive and values less than the reference value will

be negative. To exit the Zero Mode, Press and hold the Zero button for 2 seconds.