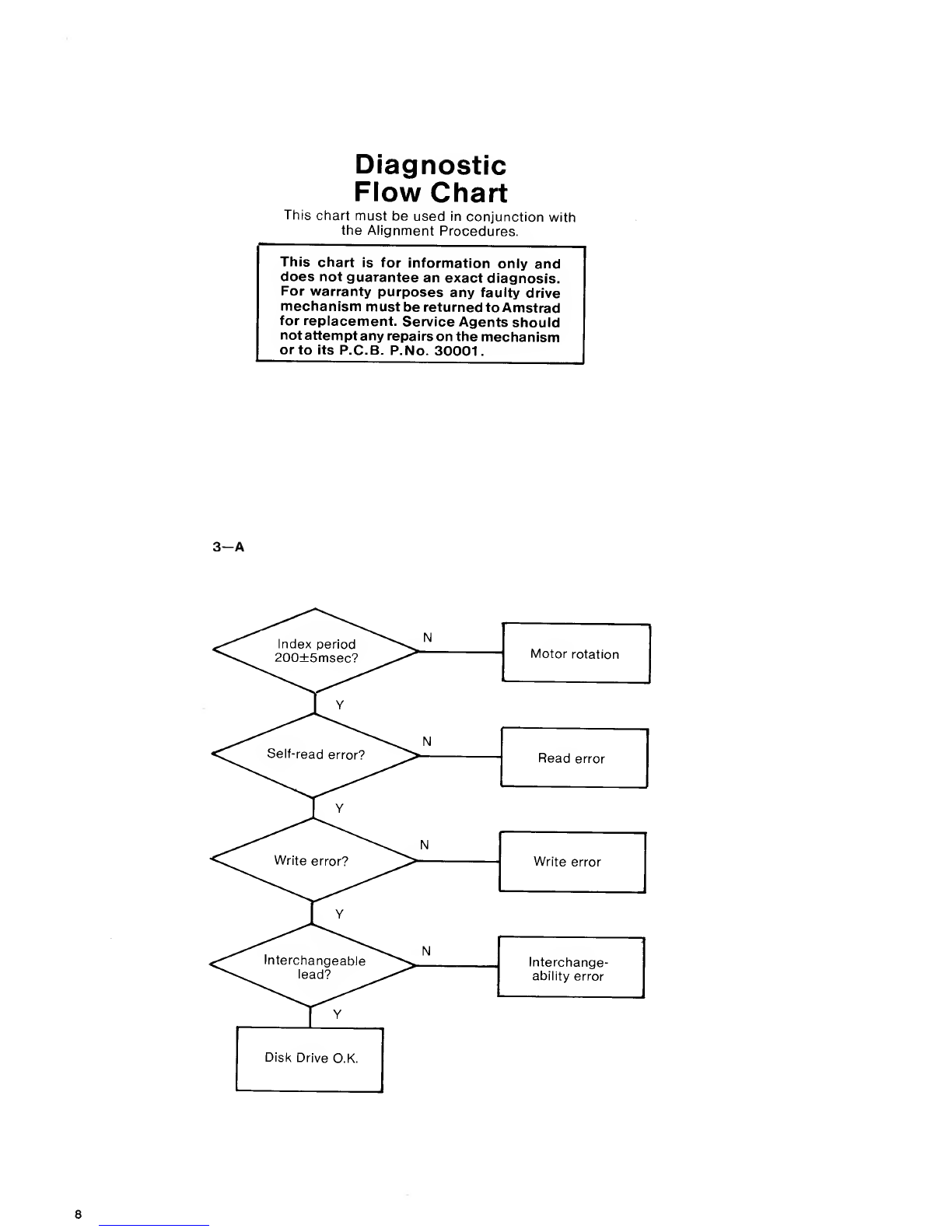

Software Errors

If adrive fault is reported the fault may be asoftware problem. Before investigating the drive

please carry out the following checks to ensure it is not asoftware problem.

Detection and Correction of "Soft Errors"

Soft errors are usually caused by the following reasons.

1) Random external noise of several usee or less.

2) Minute off-tracking and shifting of write timing that are not detected during the write operation

which can cause the soft error during the read.

To remedy such soft errors, take the following procedures at the controller side.

1) Repetitive reading on the track by 10 times or more until the data is restored.

2) When the data is not restored by step 1, access the head to the adjacent track in the same

direction as move previously, and thereafter return the head to the original track.

3) Repeat the step 1.

4) If the data is not restored by the above steps, the error cannot be remedied

Write Error

When an error is caused during the write operation, the error is usually detected during the next

rotation through the read operation called "Write check".

To correct the error, repeat the write operation again and carry out the Write check.

If the result is still incorrect even after the write operation is repeated more than 10 times, either

the disc or the drive are working incorrectly. To find out the trouble source, carry out the read

operations with another track. Should the error still be found, change the disk and repeat the above

procedures. Should error still be found, the drive should be considered defective. If the error is

removed, the original disk must be defective. Discard it.

Seek Error

1) Step motor or step motor drive circuit is defective.

2) The torque of the carriage is not correct.

Restoration procedures from the seek error.

Make the re-calibration to the track 00. Then, carry out the re-seek to the original track.

Notes:

1) Always ensure the head is clean.

2) Index/Sector Factor (Ready Defect)

As the unit has Optional Read Output

It is normally not ready until 2revolutions are made after the disk insertion.