A-1. Introduction to the AMPTEC 620VN

Some of the devices the 620VN Igniter Tester may

be used on include: fuses, squibs, igniters,

explosive bolts, rocket motor squibs, automobile

air-bag initiators and many others.

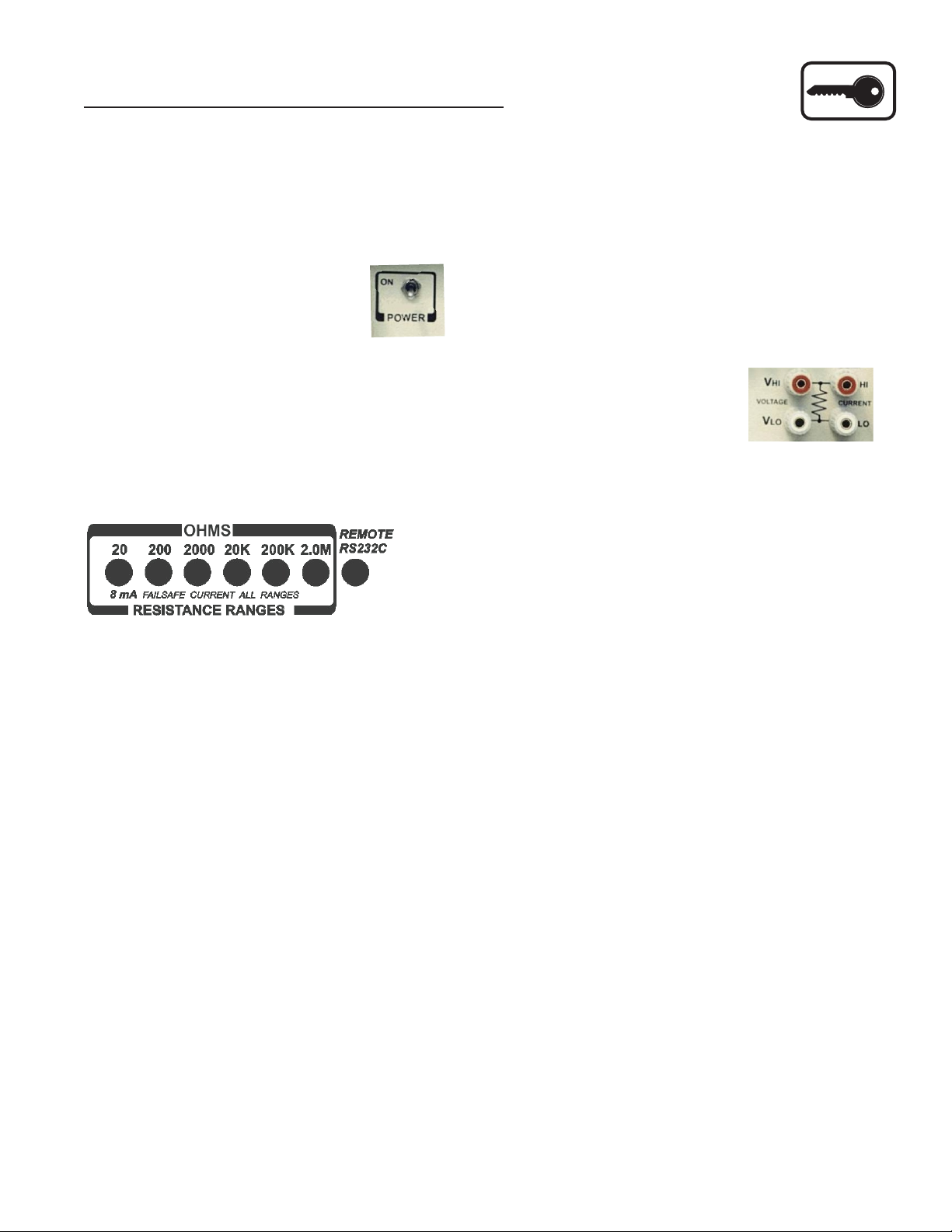

The AMPTEC 620VN is a 4-wire failsafe digital

ohmmeter which has been designed to reliably

use very low test currents for its resistance

measurement. Failsafe Output Circuitry

proprietary to AMPTEC RESEARCH ensures

that test current levels do not exceed the

specified "failsafe current" even in a worst-case

component failure situation. The failsafe feature

is tested in every instrument before shipment.

The 620VN uses the same main printed circuit

board (PCB) as all of the AMPTEC 620A Igniter

Testers. The 620VN has many features (no

resistance range gaps form 20 ohms to 2.0

megohms) which make it useful in a variety of

applications. Please check the last chapter of this

manual for addendums that may apply to the

AMPTEC 620VN .

For added safety the AMPTEC 620VN Igniter

Tester is always electrically isolated or

electrically "floating". It normally comes

configured with the 2 stage option “247”

Isolated Continuous Operating power. The first

stage of isolation with op “247” is the ACV wall

adapter (ie 120 VAC input to 24 VDC output).

This provides the first stage of initial high

frequency and high voltage (transient)

suppression.

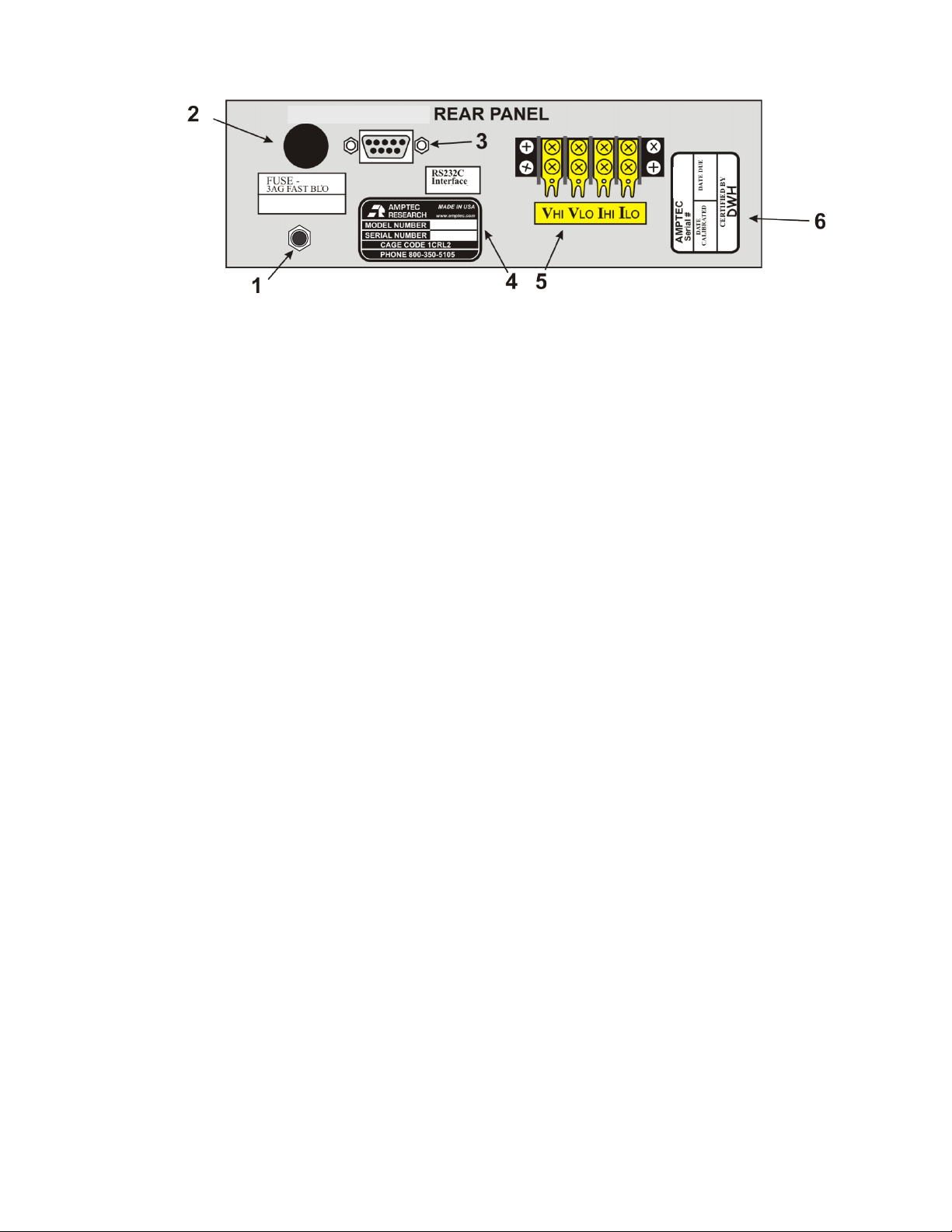

(OP 247 ) The second stage of isolation uses,

converts, isolates and conditions the +24 VDC

coming into the meters rear panel. The rear

panel input voltage (+24 VDC) is converted (via

several circuits) using a Medical Grade DC to

DC convertor into the +5.0 VDC that provides

the meters main operating power. The high

quality Medical grade DC to DC Convertor uses

essentially transformer isolation and voltage step

down principals to provide the meters main

power as a “floating” +5VDC. A 3000 VAC

Isolation (Hipot) Test Report is available from

AMPTEC’s engineering department that has

established the isolation of the 2 stage “OP247”

as being at least Isolated to the 3 KV level.

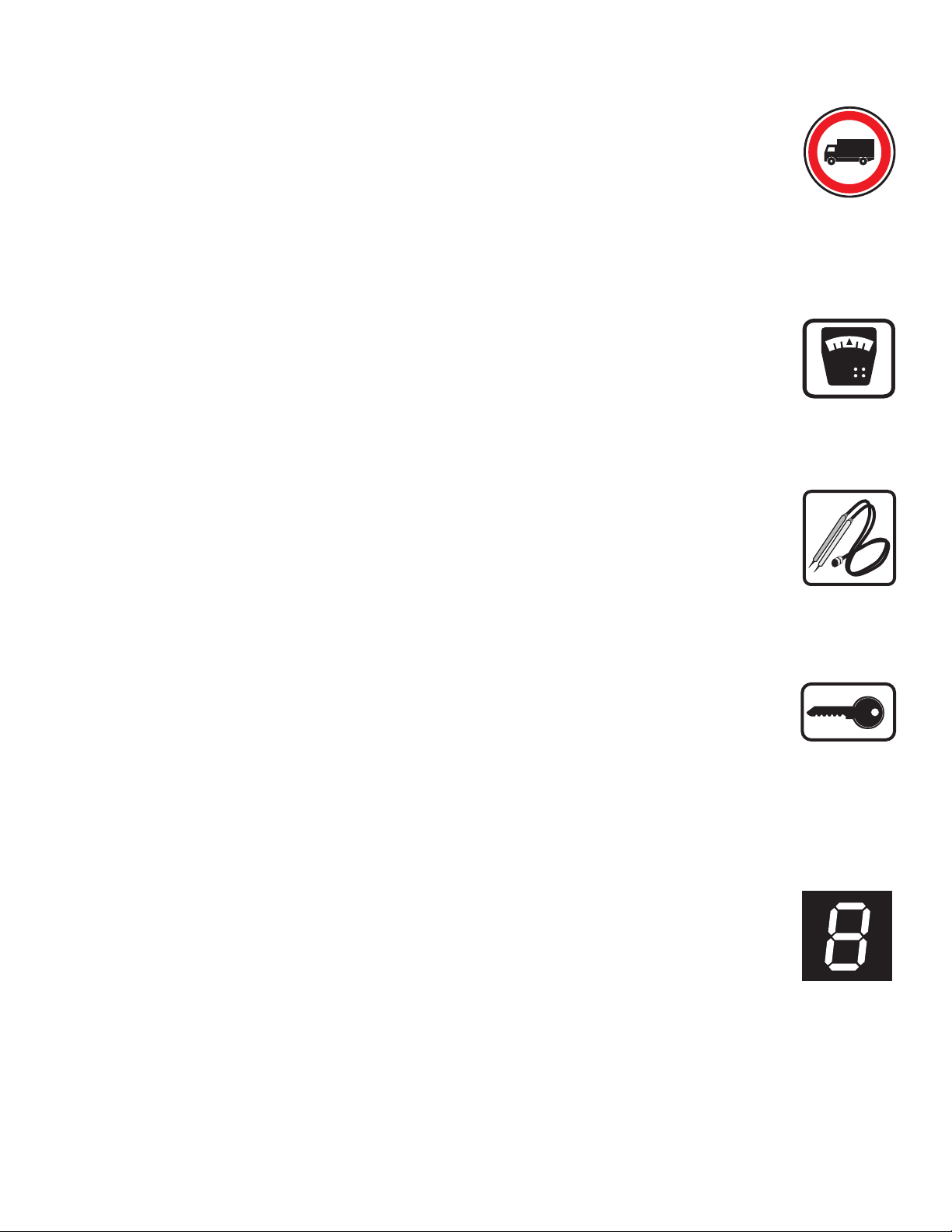

A-2. Receiving, Unpacking

and Initial Inspection

Should the AMPTEC shipping box appear

damaged upon arrival, request that the carrier's

agent (i.e. UPS) be present when the unit is

unpacked. If the 620VN appears damaged, the

carrier's agent should authorize repairs before

the unit is returned to the factory. Even if the

instrument appears undamaged, it may have

suffered internal damage in transit that may not

be evident until the unit is operated or tested to

verify conformance with its specifications.

If the unit fails to operate or

fails to meet the performance

specifications of Section B,

notify the carrier's agent and

the nearest AMPTEC Sales

Office. Retain the shipping carton for the

carrier's inspection. DO NOT return

equipment to AMPTEC RESEARCH or any

of its sales offices without first obtaining an

(RMA) Return Material Authorization number.

We need to know who to contact and how to

contact (i.e. phone number and FAX number) in

order to properly coordinate the return of the

repaired AMPTEC product.

Call AMPTEC RESEARCH first, prior to

just returning the 620VN . We can often

troubleshoot (based on the symptoms you

describe) and identify the problem. We may

possibly be able to fix the problem over the

phone and prevent you from having to return the

unit to AMPTEC for repair.

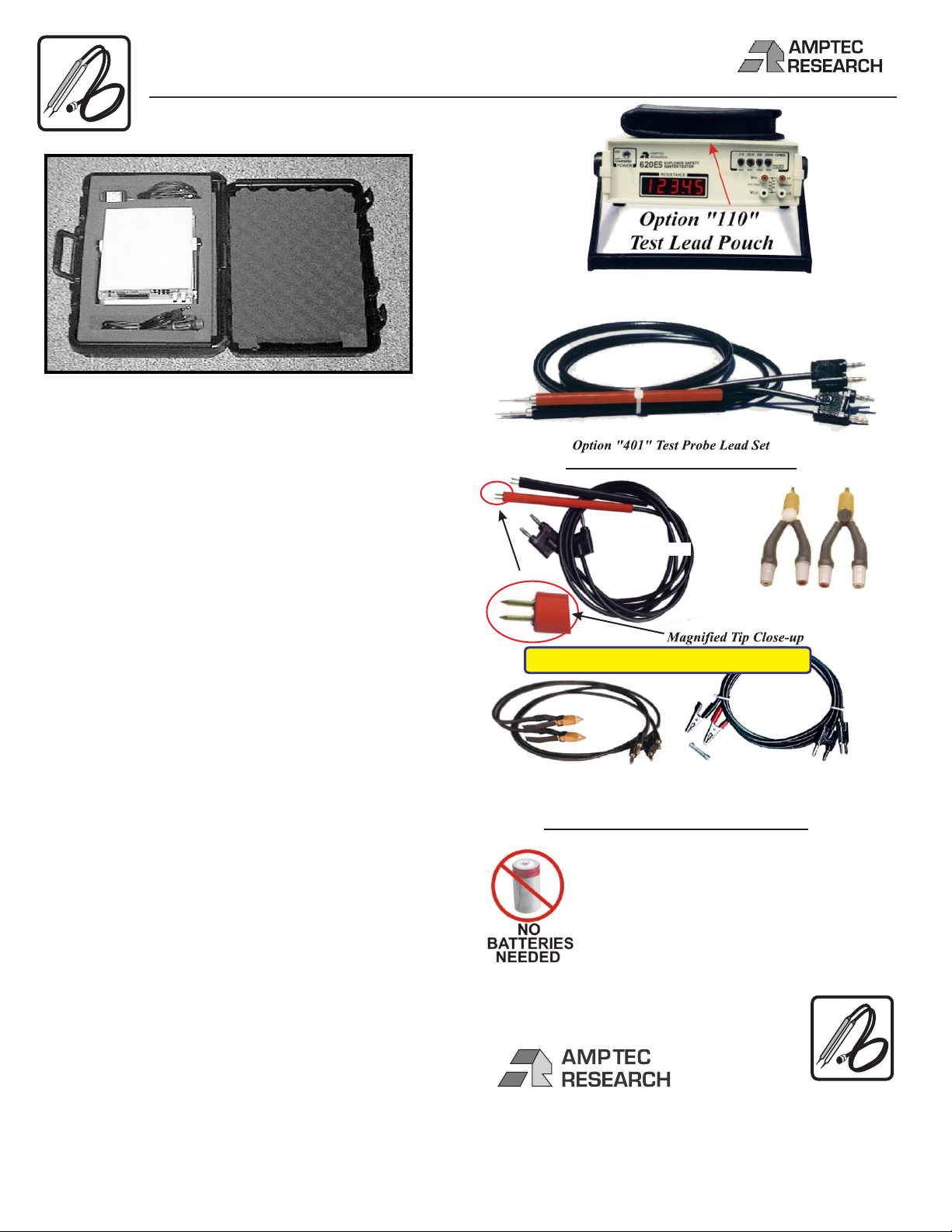

A-3. Setup and Use

The AMPTEC 620VN Igniter Tester may be

setup to operate within minute(s) of power "turn

on" (unless your in an extremely cold tempera-

ture - allow more time for warm-up - 15 min-

utes). A quick test lead integrity check and it

should be ready to use. The front panel will

display a negative or minus sign Avoid expos-

ing the AMPTEC 620VN Igniter Tester to

extremes of temperature which will affect accu-

racy.

SECTION A - RECEIVING AND INITIAL INSPECTION

R M A

page 4