The option "630-400" can clip easily to wires,

pins, and medium size (up to ½" diameter con-

ductors). The notched connector end plugs

directly into the 630’s J1 main front panel con-

nector labeled for “test leads”.

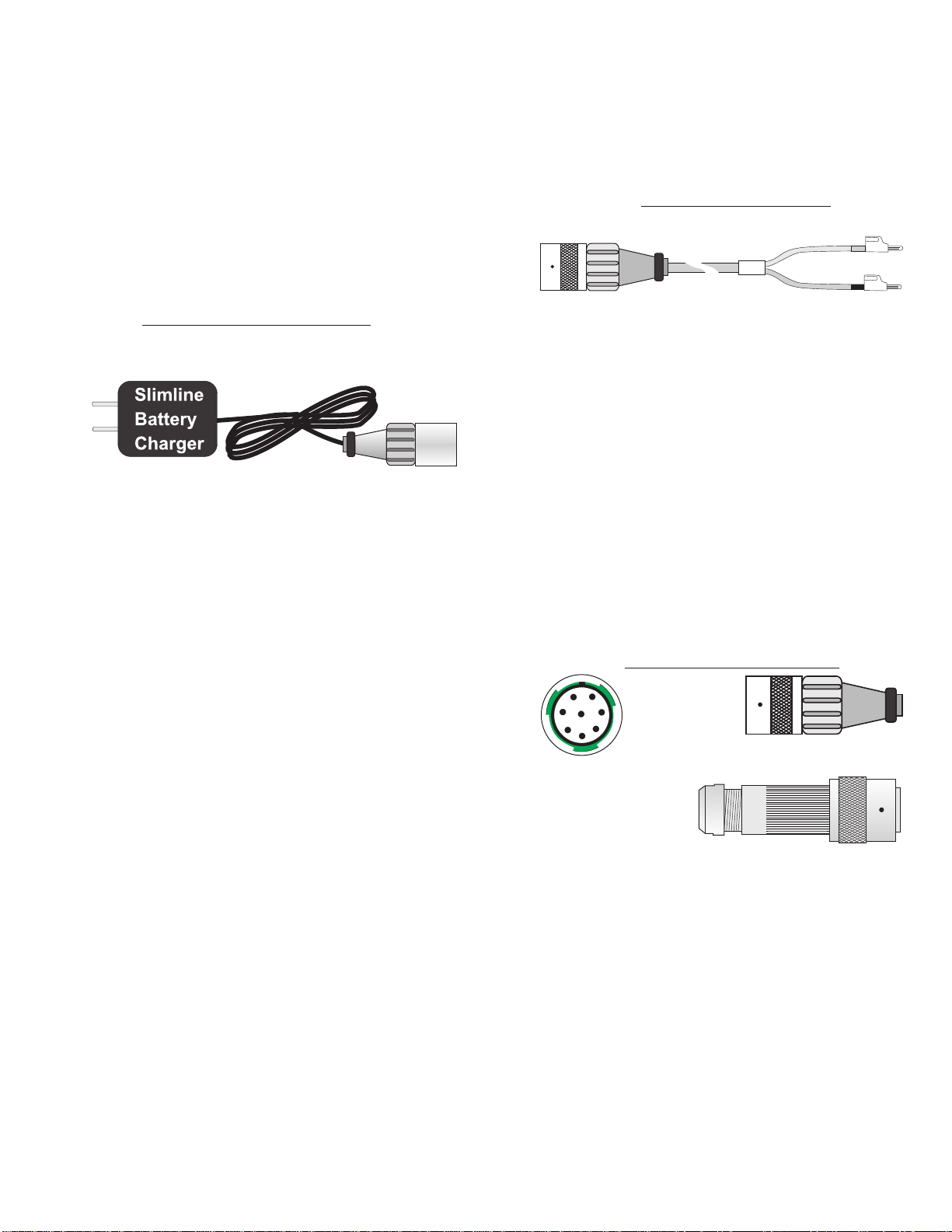

Option 630-305: Separate/Twin Banana Plug

(Red tipped and Black tipped) Cable Set

Option "630-305" is a 48" long replacement

cable set normally supplied as part of the

AMPTEC 630BN Ohmmeter package. The

Option “640-305 has two single banana plugs

(meter and common) terminated with the

630BN style notched connector. One banana

plug is red (Voltage high and Current High) and

one banana plug lead end is black (Voltage low

and Current low) . The 4-wire configuration is

maintained up to the point of the banana plug,

eliminating most cable resistance effects.

Option 630-Plug: For Custom Test Harnesses

Option "630-Plug" is the 630Test Lead Plug

along with 8 gold pin/sockets for custom wir-

ing/missile test harness applications.

Contact the sales department at AMPTEC

RESEARCH (phone 1-800-350-5105 from

inside the USA) if you have need for a special

probe, adapter, lead set, or custom option..

AMPTEC’S engineers have helped customers

with special igniter tester accessory require-

ments. Check with our website which is

http://www.amptec.com for latest AMPTEC

RESEARCH contact (address and phone #

changes) information.

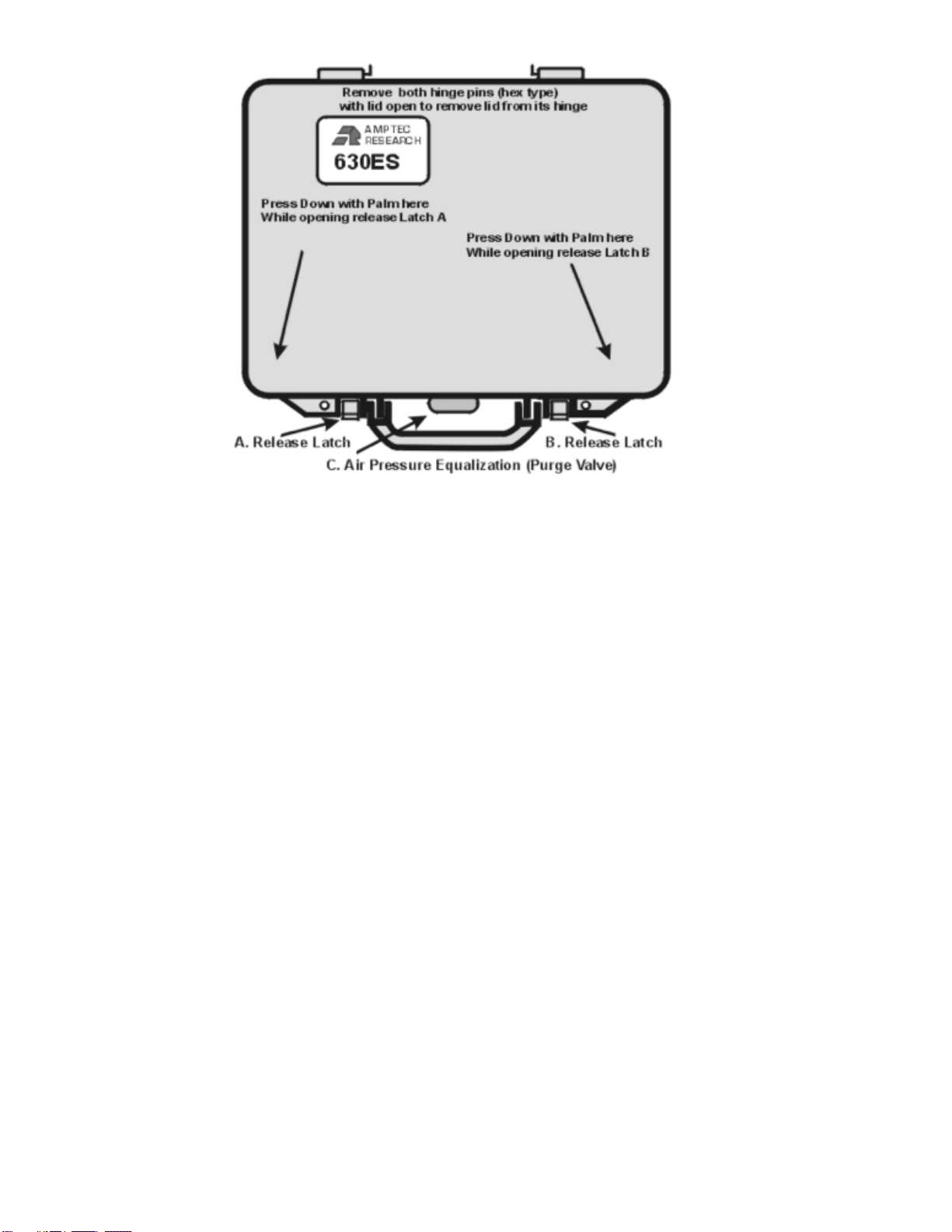

C-1. Available Accessories and Options

This manual does not list all possible

accessories that AMPTEC RESEARCH is

willing to provide as a support items for the

630BN Igniter Tester. Contact the sales

department at AMPTEC if you have a request

for an item that is not described here. Listed

below are the options available for use with the

AMPTEC 630BN Igniter Tester.

Option 630DC: Battery Charger

Option "630DC" is an AC/DC converter that

converts 115VAC line voltage to 9VDC at 1.1A.

The 630 Battery Charger is fitted with the

mating plug that connects to the unit’s J1

connector. One charger is provided as a standard

accessory with every 630ES Igniter Tester .

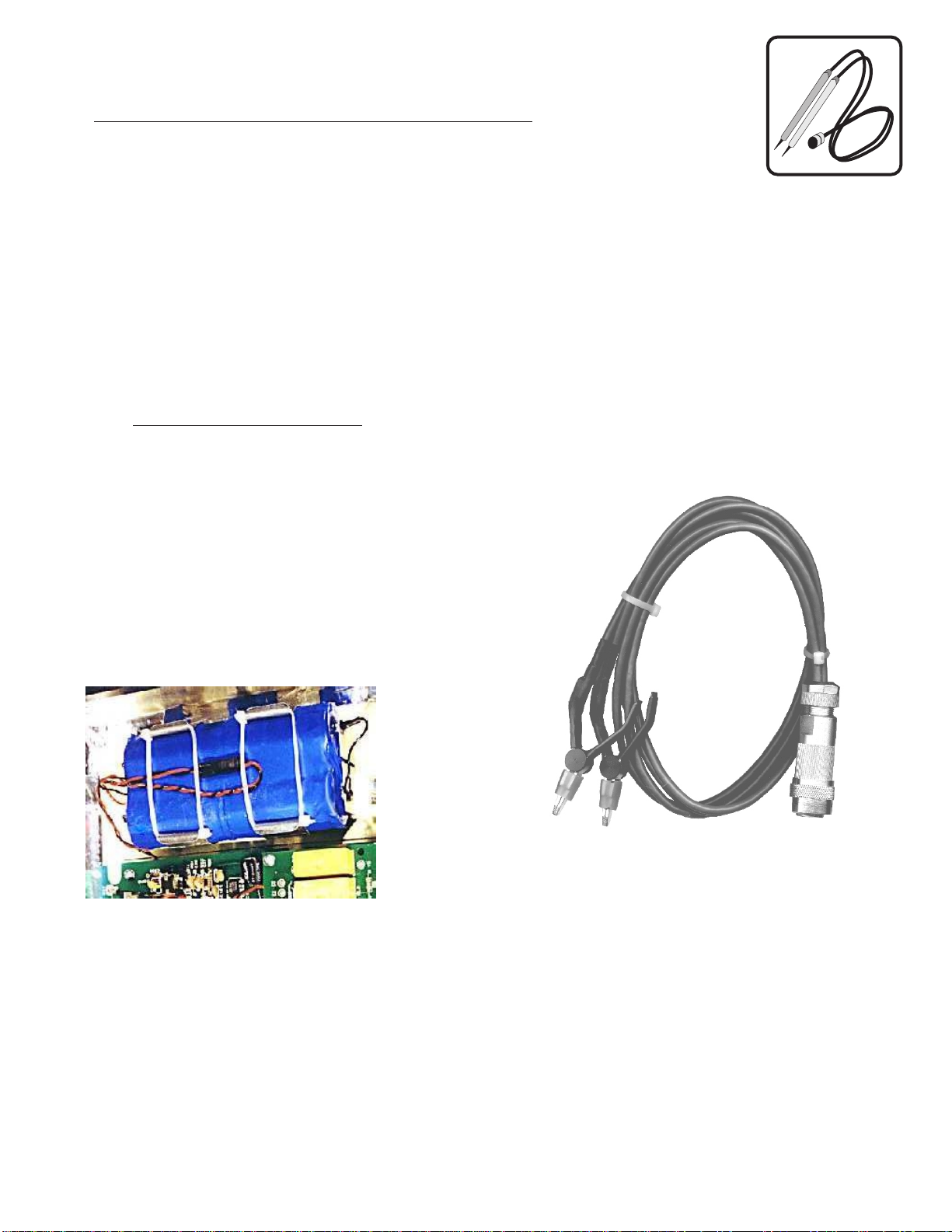

Replacement Batteries

The rechargeable NICAD batteries installed in

the 630ES should provide trouble-free

operation. Replacement, however, will

eventually be necessary. The 630ES uses four

1.2V cells (5.7 AHr recommended) installed in a

reusable battery box. The batteries are held in

place by a metal retaining plate. When

ordering replacement batteries, please specify

AMPTEC Stock #05-10117, quantity four (4).

C-2. Test Lead and Connector Sets

Option 630-400: 4 Wire Kelvin Lead Set

Option "630-400" is the recommended Kelvin

four wire lead set for the 630 Series Igniter

Testers ( especially for versions that have a 2

Ohm range). Option 630-300 is a shielded 48"

lead set terminating in ½" opening Kelvin clips.

A

B

C

D

E

F

H

G

A= I High

B= V High

C= V Low

D= I Low

E=

F= Ground (-)

G=Chassis Ground

H= +5 V